Meet SprutCAM X

Machine-aware CAD/CAM platform

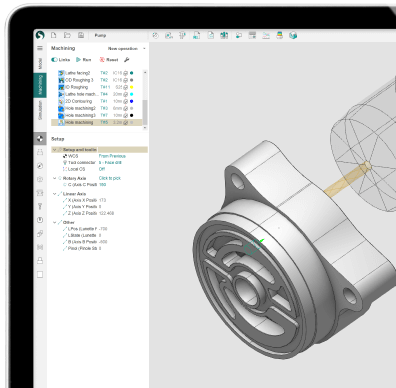

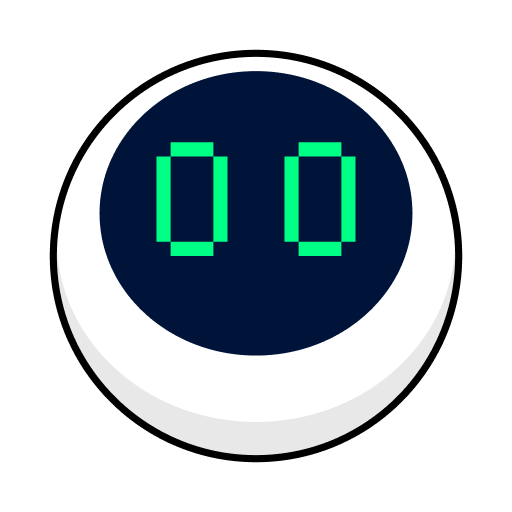

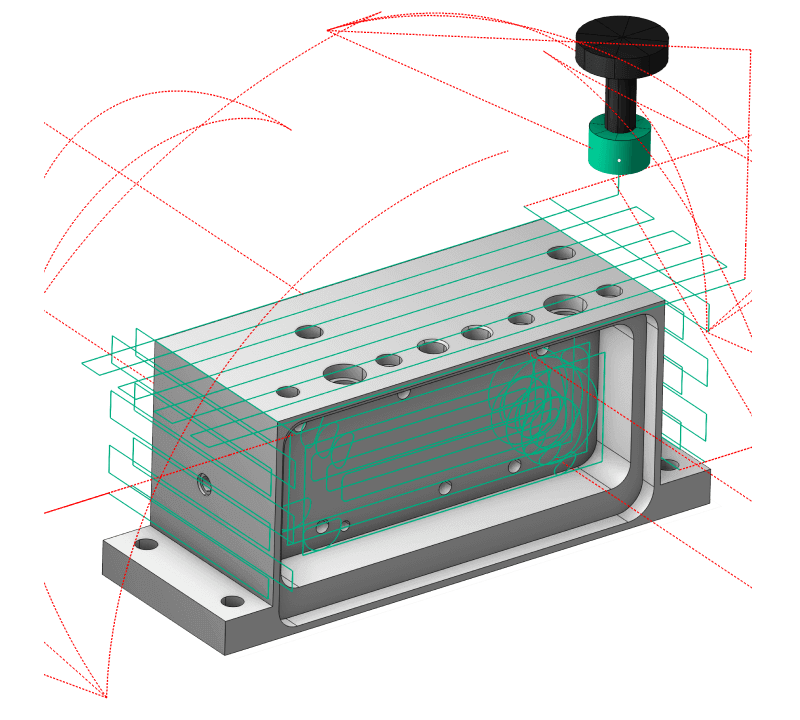

SprutCAM X introduced the Machine-Aware programming approach back in 2001, establishing it as the high-end foundation for a CAM software. This innovative approach involves considering machine limitations during the initial toolpath calculation, setting it apart from traditional CAM methods that operate in abstract space before converting to real machine code during simulation or postprocessing.

As machine kinematics become increasingly complex, the benefits of the Machine-Aware approach continue to grow. This advanced CAD/CAM software not only ensures appropriate safety for programming 5-axis and mill-turn machines but also provides a foundation for a transparent and intuitive user experience.

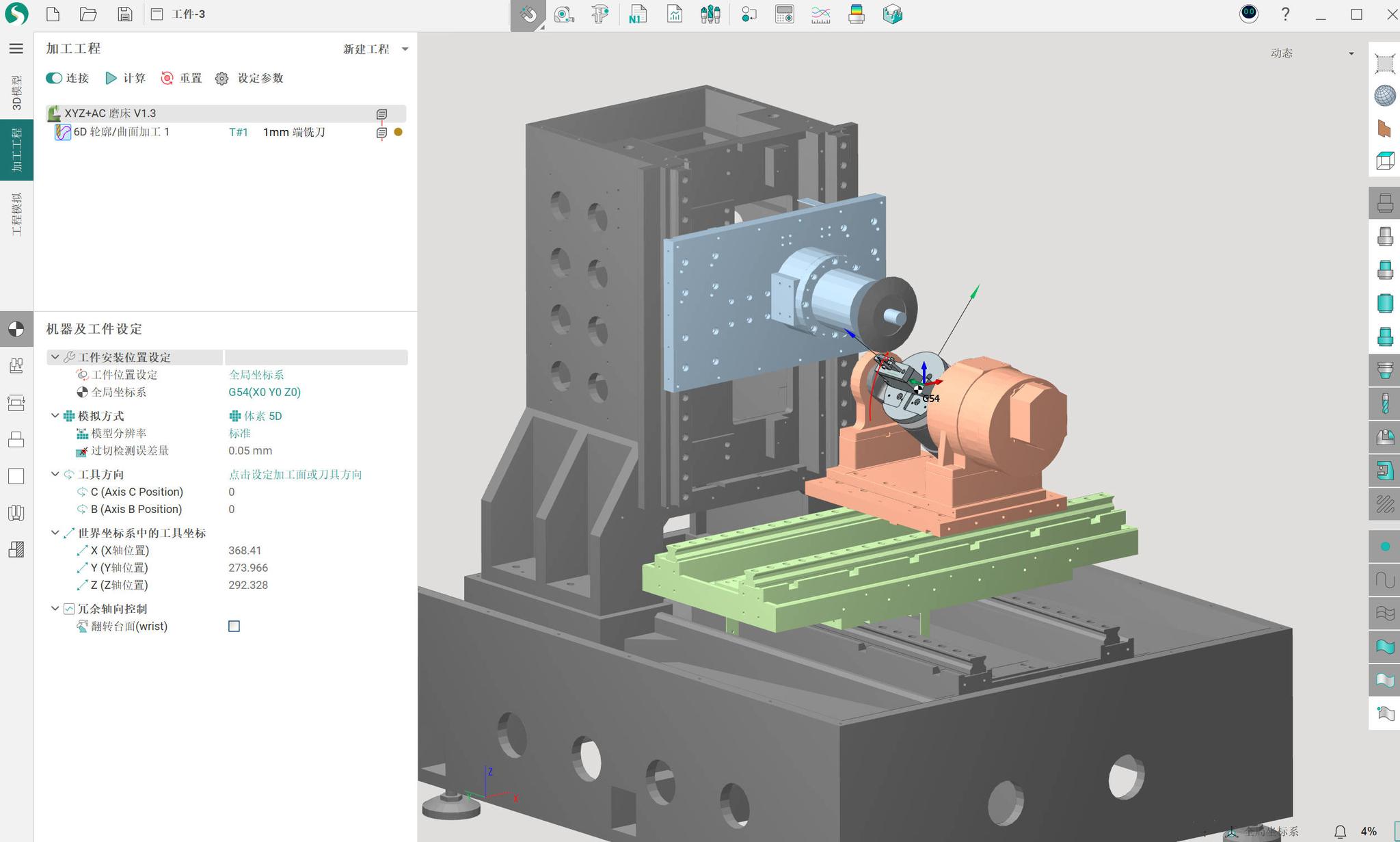

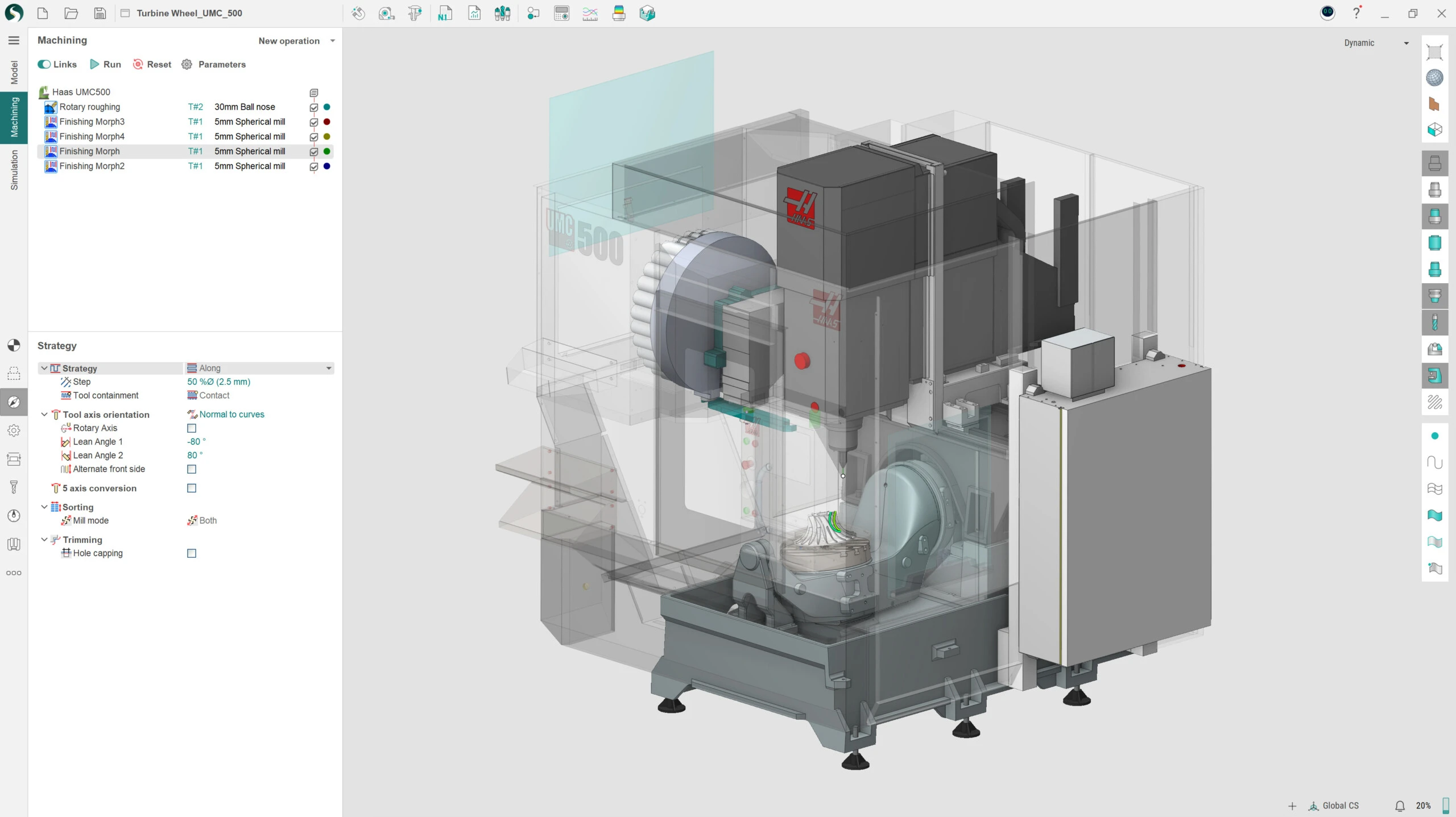

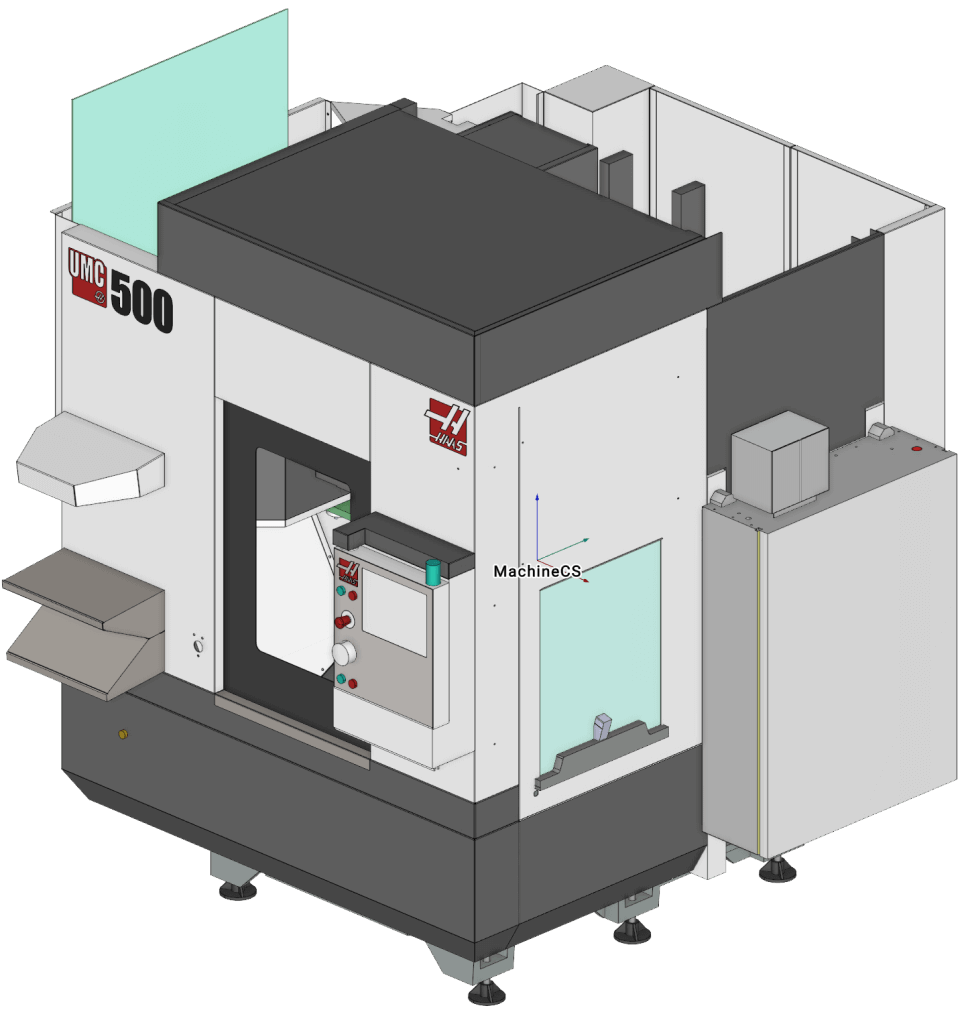

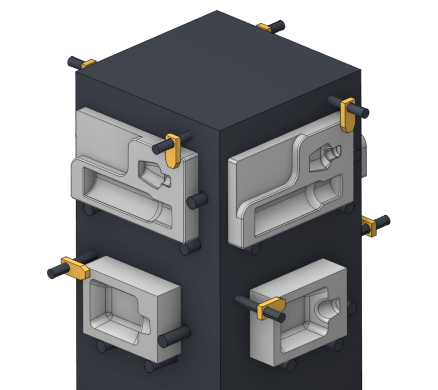

Your CNC Machine digital twin

The MachineMaker app allows you to generate a digital replica of your CNC machine in a matter of minutes. This digital twin is intended for use in programming the CNC machine within the CAD/CAM software SprutCAM X.

Furthermore, MachineMaker features an extensive library of readily available individual components, as well as complete pre-designed digital twins of CNC machines and postprocessors.

Product Highlights

Applications

Technology highlight:

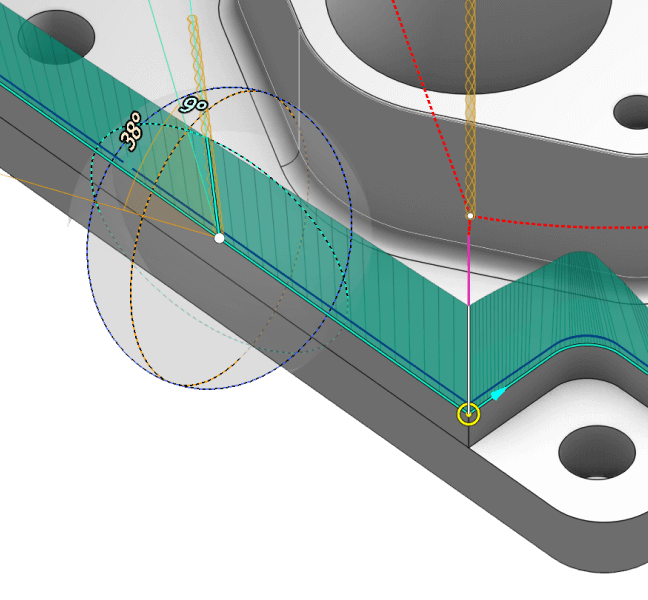

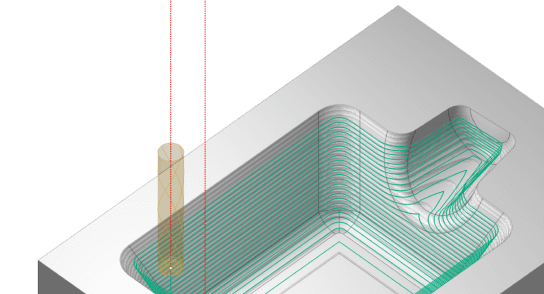

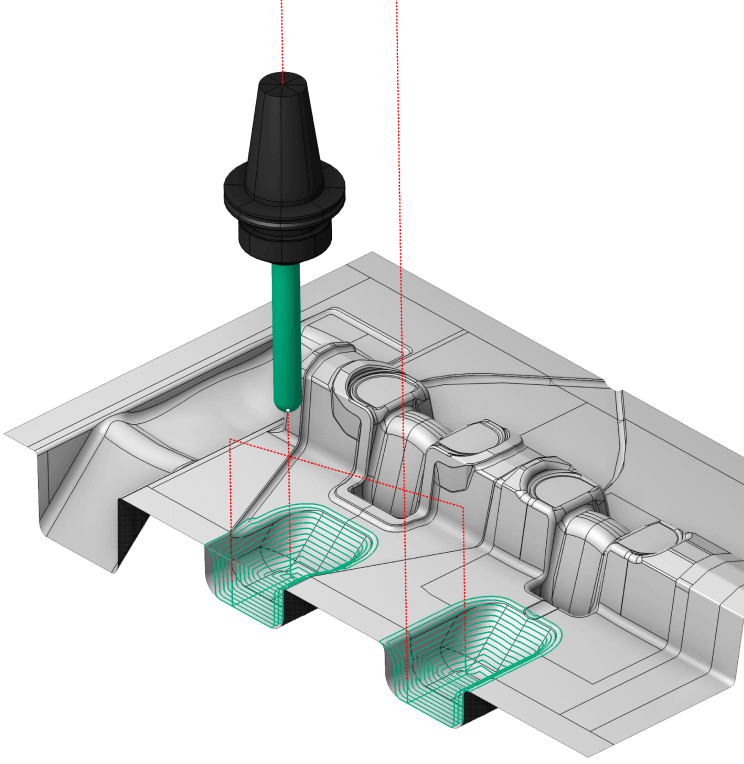

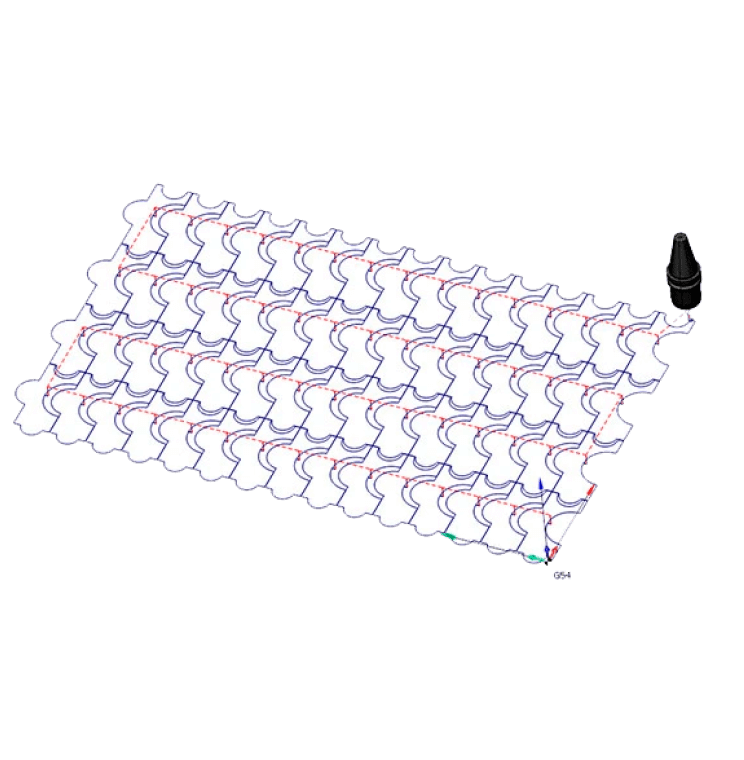

Adaptive SC

This high-speed machining cycle is specifically designed for roughing to substantially decrease cycle times and extend tool life. Its technology automatically regulates chip loads and lateral cutting forces while maintaining the cutter engagement angle and machine axes acceleration within optimal ranges.

With Adaptive SC, the machine can make deeper cuts at higher feedrates, which are also automatically optimized throughout the toolpath for maximum efficiency. In comparison to traditional machining methods, Adaptive SC provides the following benefits:

70%

reduction in cycle time

500%

increase in tool life

Applications

Technology highlight:

Adaptive SC

This high-speed machining cycle is specifically designed for roughing to substantially decrease cycle times and extend tool life. Its technology automatically regulates chip loads and lateral cutting forces while maintaining the cutter engagement angle and machine axes acceleration within optimal ranges.

With Adaptive SC, the machine can make deeper cuts at higher feedrates, which are also automatically optimized throughout the toolpath for maximum efficiency. In comparison to traditional machining methods, Adaptive SC provides the following benefits:

70%

reduction in cycle time

500%

increase in tool life

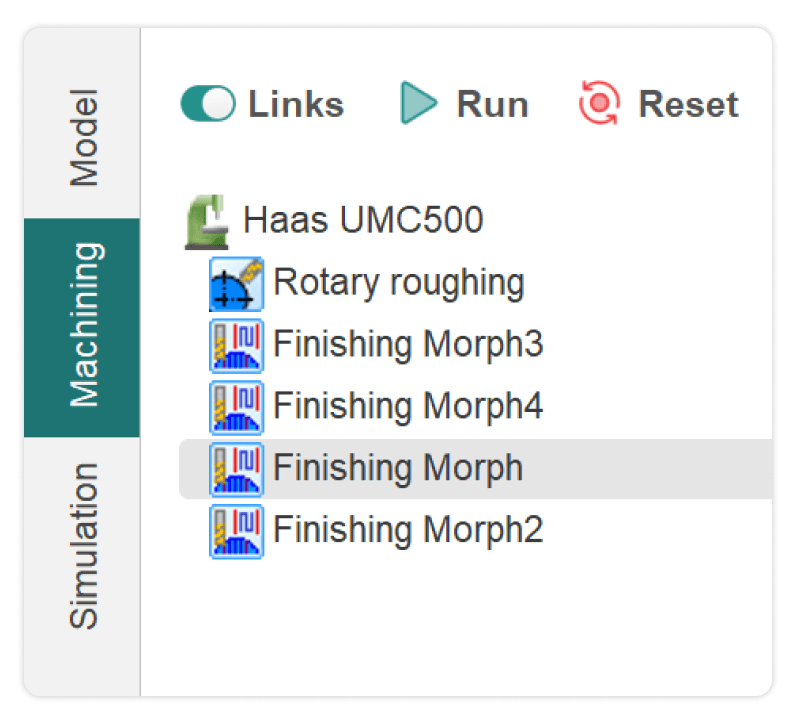

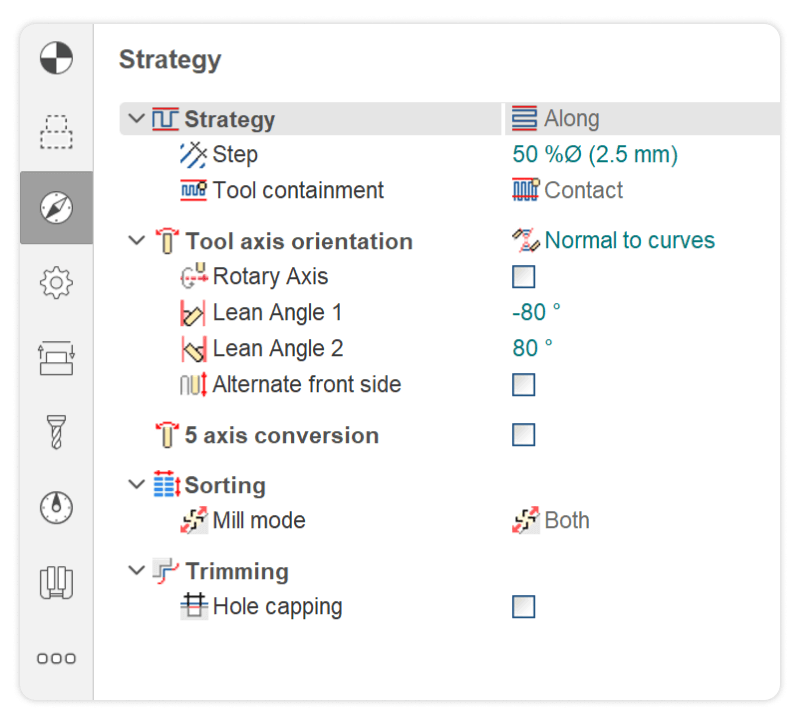

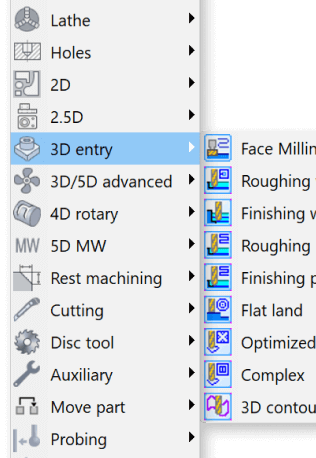

Inspector is the place there all the technology parameters are defined: job zone, toolpath strategy, tolerance, interpolation, approach and retract, links, feeds and speeds, toolpath transformation etc

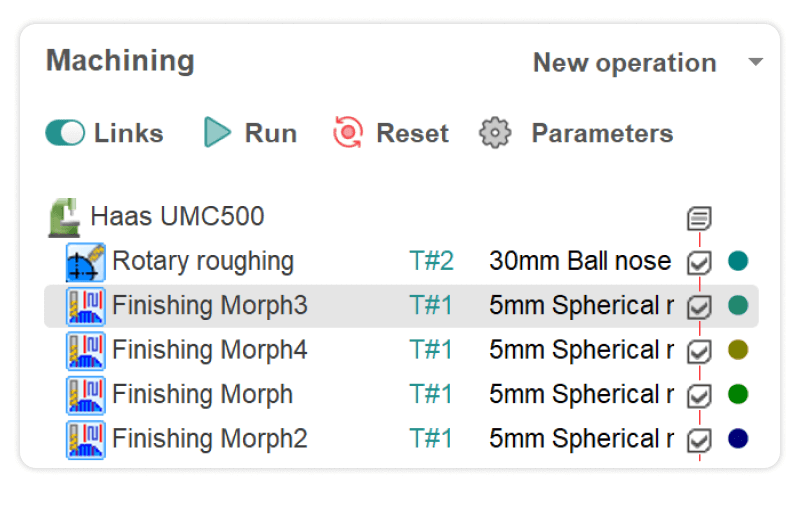

Inspector is the place there all the technology parameters are defined: job zone, toolpath strategy, tolerance, interpolation, approach and retract, links, feeds and speeds, toolpath transformation etc Machining operations sequence

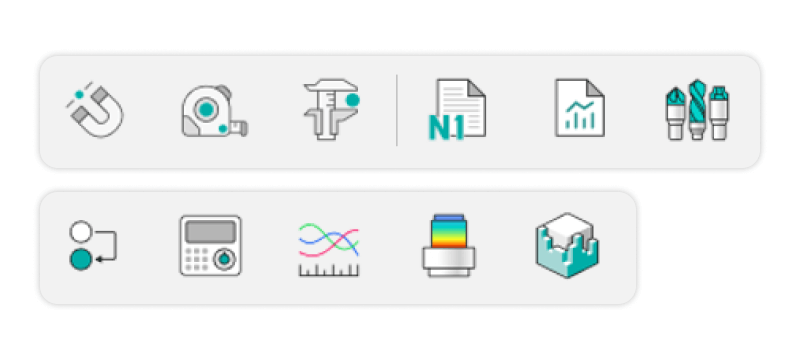

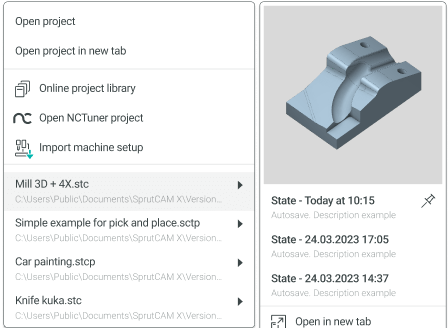

Machining operations sequence Useful tools for everyday work: virtual machine pendant, tape measure, postprocessor, machining report, tool management, verify and compare tool, tool reach inspector, axes graph and 3d model transformation tools.

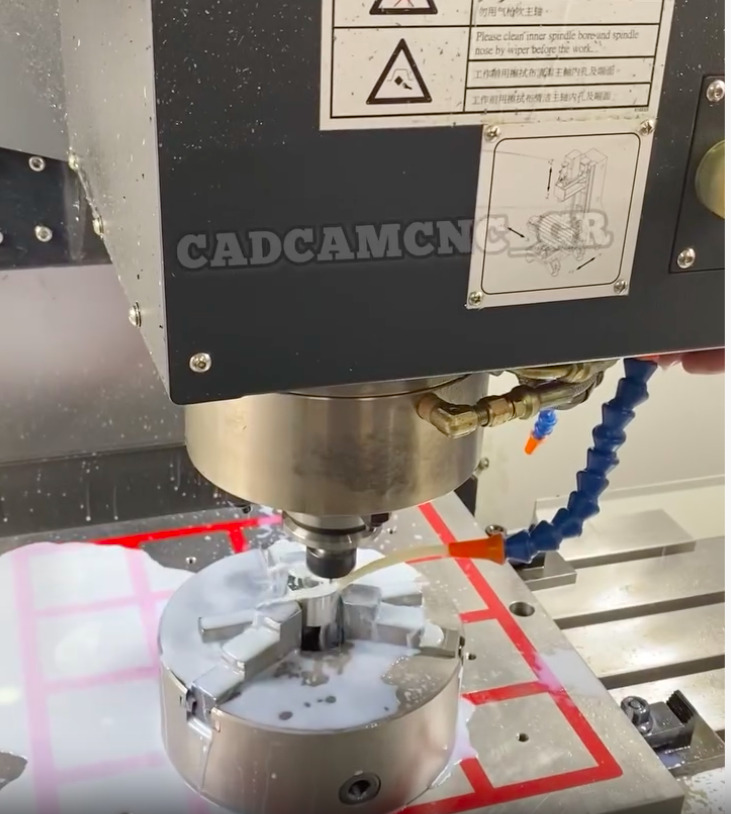

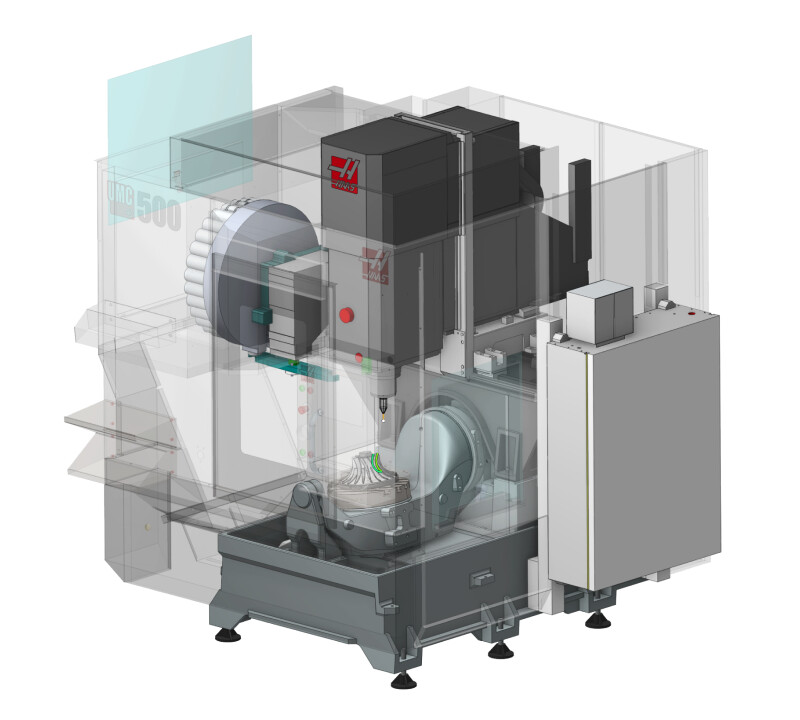

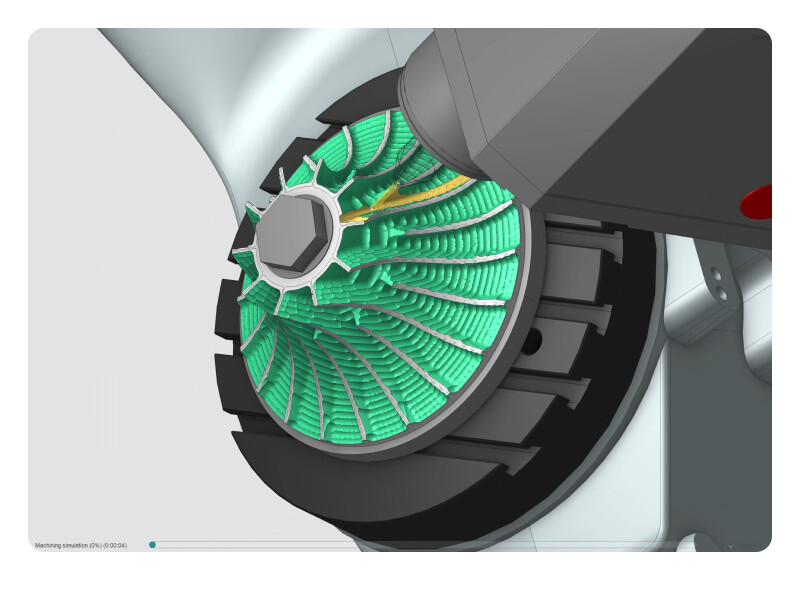

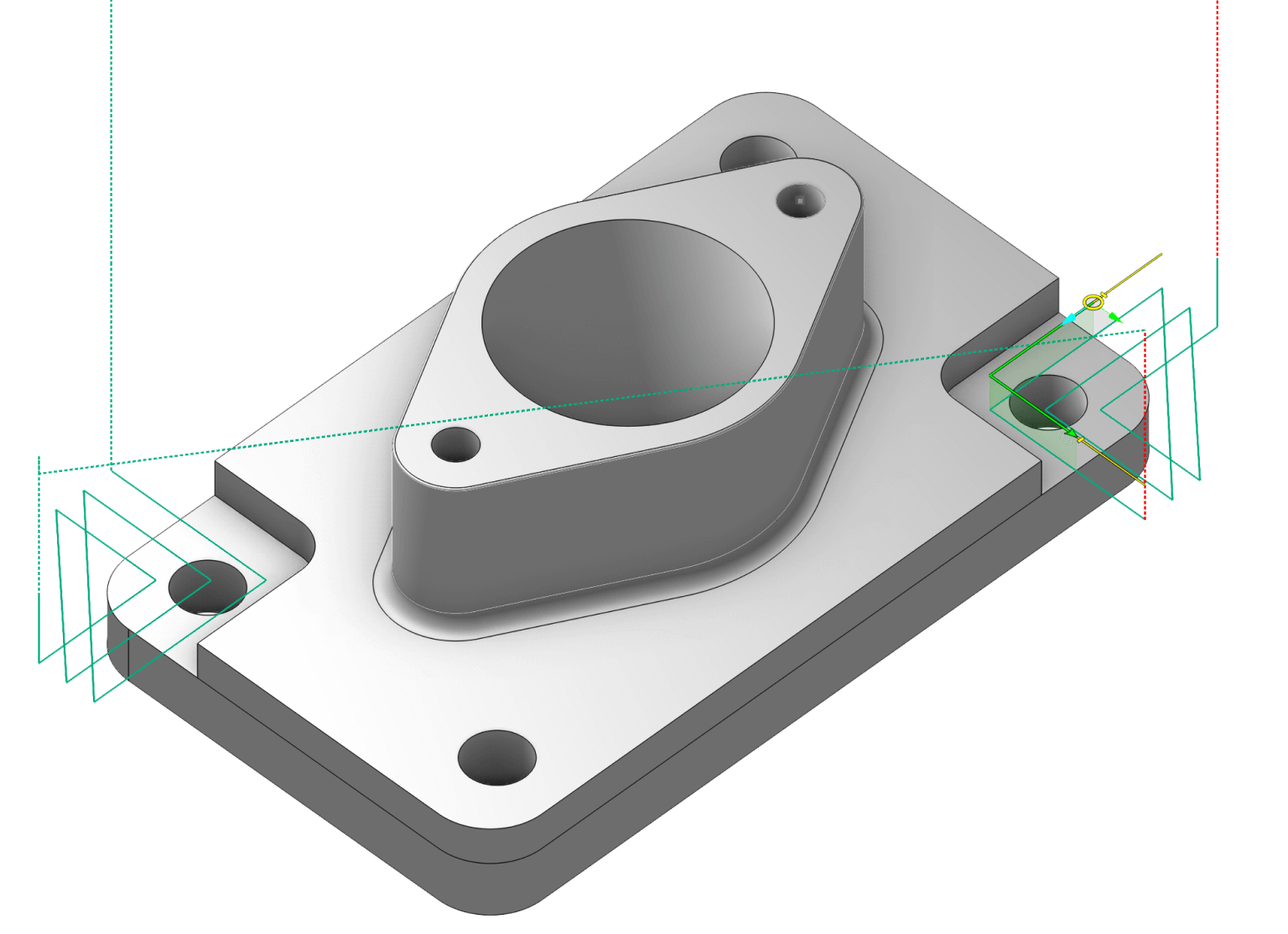

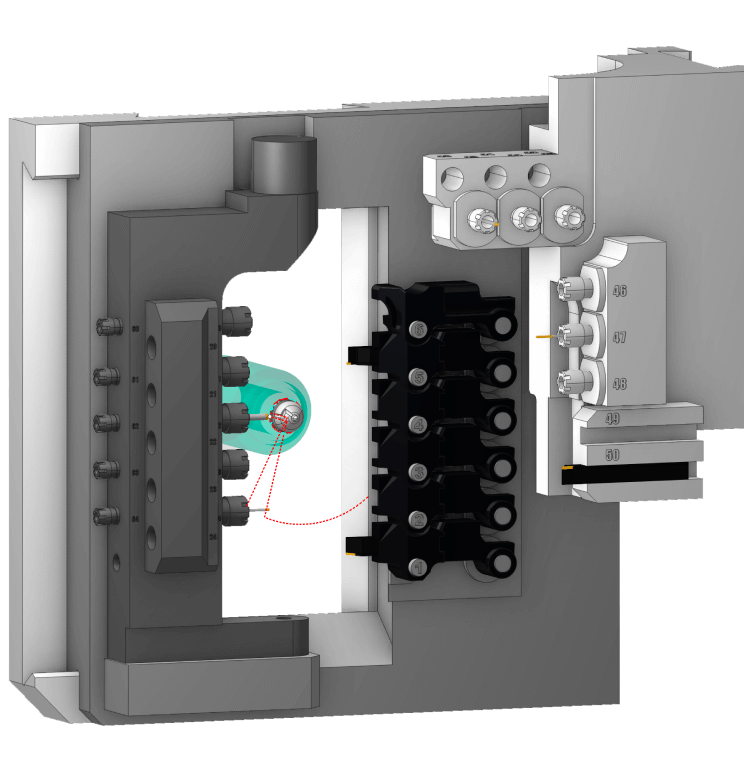

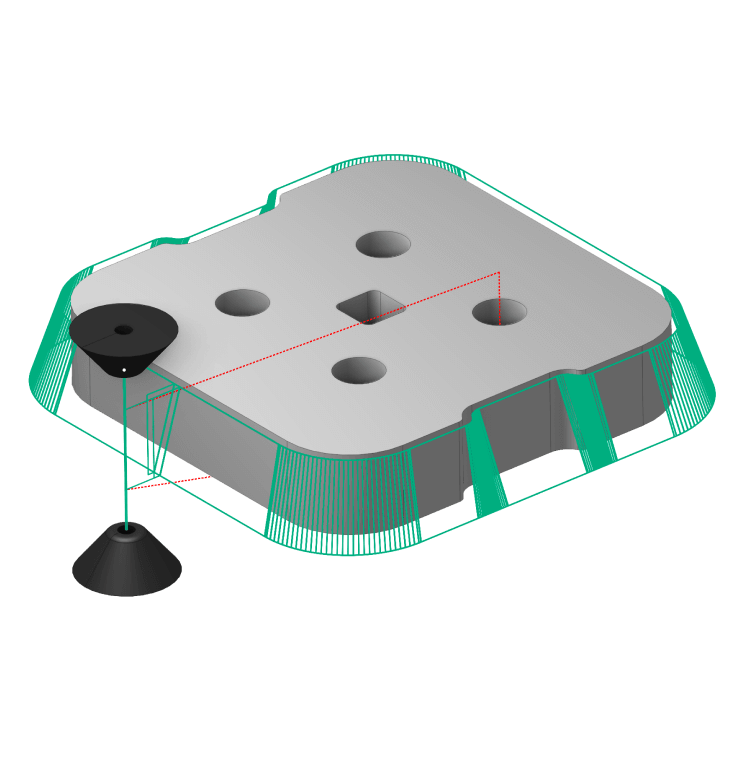

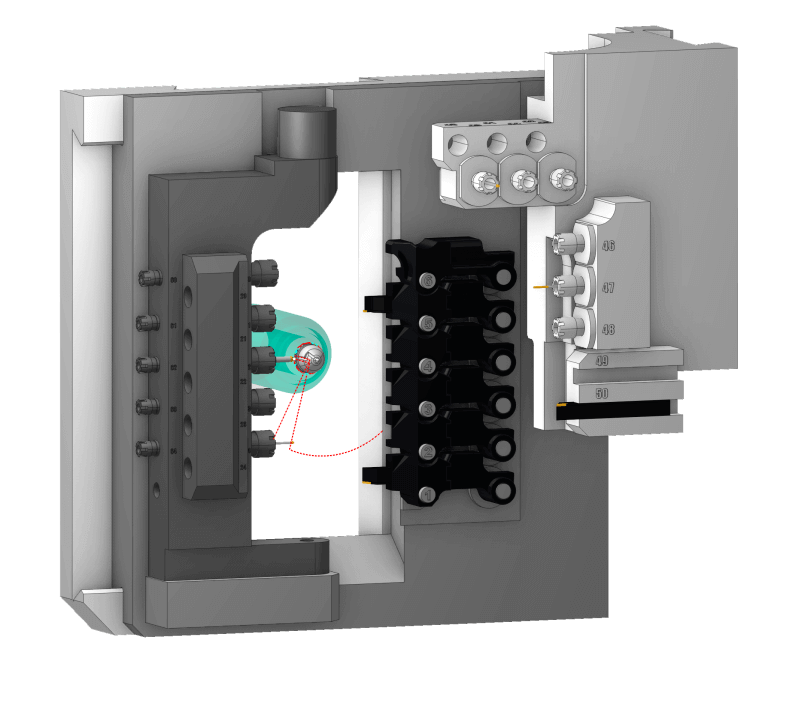

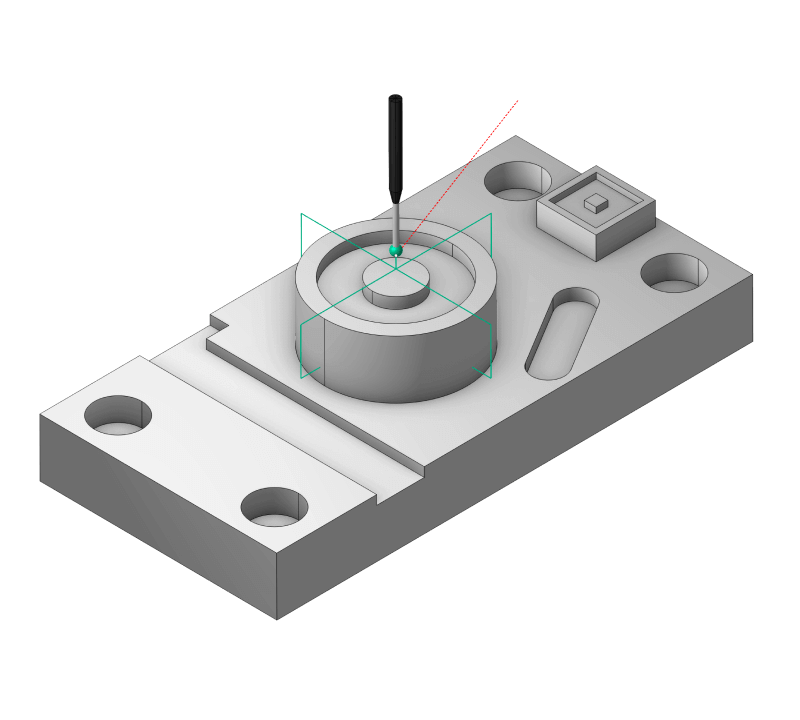

Useful tools for everyday work: virtual machine pendant, tape measure, postprocessor, machining report, tool management, verify and compare tool, tool reach inspector, axes graph and 3d model transformation tools. SprutCAM X is machine aware CAD/CAM platform. This means that toolpath calculation is performed taking into an account machine kinematics and limitations. So machine digital twin is used for toolpath calculation and simulation after that

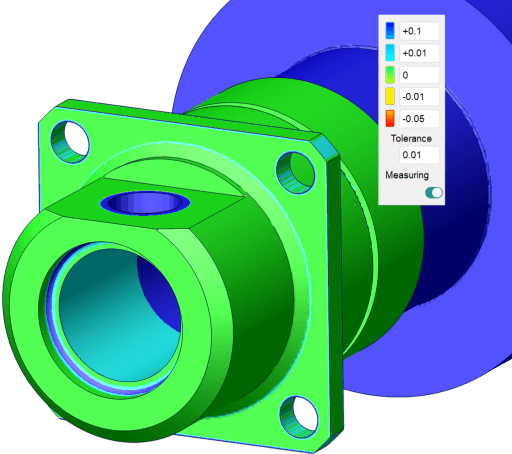

SprutCAM X is machine aware CAD/CAM platform. This means that toolpath calculation is performed taking into an account machine kinematics and limitations. So machine digital twin is used for toolpath calculation and simulation after that Precise and smooth simulation of workpiece evolution through the machining process. Either for machining or for additive processes

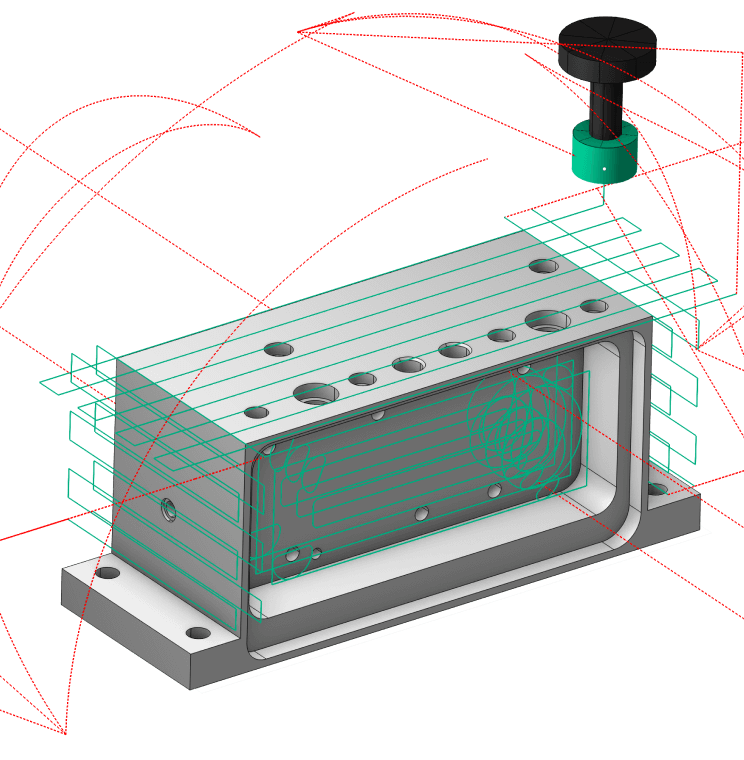

Precise and smooth simulation of workpiece evolution through the machining process. Either for machining or for additive processes The main working area. Here are machine digital twin, part, workpiece, tools are shown. SprutCAM X Robot shows the interactive elements and simulation in this area

The main working area. Here are machine digital twin, part, workpiece, tools are shown. SprutCAM X Robot shows the interactive elements and simulation in this area

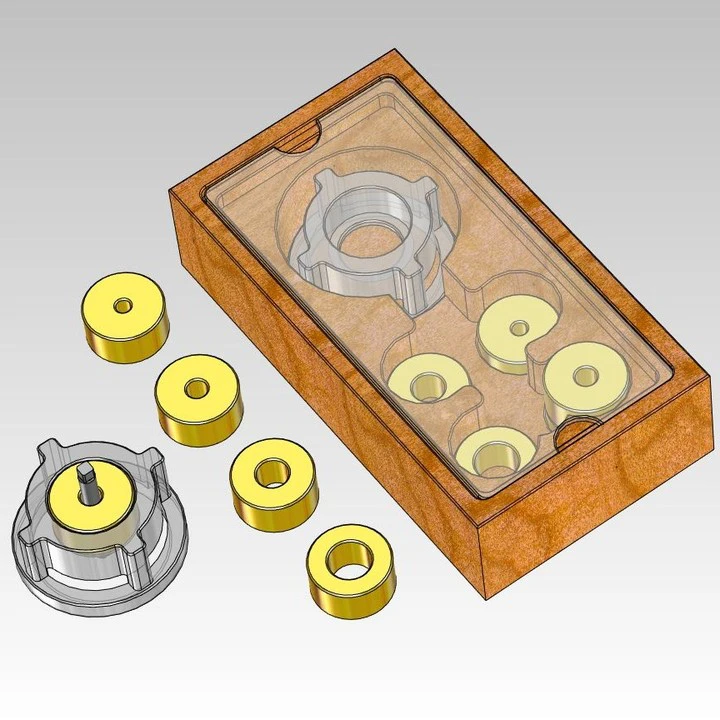

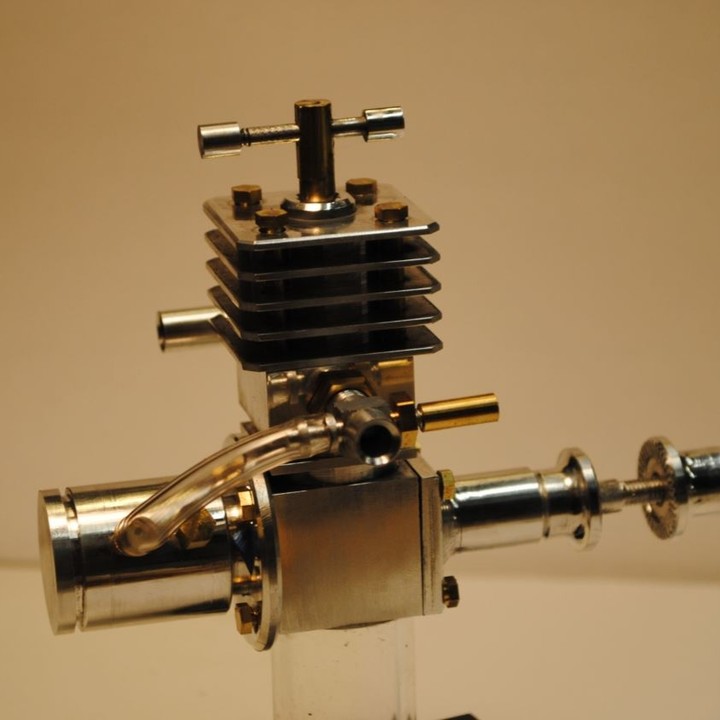

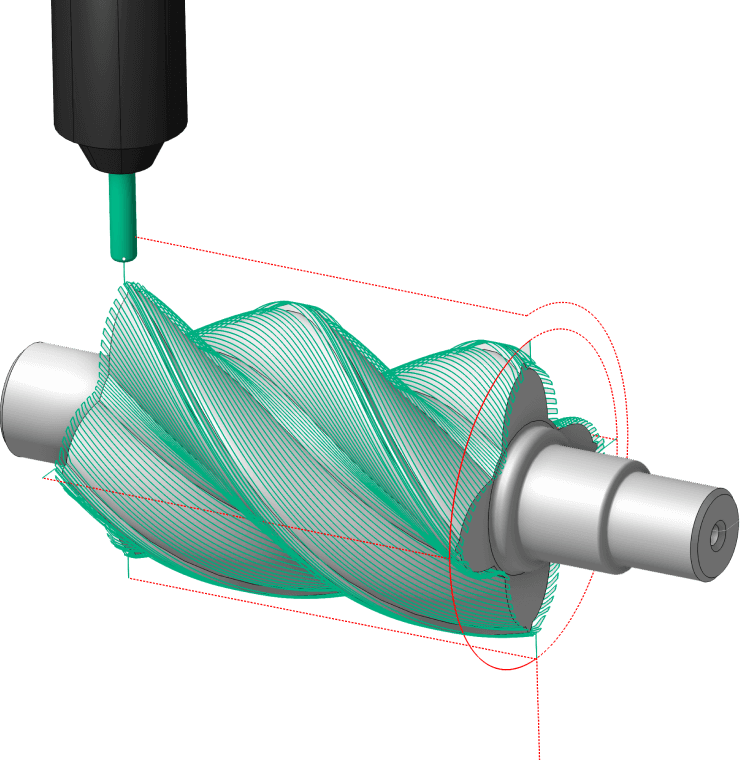

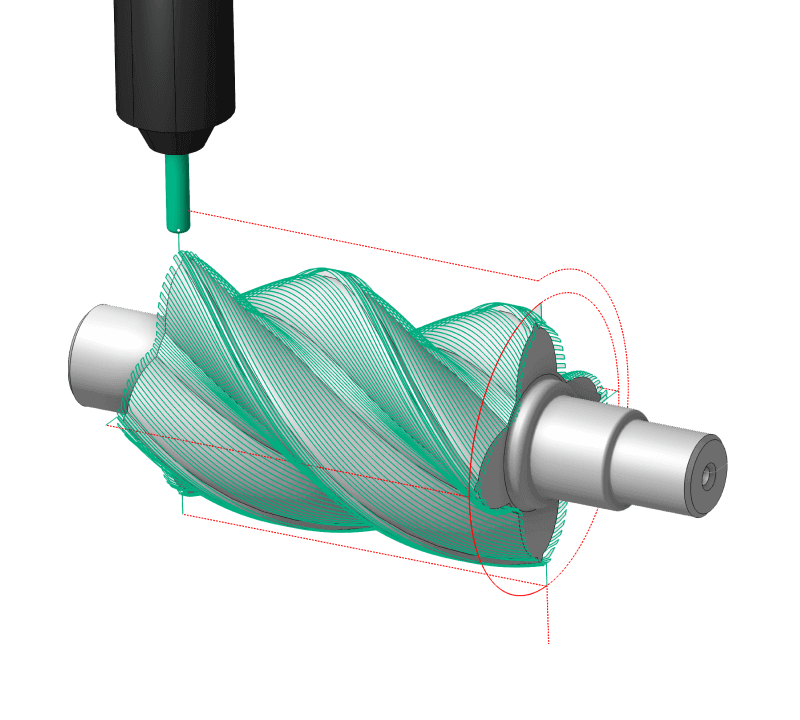

Production of screws, blades, gear wheels, balusters

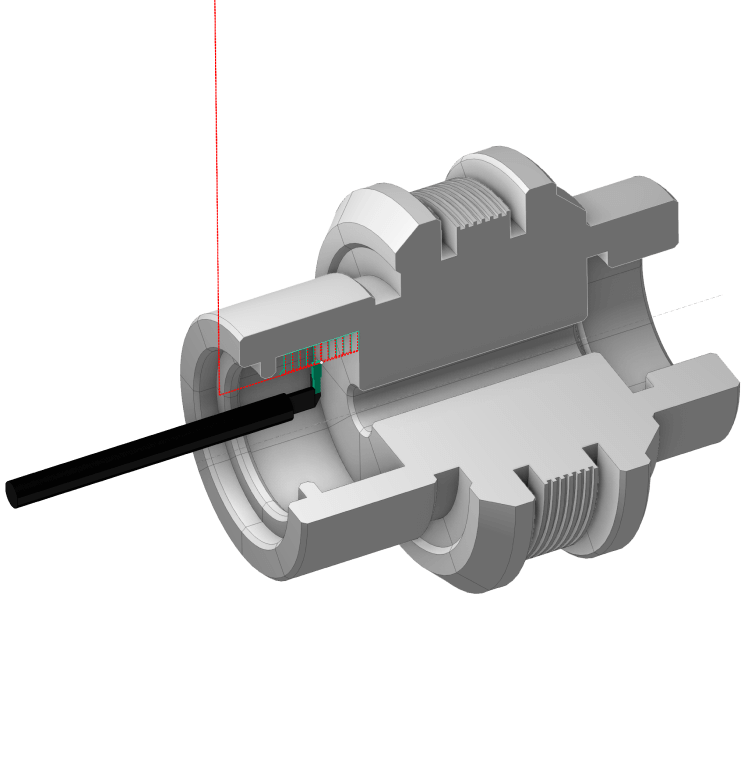

Production of screws, blades, gear wheels, balusters Turning and boring, threading, trimming, drilling, reaming

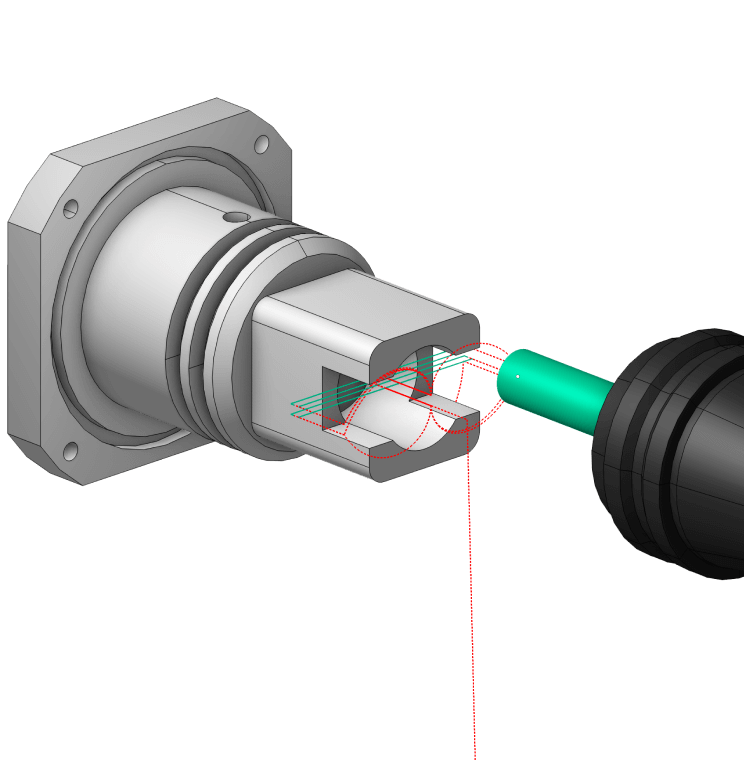

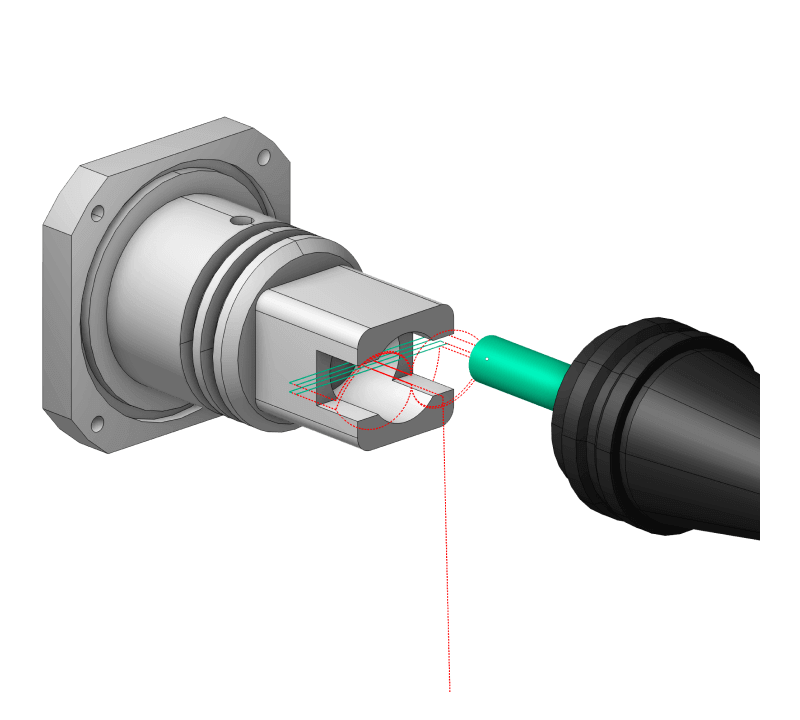

Turning and boring, threading, trimming, drilling, reaming Turning and milling combined in one setup

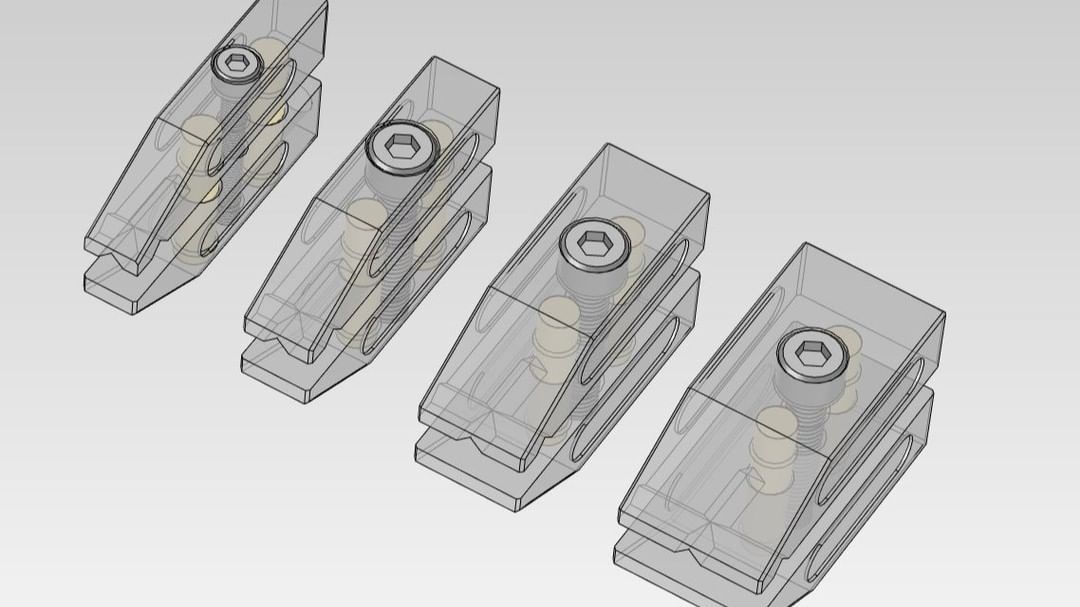

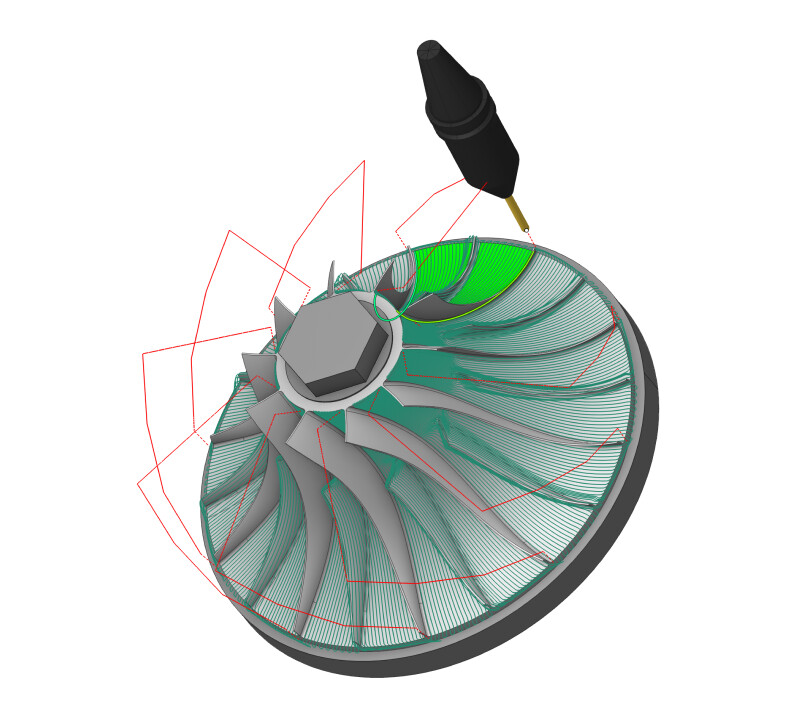

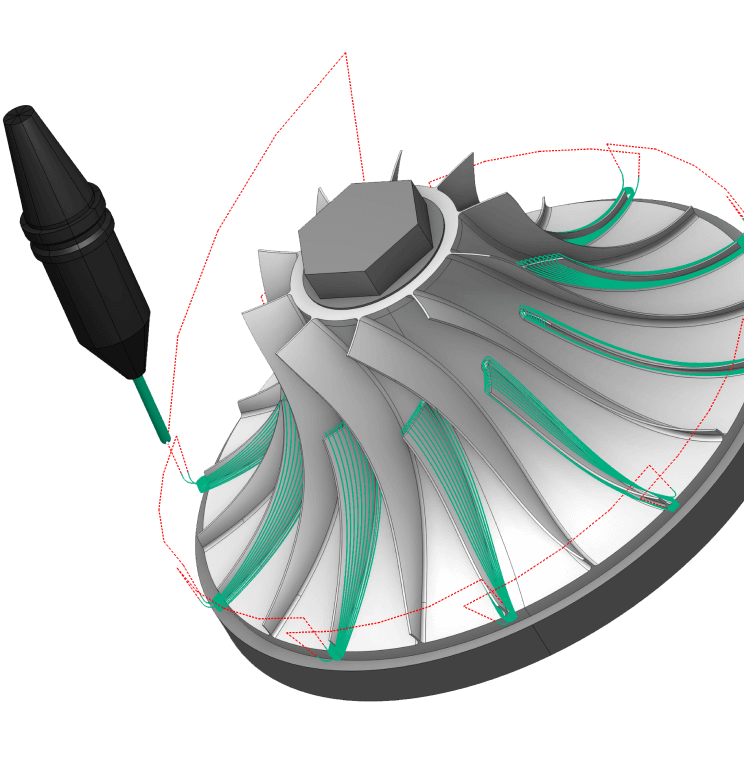

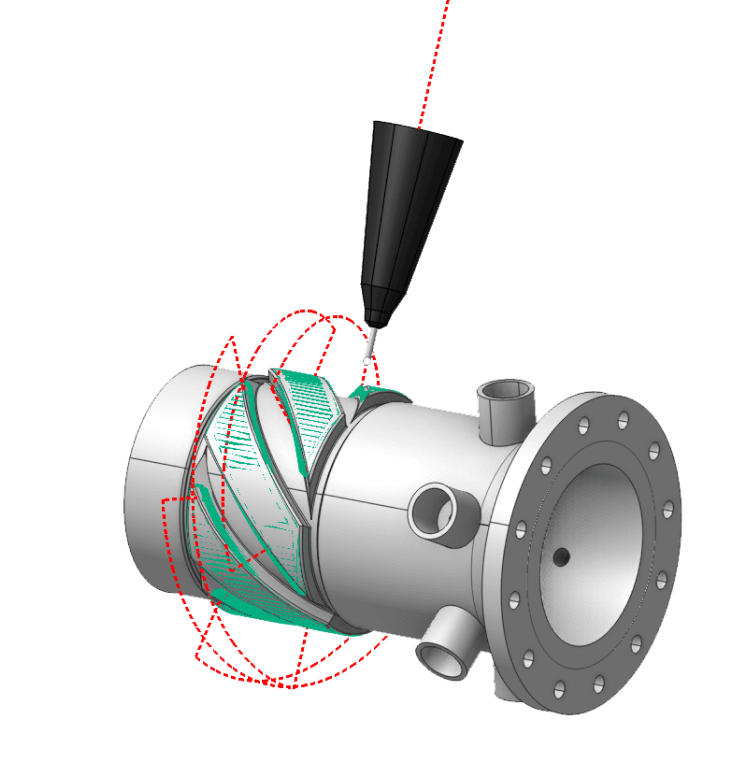

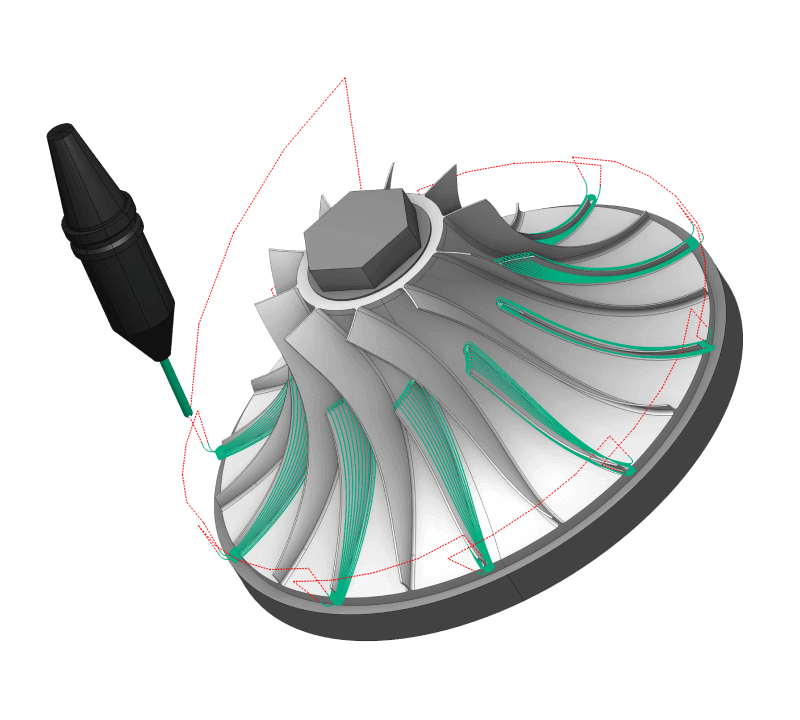

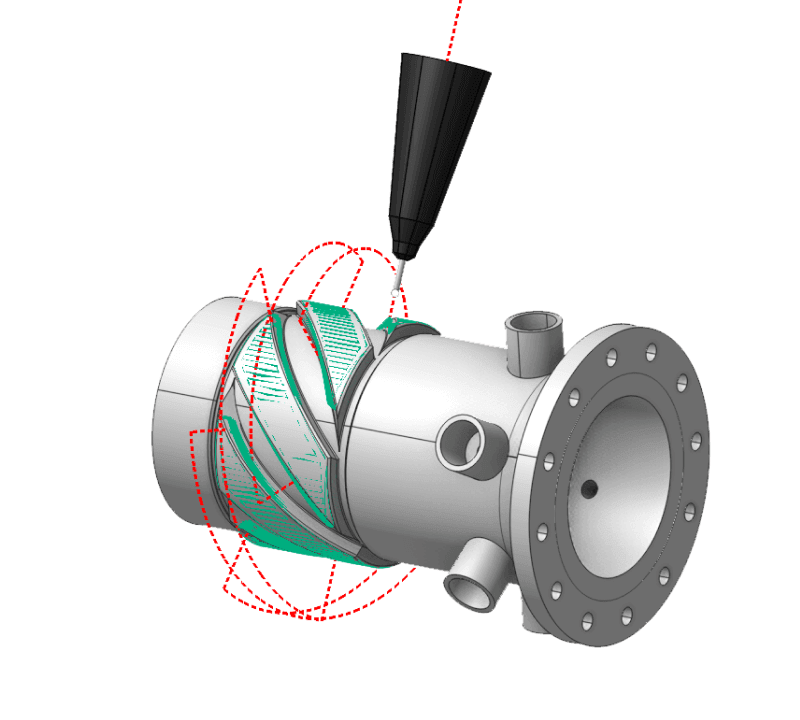

Turning and milling combined in one setup Index (3+2) and simultaneous 5 axis milling. For turbine wheels, blades, ports

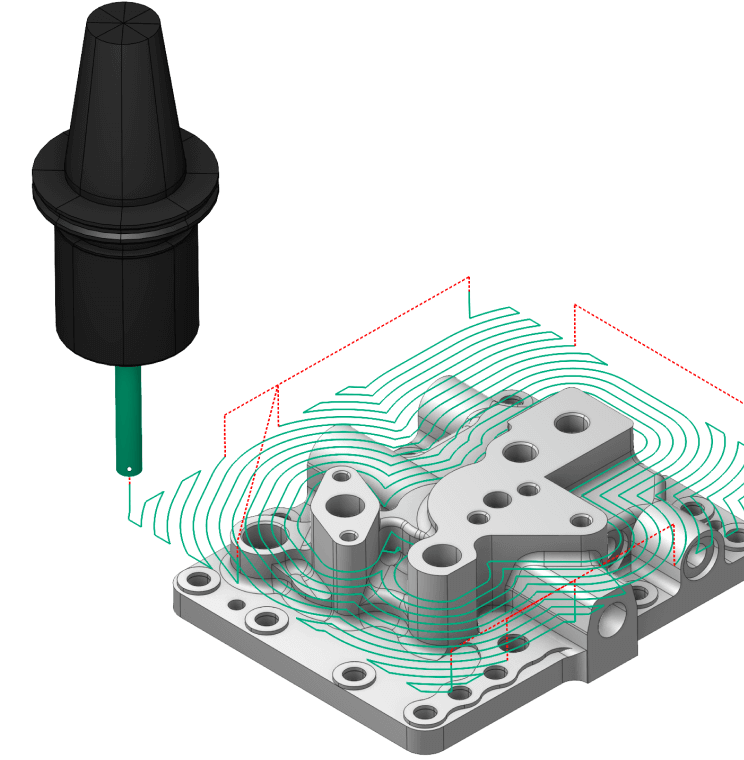

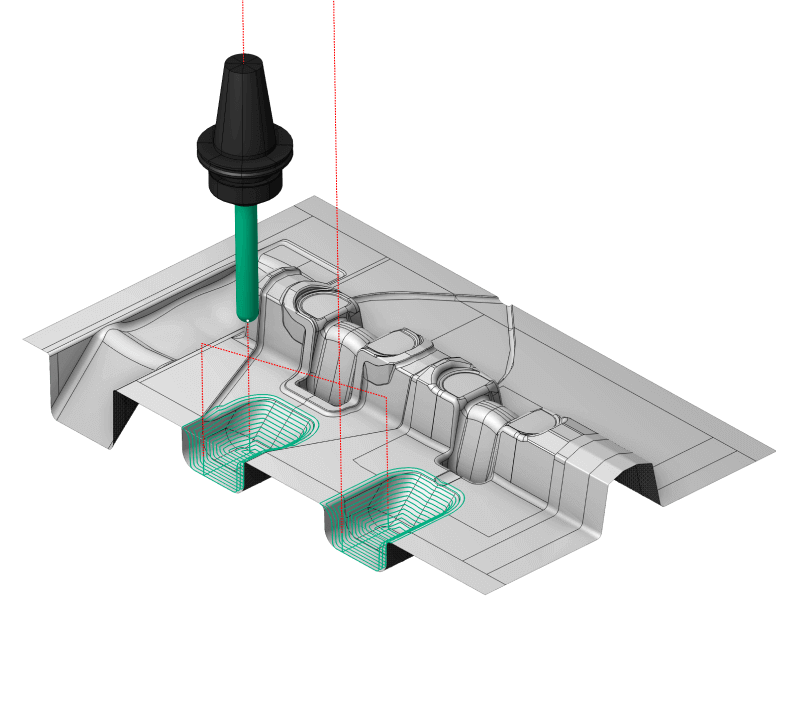

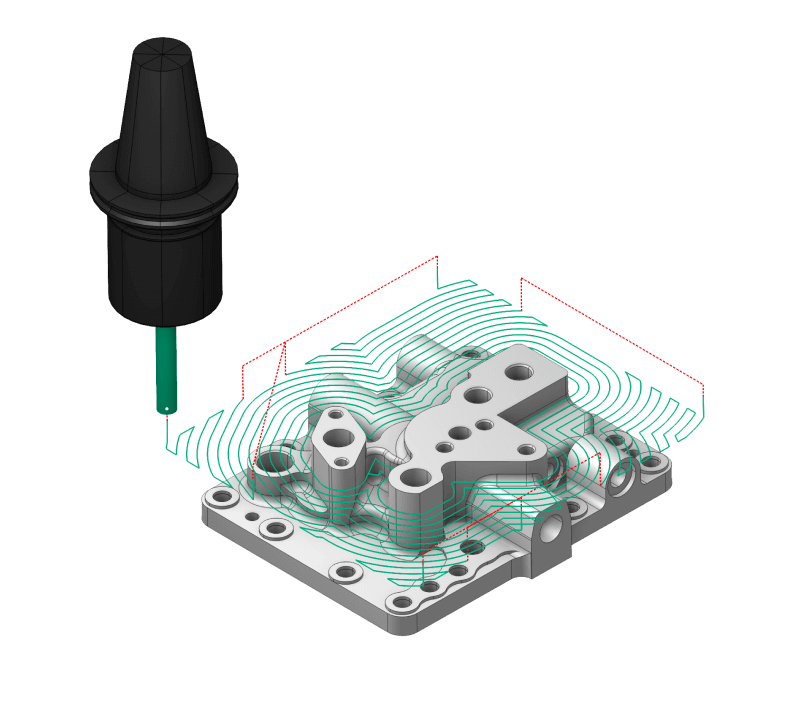

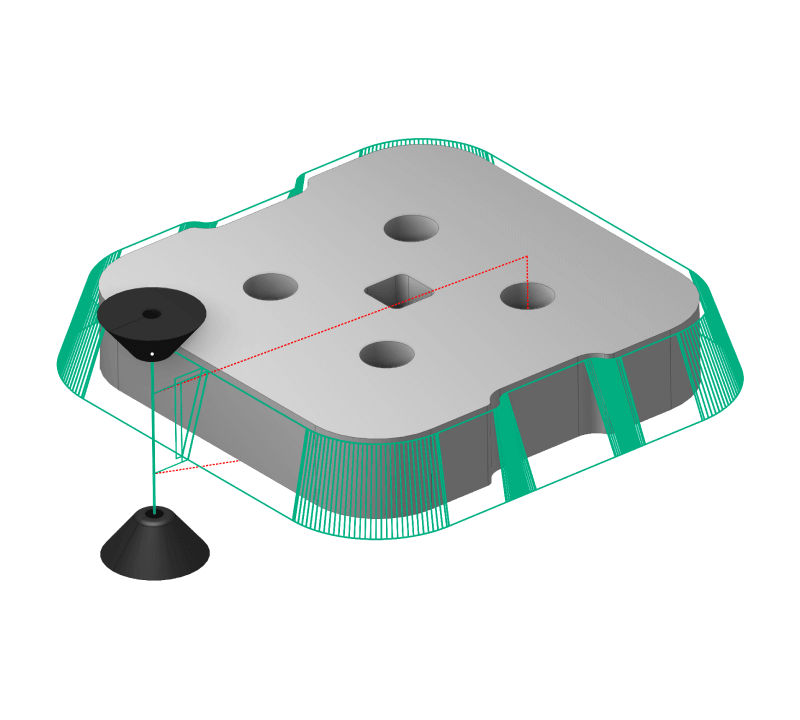

Index (3+2) and simultaneous 5 axis milling. For turbine wheels, blades, ports High speed and adaptive toolpaths for quick material removal with extended tool life

High speed and adaptive toolpaths for quick material removal with extended tool life Swiss-type machines and MTM (multi-channel machining) with synchronization

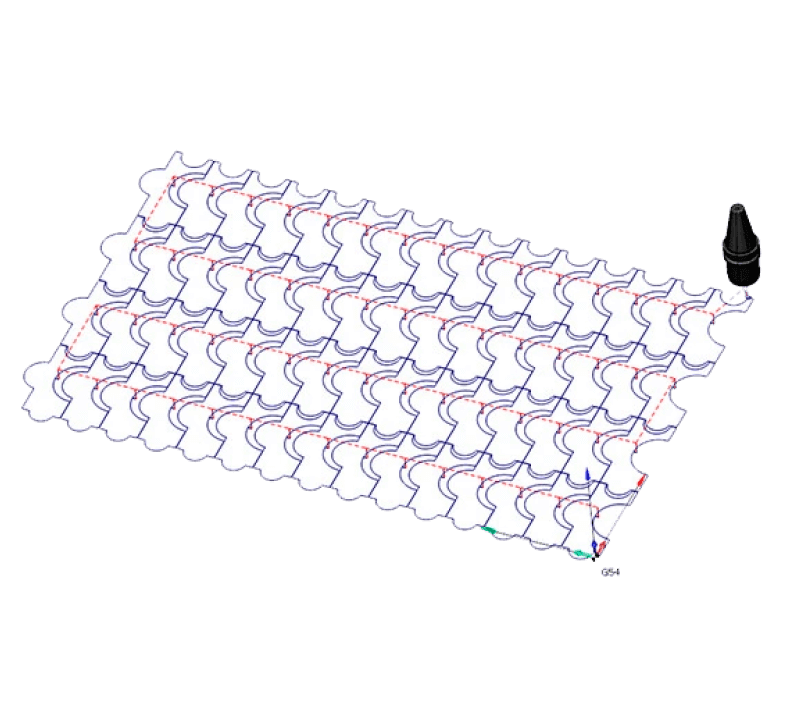

Swiss-type machines and MTM (multi-channel machining) with synchronization CNC programming of cutting, trimming, 6D knife cutting. Mill, laser, water, plasma, knife

CNC programming of cutting, trimming, 6D knife cutting. Mill, laser, water, plasma, knife Cladding, hybrid technology on 5-axis, mill-turn machines and robots

Cladding, hybrid technology on 5-axis, mill-turn machines and robots 2 – 4 axis strategies for wire EDM machining

2 – 4 axis strategies for wire EDM machining Programming of laser, waterjet, plasma, oxy-fuel cutting and knife cutting

Programming of laser, waterjet, plasma, oxy-fuel cutting and knife cutting G-code verification in SprutCAM

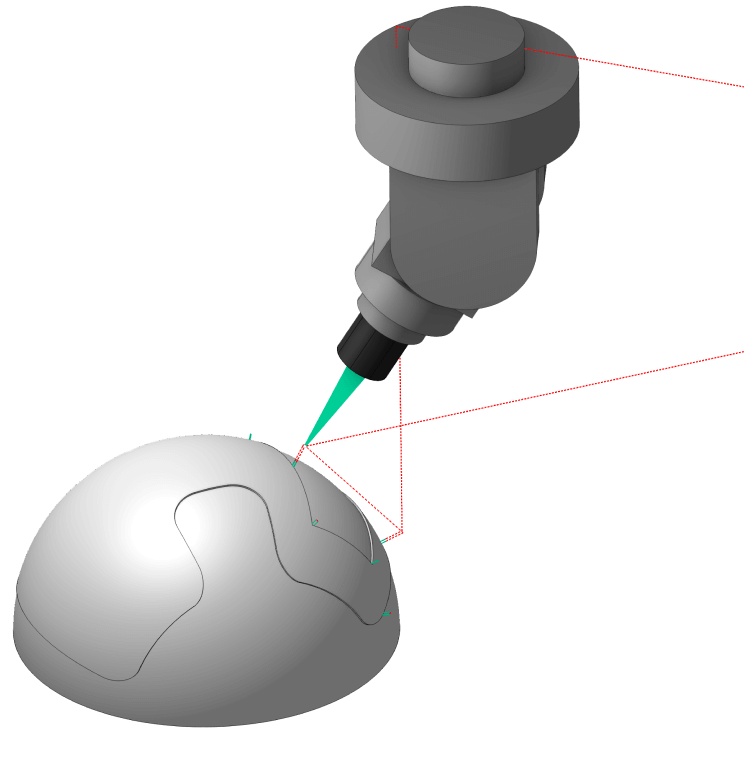

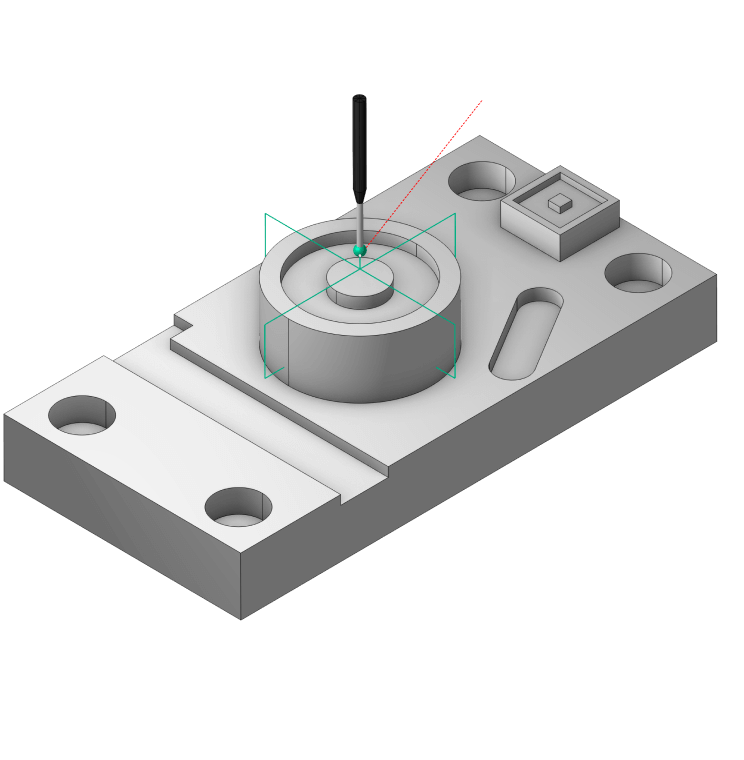

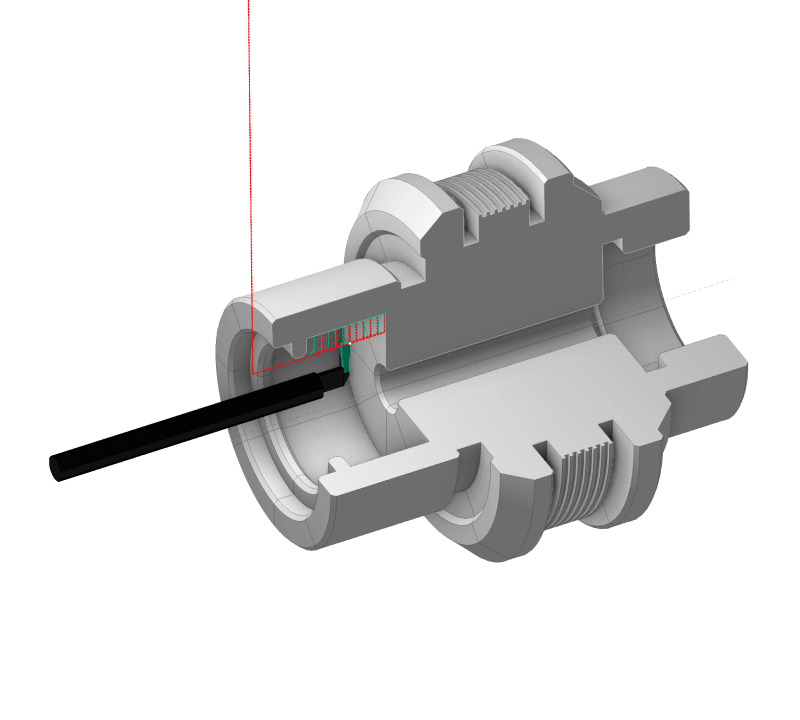

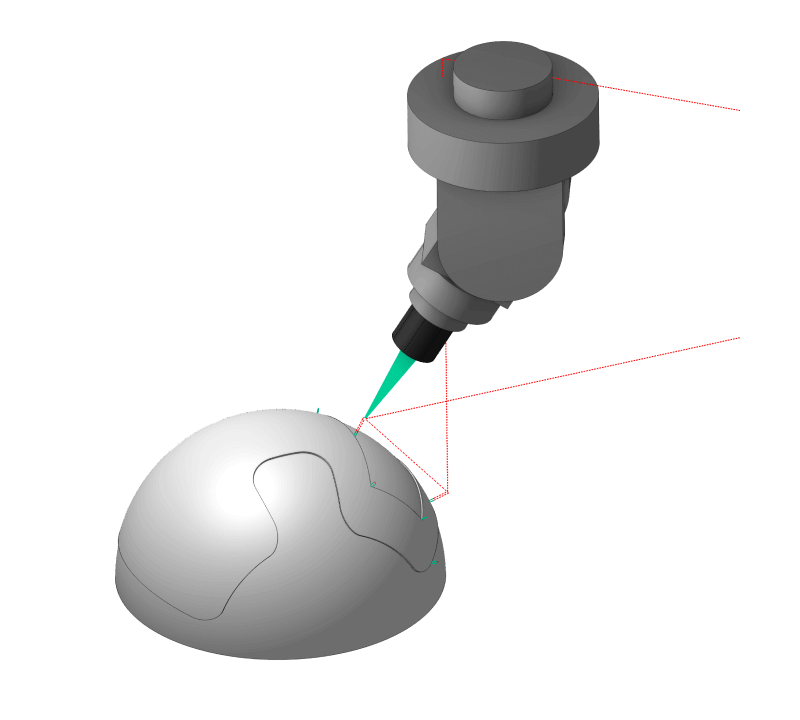

G-code verification in SprutCAM Probing cycles for Milling and Lathe Machines

Probing cycles for Milling and Lathe Machines