Mold manufacturing with SprutCAM X: a case from Greece

Mold manufacturing case from Greece

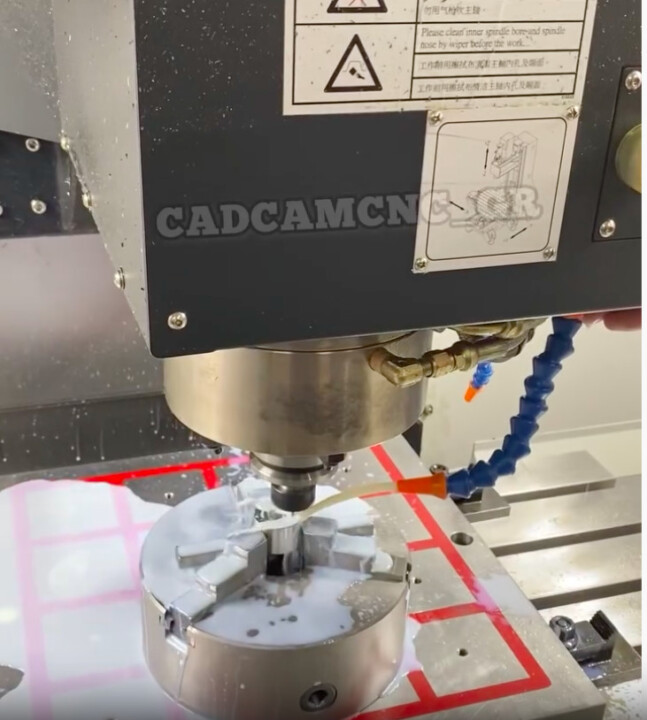

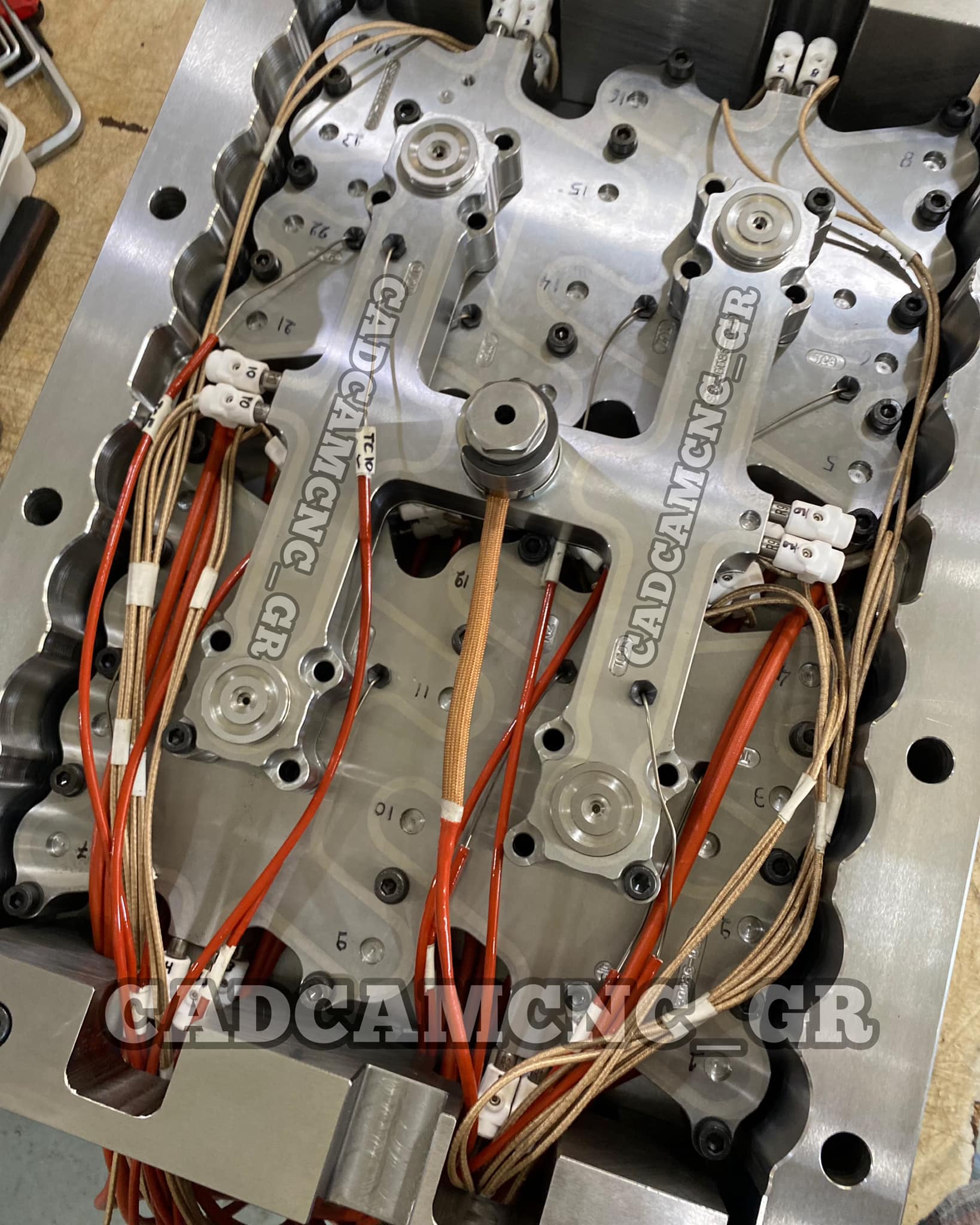

There are countless techniques in the world of mold manufacturing, from traditional craftsmanship to cutting-edge technology. Our esteemed partner from Greece, Yuri Redko of CADCAMCNC GR, offers a fascinating glimpse into the creation of an intricate metal mold.

Witness the intricate journey of mold manufacturing and see the final masterpiece in our gallery below.

And remember to stay connected with SprutCAM X on our social networks, where we share the adventures of our team, present interesting projects and provide valuable insights. Follow us on Instagram for an exclusive glimpse into our world.

Mold manufacturing using CNC machines programmed in CAM systems

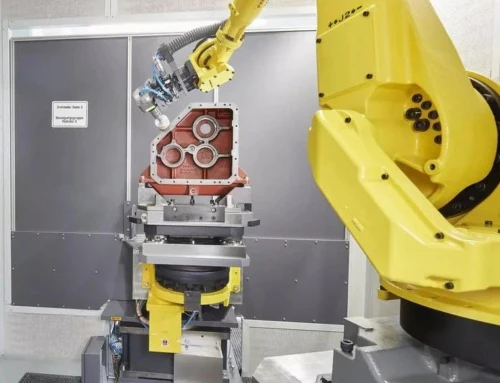

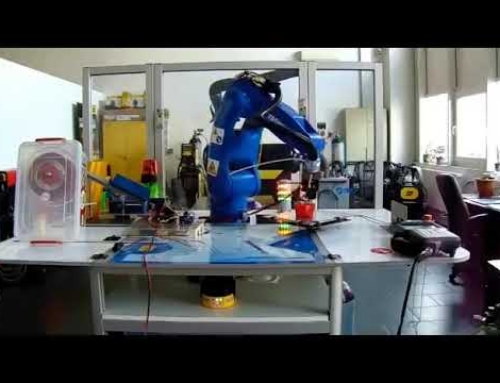

Metal mold manufacturing on CNC machines has revolutionized the manufacturing industry by providing a cost-effective and efficient way to produce high-quality molds. The use of Computer-Aided Manufacturing (CAM) systems has further enhanced the precision and accuracy of the machining process, allowing for complex geometries to be machined with ease.

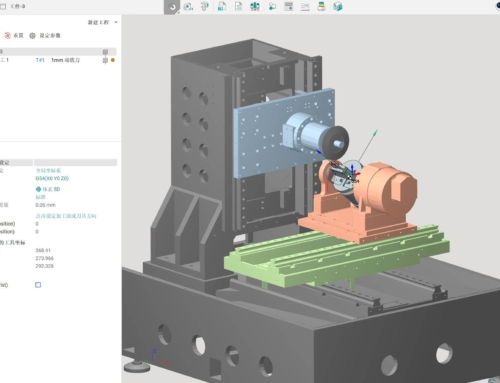

The process of metal mold manufacturing involves several machining operations that are performed on CNC machines. These operations include milling, drilling, turning, and grinding. Each operation requires a different tool and cutting strategy to achieve the desired result.

Milling is the most commonly used operation in metal mold manufacturing. It involves the use of a rotating cutting tool to remove material from the workpiece. The tool is moved along multiple axes to create complex shapes and contours. CAM software is used to program the milling operation by specifying the tool path, speed, and feed rate.

Drilling is another important operation in metal mold manufacturing. It involves creating holes in the workpiece using a rotating drill bit. CAM software is used to program the drilling operation by specifying the location, size, and depth of the holes.

Turning is used to create cylindrical shapes on the workpiece. It involves rotating the workpiece while a cutting tool is moved along its length. CAM software is used to program the turning operation by specifying the diameter, length, and surface finish of the cylindrical shape.

Grinding is used to achieve a high level of surface finish on the workpiece. It involves the use of an abrasive wheel to remove material from the workpiece. CAM software is used to program the grinding operation by specifying the surface finish, depth of cut, and speed of the abrasive wheel.

SprutCAM X for mold manufacturing… Milling and much more

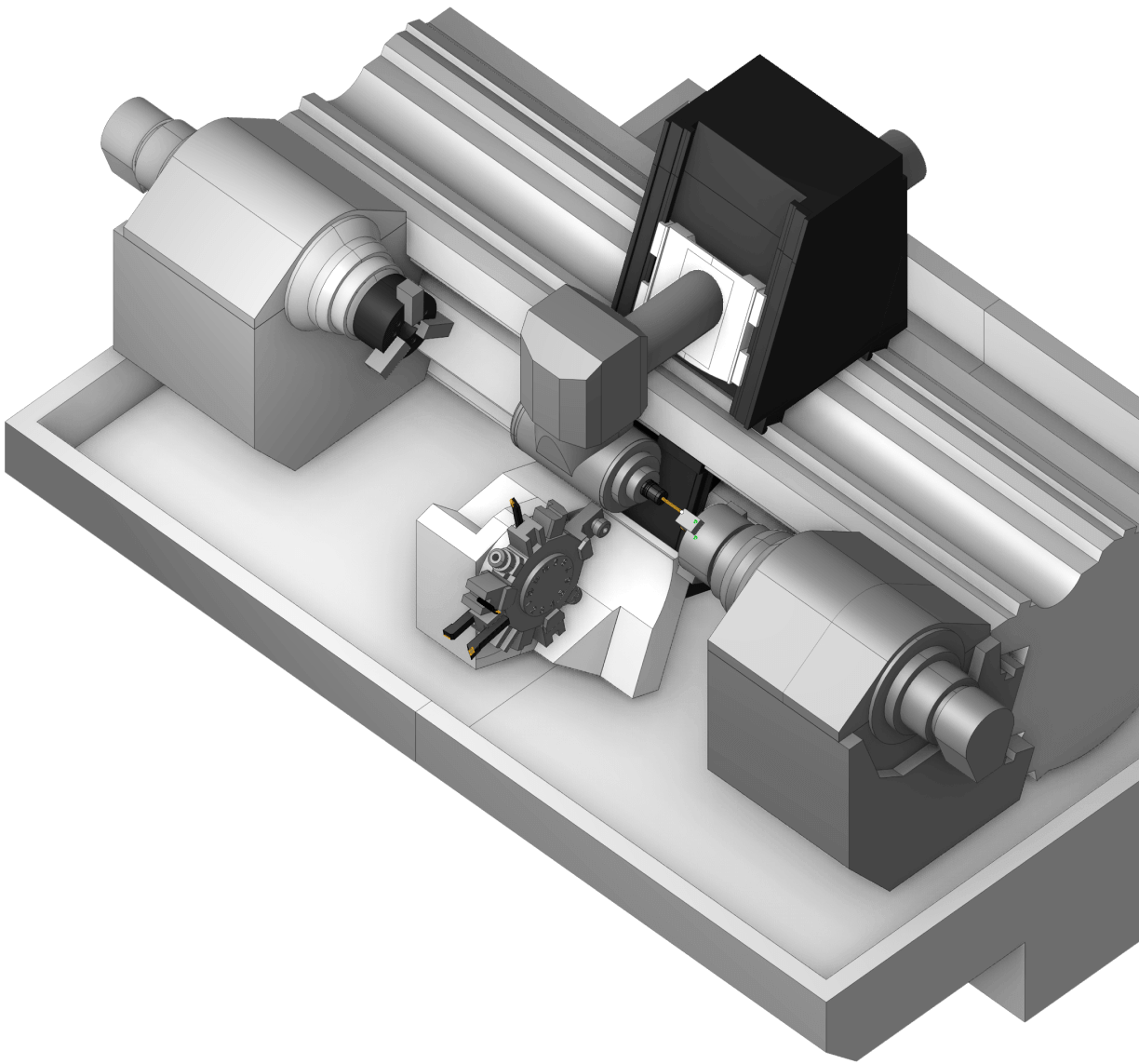

CAM software plays a crucial role in metal mold manufacturing by providing a user-friendly interface for programming CNC machines. One fine example of CAM software used for metal mold manufacturing is SprutCAM X. SprutCAM X offers a wide range of features for programming milling, drilling, turning, and grinding operations.

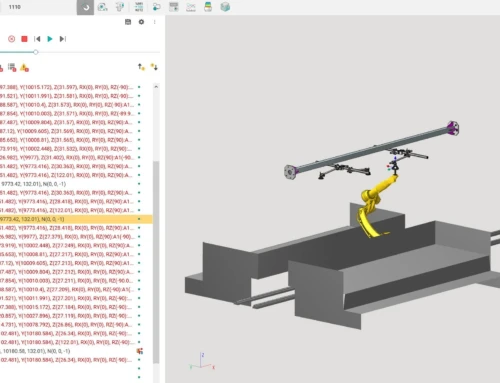

SprutCAM X allows users to create 3D models of the part using Computer-Aided Design (CAD) software. The 3D model is then smoothly passed onto the CAM part, where the user can define the machining operations and tool paths. SprutCAM X offers a variety of tool path strategies, including adaptive roughing, rest machining, and high-speed machining.

Adaptive roughing is a tool path strategy that optimizes the material removal rate by adjusting the cutting conditions based on the geometry of the part. Rest machining is used to remove material from areas that were not machined in the previous operation. High-speed machining is used to achieve faster machining times by increasing the cutting speed and reducing the depth of cut.

SprutCAM X also offers simulation tools that allow users to visualize the machining process before it is executed on the CNC machine. The simulation tools provide a realistic representation of the part and the machining process, allowing users to identify potential issues and optimize the tool paths.

So, in short, about mold manufacturing

Metal mold manufacturing on CNC machines has become an essential part of the manufacturing industry. The use of CAM software, such as SprutCAM X, has further enhanced the precision and accuracy of the machining process. CAM software allows users to program a wide range of machining operations, including milling, drilling, turning, and grinding. It also provides simulation tools that allow users to visualize the machining process before it is executed on the CNC machine. With these advancements in technology, metal mold manufacturing has become more efficient and cost-effective than ever before.