Offline

programming (OLP)

with SprutCAM X Robot

Offline

programming (OLP)

with SprutCAM X Robot

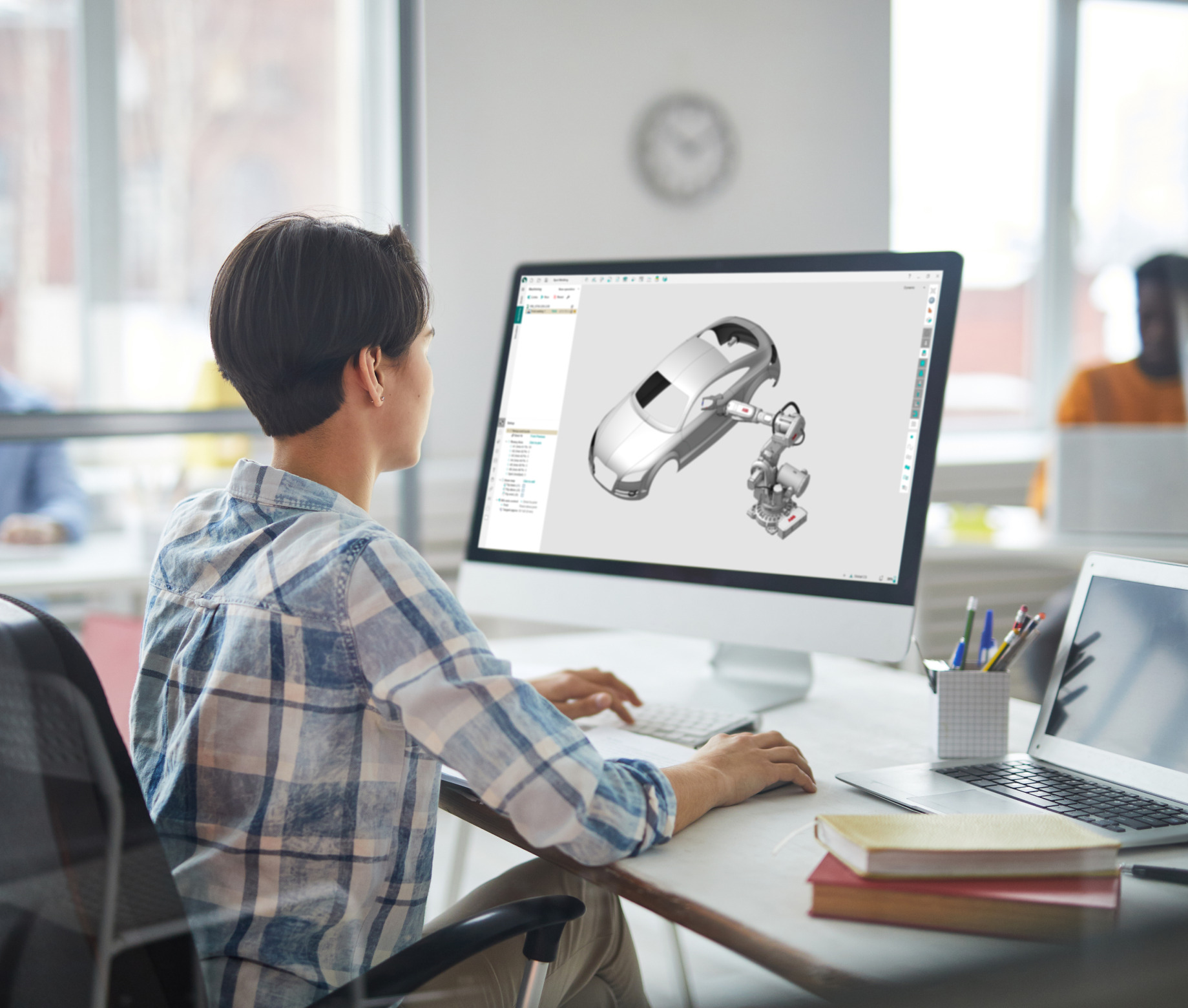

Did you know that SprutCAM X Robot offers a natural, easy and convenient way to program robots?

There are 2 main ways to program robots: offline and online

Key benefits of using OLP

Offline programming (OLP)

Is carried out on a separate PC using specialized software capable of simulating the processing on a digital model of a specific robot. With digital twin technology, you can continue to use a real robot at a production site without disrupting the manufacturing process while the next executable program is being developed in an external 3D design system.

Using OLP, a new processing program is launched on the robot in just a few hours, which are only required to set it up in real production conditions.

Key benefits of using OLP:

SprutCAM X Robot provides a convenient and natural robot programming environment,

in which the interaction of an engineer with a robot, tool and product is as close to reality as possible.

It seamlessly integrates offline programming, simulation and code generation, delivering quick, error-free industrial robot programs. Some robotic solutions require the purchase of a separate CAM system for full operation. In the case of SprutCAM X Robot, you do not need anything else.

SprutCAM X Robot is a complete, seamless offline industrial robot programming solution that provides:

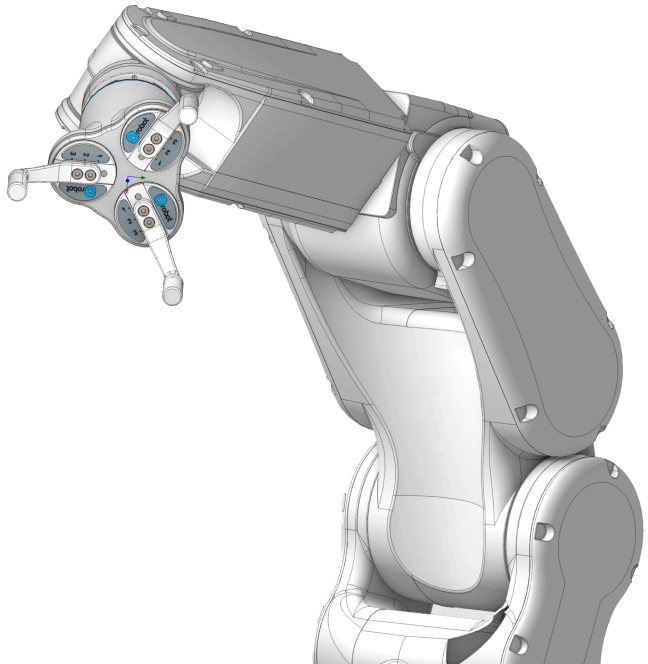

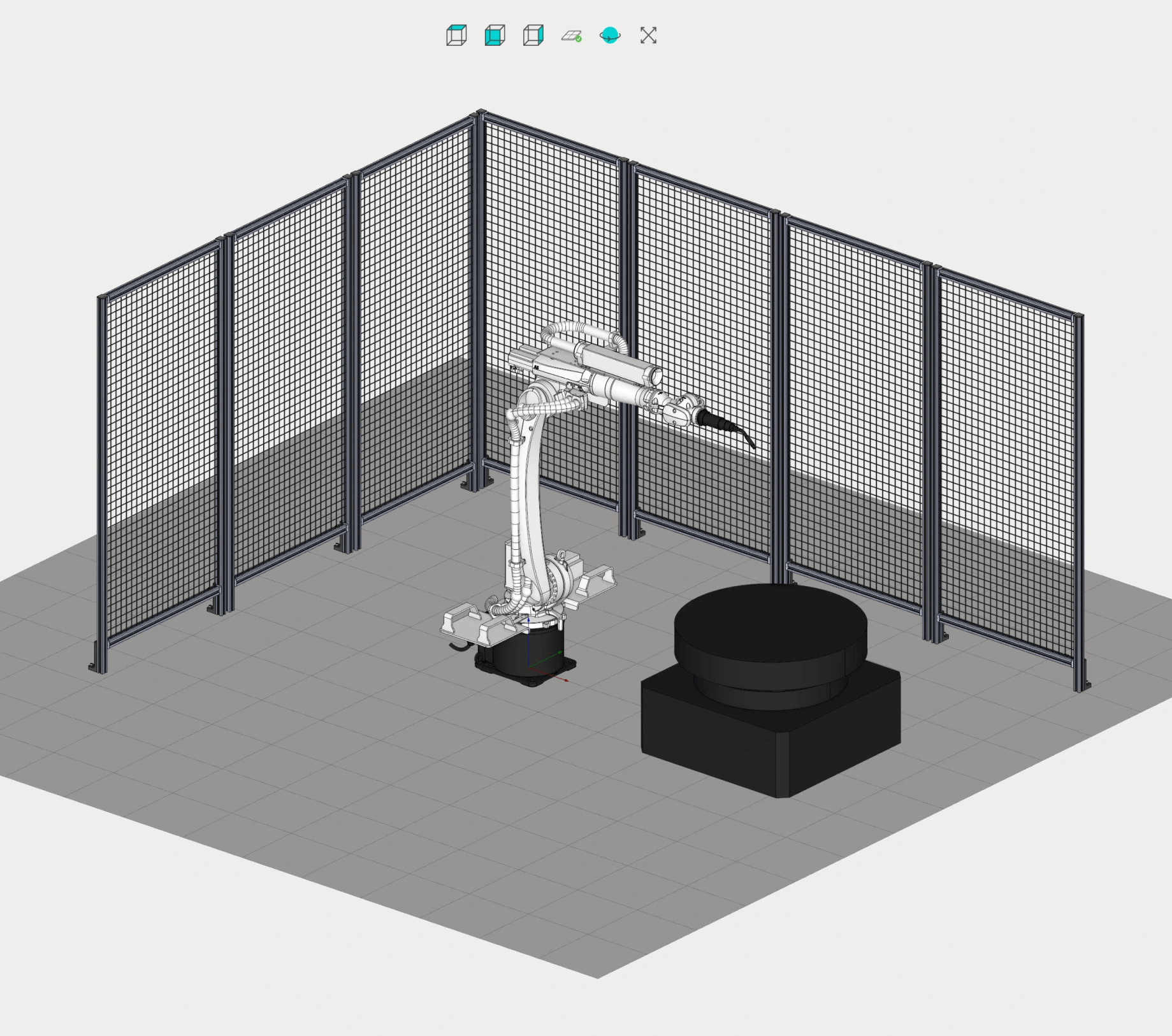

- Robotic cell zero-code digital twin builder

- Technology setup and toolpath calculation

- Simulation

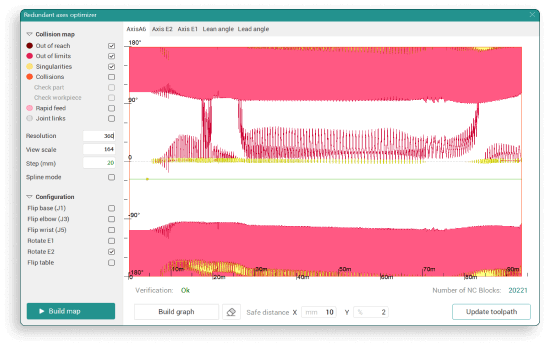

- Robot kinematics optimization for singularity avoidance and collision free movements

- Postprocessing

- G-code verification

SprutCAM X Robot is the ideal offline robot programming and robot simulation software solution for all applications that require CAD/CAM for robots.