Go beyond

traditional robot simulation software

SprutCAM X Robot is a single integrated software unit that includes

SprutCAM X Robot calculates native 6-axis toolpaths. No additional adjustments required to accommodate the robot’s

6-axis kinematics

Robot programming workflow

Generate toolpath

Generate the optimal toolpaths for robotic milling coming from the advanced CAM software, SprutCAM X, customized for robots. As well as robot-specific toolpaths.

Roughing toolpaths:

Waterline: parallel, equidistant, high-speed, adaptive. Rotary and 5 axis roughing. Hole machining with FBM.

Finishing toolpaths:

Simple finishing: waterline, plane, combined.

Sophisticated finishing: scallop, spiral, morph.

Contouring toolpaths:

2D, 2.5D, 3D, 5D and 6D contouring.

Special toolpaths:

Stone roughing, welding, painting, pick-and-place, grinding, deburring.

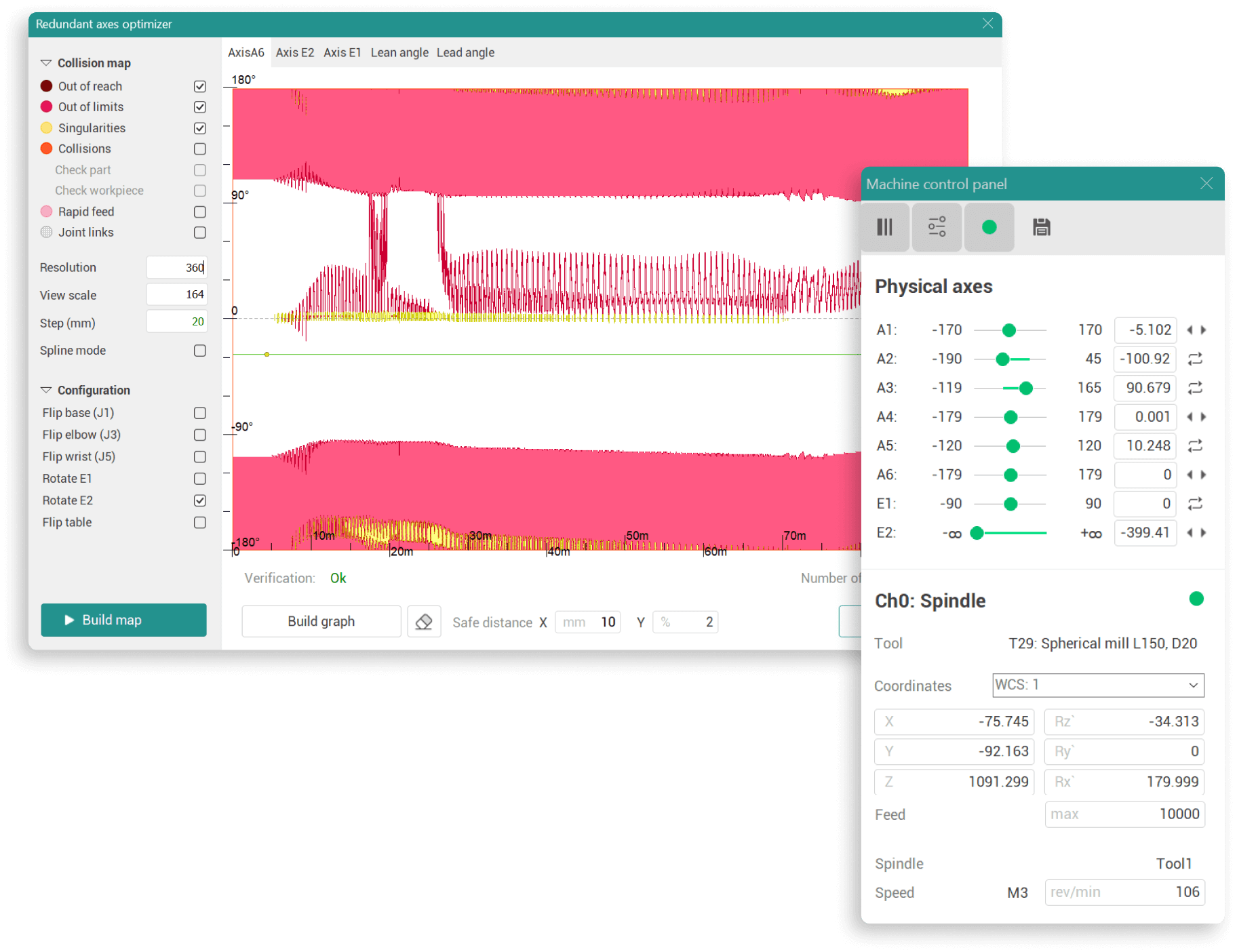

Manage robot kinematics

Handle singularities, collisions, reach zone limits and control redundant axes movements with dedicated tools

Robot axis map

Gain full control over singularities, collisions, reach zone limits, and redundant degree of freedom provided by 6th axis using a dedicated and powerful tool: the robot axis map.

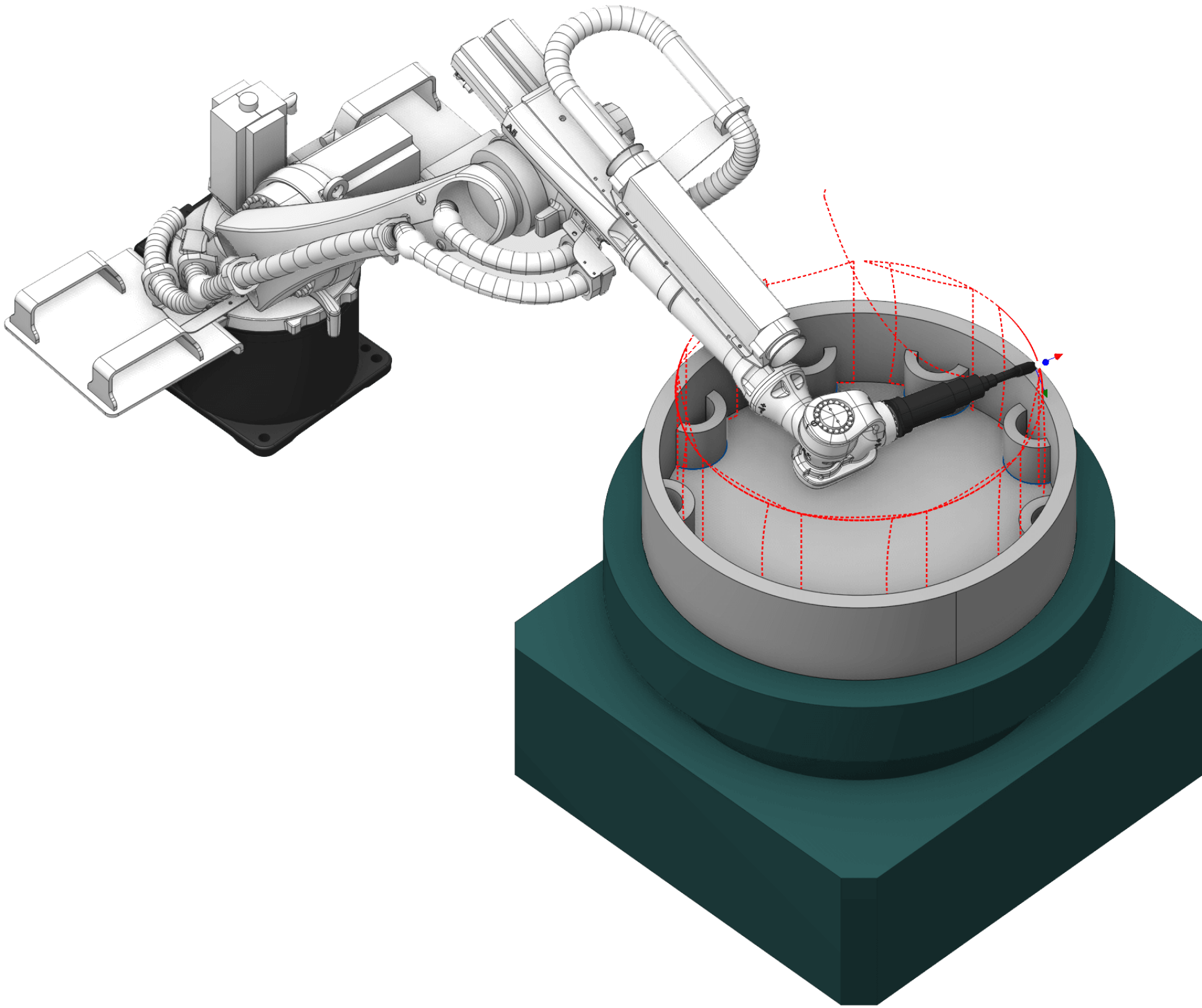

Utilizing rotary tables, positioners, and rails

Leverage the advanced capabilities of SprutCAM X Robot to define the specific behavior of optional equipment with special features.

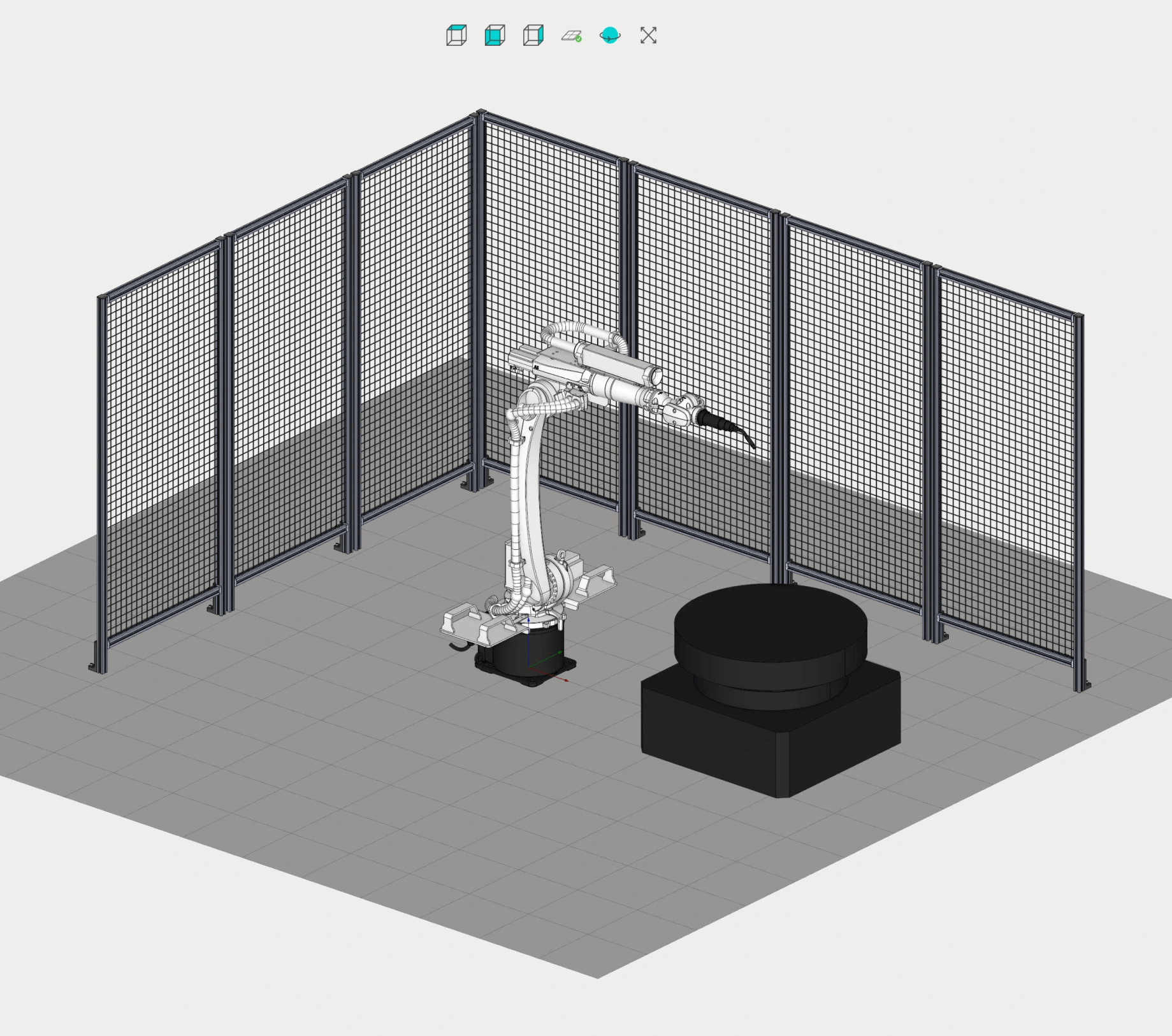

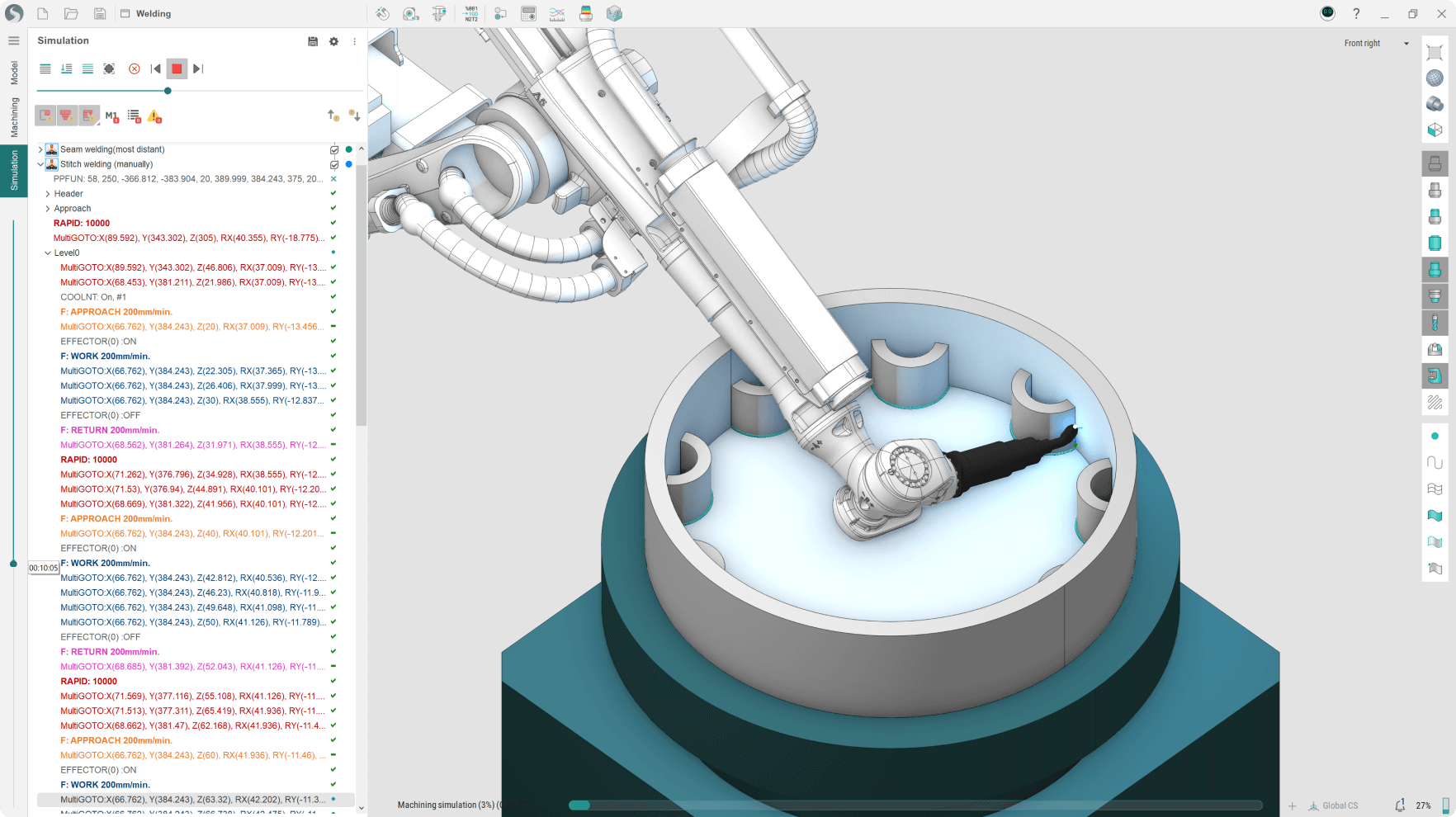

Simulate with Digital Twin

Experience full robotic cell simulation with high resolution and smoothness.

Complete robot cell simulation:

SprutCAM X Robot offers advanced simulation capabilities that include the full robotic cell simulation with the utilization of imported geometry such as robots, tables, rails, end effectors, fences, fixtures, and tool magazines.

Material removal, additive, painting:

SprutCAM X Robot provides dedicated simulation modes for material removal, additive processes, and painting, enabling precise result control.

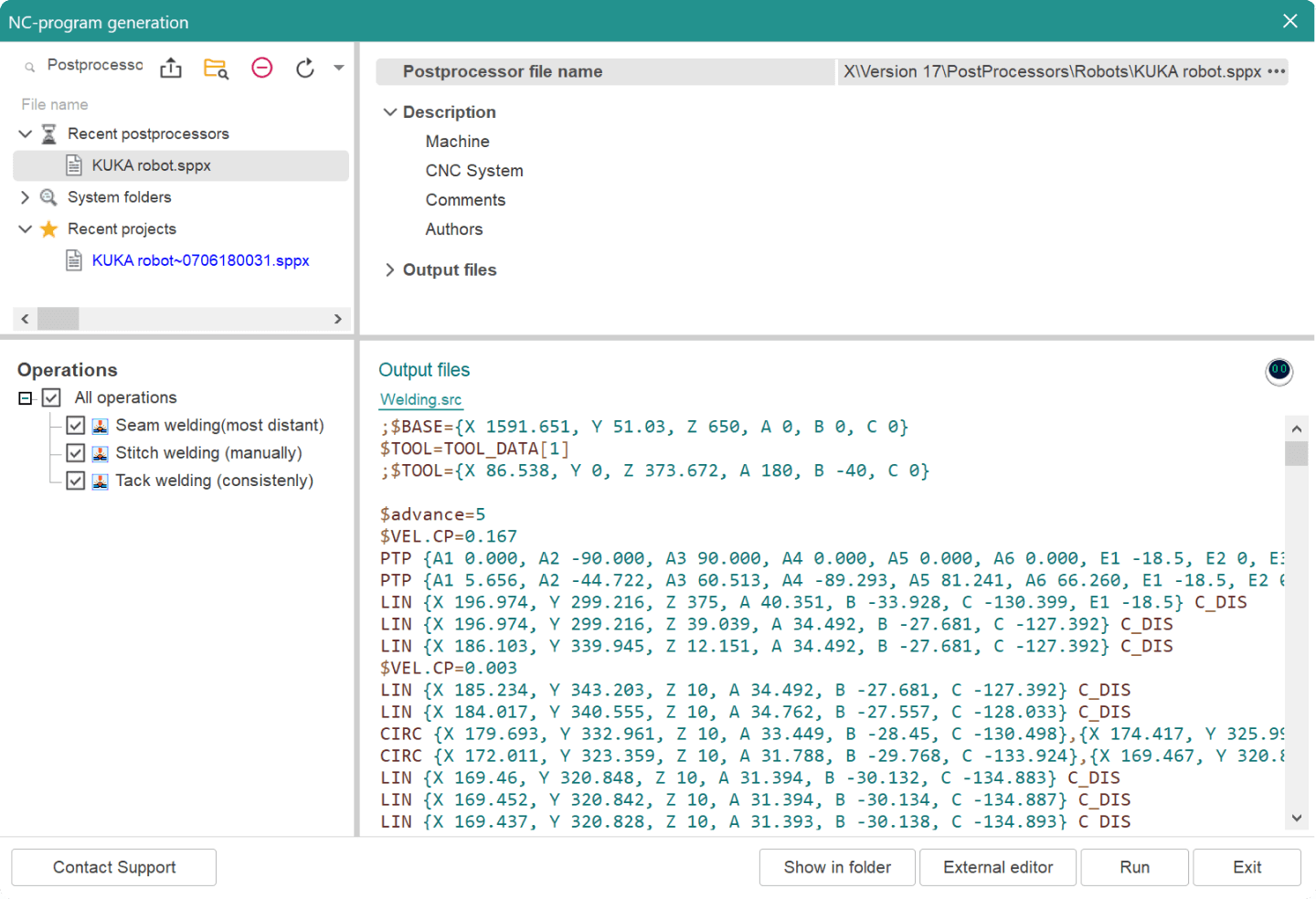

Postprocess

Generic and tailor-made post processors

SprutCAM X Robot proudly comes with out-of-the-box post processors for leading robot manufacturers such as Kuka, Fanuc, Motoman, ABB, Staubli, Nachi and many more.

In partnership with our extensive dealer network, we’re committed to providing a seamless, turn-key experience for every customer. That’s why we offer customized, tailor-made post processors designed to meet your unique needs and requirements. Trust SprutCAM X Robot to deliver a streamlined solution that maximizes efficiency and performance.

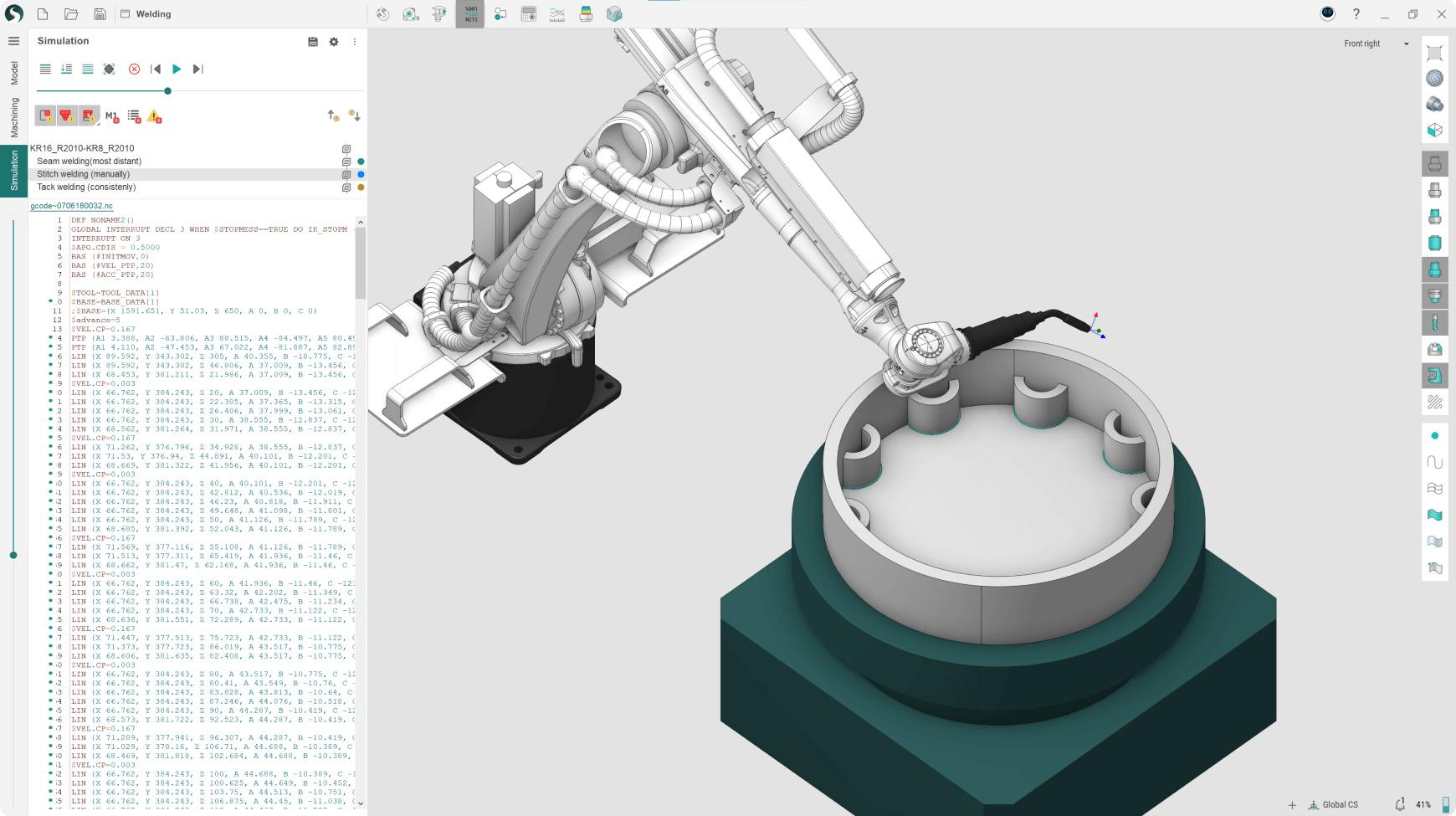

Verify G-code

Leverage the power of G-code verification

Experience unparalleled peace of mind with our enhanced pre-launch verification feature. This cutting-edge technology enables users to thoroughly examine and validate post-processed control programs prior to launch. As the crucial final step in our safety protocol, this feature harnesses the power of digital twin simulation to ensure your control program is optimized, reliable, and ready for deployment. Don’t leave anything to chance – let our advanced verification process safeguard your success.

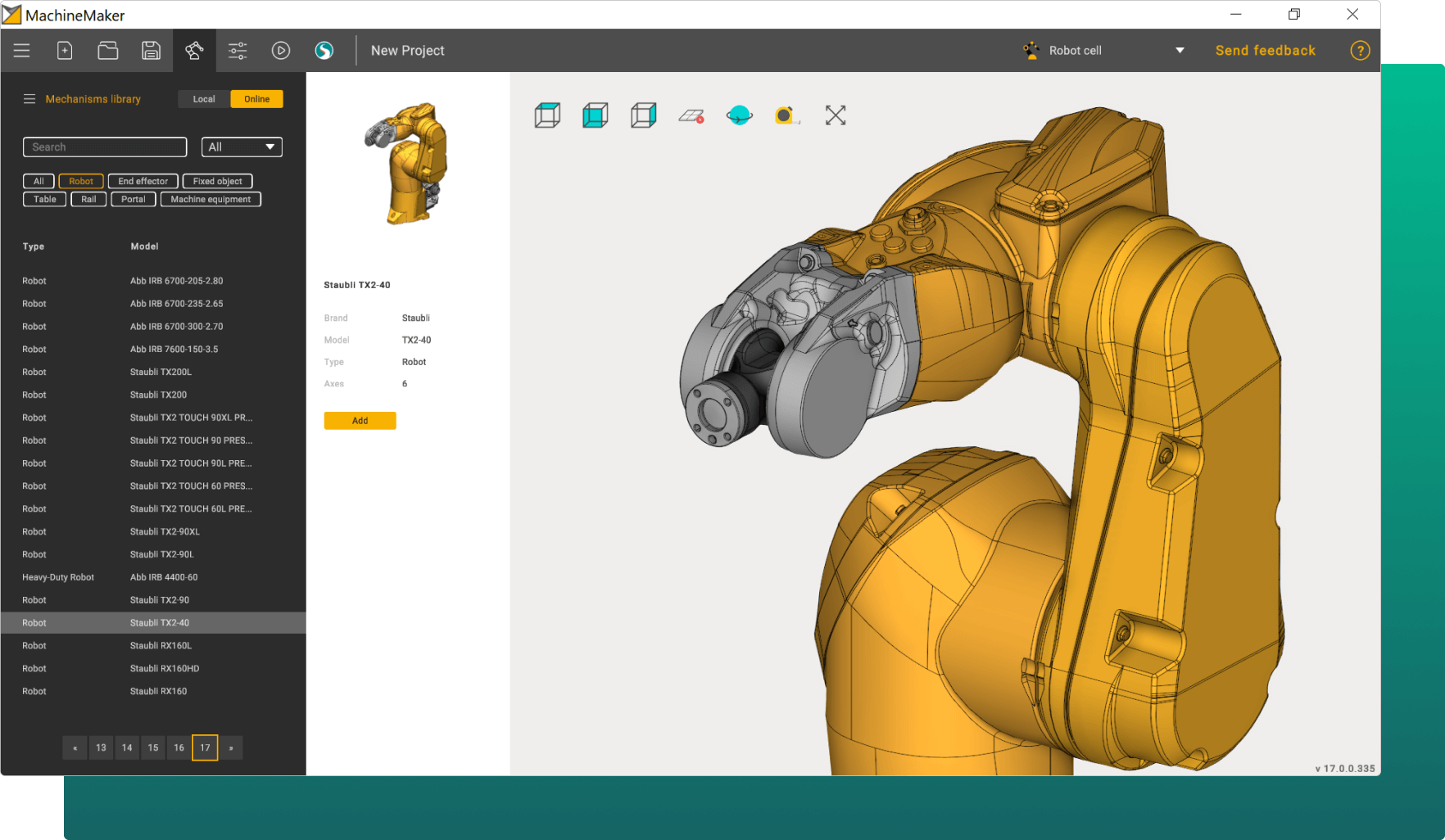

Robot library

The SprutCAM X Robot Library contains a wide range of robots from most manufacturers, including:

- Fanuc

- ABB

- KUKA

- Mitsubishi

- Toshiba

- Motoman

- Staubli

- Nachi

- and many more.