Conozca la SprutCAM X

Plataforma CAD/CAM consciente de la máquina

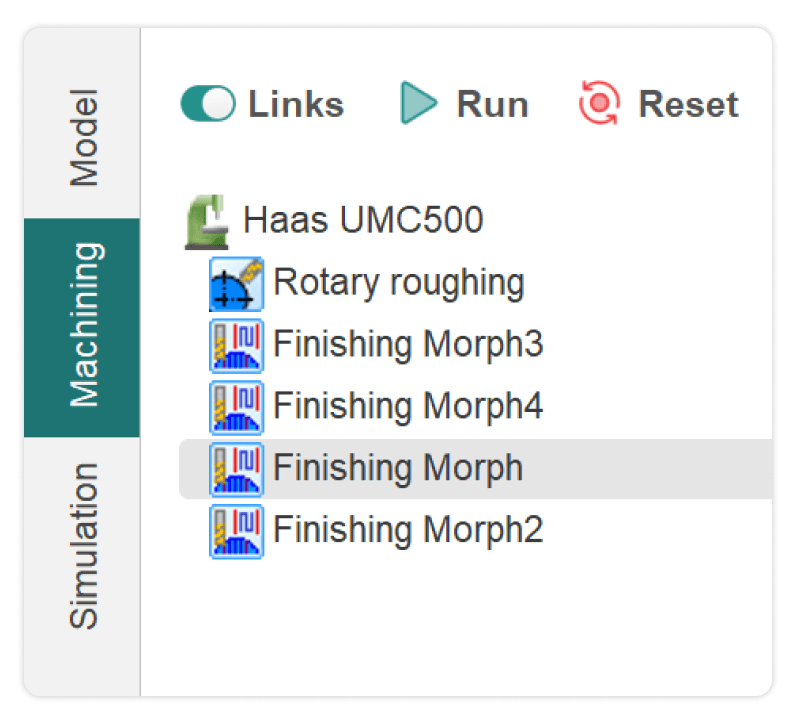

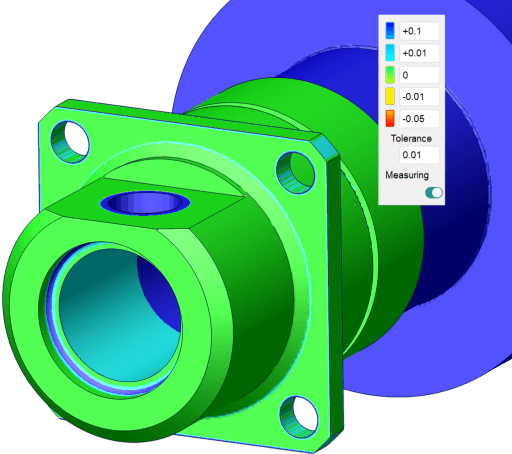

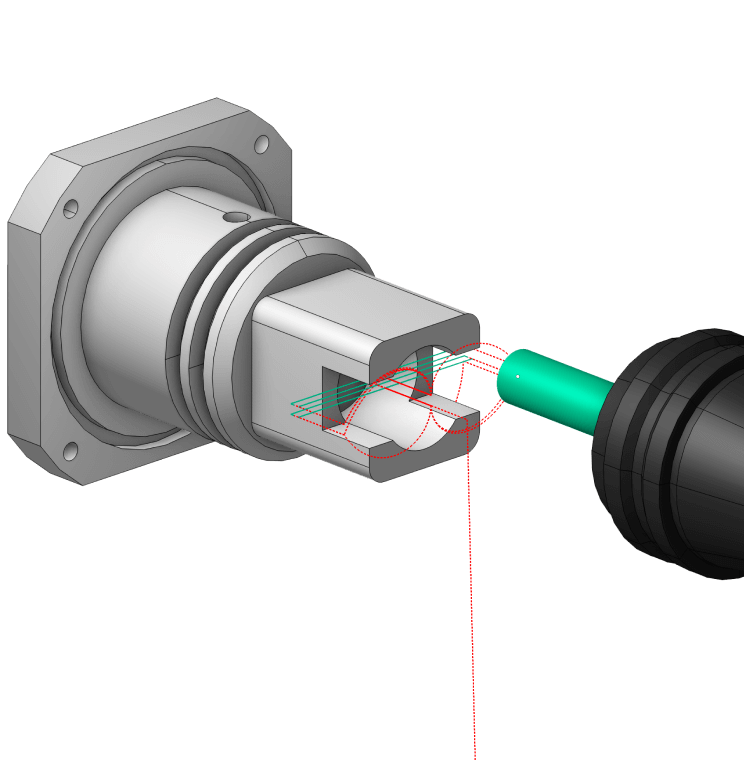

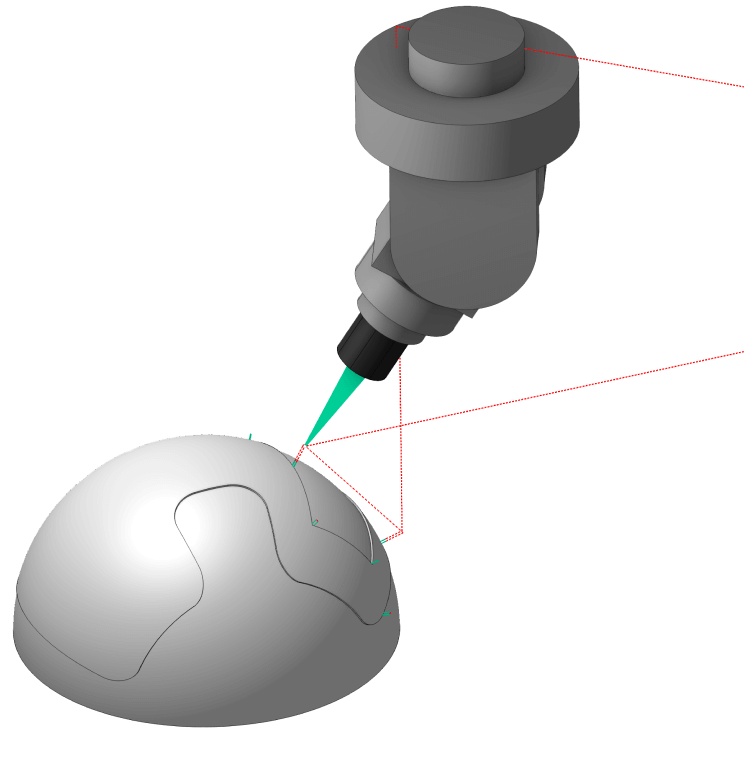

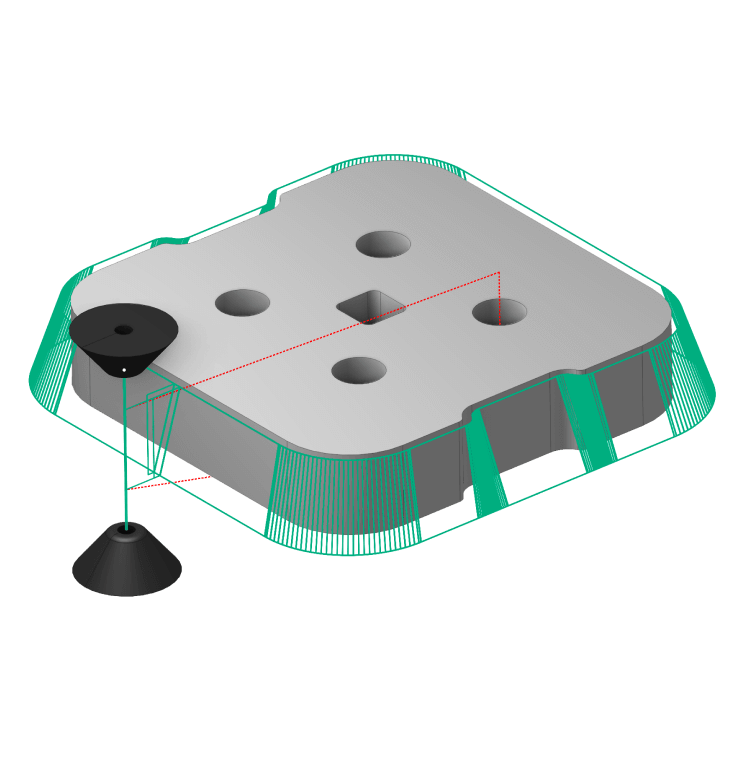

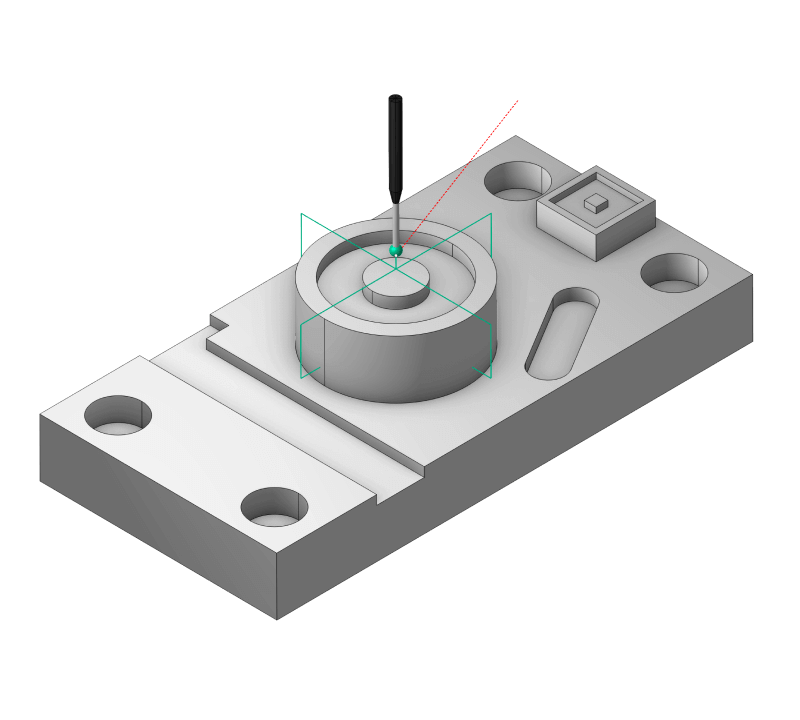

SprutCAM X introdujo el enfoque de programación Machine-Aware en 2001, estableciéndolo como la base de gama alta para un software CAM.

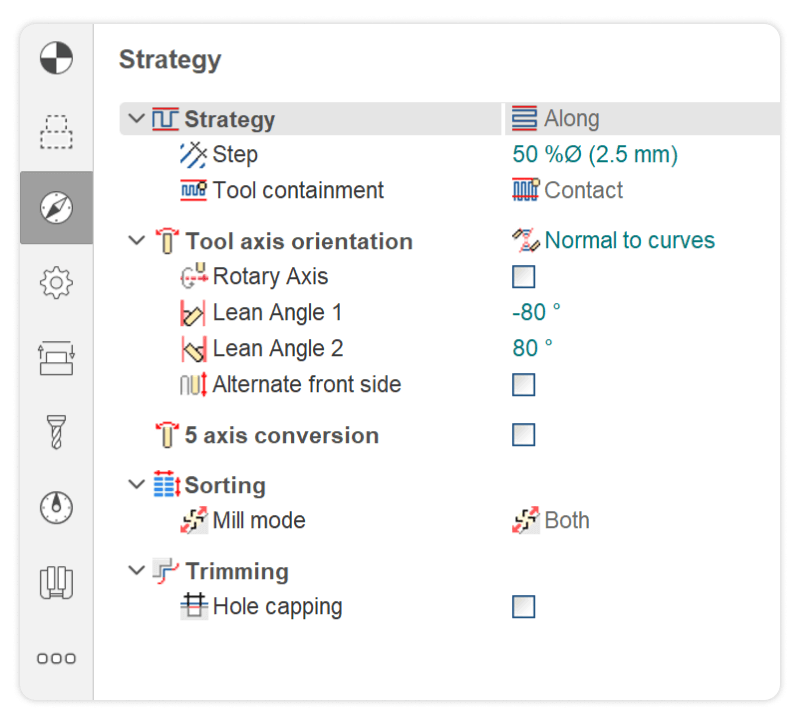

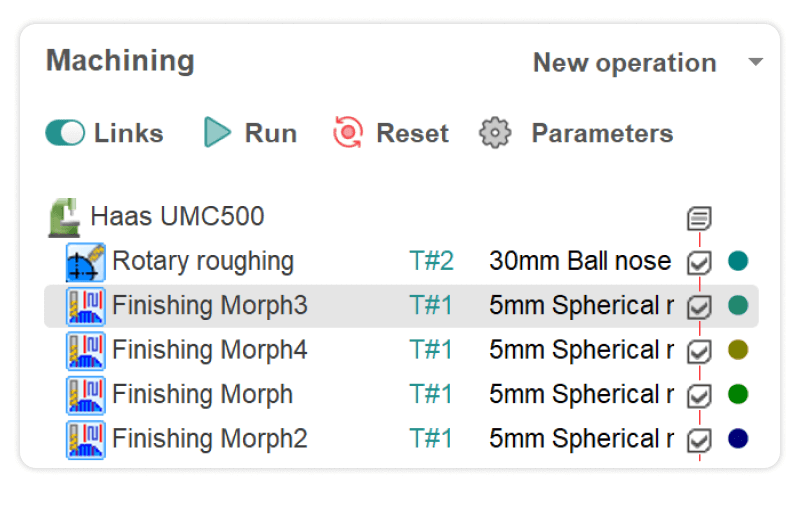

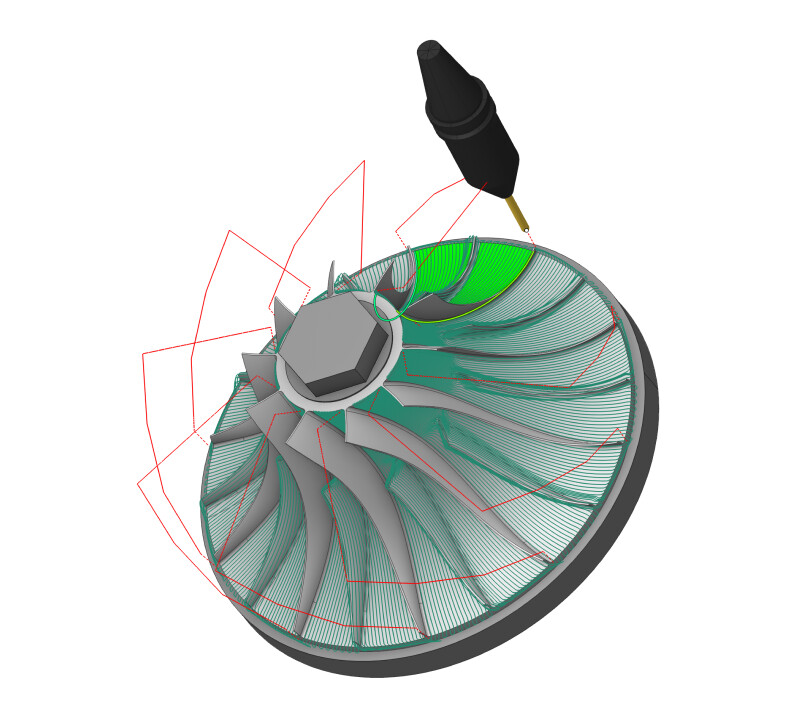

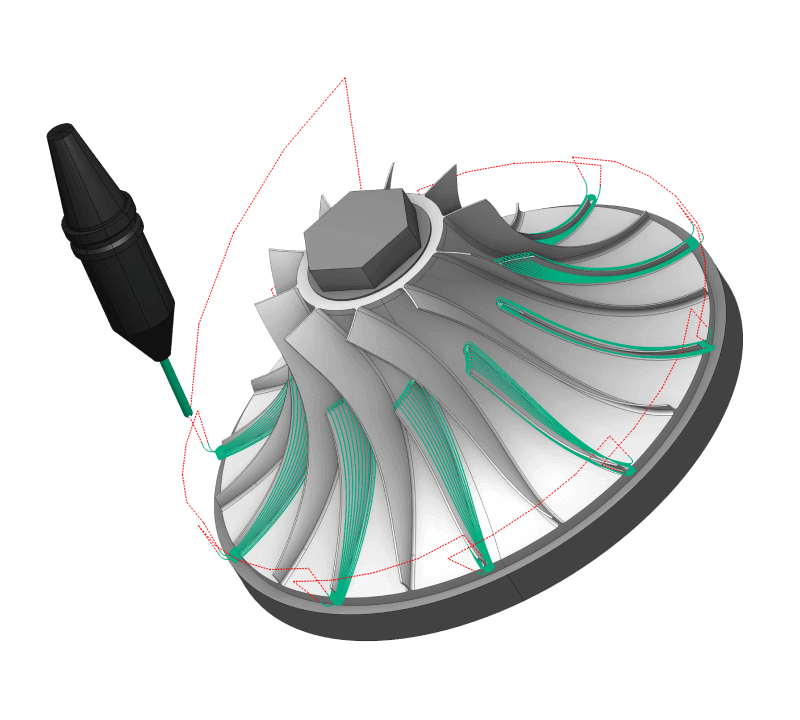

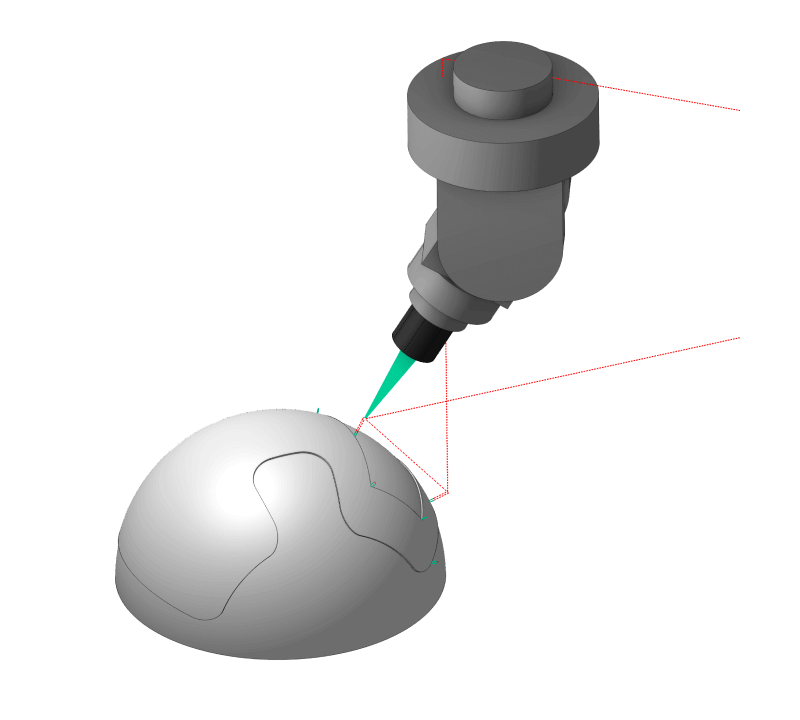

Este enfoque innovador implica tener en cuenta las limitaciones de la máquina durante el cálculo inicial de la trayectoria de la herramienta, lo que lo diferencia de los métodos CAM tradicionales que operan en un espacio abstracto antes de convertirlo en código de máquina real durante la simulación o el postprocesado.

A medida que la cinemática de las máquinas se vuelve cada vez más compleja, las ventajas del enfoque Machine-Aware siguen aumentando.

Este avanzado software CAD/CAM no sólo garantiza la seguridad adecuada para la programación de máquinas de 5 ejes y de fresado-torneado, sino que también proporciona una base para una experiencia de usuario transparente e intuitiva.

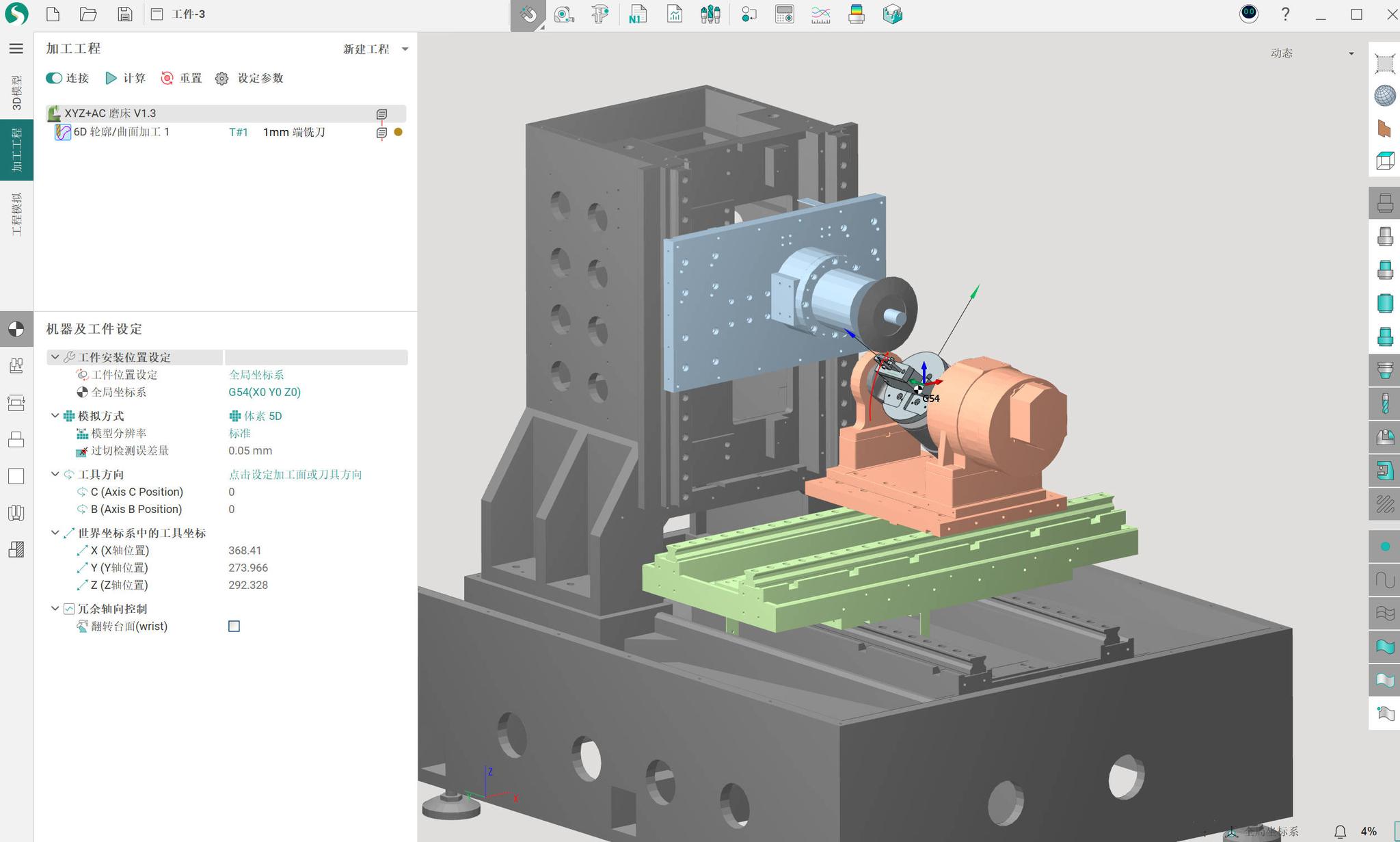

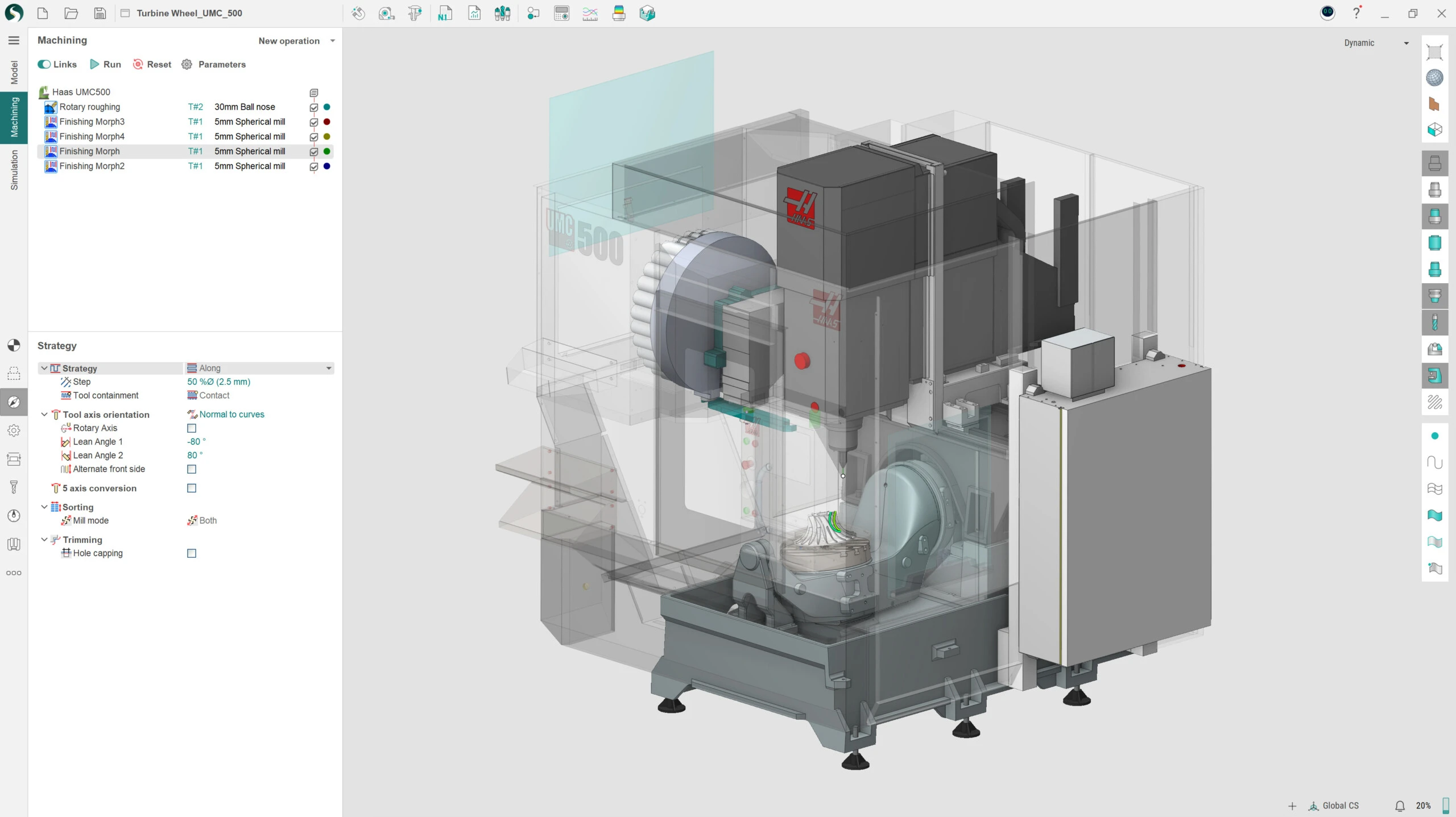

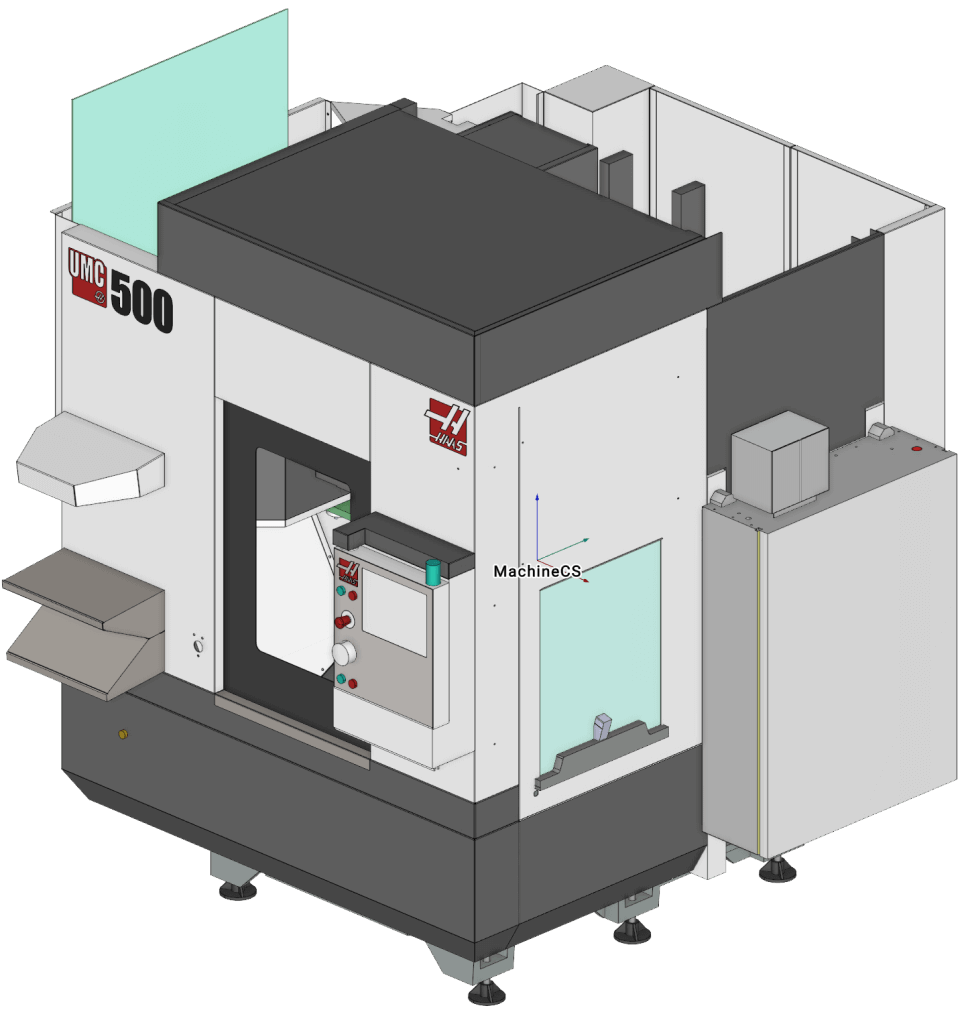

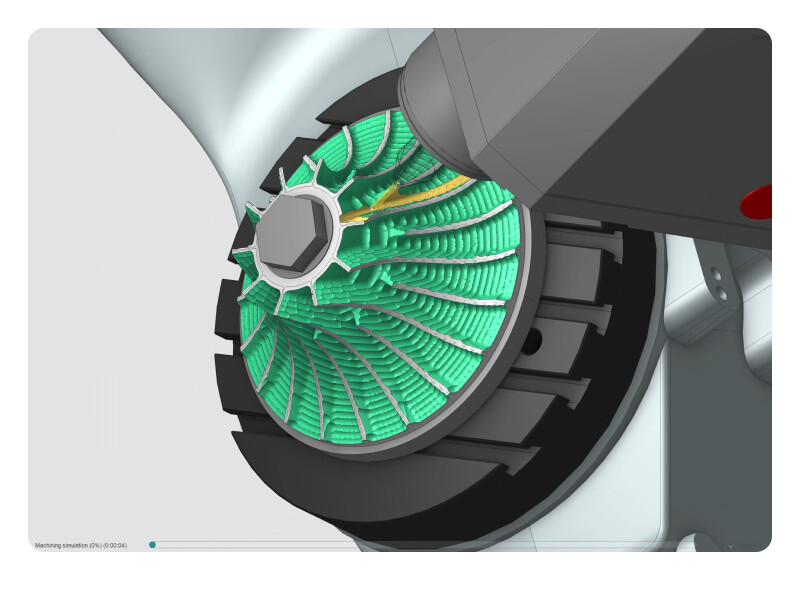

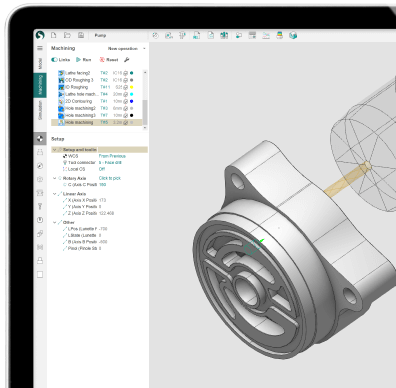

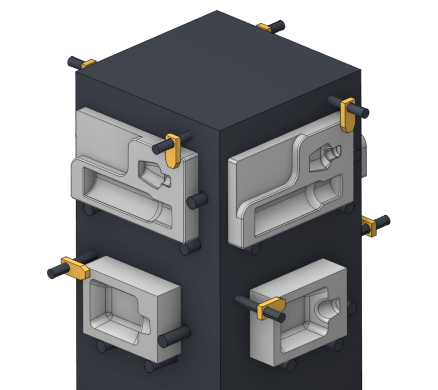

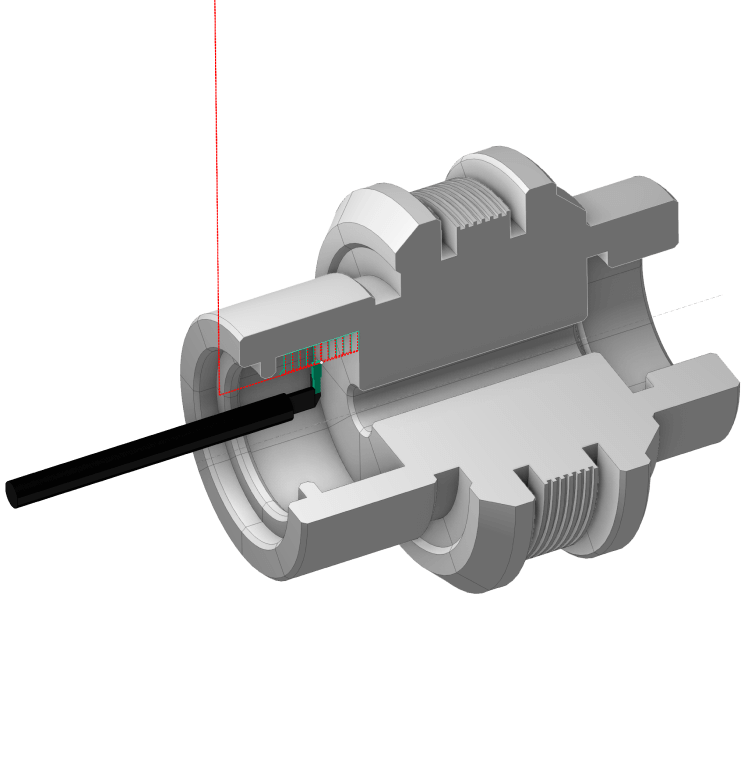

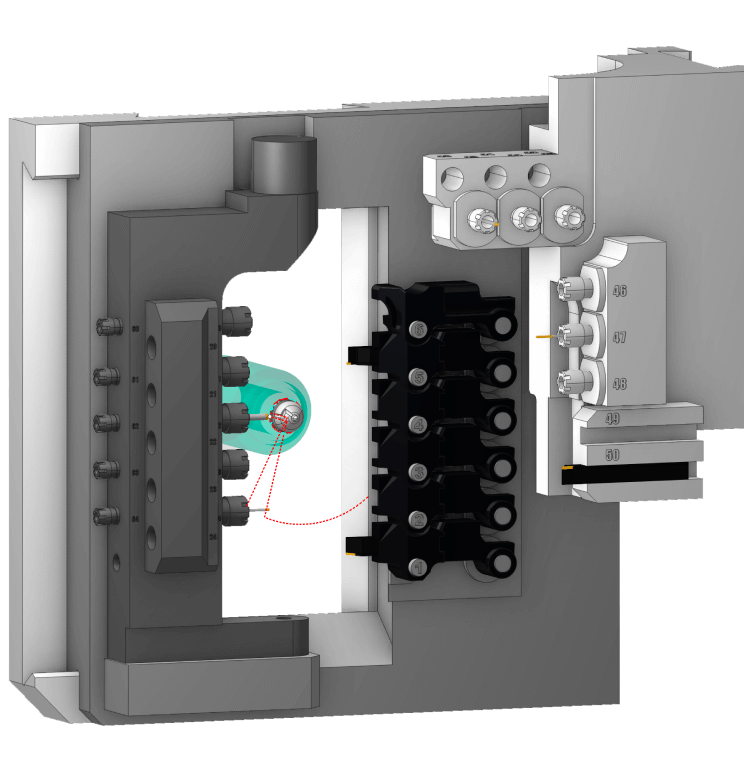

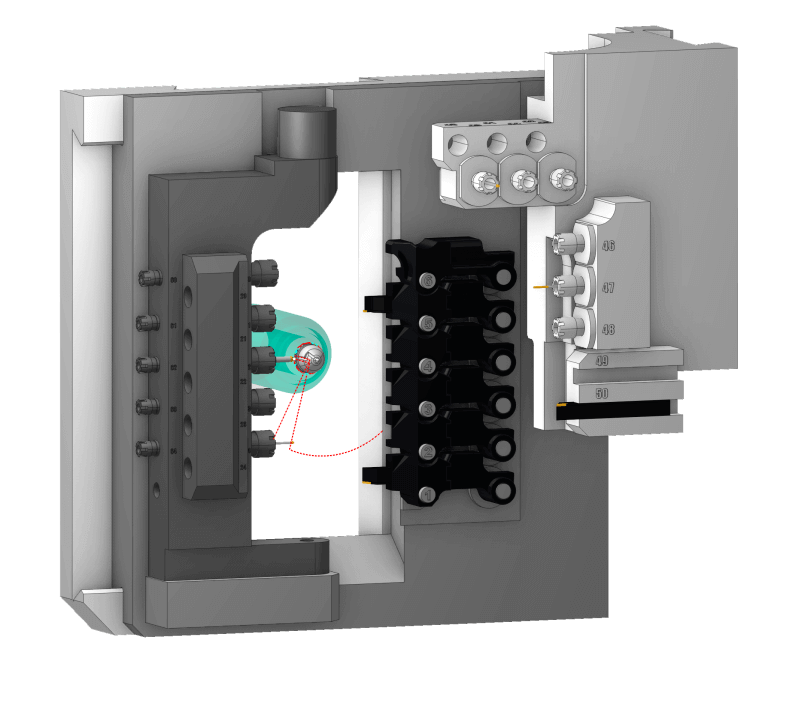

Su máquina CNC gemela digital

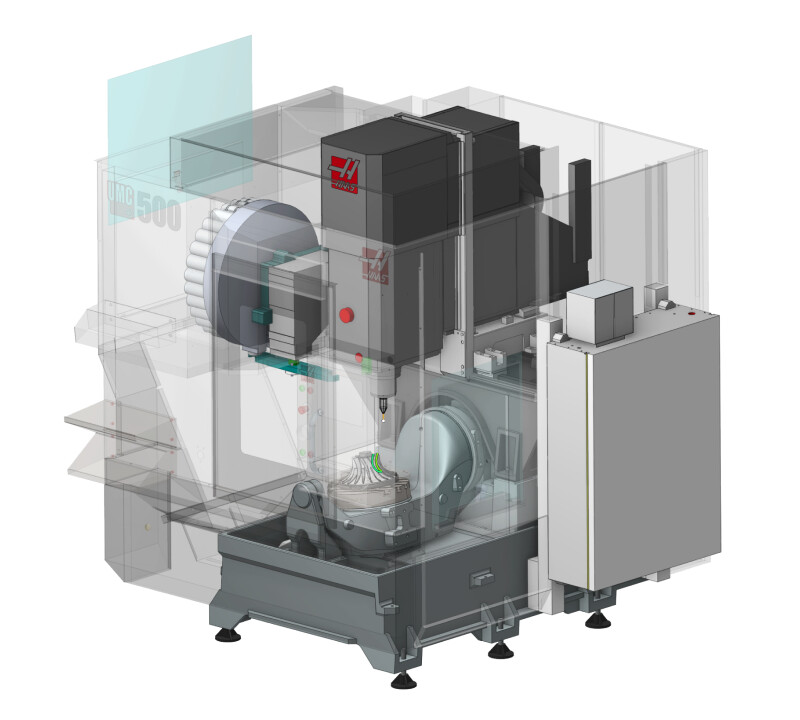

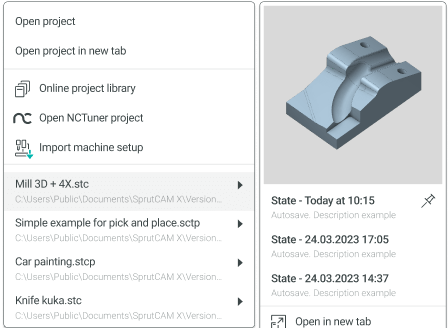

La aplicación MachineMaker le permite generar una réplica digital de su máquina CNC en cuestión de minutos. Este gemelo digital está pensado para su uso en la programación de la máquina CNC dentro del software CAD/CAM SprutCAM X.

Además, MachineMaker cuenta con una amplia biblioteca de componentes individuales fácilmente disponibles, así como gemelos digitales completos prediseñados de máquinas CNC y postprocesadores.

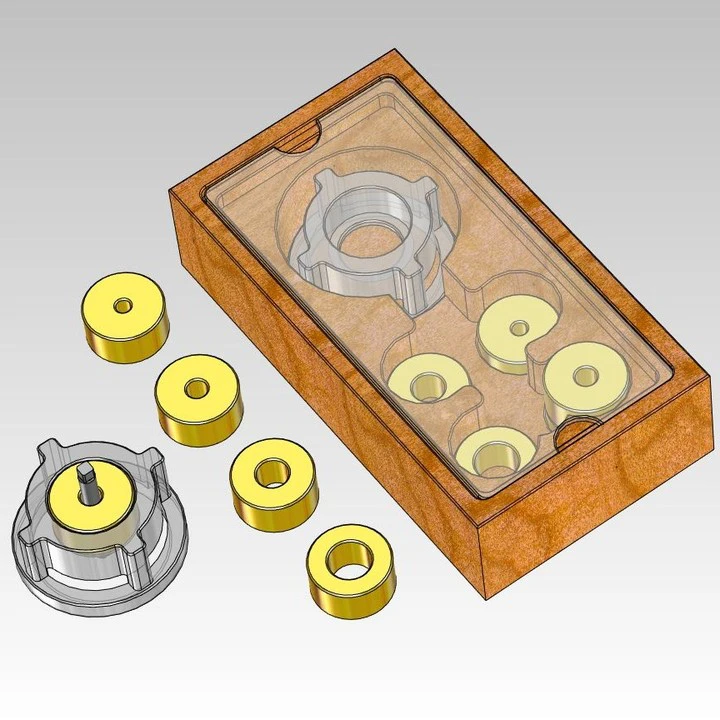

Productos destacados

Aplicaciones

Lo más destacado en tecnología:

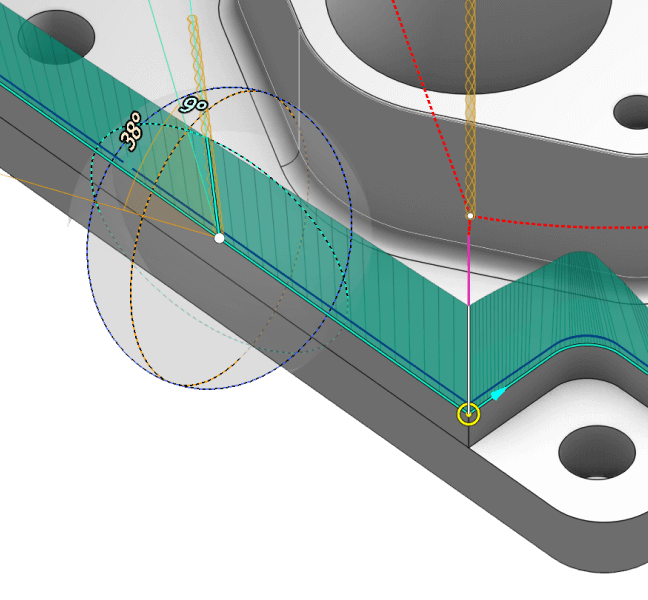

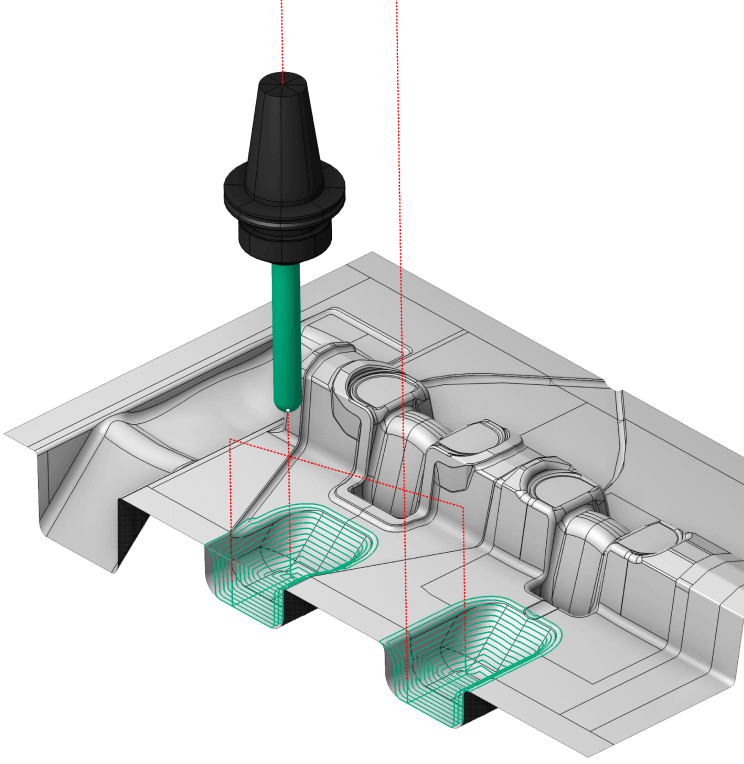

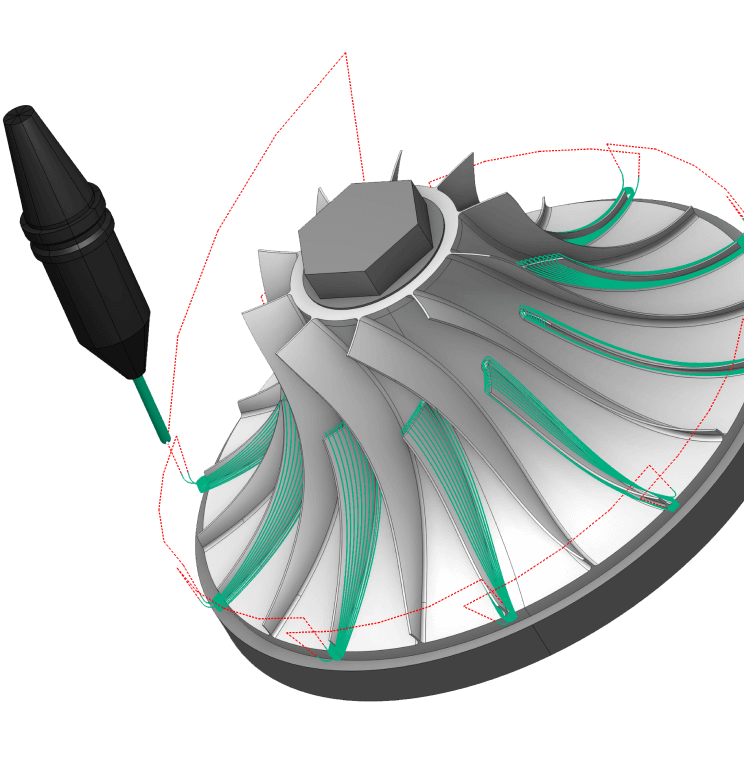

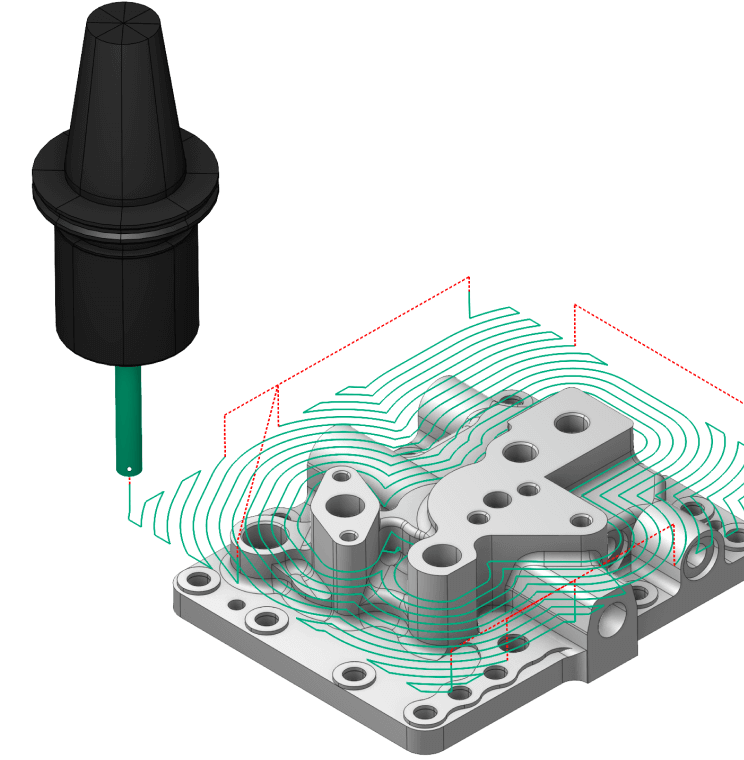

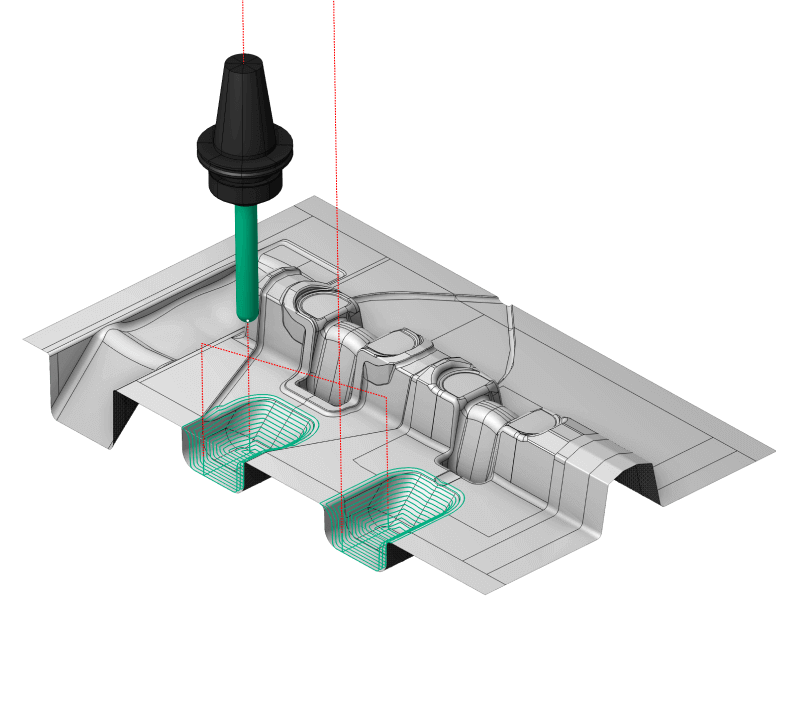

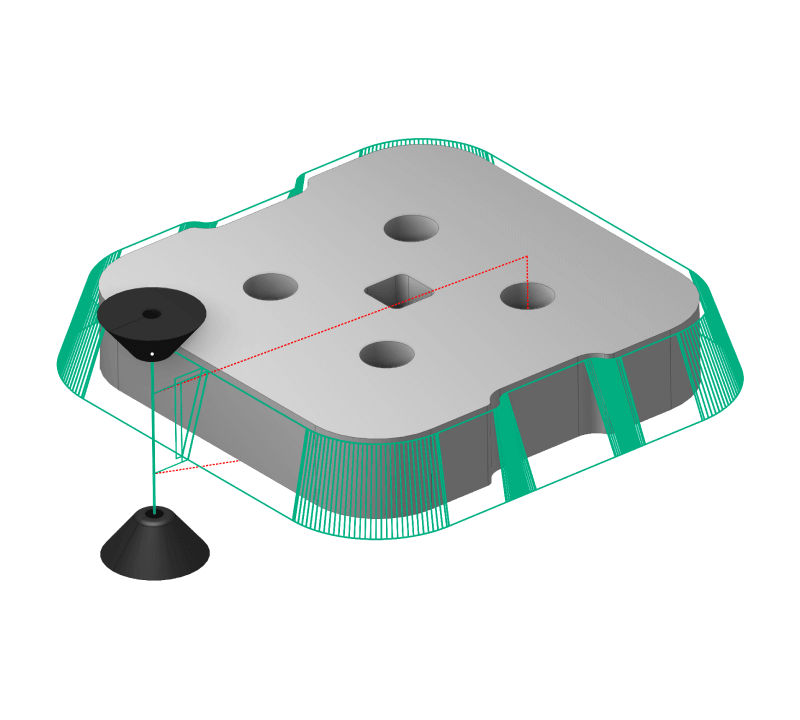

SC adaptable

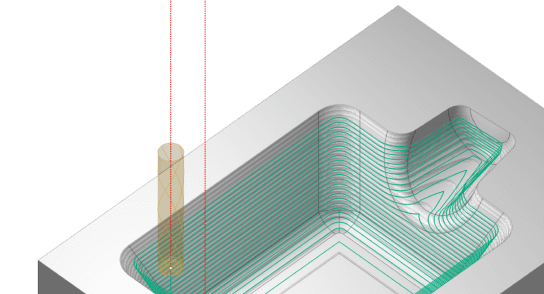

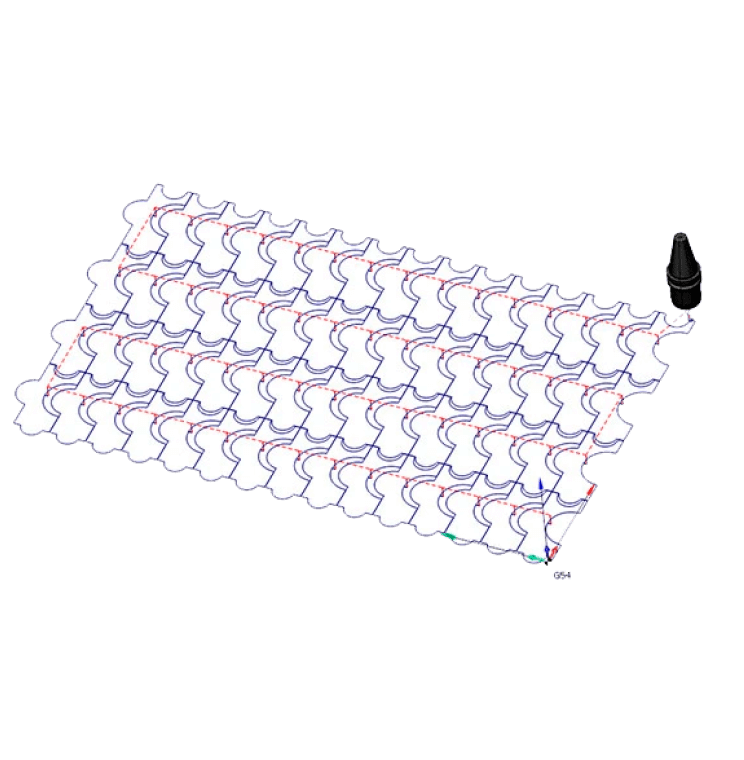

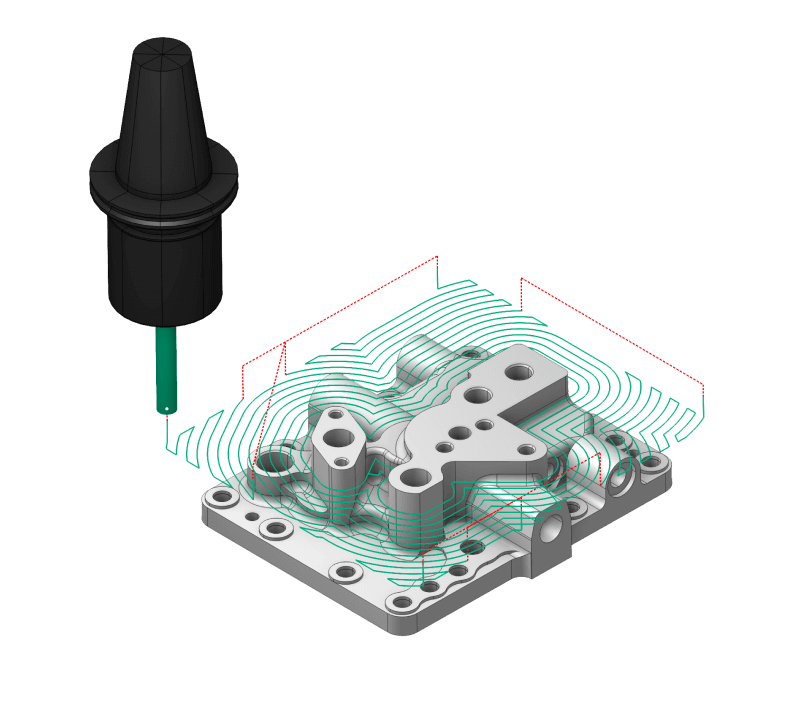

Este ciclo de mecanizado de alta velocidad está diseñado específicamente para el desbaste con el fin de reducir sustancialmente los tiempos de ciclo y prolongar la vida útil de la herramienta.

Su tecnología regula automáticamente las cargas de viruta y las fuerzas de corte laterales al tiempo que mantiene el ángulo de engrane de la fresa y la aceleración de los ejes de la máquina dentro de unos rangos óptimos.

Con Adaptive SC, la máquina puede realizar cortes más profundos a velocidades de avance más elevadas, que además se optimizan automáticamente en toda la trayectoria de la herramienta para obtener la máxima eficacia.

En comparación con los métodos de mecanizado tradicionales, Adaptive SC proporciona las siguientes ventajas:

70%

reducción del tiempo de ciclo

500%

aumento de la vida útil de la herramienta

Aplicaciones

Lo más destacado en tecnología:

SC adaptable

Este ciclo de mecanizado de alta velocidad está diseñado específicamente para el desbaste con el fin de reducir sustancialmente los tiempos de ciclo y prolongar la vida útil de la herramienta.

Su tecnología regula automáticamente las cargas de viruta y las fuerzas de corte laterales al tiempo que mantiene el ángulo de engrane de la fresa y la aceleración de los ejes de la máquina dentro de unos rangos óptimos.

Con Adaptive SC, la máquina puede realizar cortes más profundos a velocidades de avance más elevadas, que además se optimizan automáticamente en toda la trayectoria de la herramienta para obtener la máxima eficacia.

En comparación con los métodos de mecanizado tradicionales, Adaptive SC proporciona las siguientes ventajas:

70%

reducción del tiempo de ciclo

500%

aumento de la vida útil de la herramienta

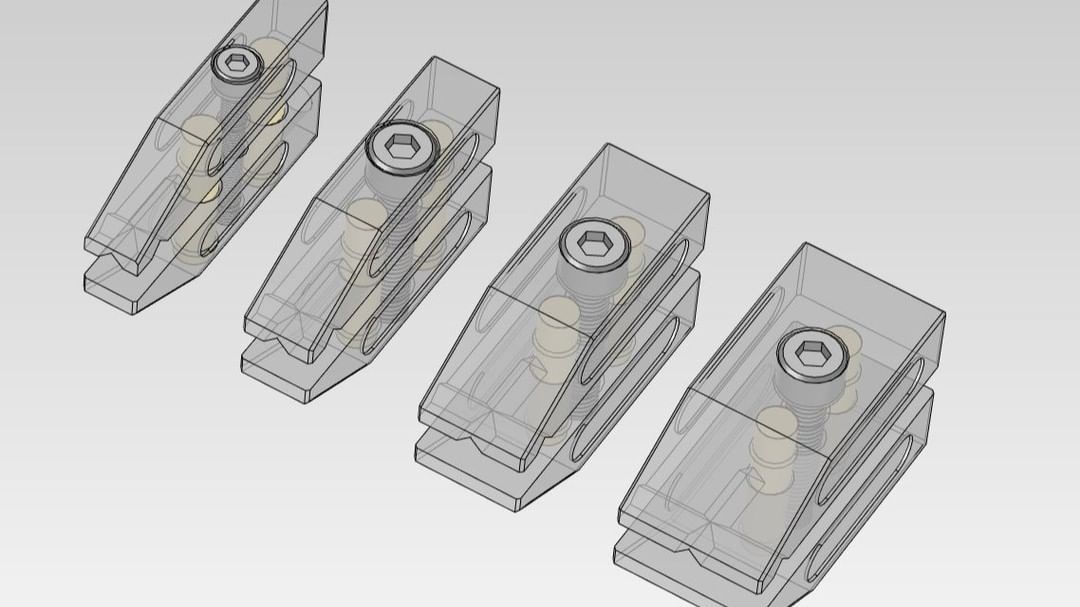

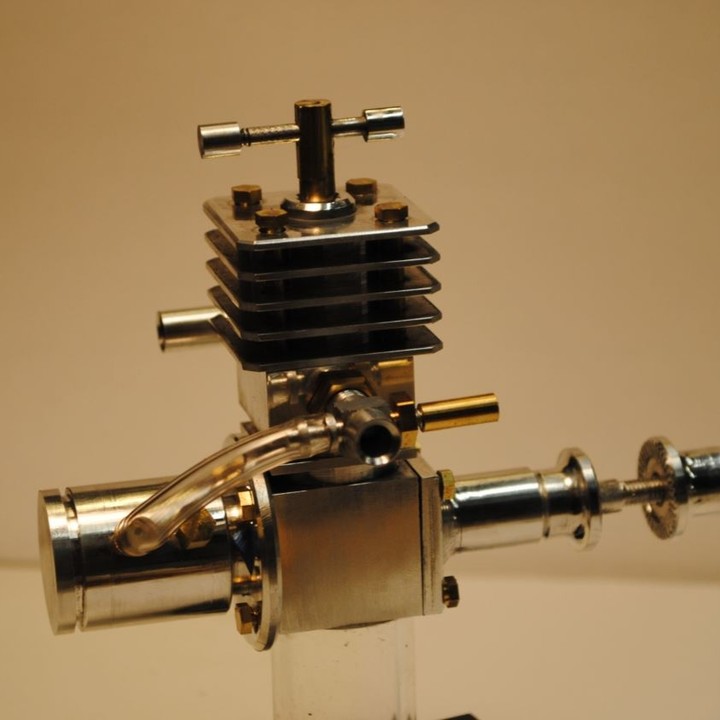

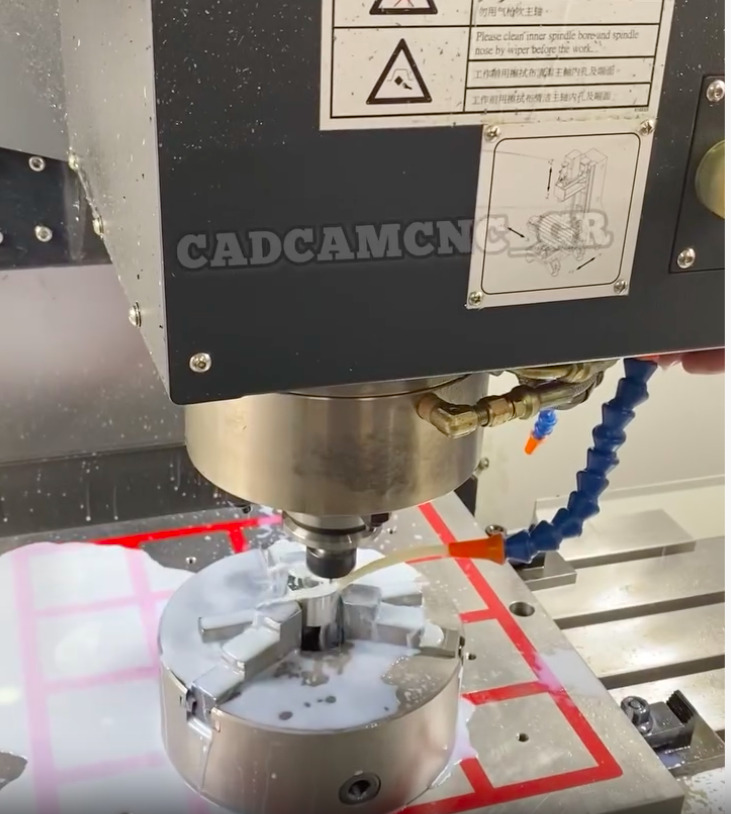

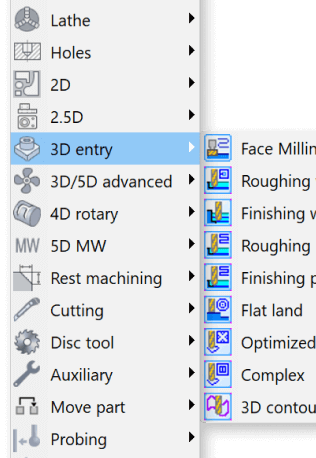

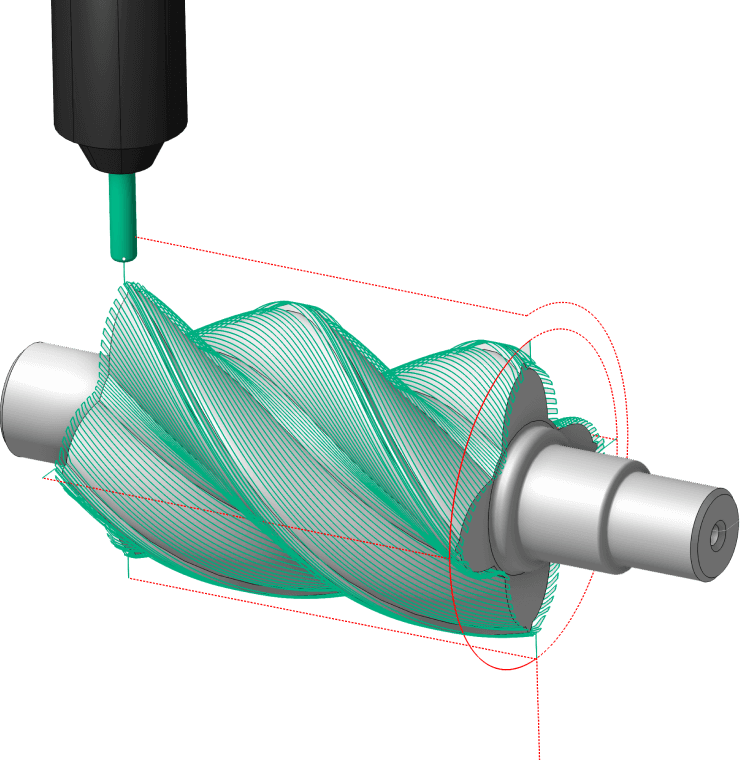

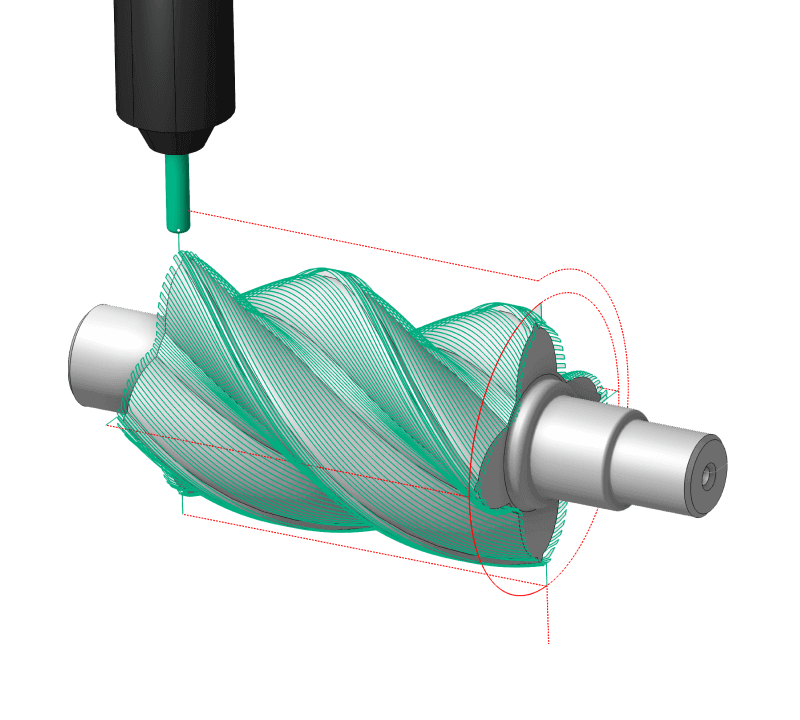

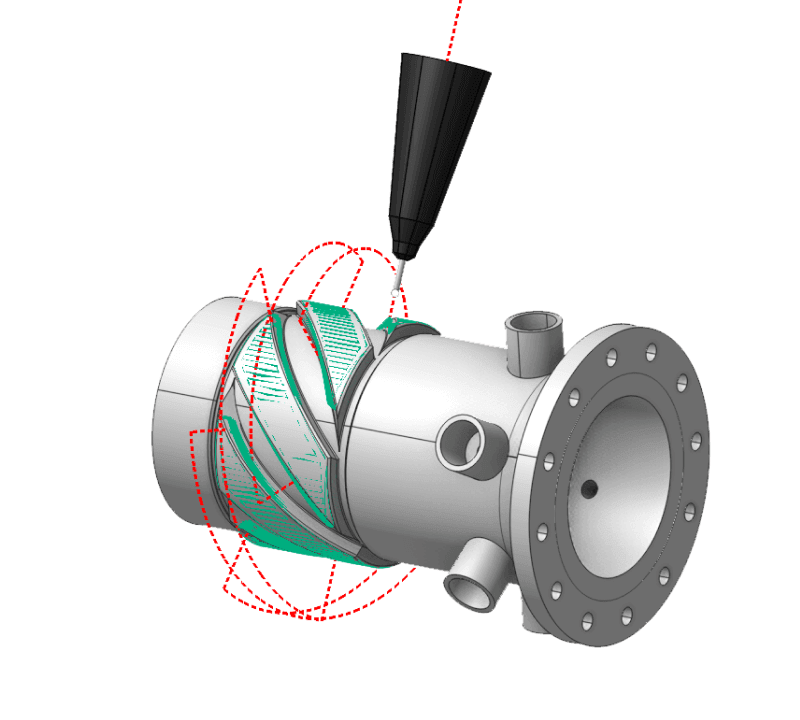

Producción de tornillos, cuchillas, ruedas dentadas, balaustres

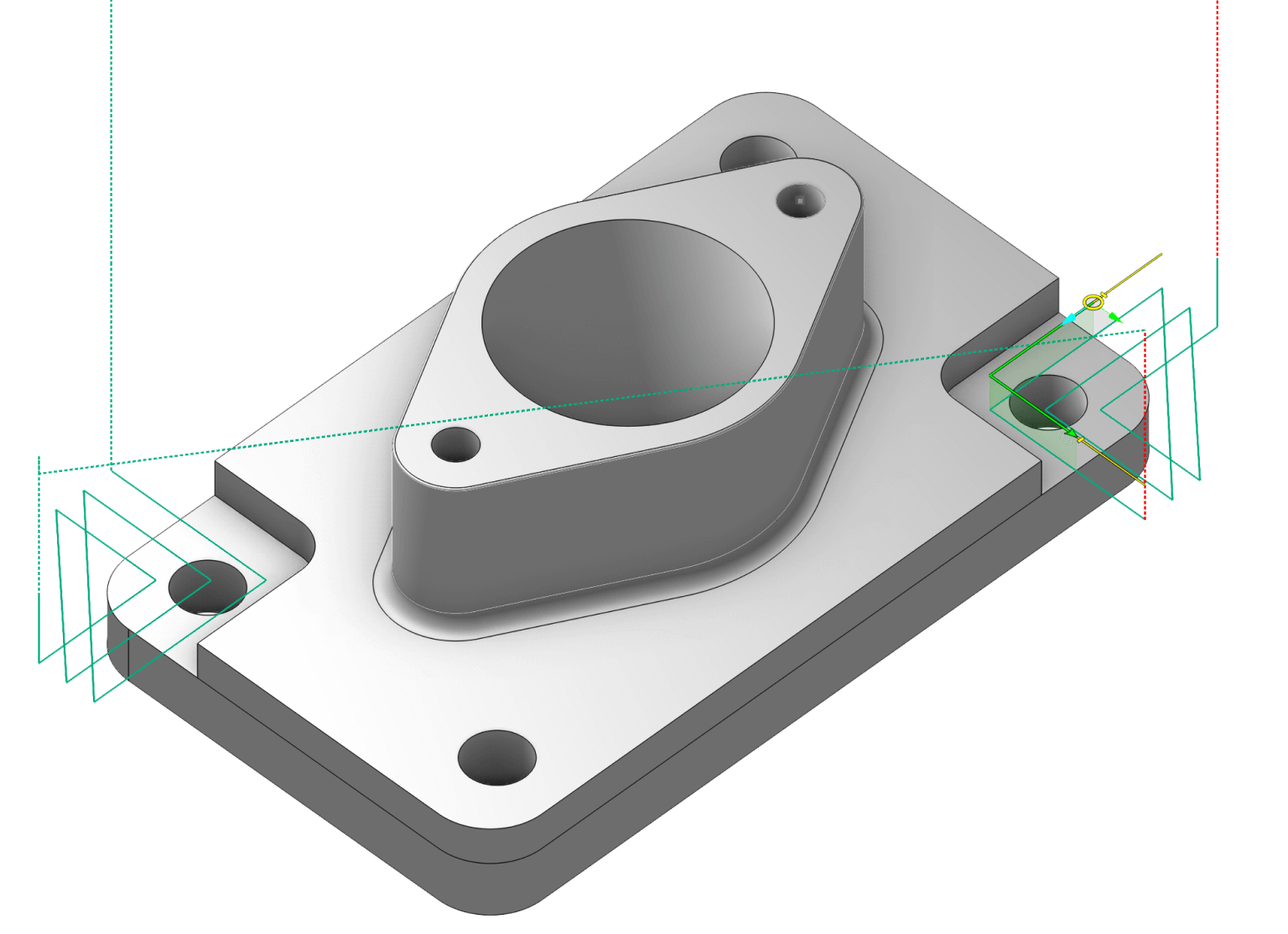

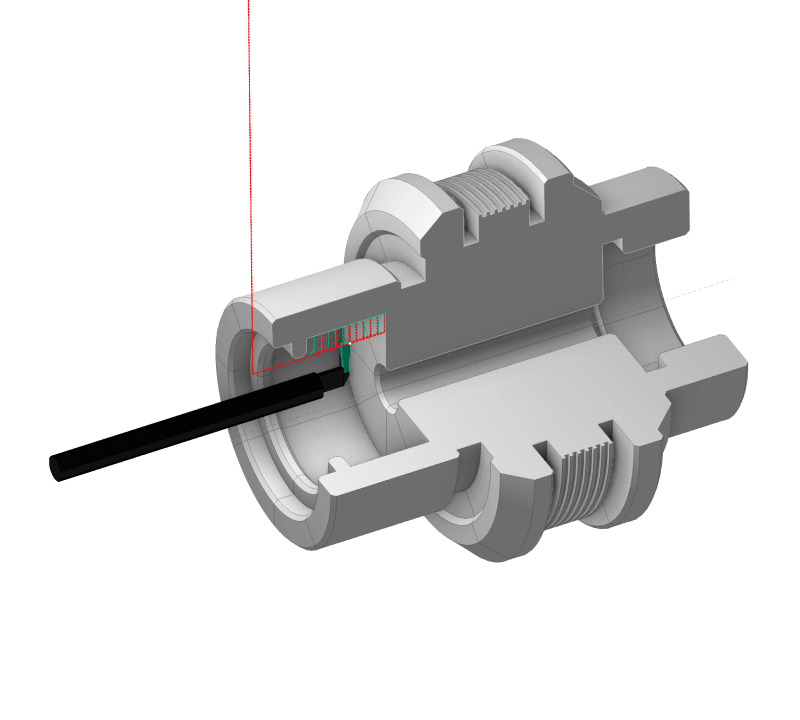

Producción de tornillos, cuchillas, ruedas dentadas, balaustres Torneado y mandrinado, roscado, recorte, taladrado, escariado

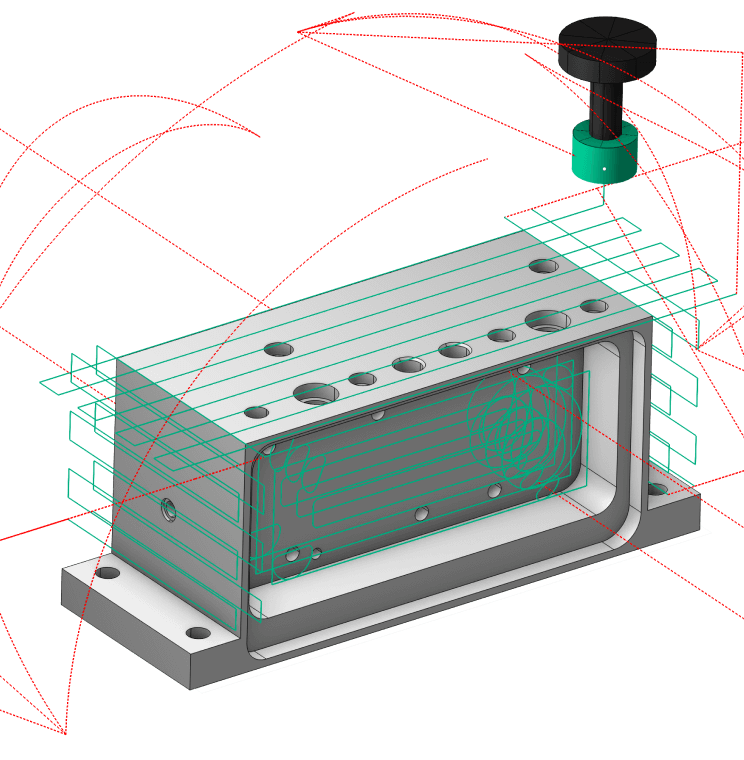

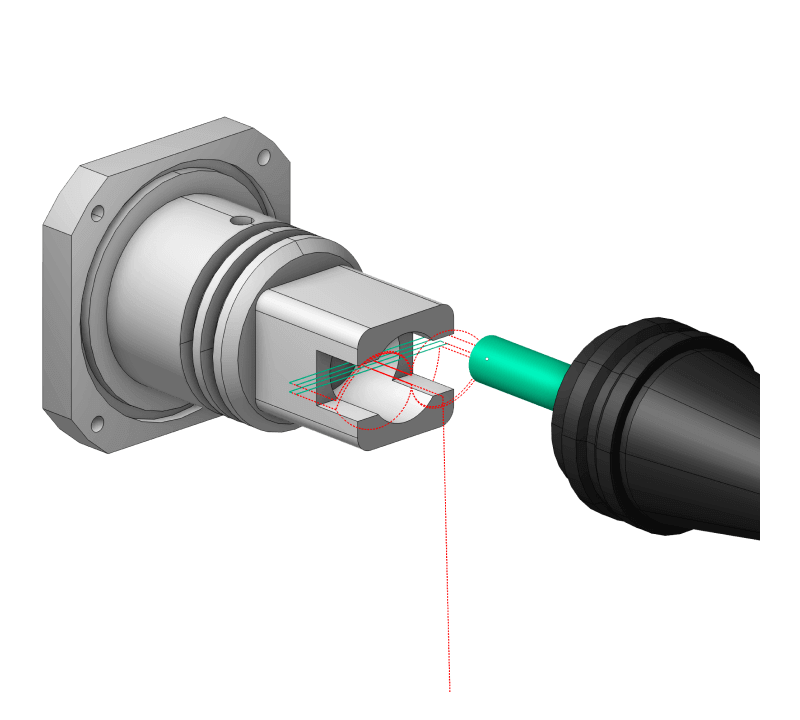

Torneado y mandrinado, roscado, recorte, taladrado, escariado Torneado y fresado combinados en una sola configuración

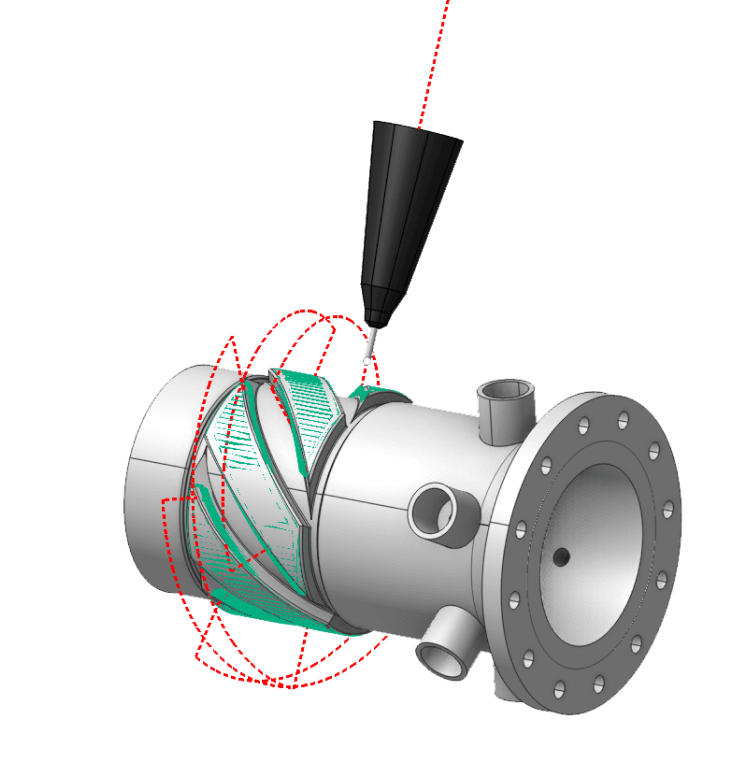

Torneado y fresado combinados en una sola configuración Índice (3+2) y fresado simultáneo de 5 ejes.

Índice (3+2) y fresado simultáneo de 5 ejes. Alta velocidad y trayectorias adaptables para un rápido arranque de material con una mayor vida útil de la herramienta

Alta velocidad y trayectorias adaptables para un rápido arranque de material con una mayor vida útil de la herramienta Máquinas de decoletaje y multiejes (máquinas multi canal) con sincronización

Máquinas de decoletaje y multiejes (máquinas multi canal) con sincronización Programación CNC de corte, recorte, corte con cuchilla 6D.

Programación CNC de corte, recorte, corte con cuchilla 6D. Revestimiento, tecnología híbrida en 5 ejes, fresadoras-tornos y robots

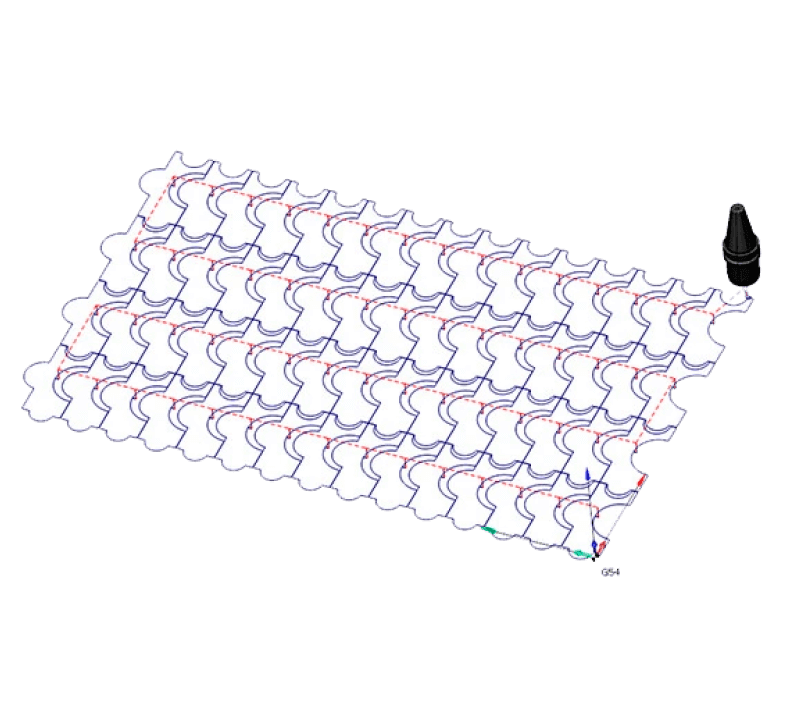

Revestimiento, tecnología híbrida en 5 ejes, fresadoras-tornos y robots Estrategias de 2 – 4 ejes para el mecanizado por electroerosión por hilo

Estrategias de 2 – 4 ejes para el mecanizado por electroerosión por hilo Programación de corte por láser, chorro de agua, plasma, oxicorte y corte por cuchilla

Programación de corte por láser, chorro de agua, plasma, oxicorte y corte por cuchilla Verificación del código G en SprutCAM

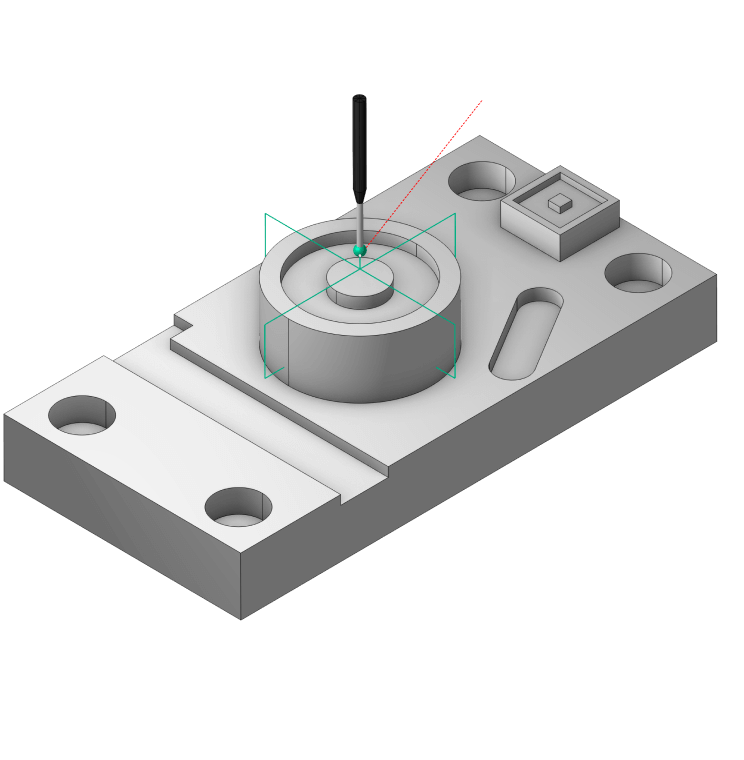

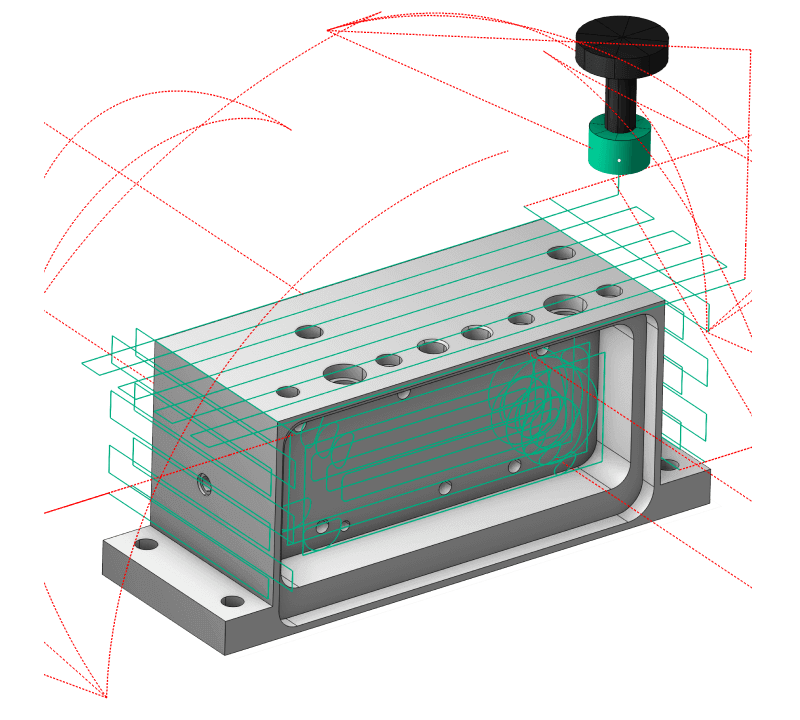

Verificación del código G en SprutCAM Ciclos de palpado para fresadoras y tornos

Ciclos de palpado para fresadoras y tornos