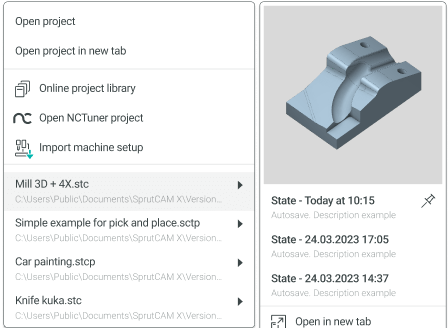

認識 SprutCAM X

機器感知型 CAD/CAM 平臺

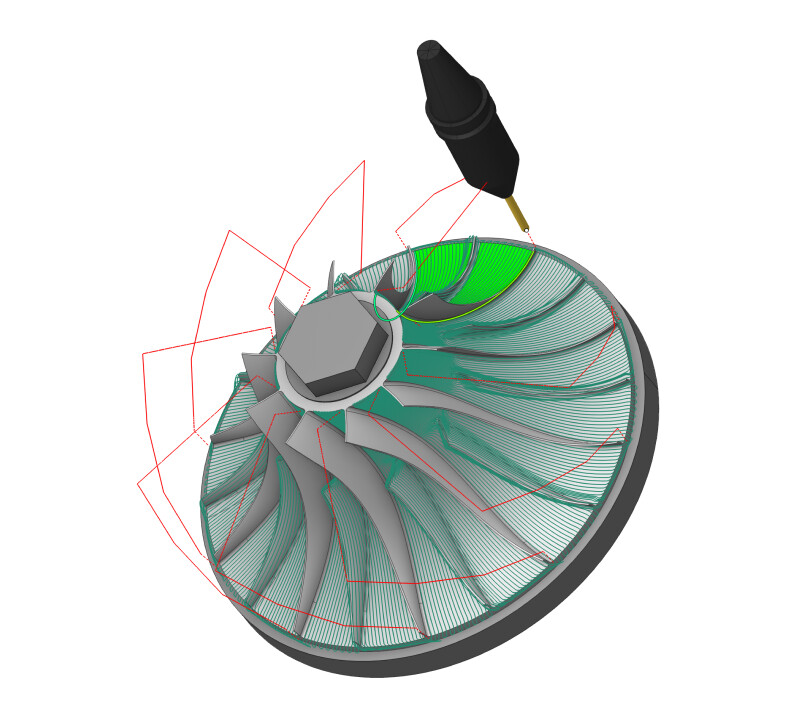

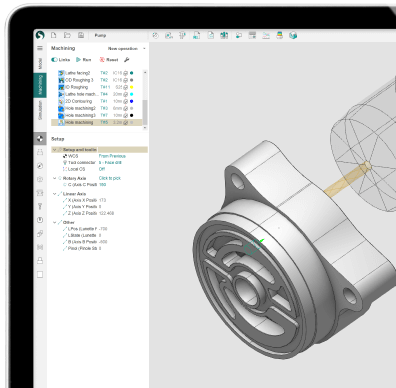

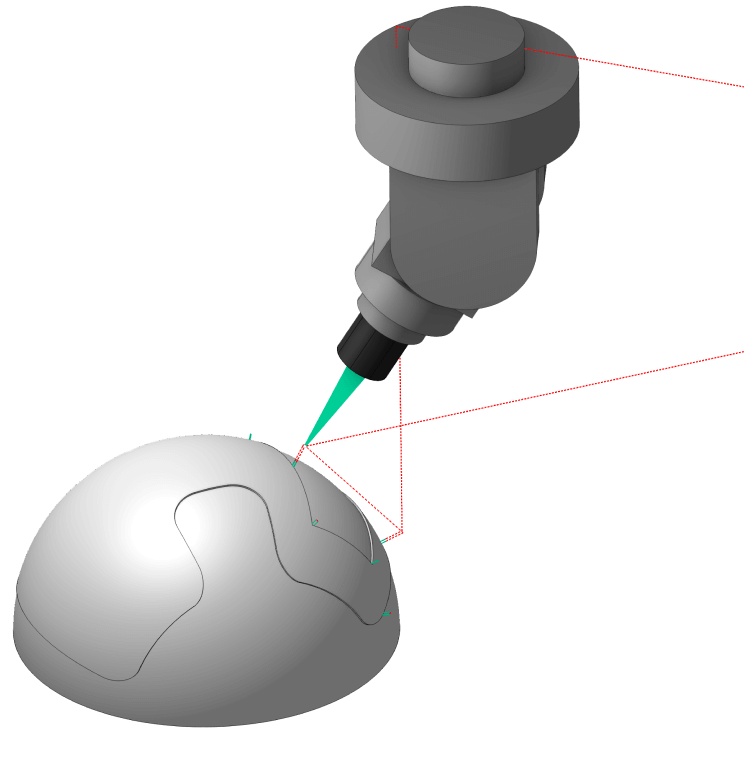

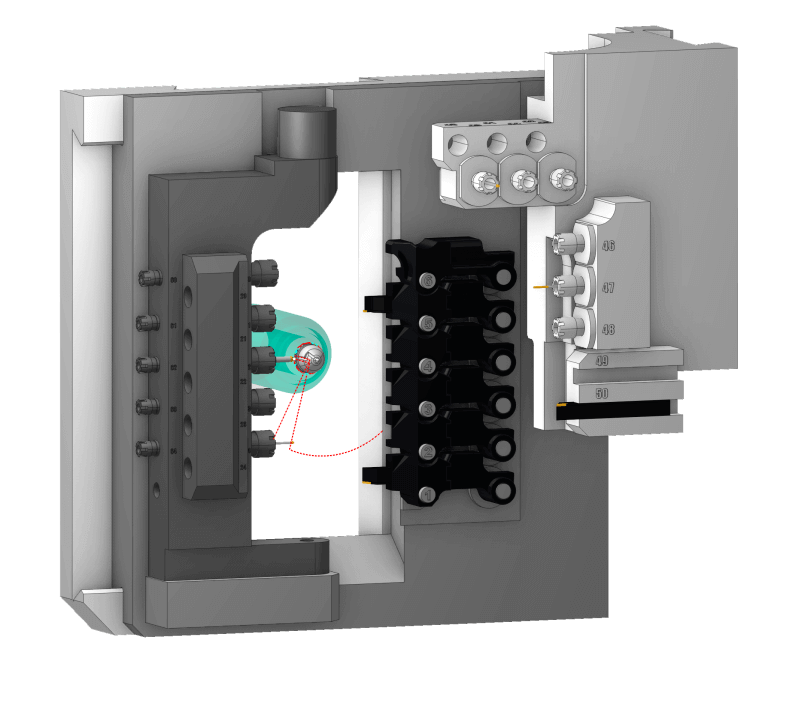

SprutCAM X 早在 2001 年就引入了機器感知程式設計方法,使其成為 CAM 軟體的高端基礎。

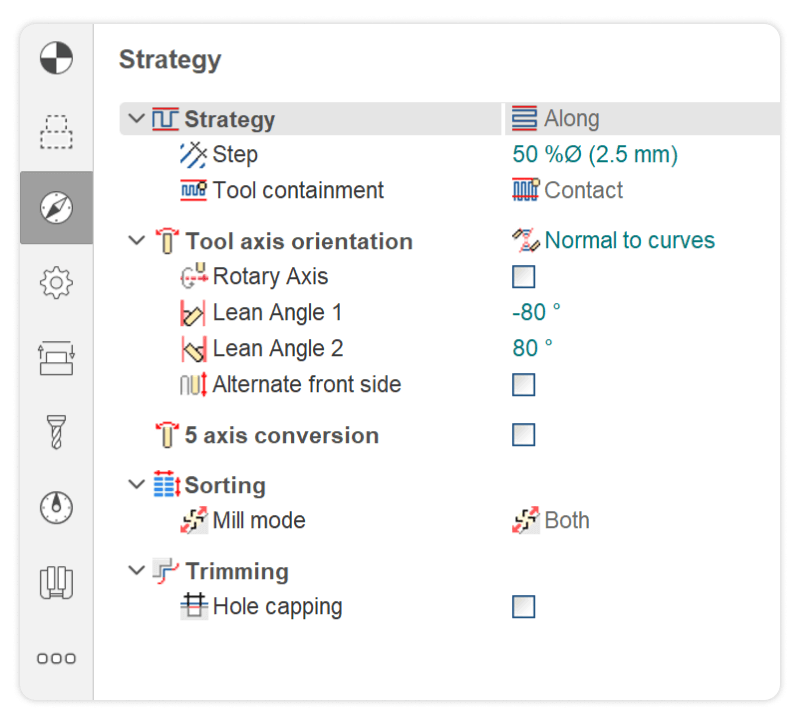

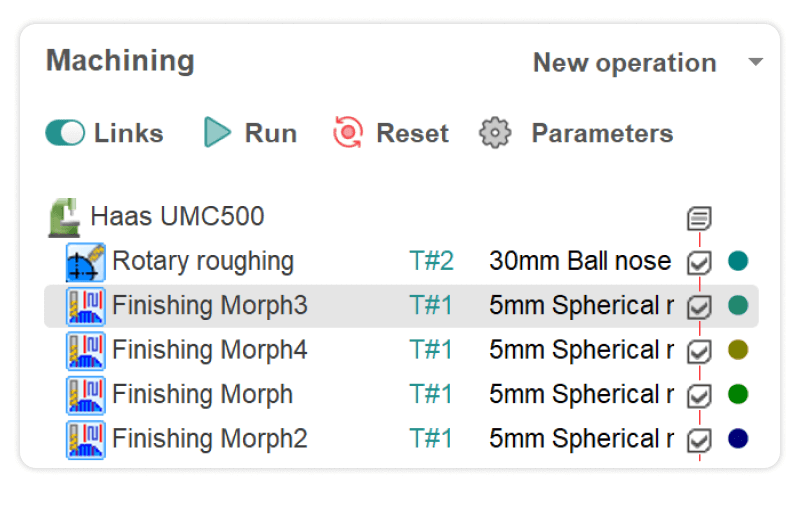

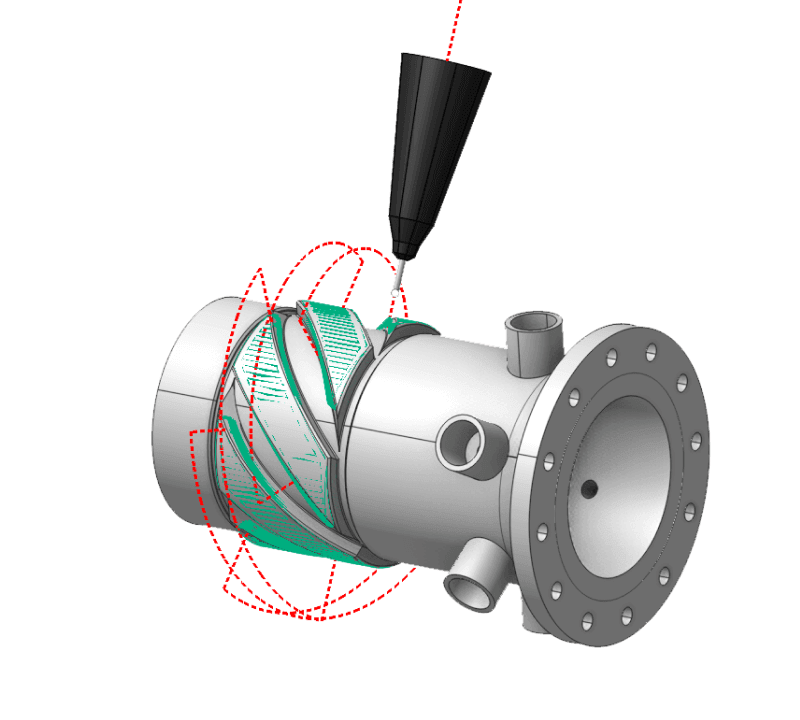

這種創新方法涉及在初始刀具路徑計算過程中考慮機床限制,使其與傳統的 CAM 方法區分開來,後者在模擬或後處理期間轉換為真實機器代碼之前在抽象空間中運行。

隨著機器運動學變得越來越複雜,機器感知方法的優勢也在不斷增長。

這種先進的 CAD/CAM 軟體不僅確保了 5 軸和車銑機床程式設計的適當安全性,而且還為透明和直觀的用戶體驗奠定了基礎。

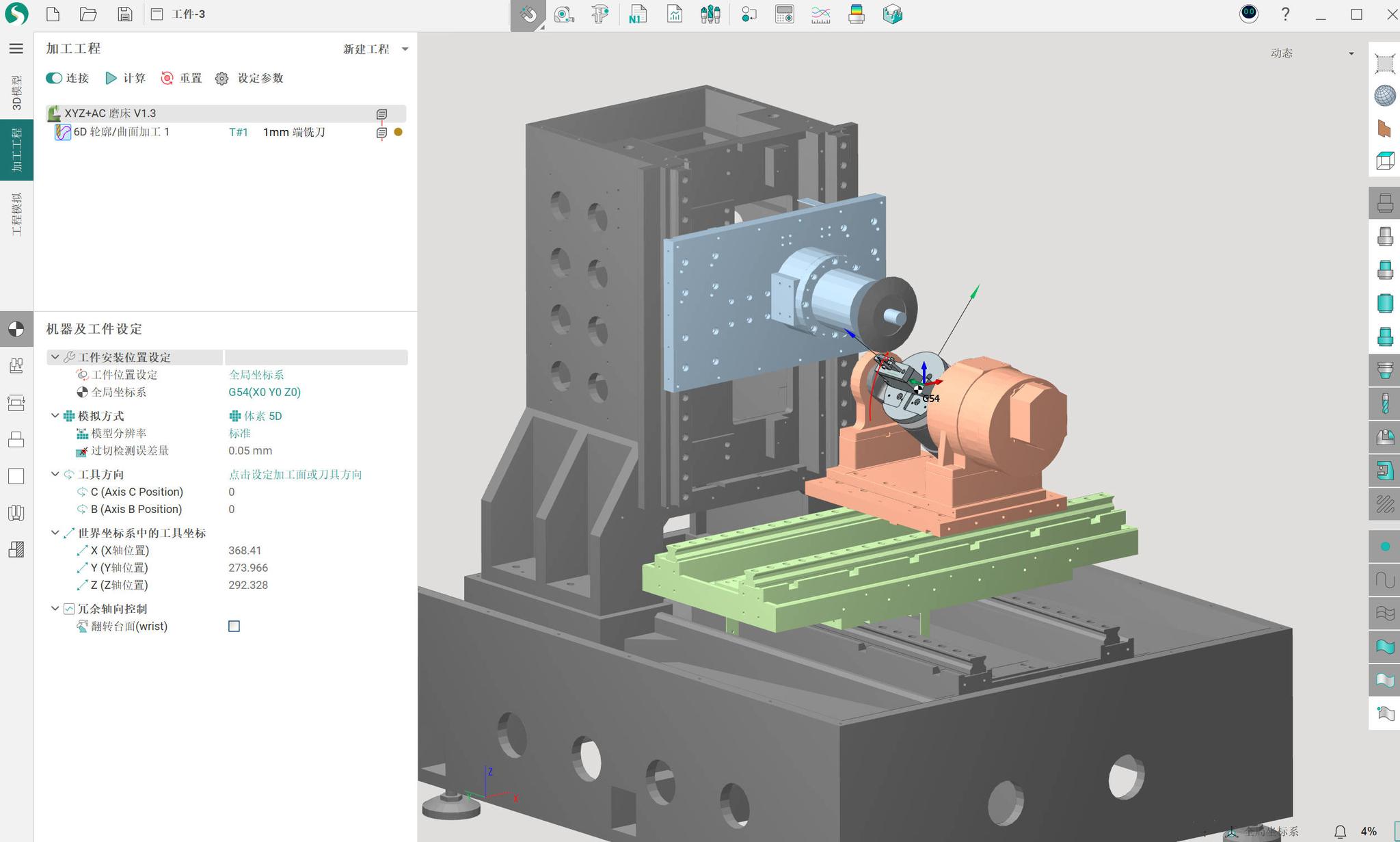

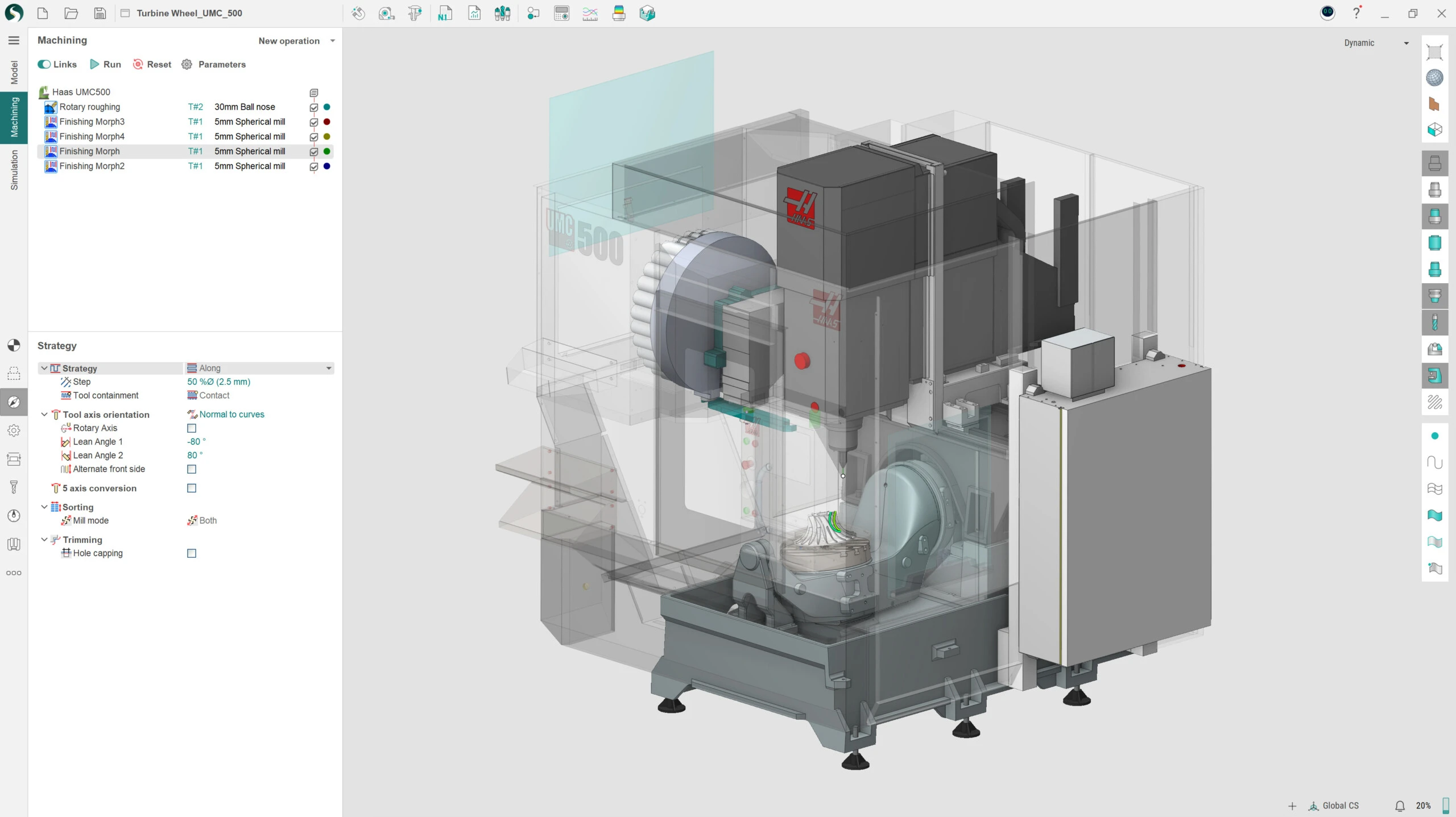

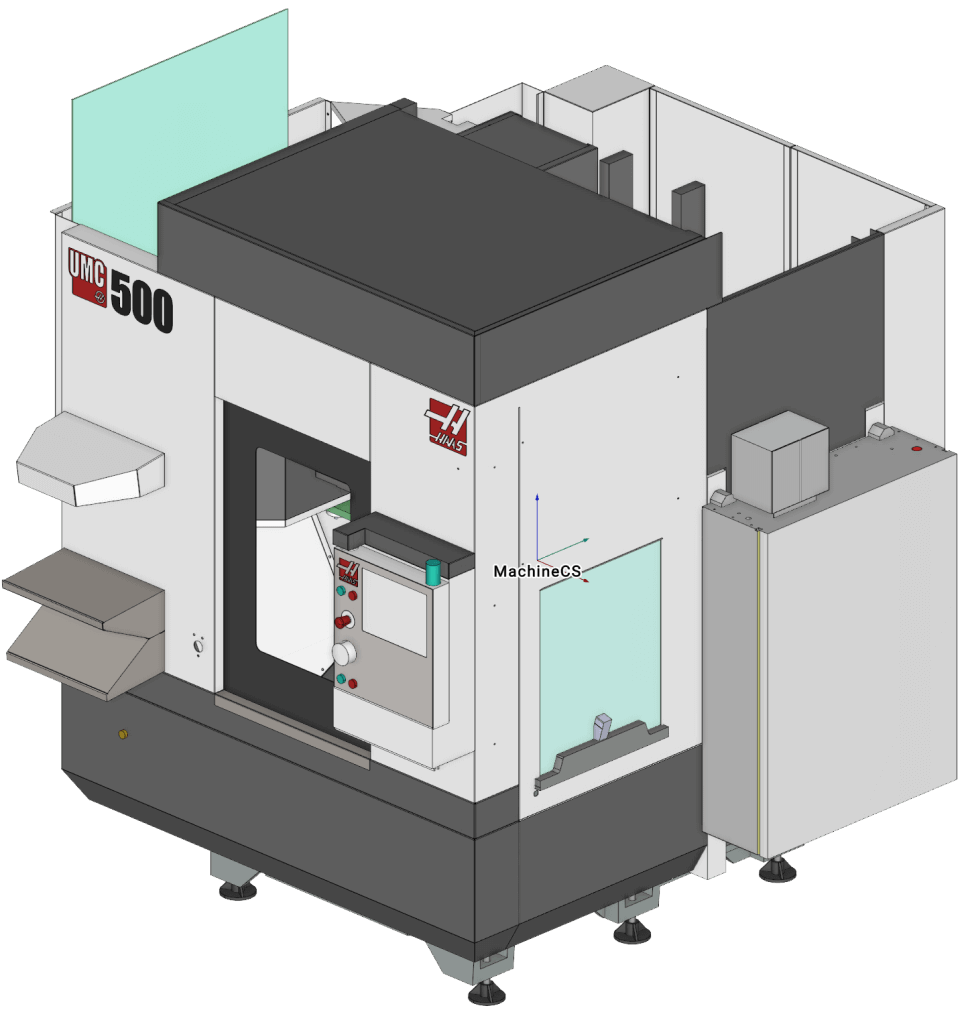

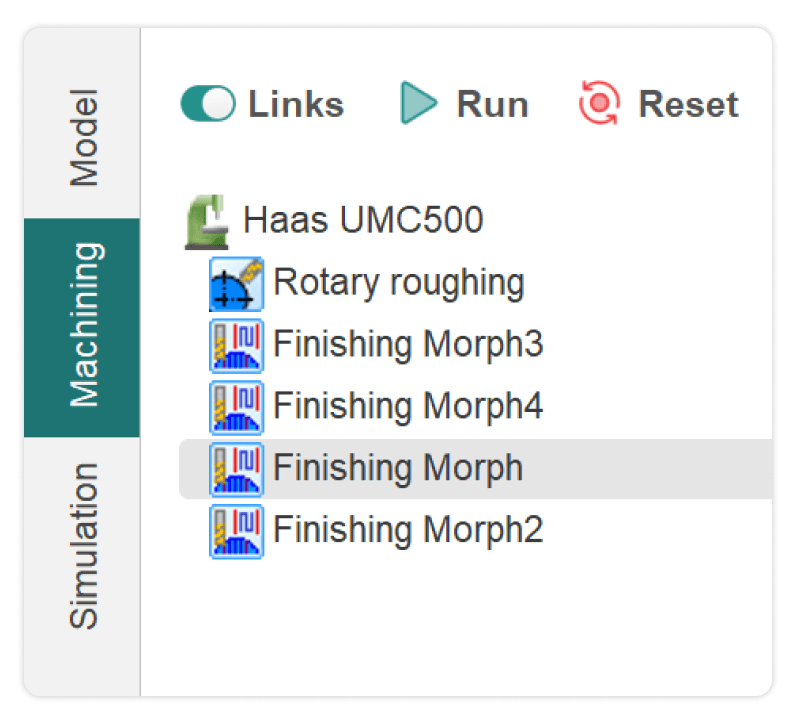

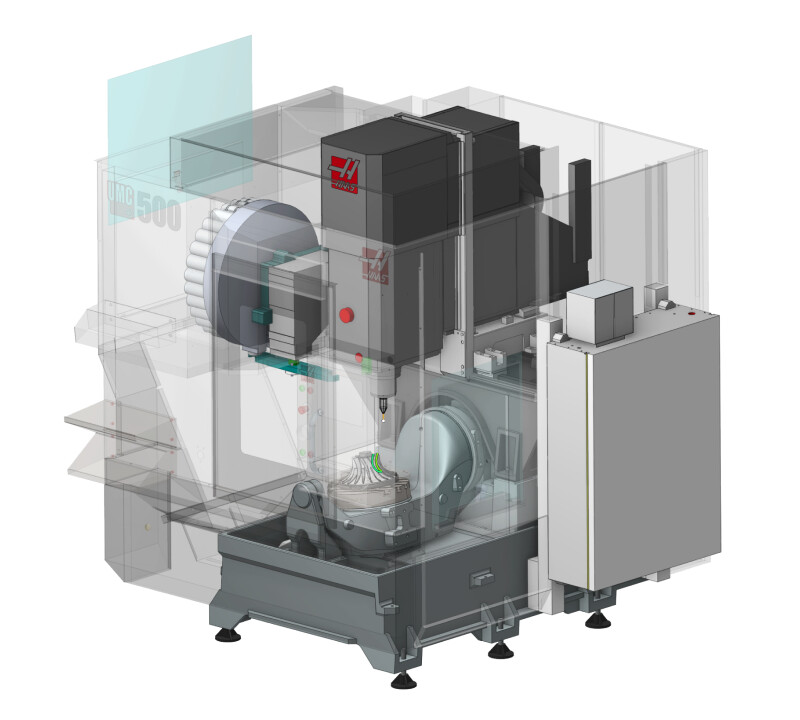

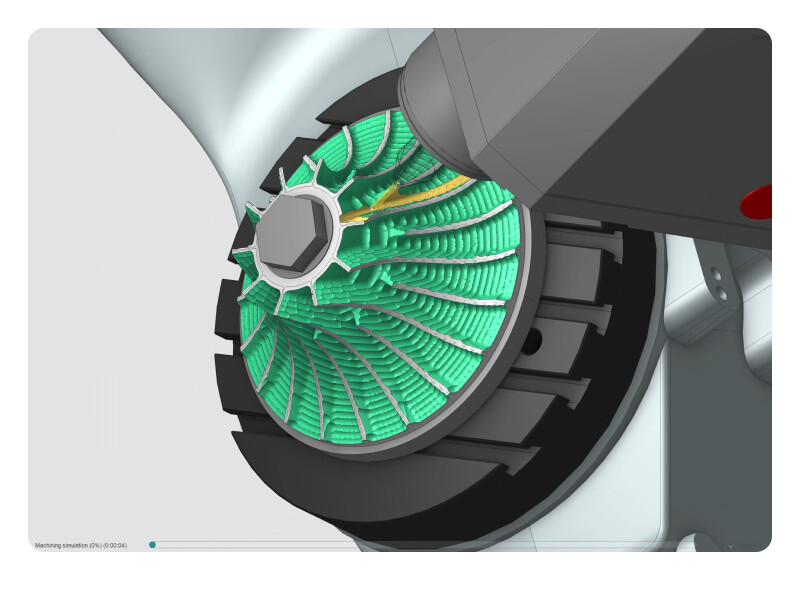

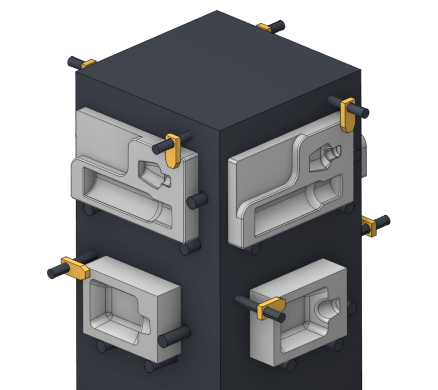

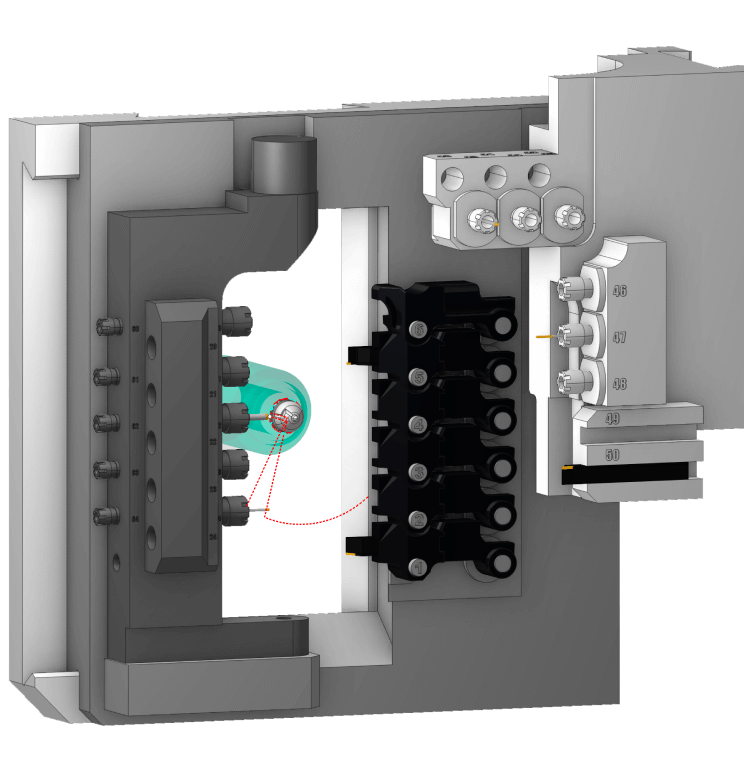

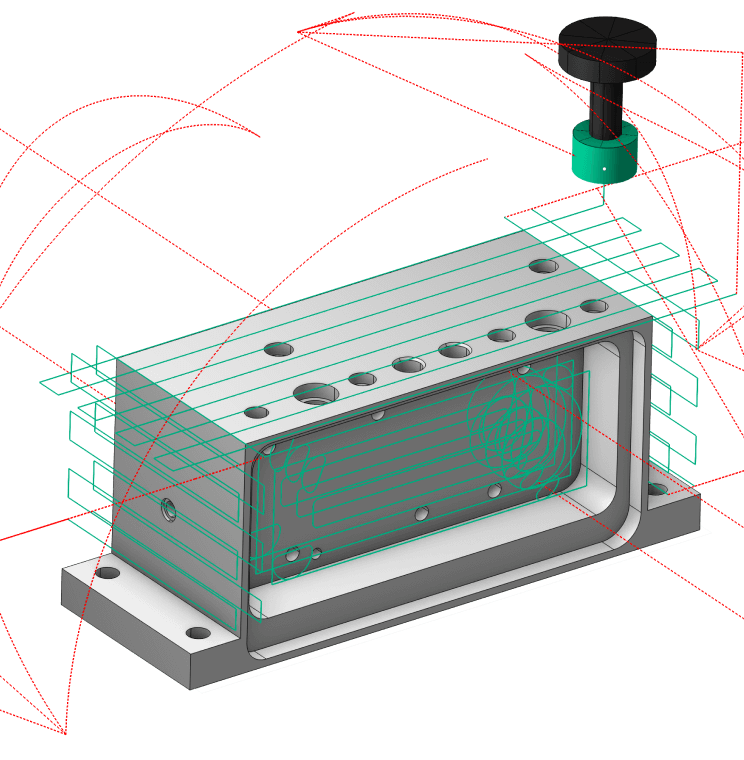

您的數控機床數字孿生

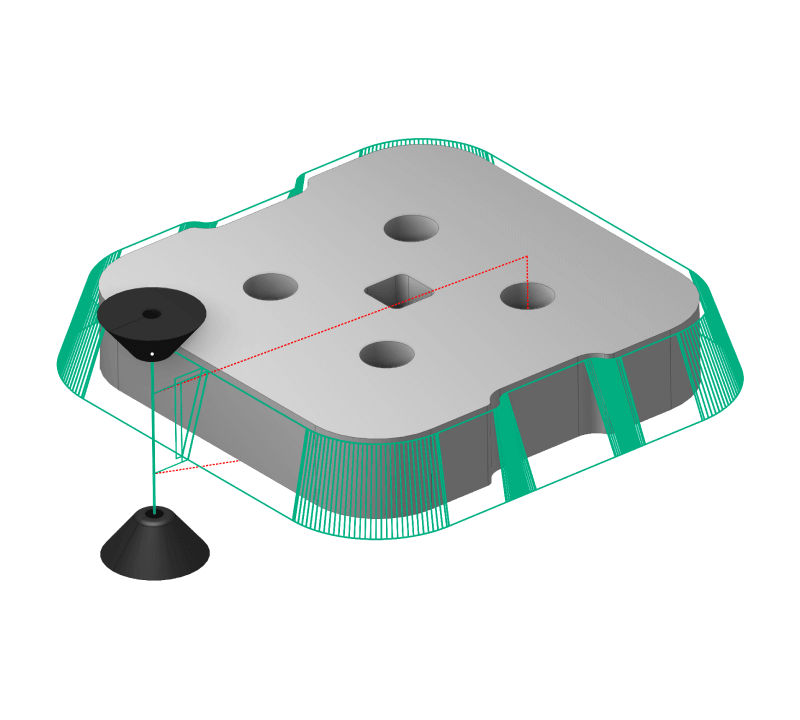

MachineMaker 應用程式允許您在幾分鐘內生成 CNC 機床的數位複製品。 該數位孿生旨在用於在 CAD/CAM 軟體 SprutCAM X 中對 CNC 機床進行程式設計。

此外,MachineMaker 還具有廣泛的現成單個元件庫,以及完整的 CNC 機床和後處理器的預先設計的數位孿生。

產品亮點

應用

技術亮點:

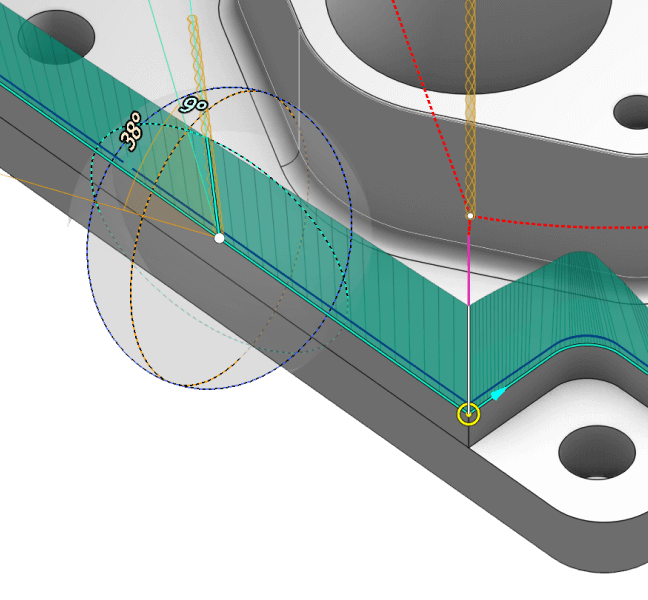

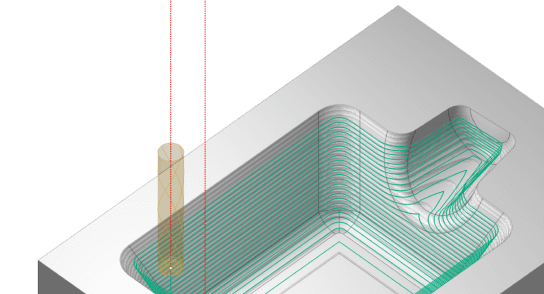

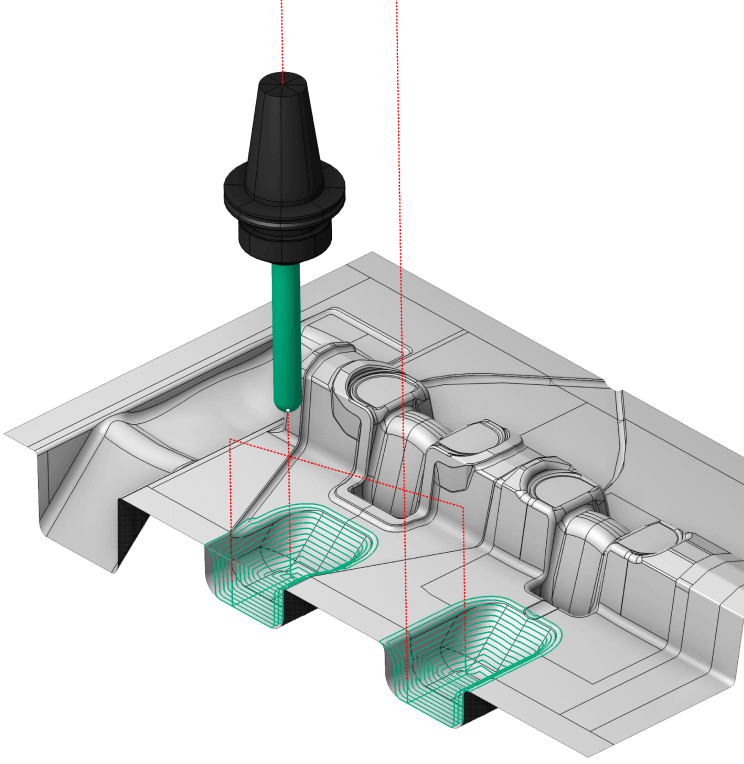

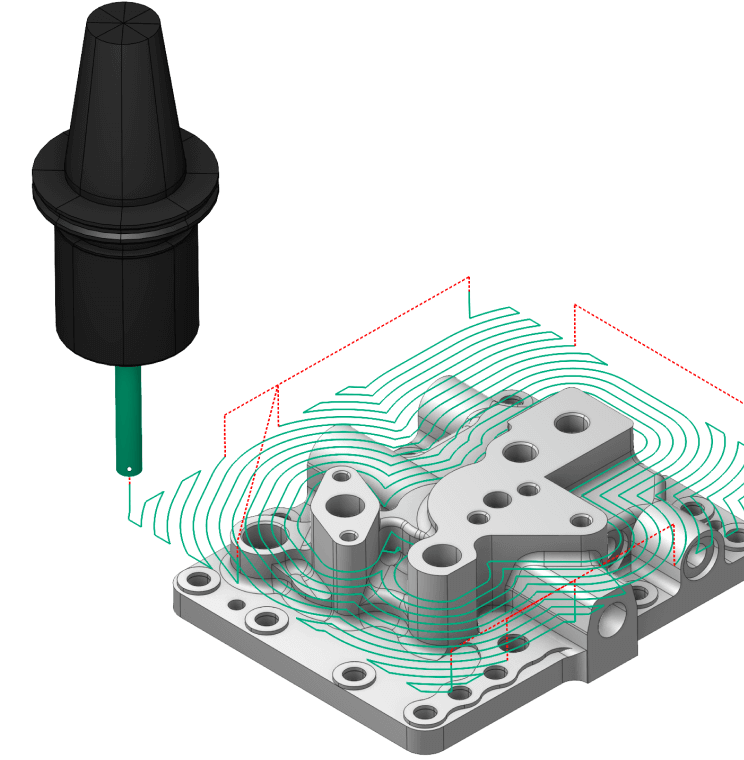

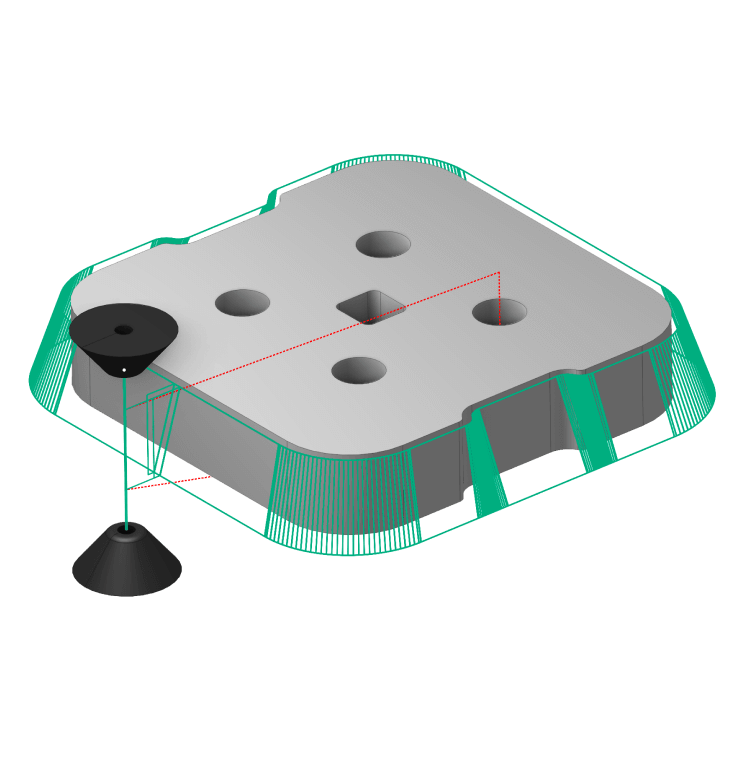

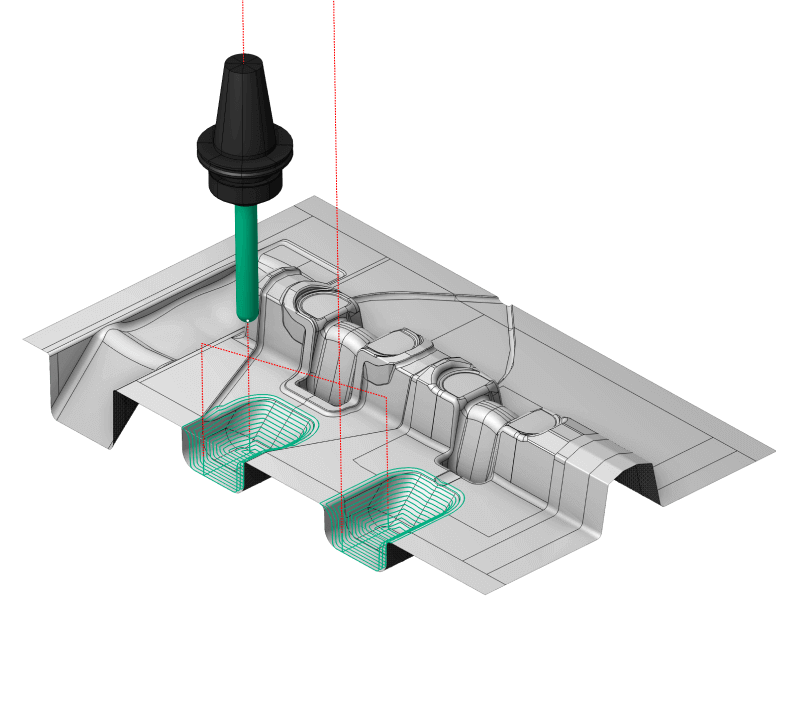

自適應 SC

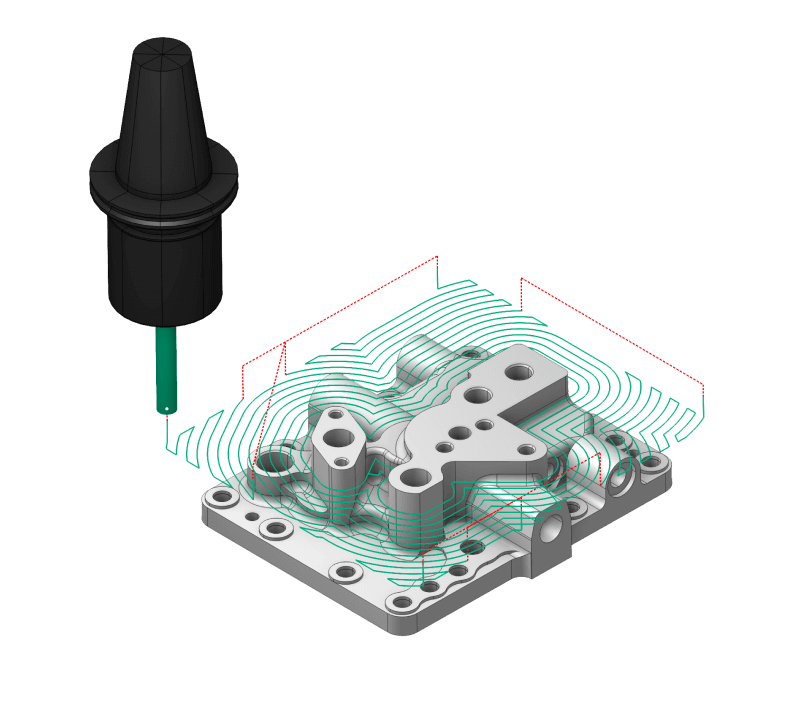

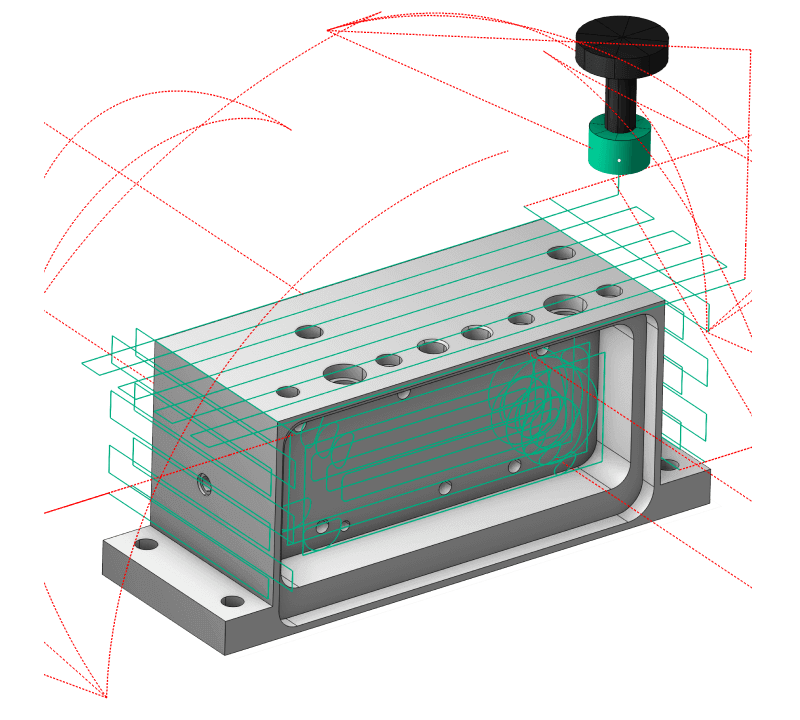

這種高速加工迴圈專為粗加工而設計,可大幅縮短循環時間並延長刀具壽命。

其技術可自動調節切屑負載和橫向切削力,同時將刀具啮合角和機床軸加速度保持在最佳範圍內。

借助 Adaptive SC,機床可以以更高的進給率進行更深的切削,並在整個刀具路徑中自動優化,以實現最大效率。

與傳統加工方法相比,Adaptive SC 具有以下優勢:

70%

縮短循環時間

500%

延長刀具壽命

應用

技術亮點:

自適應 SC

這種高速加工迴圈專為粗加工而設計,可大幅縮短循環時間並延長刀具壽命。

其技術可自動調節切屑負載和橫向切削力,同時將刀具啮合角和機床軸加速度保持在最佳範圍內。

借助 Adaptive SC,機床可以以更高的進給率進行更深的切削,並在整個刀具路徑中自動優化,以實現最大效率。

與傳統加工方法相比,Adaptive SC 具有以下優勢:

70%

縮短循環時間

500%

延長刀具壽命

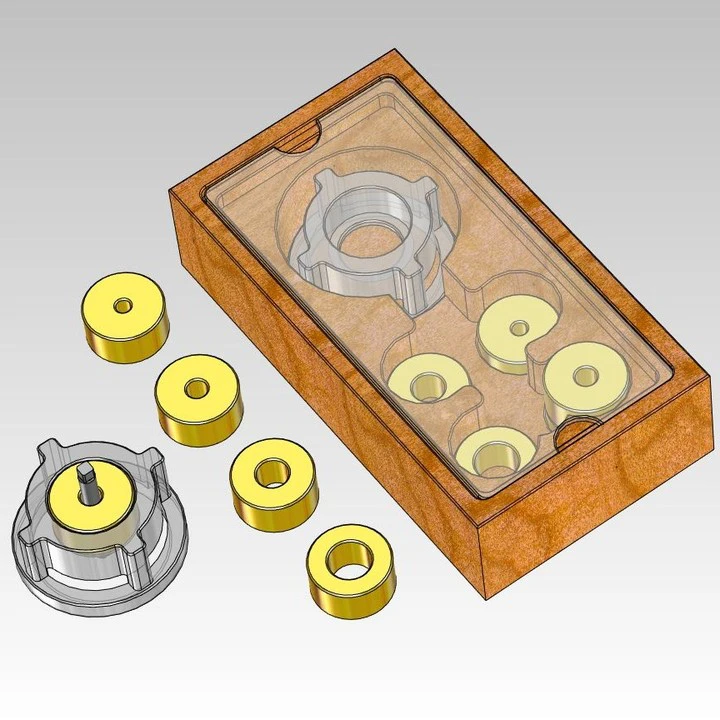

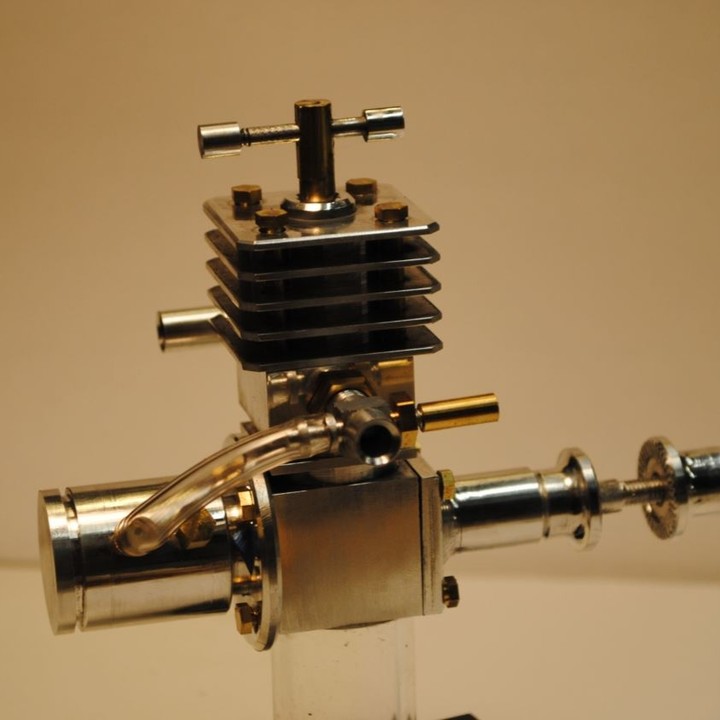

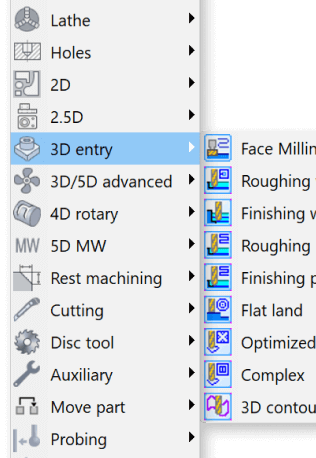

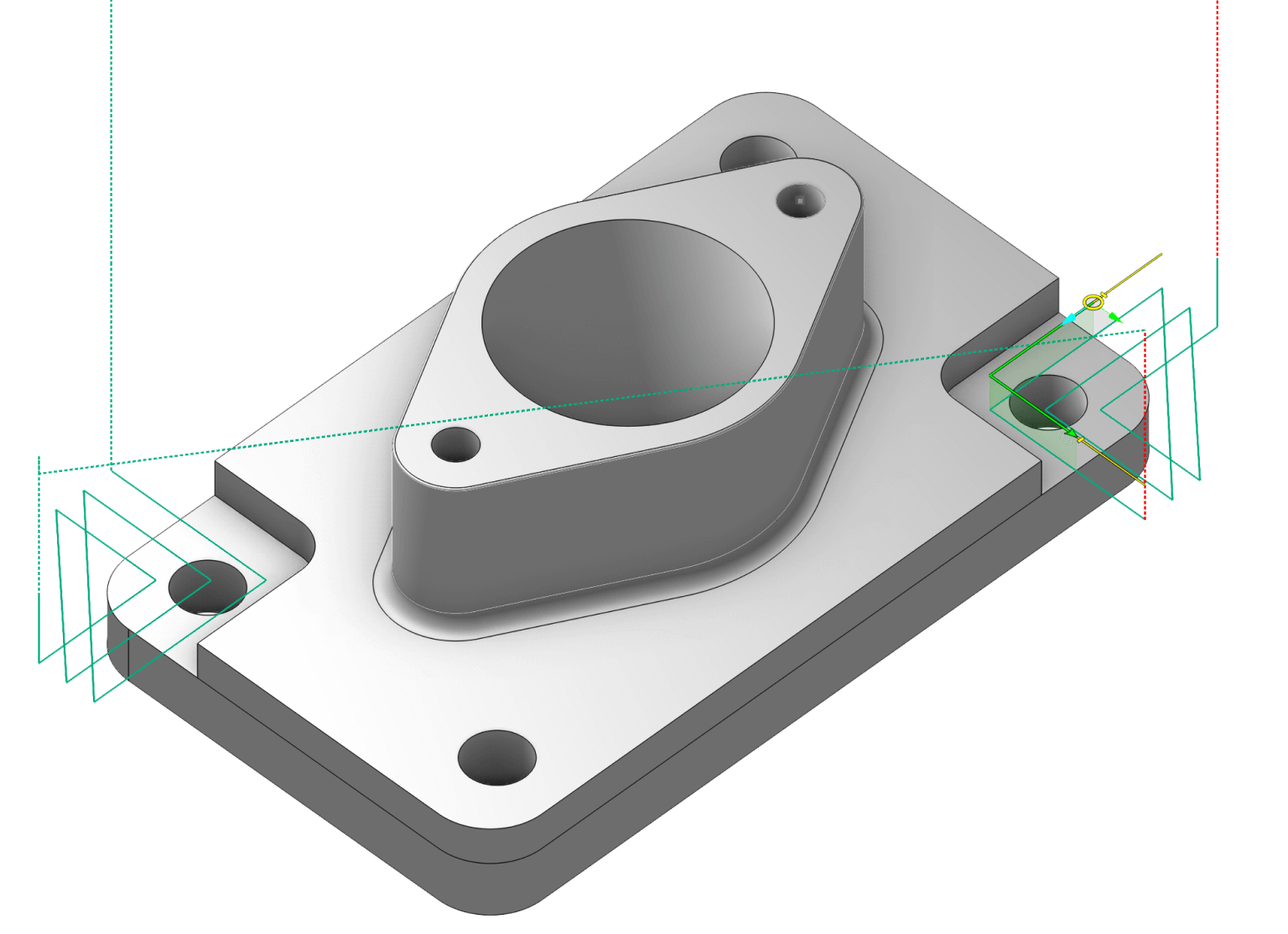

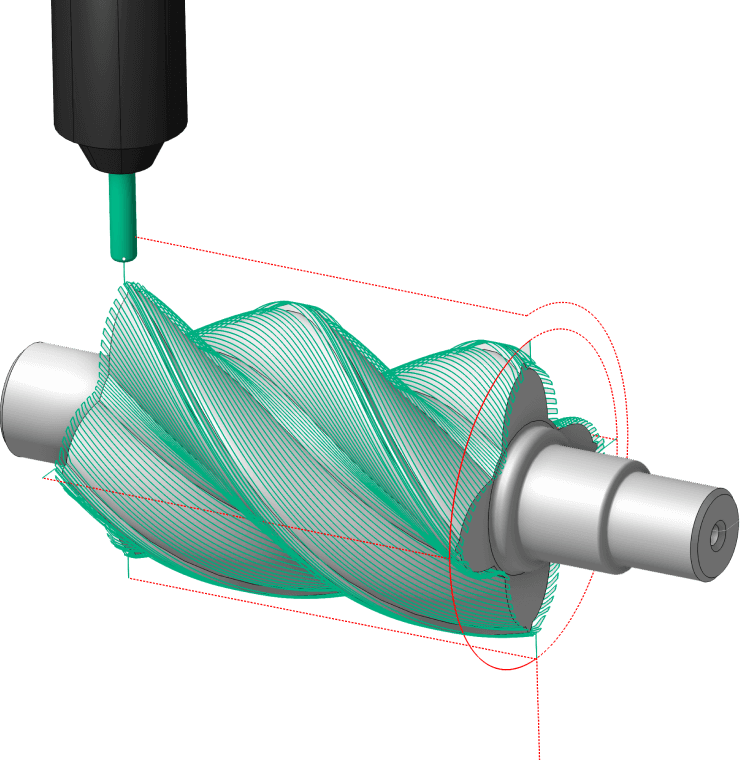

生產螺釘、刀片、齒輪、欄杆

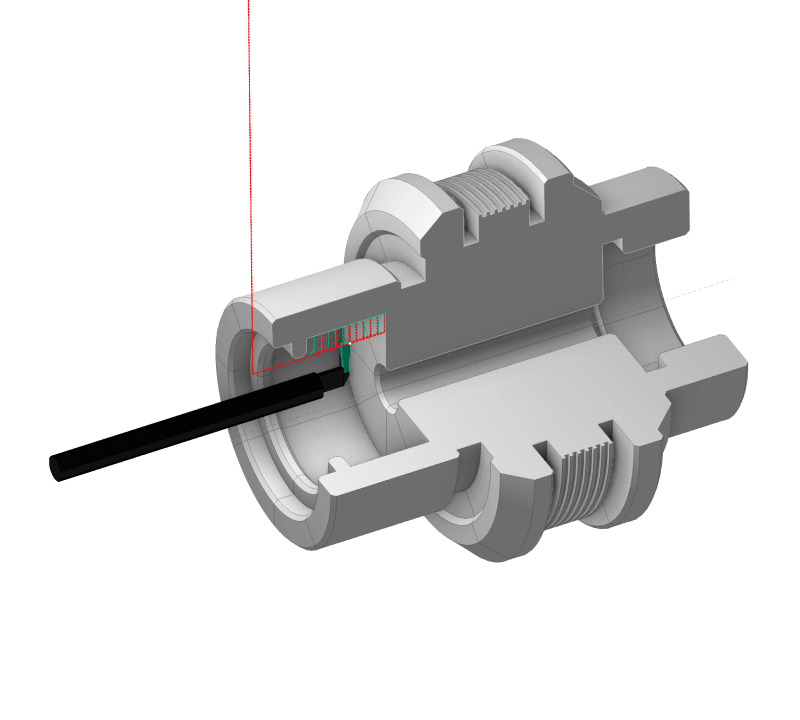

生產螺釘、刀片、齒輪、欄杆 車削和鏜孔、螺紋加工、修邊、鑽孔、鉸孔

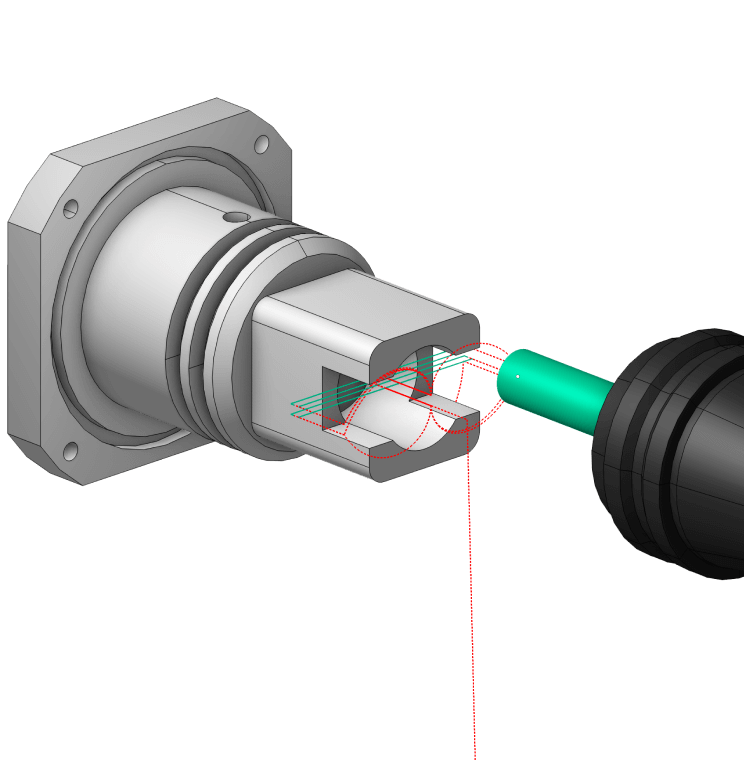

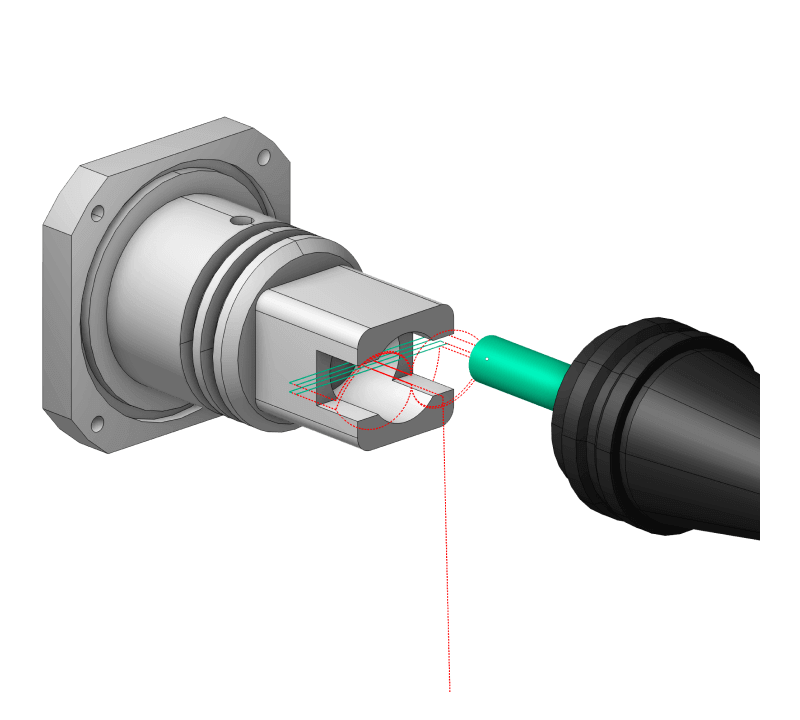

車削和鏜孔、螺紋加工、修邊、鑽孔、鉸孔 車削和銑削結合在一個設置中

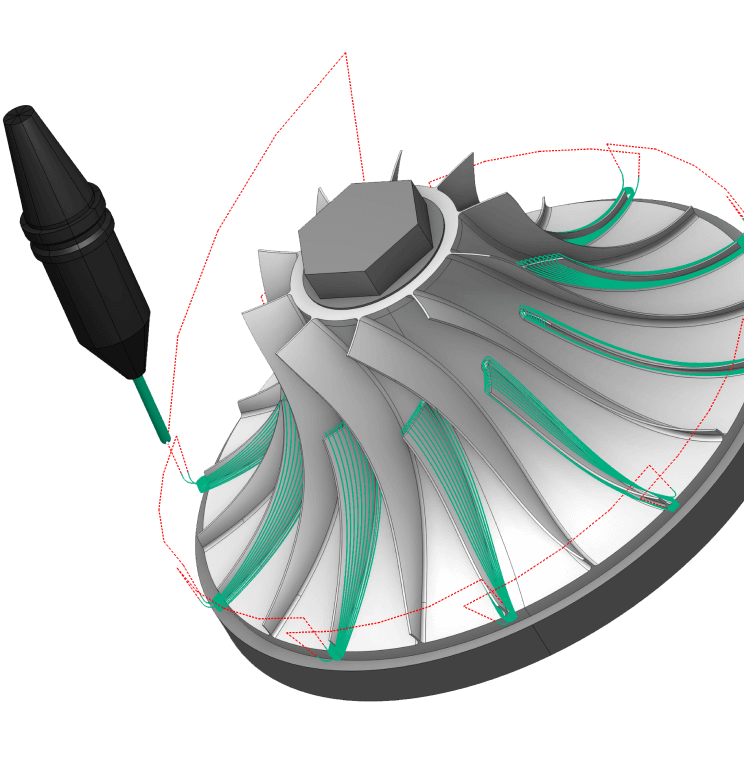

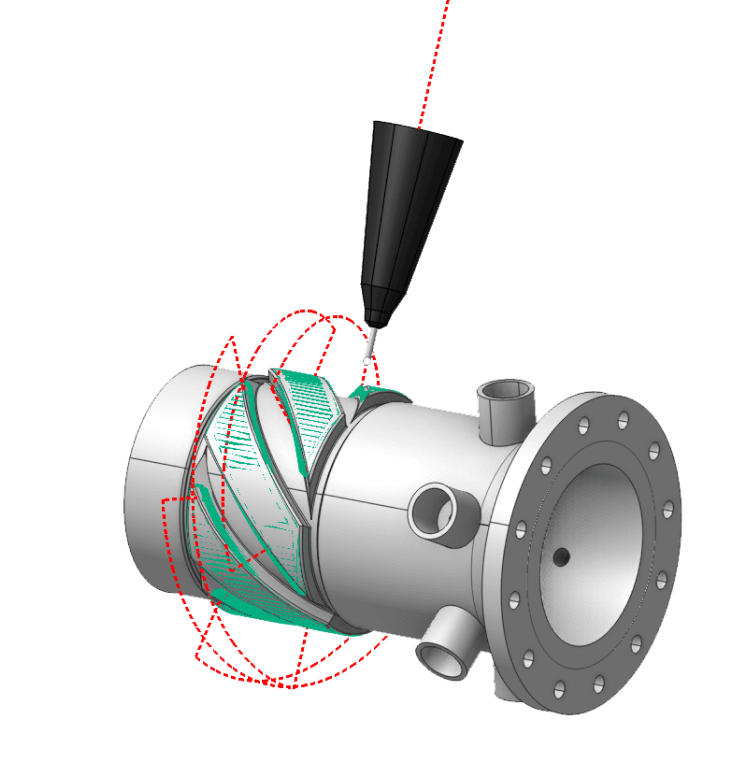

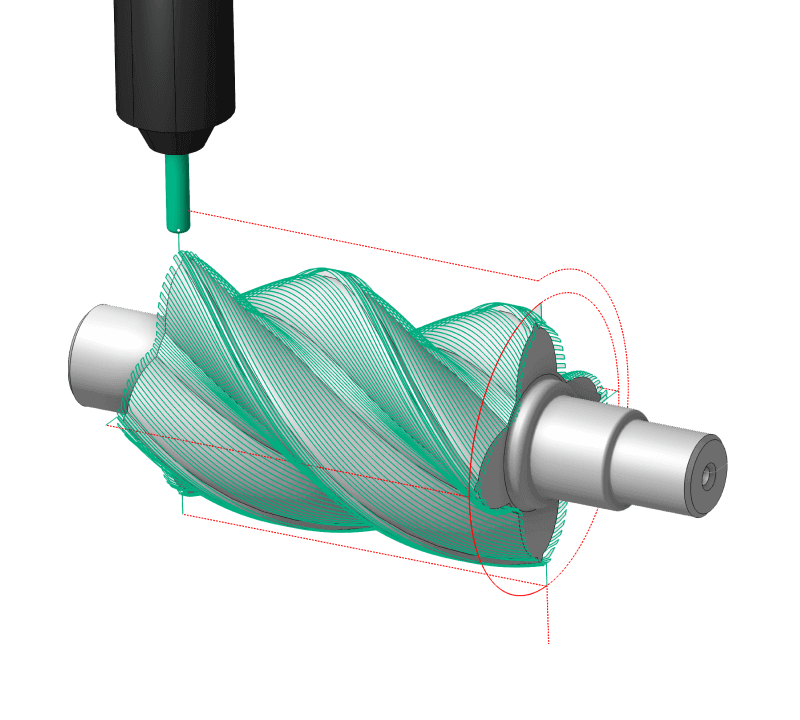

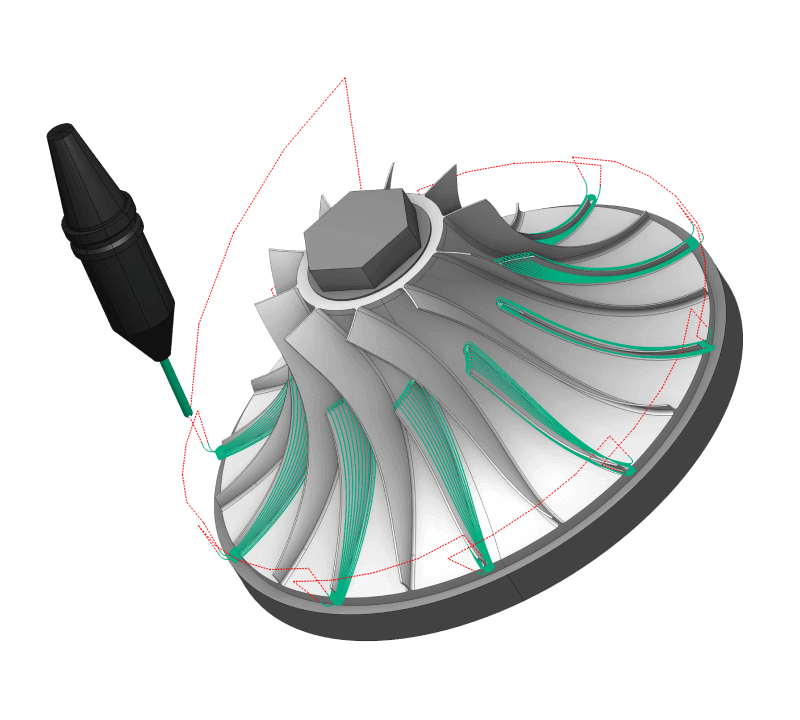

車削和銑削結合在一個設置中 分度 (3+2) 和同步 5 軸銑削。

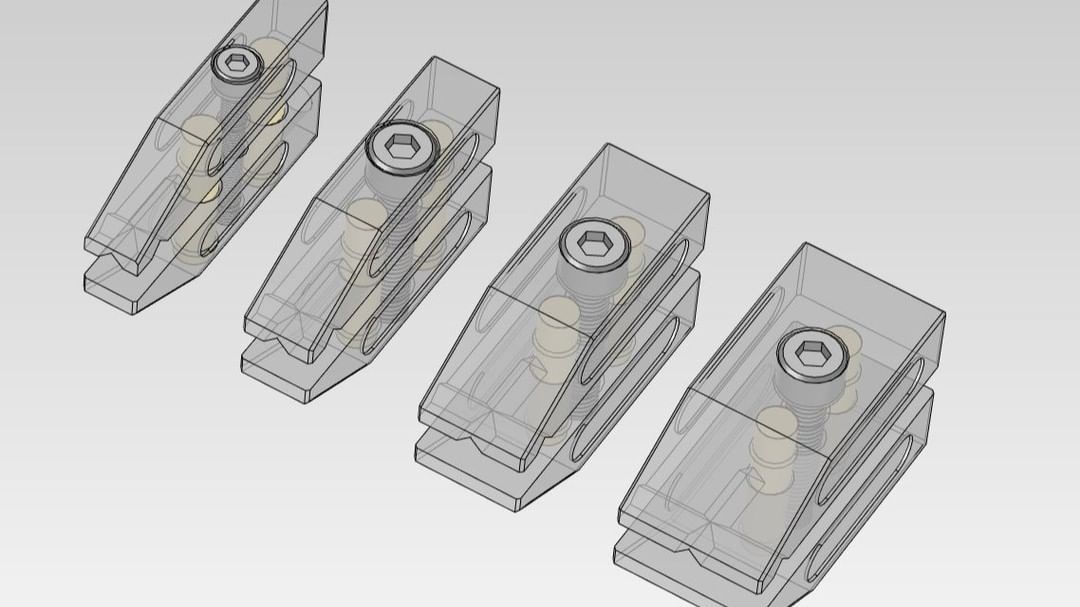

分度 (3+2) 和同步 5 軸銑削。 高速和自適應刀具路徑,可快速去除材料,延長刀具壽命

高速和自適應刀具路徑,可快速去除材料,延長刀具壽命 瑞士型機器和多任務型機器同步加工

瑞士型機器和多任務型機器同步加工 切割、修邊、6D刀切的CNC程式設計。

切割、修邊、6D刀切的CNC程式設計。 覆層、5 軸混合技術、車銑機和機器人

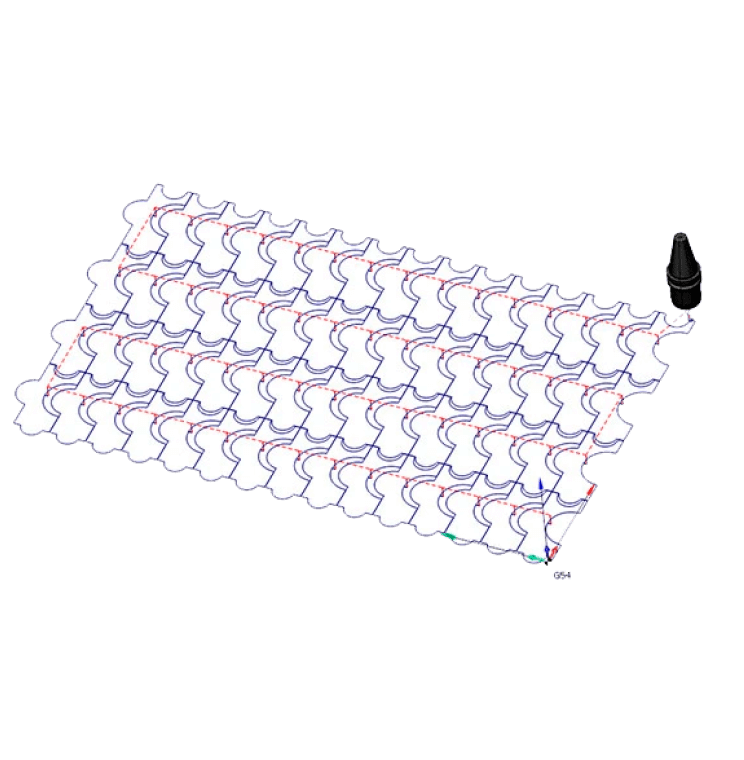

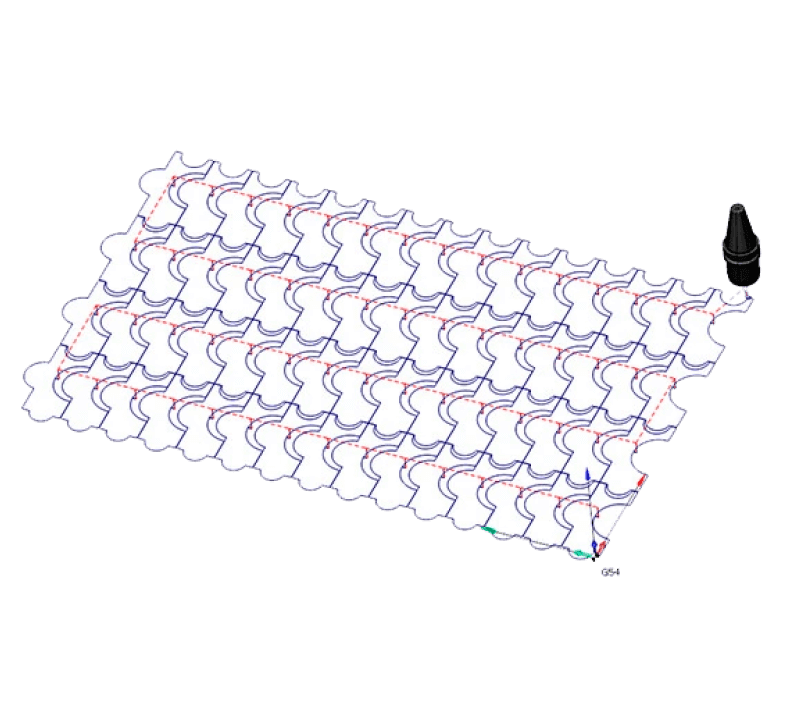

覆層、5 軸混合技術、車銑機和機器人 用於線切割加工的 2 – 4 軸策略

用於線切割加工的 2 – 4 軸策略 鐳射、水射流、等離子切割、純氧切割和刀切割程式設計

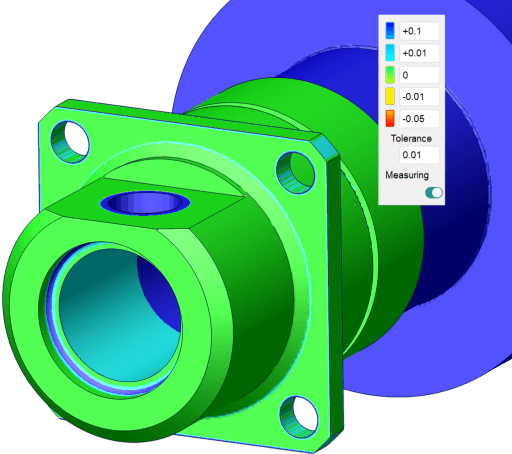

鐳射、水射流、等離子切割、純氧切割和刀切割程式設計 SprutCAM中的G代碼驗證

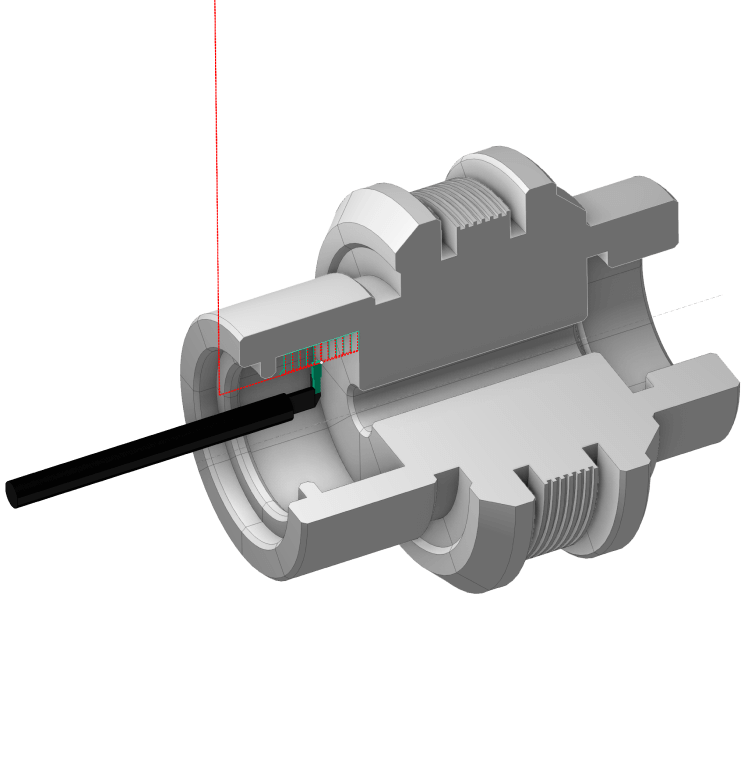

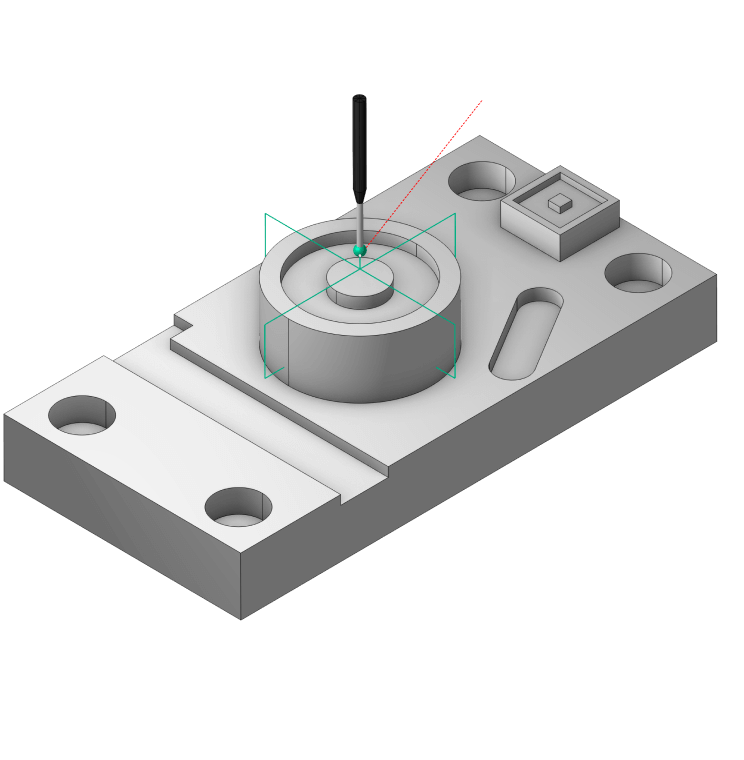

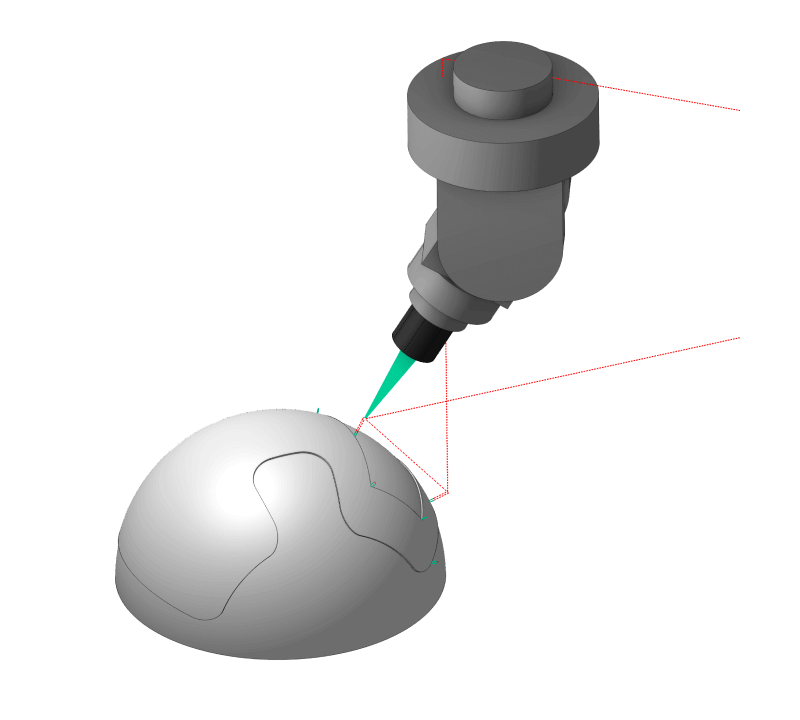

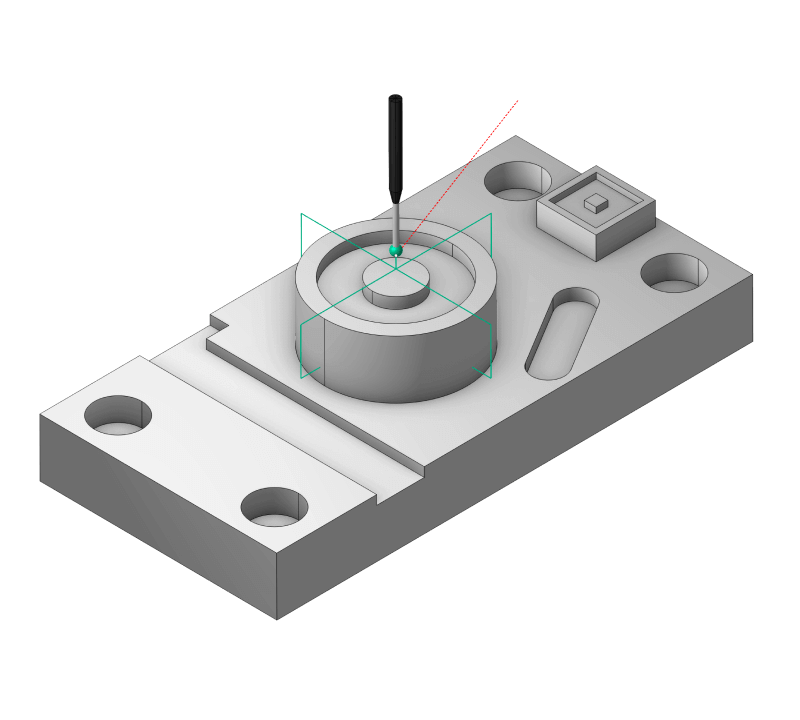

SprutCAM中的G代碼驗證 銑床和車床的探測週期

銑床和車床的探測週期