Automotosport

The automotosport industry is where vehicular prowess meets high-speed competition. From the smooth tarmac of Formula 1 circuits to the rugged terrains of rally championships, this dynamic field continuously evolves. Cutting-edge advancements, such as hybrid powertrains and telemetry-based strategies, are emerging as the frontrunners. Additionally, the rise of electric racing series and sustainable fuels marks a transformative shift towards greener competitions.

Gearing Up: Core Components of Performance

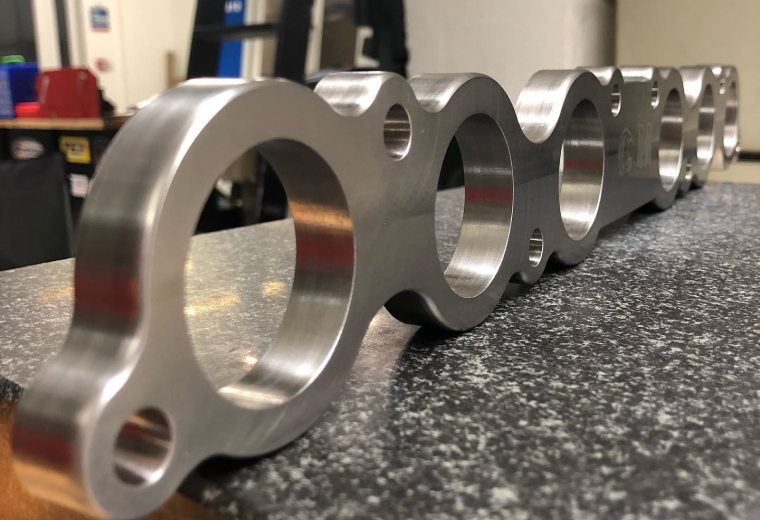

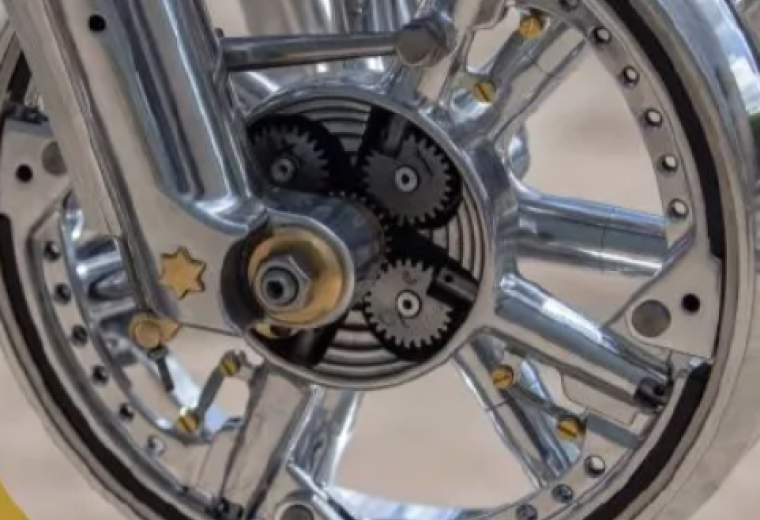

Central to the automotosport industry’s appeal are the machines themselves, marvels of modern engineering. Turbocharged engines deliver raw power, while innovative aerodynamics ensure stability at high speeds. Lightweight but robust materials form the chassis, making agility a focal point. Multi-piston brake calipers, adaptive suspensions, and advanced tire technologies are among the myriad parts working in harmony, allowing drivers to push boundaries while ensuring safety and performance.

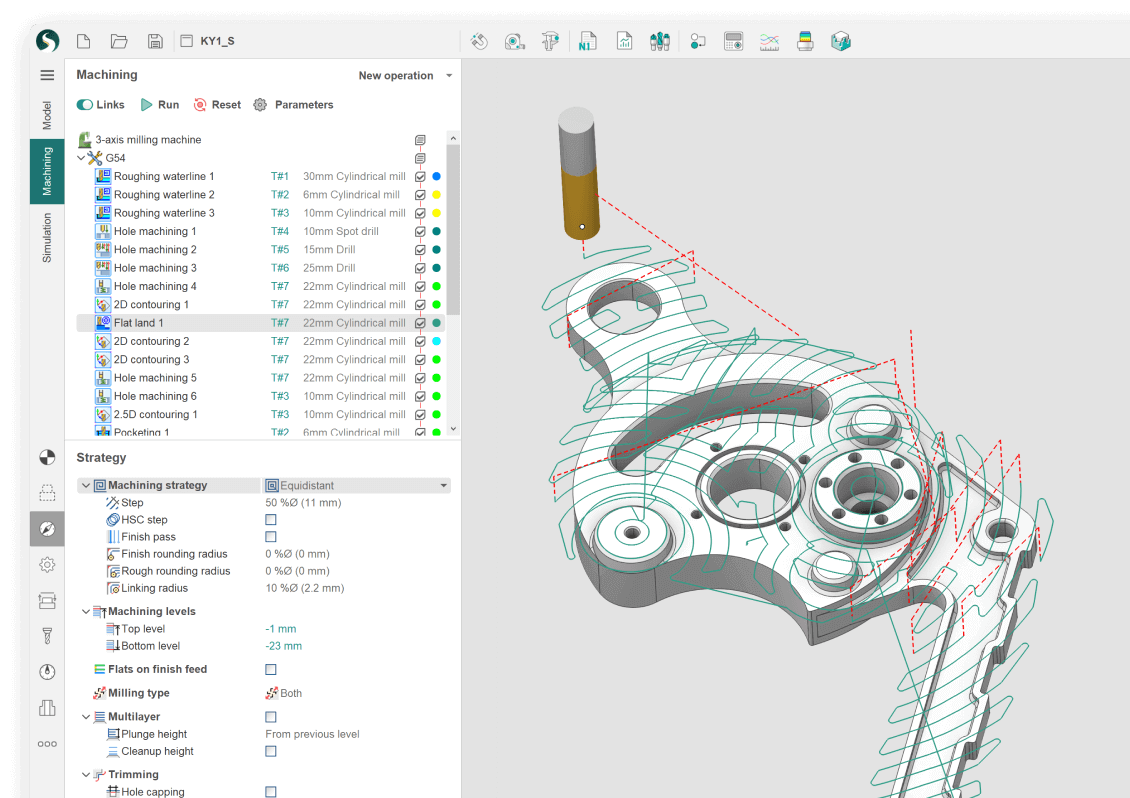

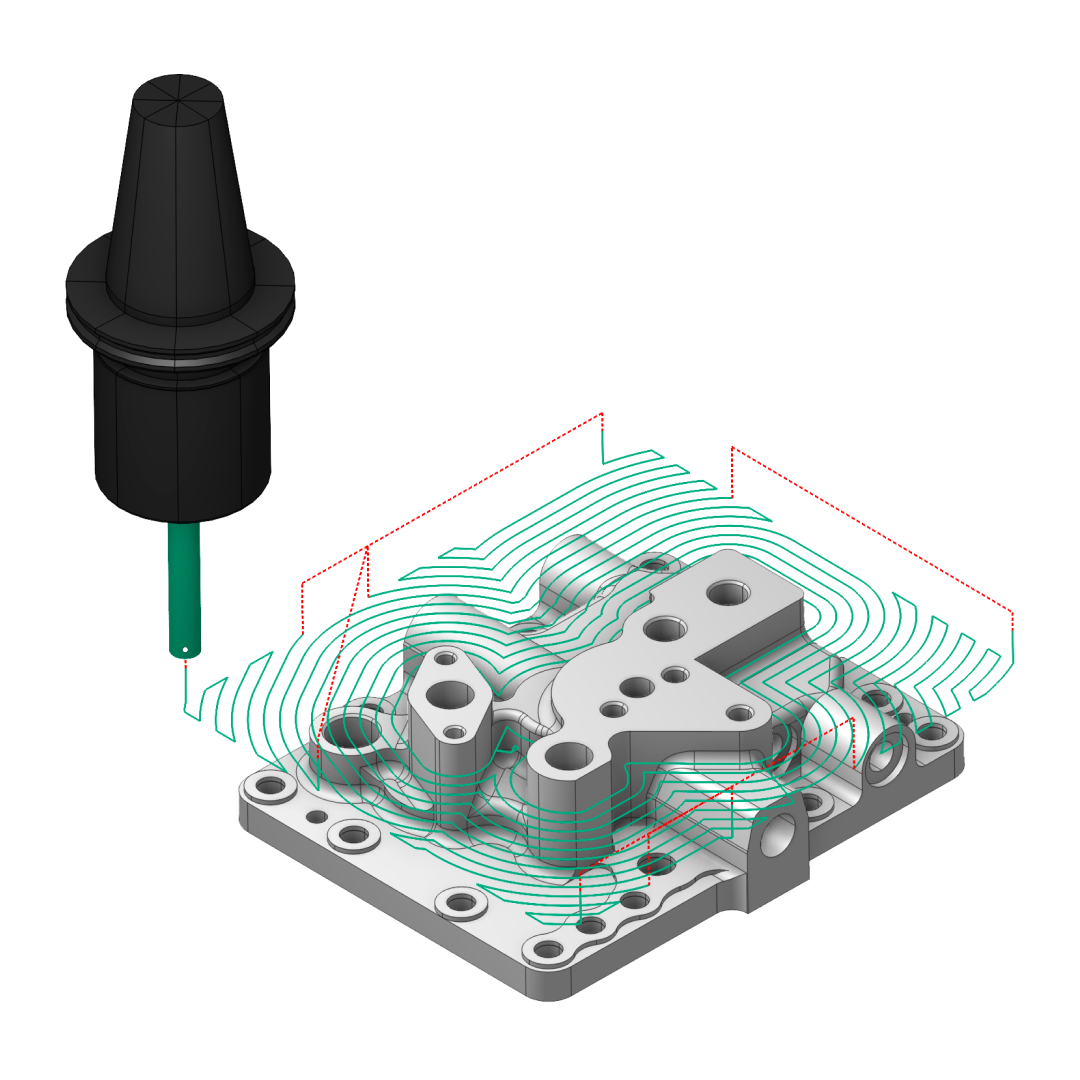

...we purchased a software package called SprutCAM X and since then have been using the bike build as the learning curve, exceeding the potential of what we would generally use the CAM package for. As we are a machine shop, we decided to machine all parts and with no welding, only interference fit’s, bonding adhesive and rivets to fix the frame together. We have machined every single component on this bike apart from the tyres, engine internals i.e., crank, cams, piston, bolts (apart from the star bolts spotted around the bike), bearings and gearbox sprockets.

Jordan Hicks

Lamb Engineering

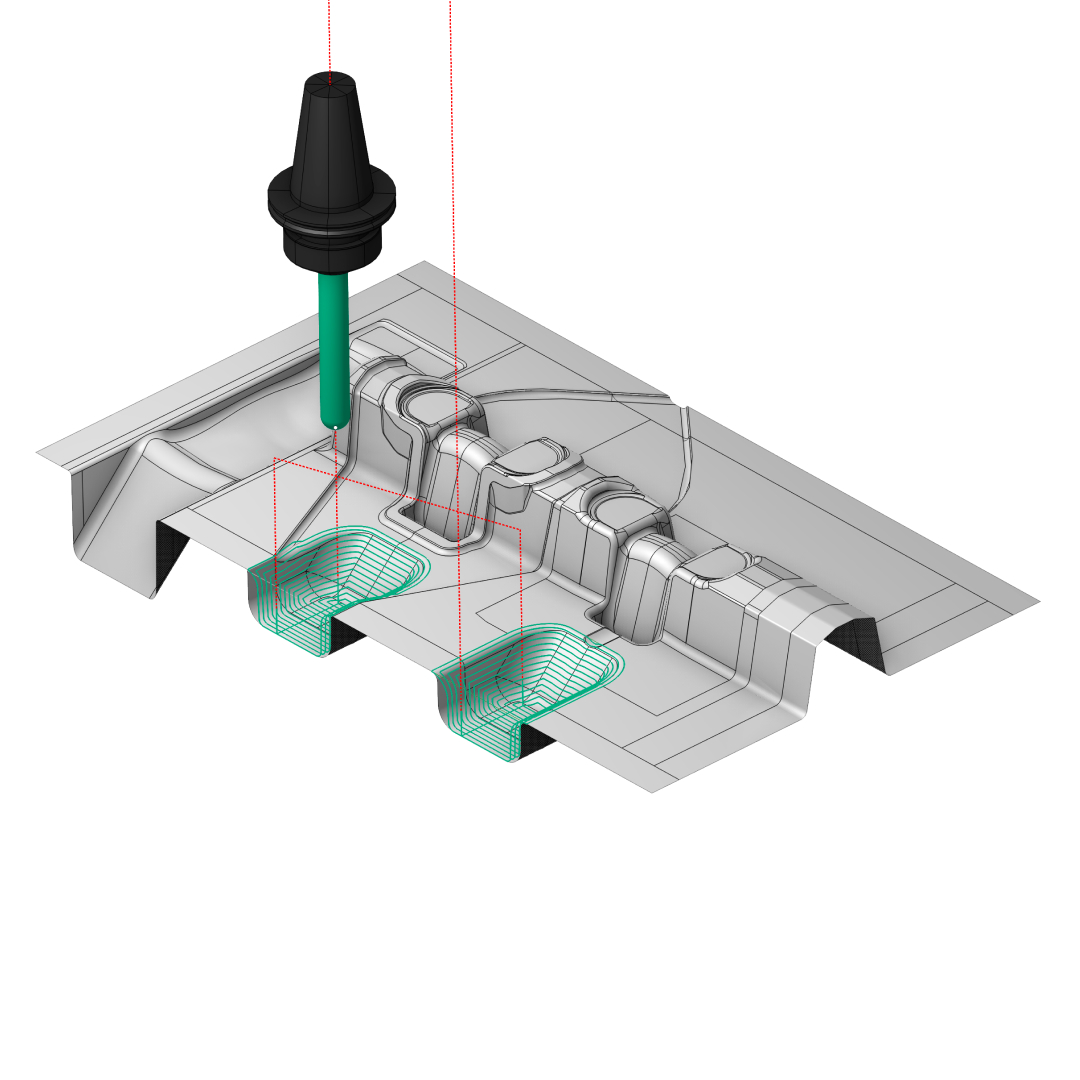

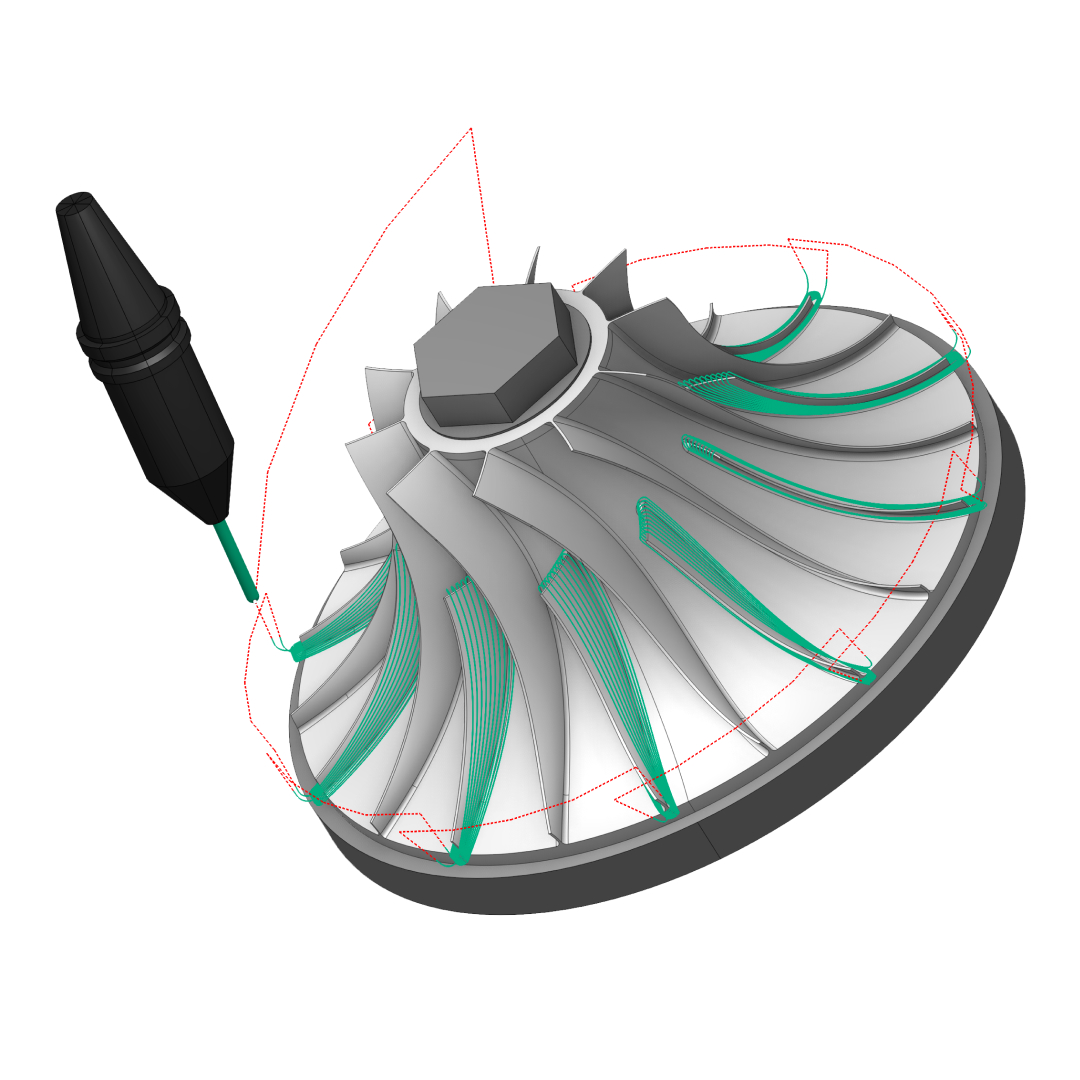

SprutCAM X Robot allows users to create free-form surfaces and program their 3D printing and milling. The control of robotic systems has been part of SprutCAM’s daily routine for a long time and different robot models can be controlled in the system without any trouble. Additionally SprutCAM X Robot offers a method to slice parts in all axes, i.e. not only in 3-axis. This means that machined parts can also be printed laterally. Whether the extruder is mounted on the robot or the additive part is attached to the robot, makes no difference.

Datentechnik Reitz

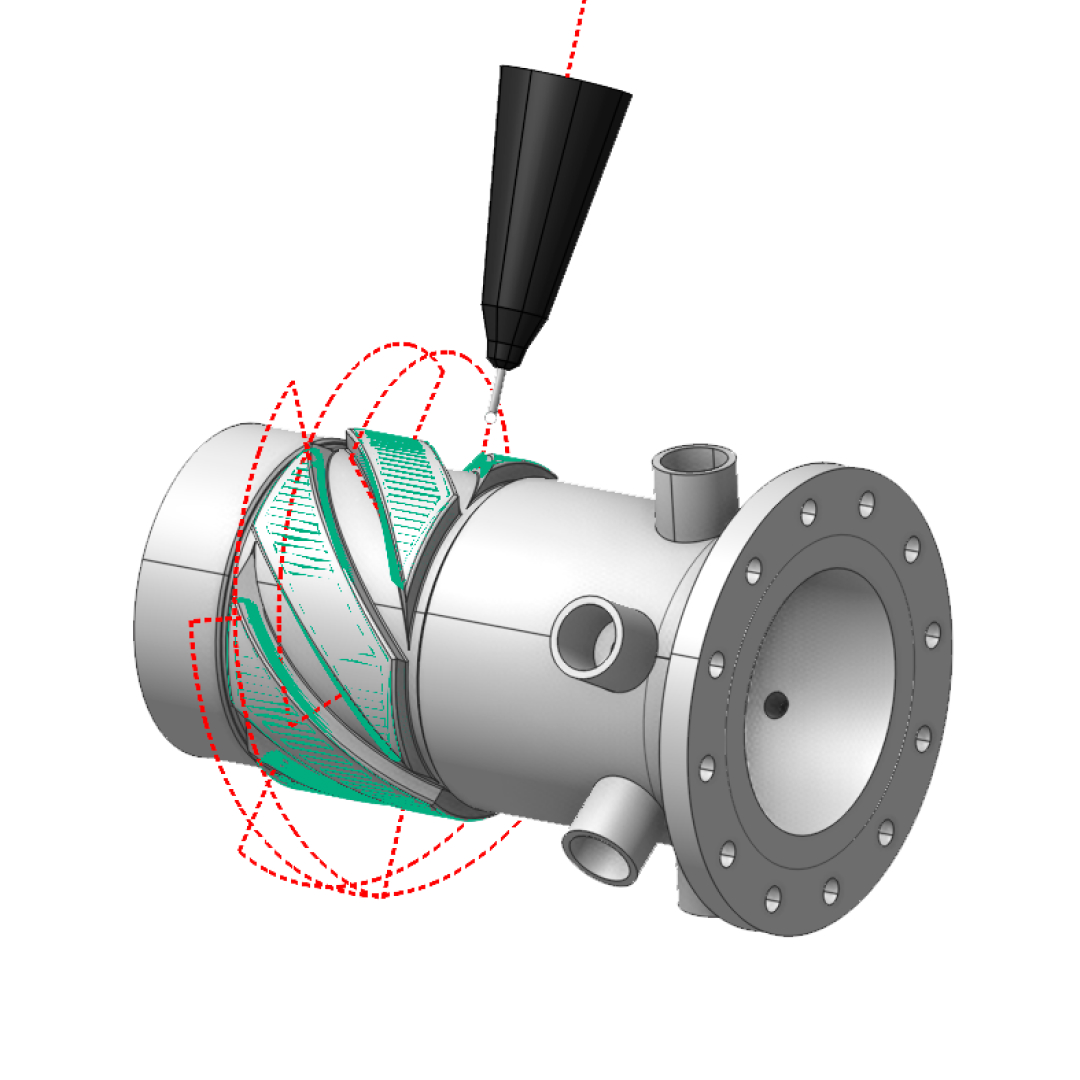

At the Formula Student Team Delft, we have the pleasure of using SprutCAM X as our new CAM software for the production of the DUT14. Using the tutorials it was easy to program simple operations at first and gradually increase the difficulty towards 3-axis milling complex shapes. After 5 weeks of producing over 1500 parts, of which around 20 were done on our CNC, the production of the DUT4 was finished.

Sietse van Schouwenburg

DUT Racing