CAD CAM software of choice for woodworking at Solid, Belgium

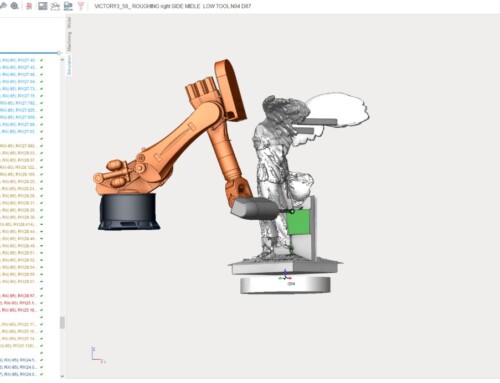

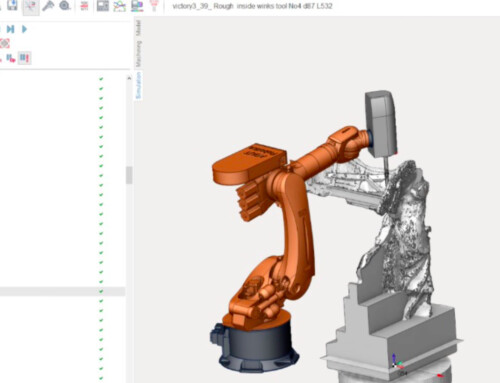

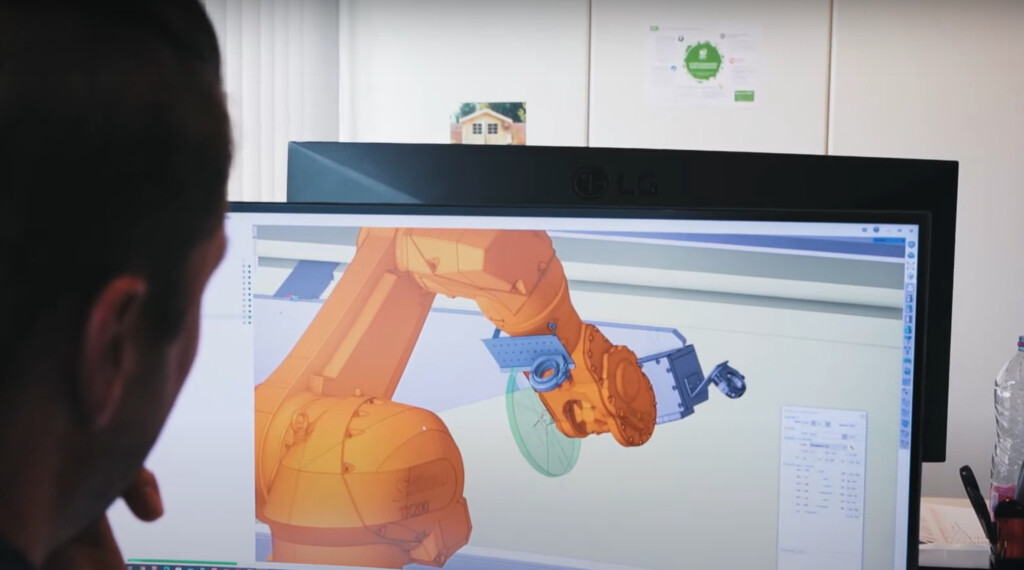

Solid company technical designer is programming the woodworking in SprutCAM X Robot CAD CAM system

Here is a successful use case on CAD CAM for wood working from our partner in Belgium, CNC Solutions.

Solid is a Belgian manufacturer of garden houses and carports, which are delivered in ready-made kits. For the production of top gables for garden houses, Solid was looking for a flexible solution.

Peter Ide, director at Solid, Belgium

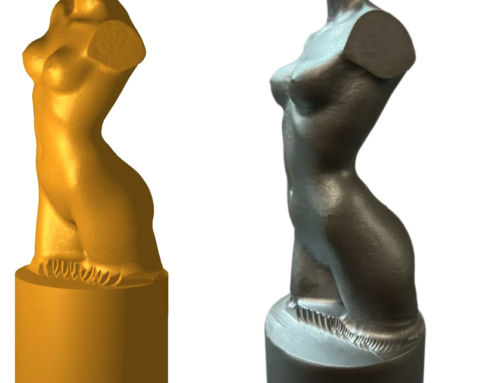

“The machine produces a semi-manufactured product that we subsequently use in the packaging of garden sheds. A top we use to complete the shed’s roof section. And that calls for a finish that is very difficult to do by hand nowadays.

The technical designer uses SprutCAM X Robot to upload the technical drawings into a sawing scheme in the robot.

That way the robot can process the exact technical drawing to a semi-manufactured product that we will then process in the garden shed.”

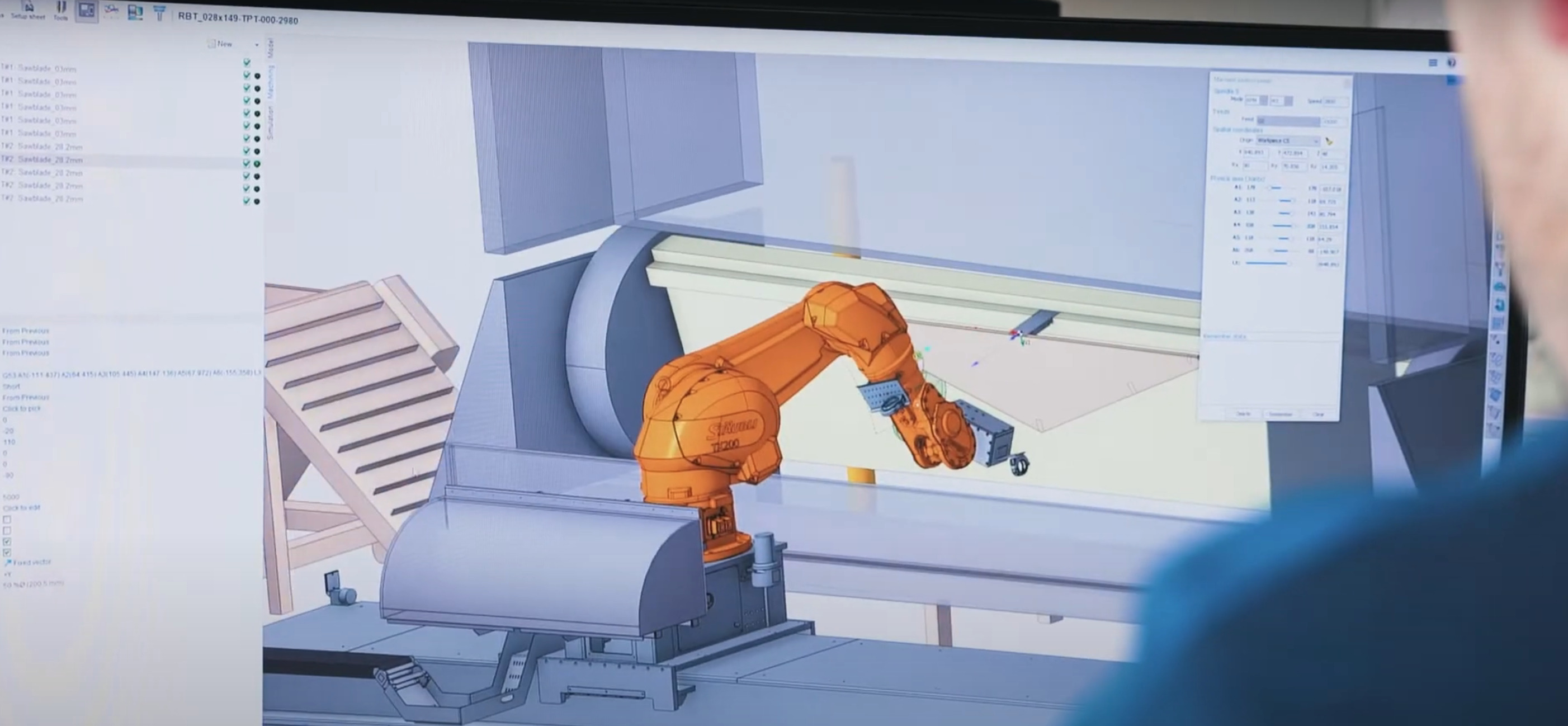

“At the machine, the operator lays down a number of boards. Then the robot mills the shape of the top and also provides accurate infeeds. Those contours and infill cuts are determined in advance in SprutCAM, where we convert the technical drawing into the right operations for the machine”

Peter Ide continues:

That way the robot can process the exact technical drawing to a semi-manufactured product that we will then process in the garden shed. Formerly, we had to hire a sheltered workshop to produce these pieces in large series. Nowadays, CNC Solutions’ machine enables us to produce the exact numbers the day before we need them. Because of the reliability and accuracy, we know we can build today what we need tomorrow. The collaboration with CNC Solutions is going very well. The communication with the company is excellent. Both with the management and the people who provide us with the technical solutions. Very good communication. Definitely!

Solid warehouse, Belgium

Solid's robotic cell

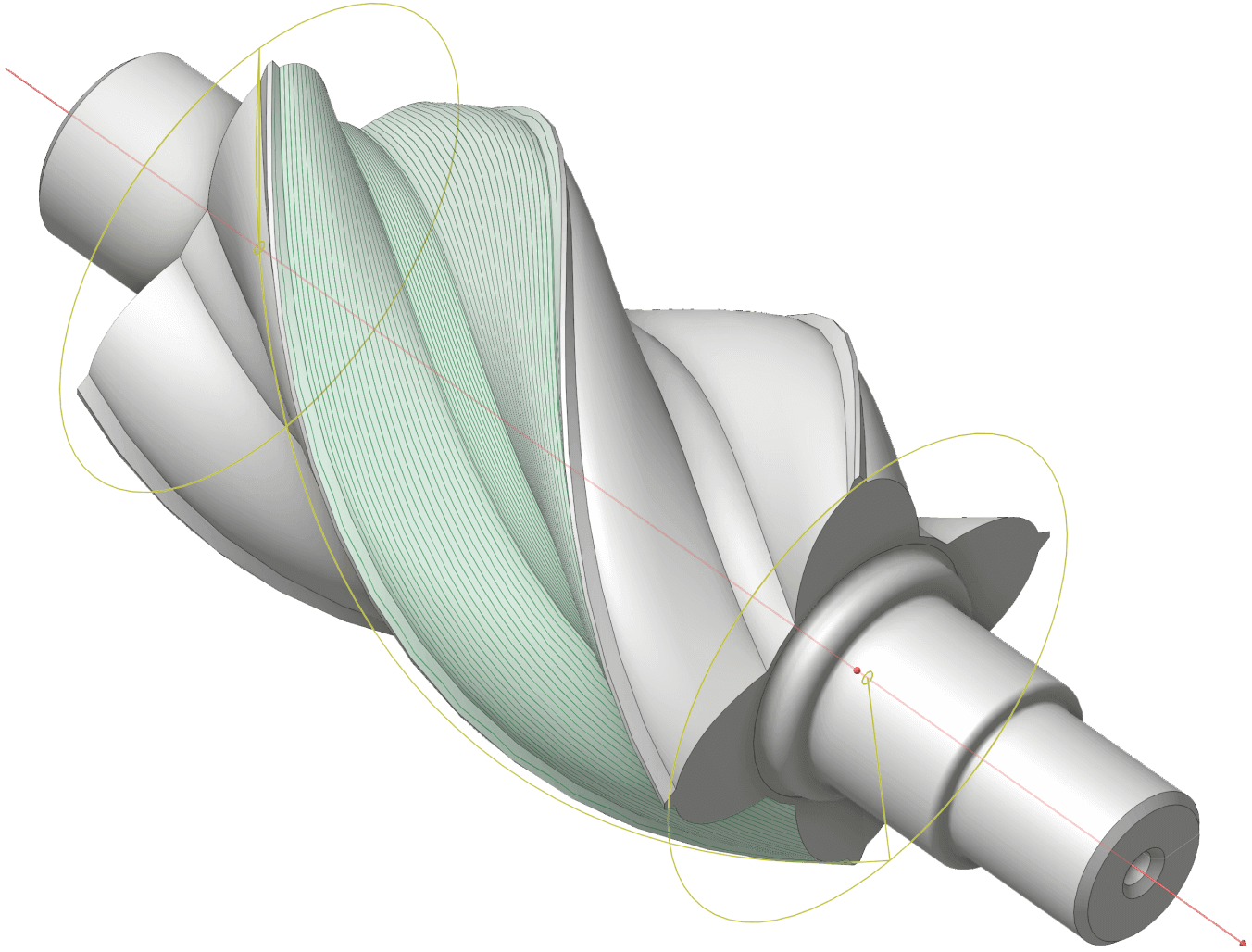

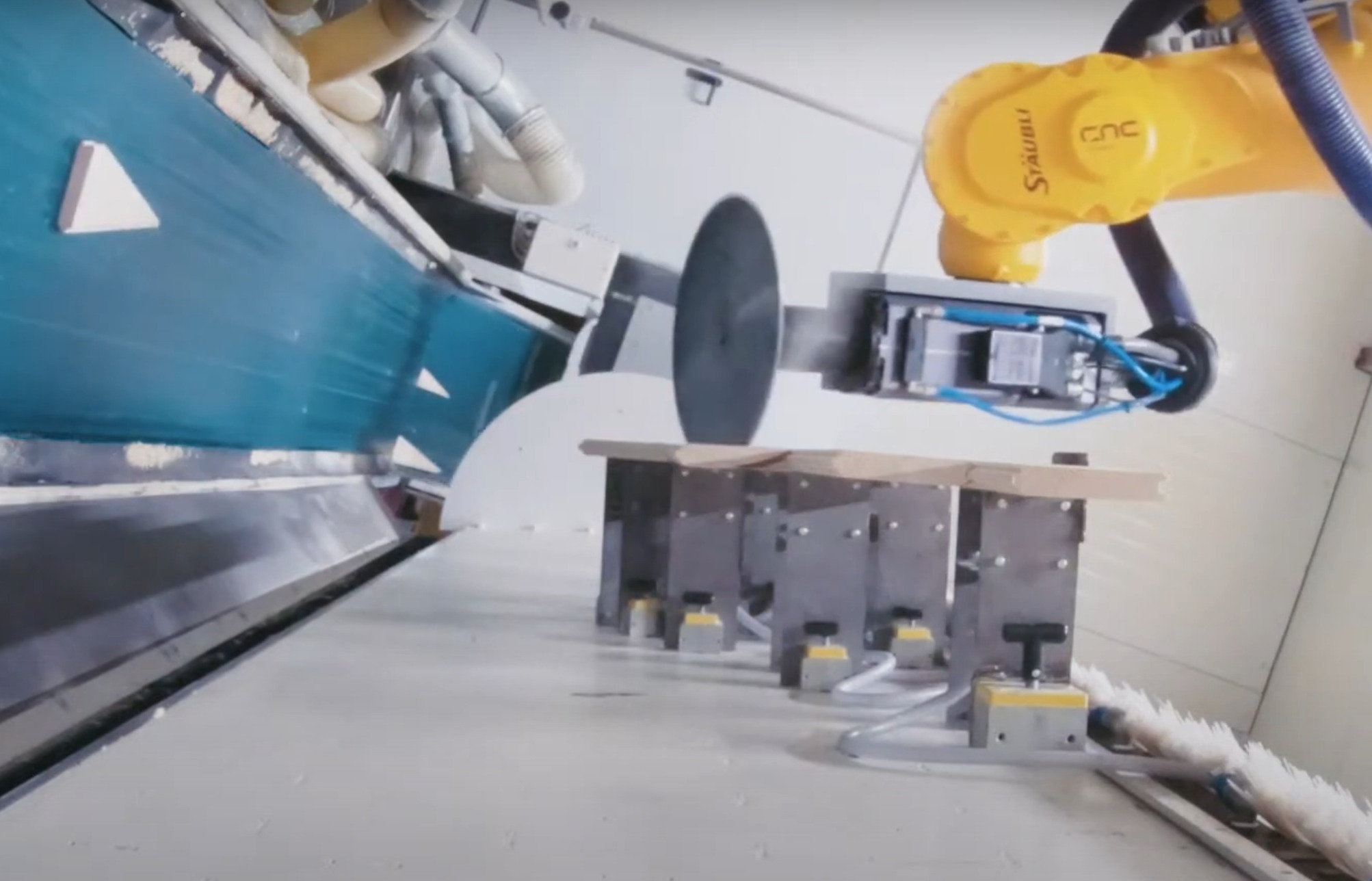

Disc cutting done by Stäubli robot programmed in SprutCAM X CAD CAM system

Disc cutting done by Stäubli robot programmed in SprutCAM X CAD CAM system

Why the company chose SprutCAM CAD CAM software for their woodworking businessX?

That’s what Lander Debruyne, from CNC Solutions, SprutCAM Tech partner in Belgium has to say about it:

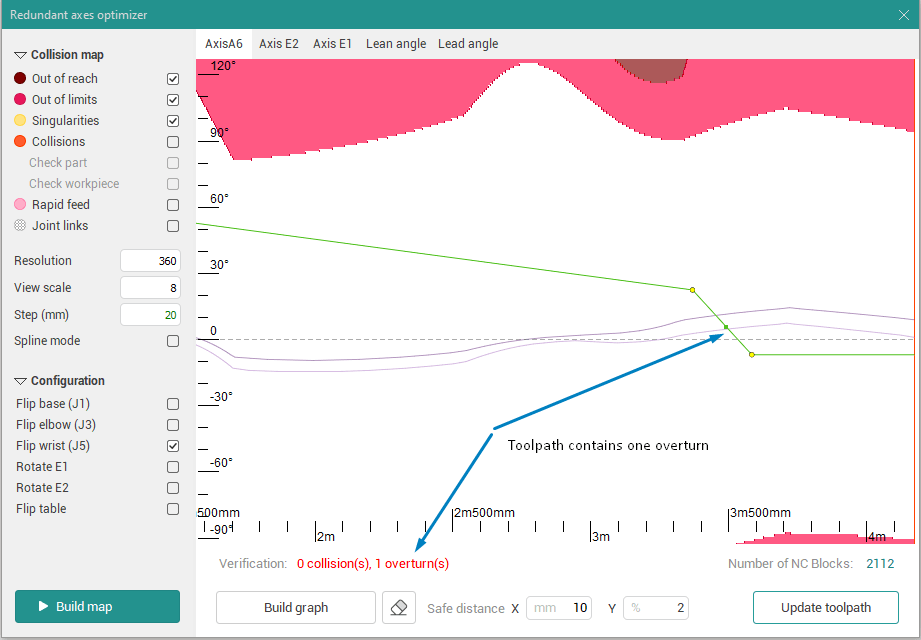

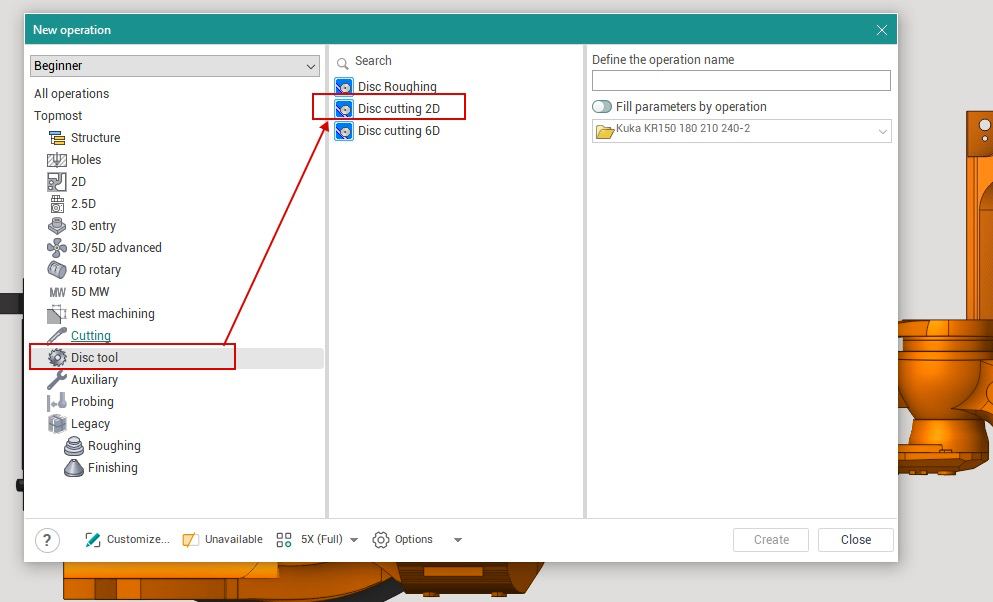

They chose SprutCAM because the external linear axis is fully integrated, almost all cutting operations are done with the robot and the linear axis synchronised. The Axesmap was also a great added value: here, it is easy to change the position of the linear axis somewhat in relation to the robot to avoid any collisions, singularities or axis limits. As the customer works almost exclusively with saws, the Disc cutting 2D toolpath was also a great added value: here it is very easy to set the lead-in, lead-out and cutting depth.

Robot Axis Map function enables manually setting and fine-tuning the automatic control rules for the excessive degrees of freedom of a robot (the 6th axis, the rail axes, the rotary table axes).

Disc cutting operation in SprutCAM X CAD CAM system