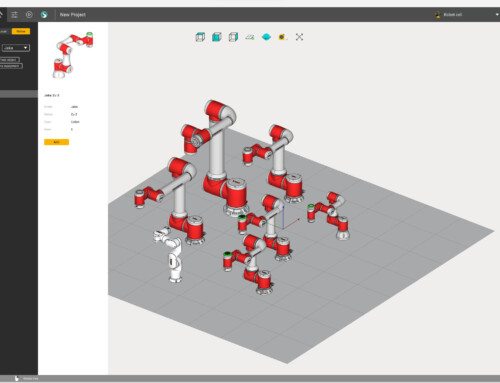

“The primary reason I chose SprutCAM X Robot is because it’s an all-in-one CAD/CAM/OLP solution”

User experiences and industry predictions presented at the Robotics Applications Conference (RAC’23).

The second annual RAC’23 took place on October 18th and featured six distinct themed sessions. The conference garnered nearly 700 registrants, and more than 300 attendees joined at least one session.

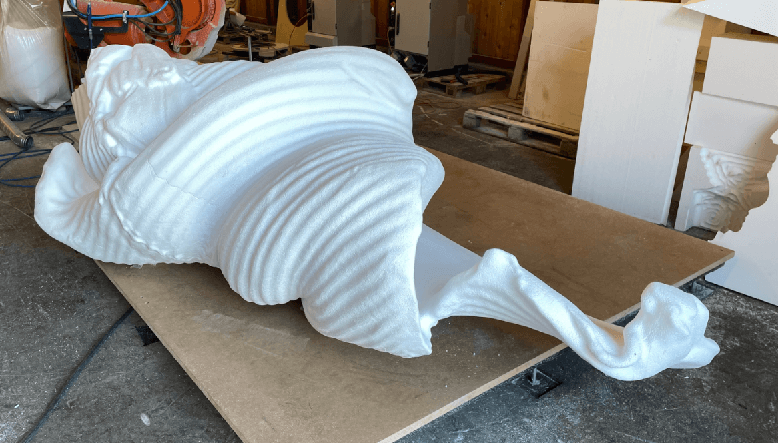

The “Milling and Machine Tending” session drew over 380 registrants and boasted more than 100 attendees. Andrei Kharatsidi, co-founder and managing director of SprutCAM Tech Ltd., received an invitation from the conference organizers to serve as the keynote speaker for this session. Joining Mr. Kharatsidi on the panel was Joakim Målare, the founder of nioform, a 3D scanning and robotic milling service catering to artists, designers, and architects. Eugene Demaitre, the editorial director of Robotics 24/7, effectively moderated this engaging discussion.

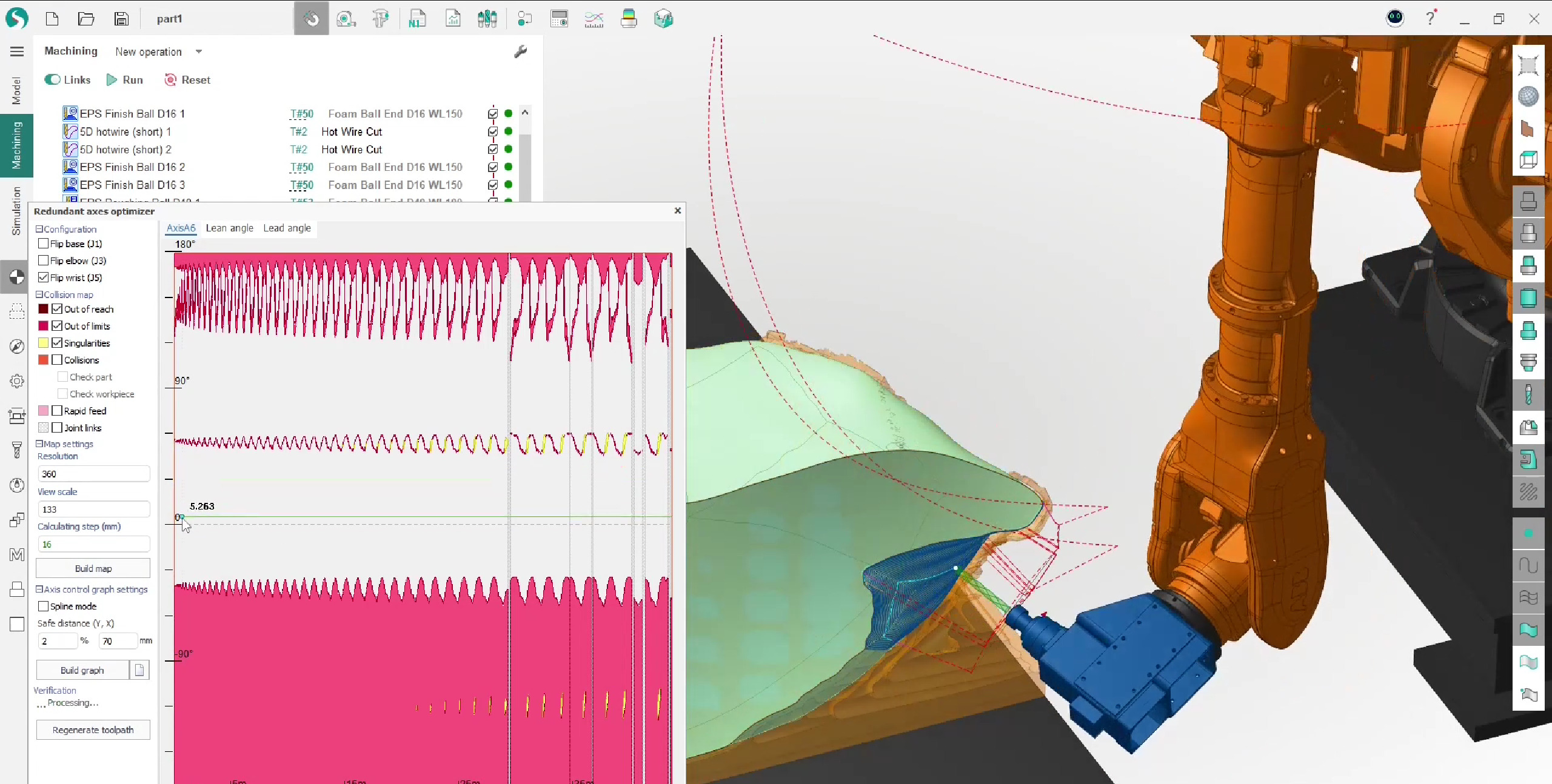

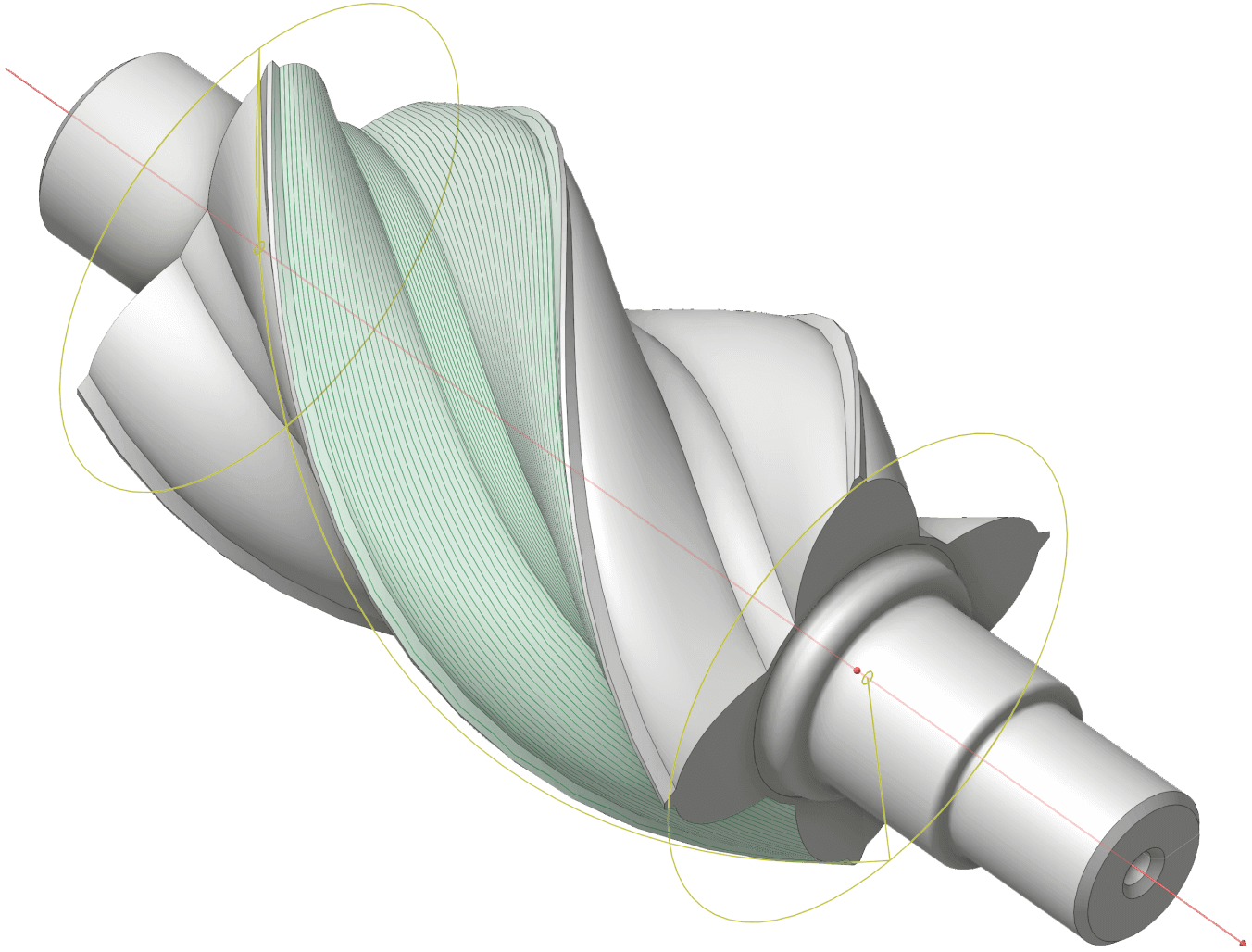

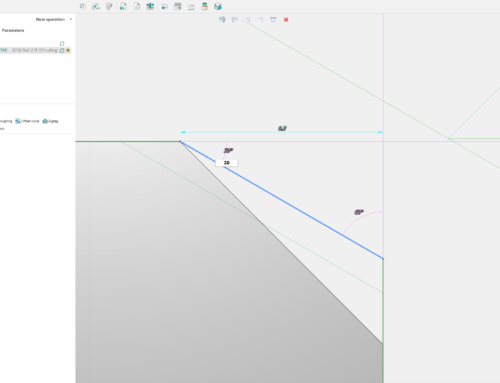

Joakim Målare shared his experience of using and implementation industrial robot programming software: “The primary reason I chose SprutCAM X Robot is because it’s an all-in-one solution. And you don’t have to worry about data loss when translating from a general 5-axis program to a robot program. On the software’s side, it was easy to integrate SprutCAM X Robot. I’ve done everything myself. I didn’t have any support from anyone other than SprutCAM Tech themselves.”

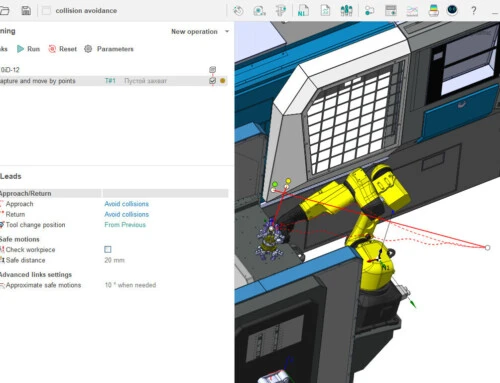

Considering the industry’s forecast for robotics applications, Andrei Kharatsidi expressed his views, stating, “I believe that some kind of fusion between two worlds, offline and online robot programming, will give a really good results, especially for machine tending, when there are a lot of work pieces in the work area, and the machine with a lot of some mechanisms in the work area. And I believe that when sensor technology becomes widespread and most of robots are equipped with some kind of sensor, the world of robot programming will change.”

The discussion also addressed various questions, including:

“What types of tasks do you automate at nioform? Where would you like to add automation in the future?”

“Collaborative robot arms have become more precise. How is sensing part of that improvement? Where do you see cobots and sensing improving in the near future?”

“How is software like SprutCAM X Robot enabling collaborative robots to be useful in a wider range of applications? How is milling similar to or different from other applications, such as pick and place, welding, or painting?”

“How difficult was it to integrate robotics with nioform’s other processes and systems? Did you reply on SprutCAM Tech or a third party integrator?”

“Cobots are supposed to be easy to reprogram. How much time required to prepare one for a new task and for calibration? What’s required to prepare the robot for more complex tasks? What are some of the requirements for the arts and entertainment industry?”

For those who missed the conference broadcast, here’s a link to register and watch the “Milling and Machine Tending” session, which will remain accessible for a year.