Experience the innovative all-in-one software suite for complex and creative robotics tasks

SprutCAM X Robot: innovative all-in-one CAD/CAM/OLP for robots

Get a quote Download trial

MeetSprutCAM X Robot

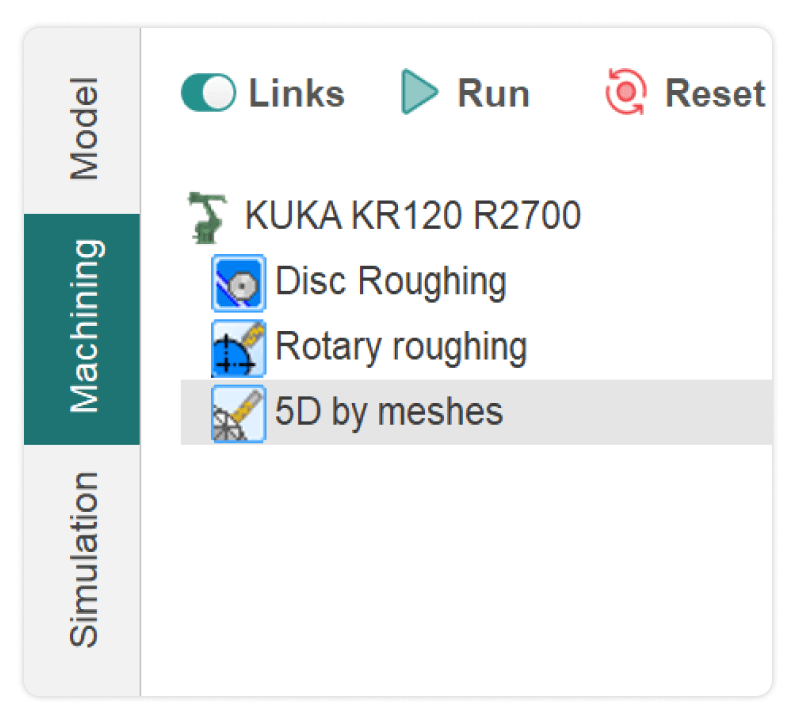

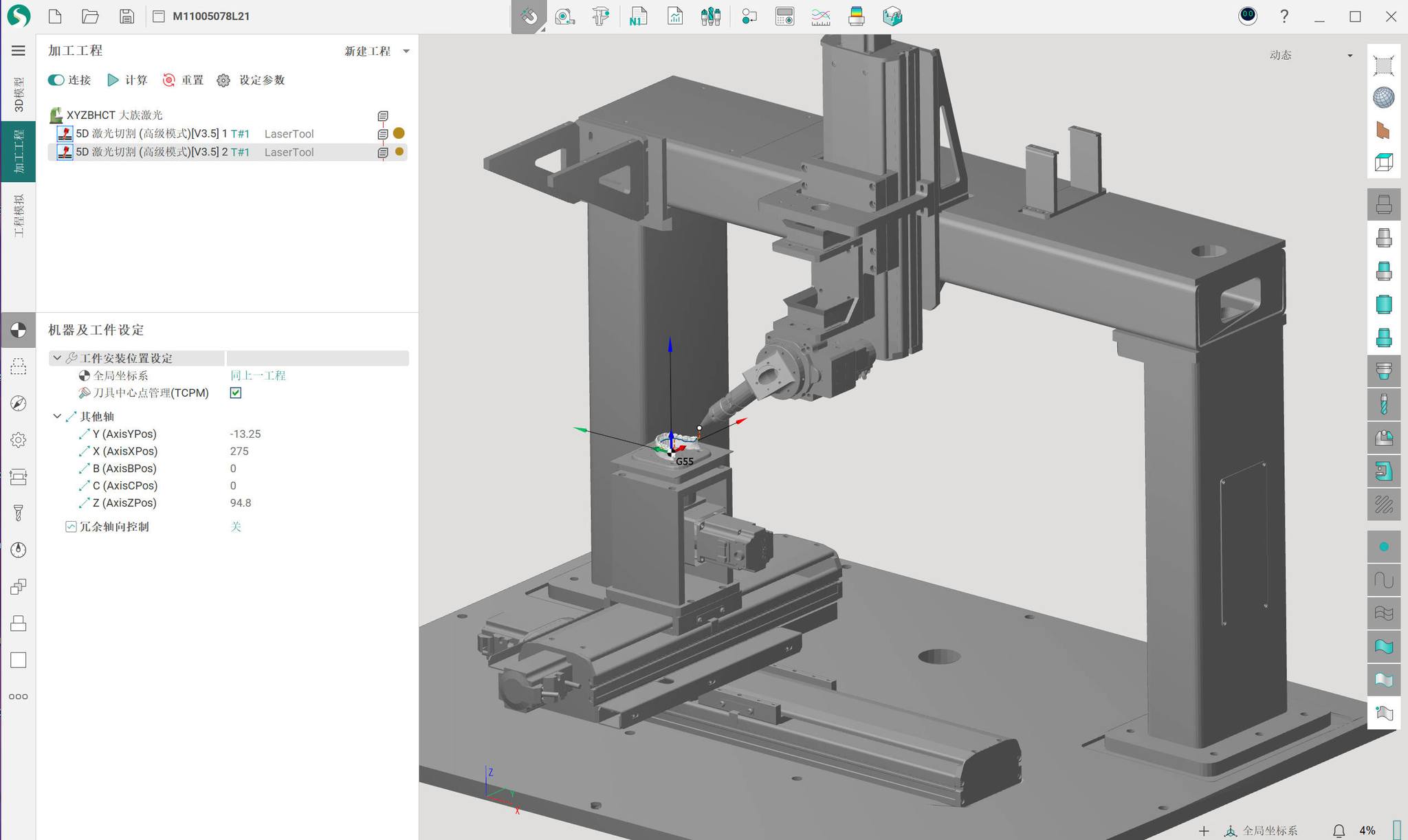

- Model tab is for 3D model design, import and transformation

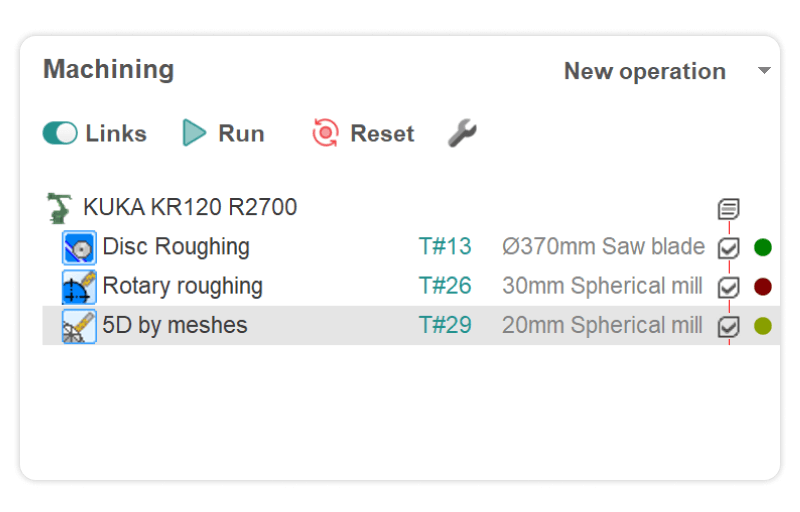

- Machining tab is for creation of technological sequence. 80% of job is done here

- Simulation speaks for itself

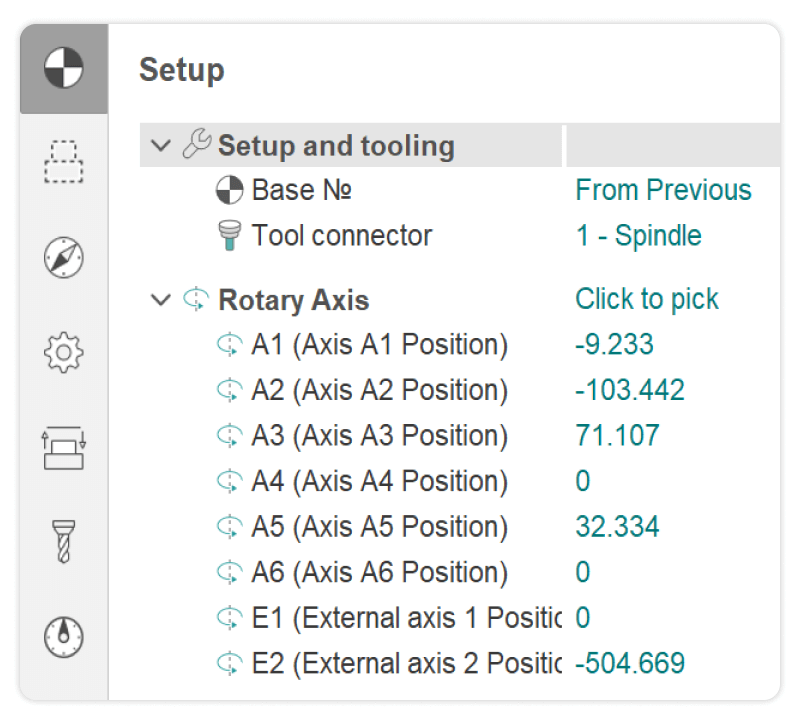

Inspector is the place there all the technology parameters are defined: job zone, toolpath strategy, tolerance, interpolation, approach and retract, links, feeds and speeds, toolpath transformation etc

Inspector is the place there all the technology parameters are defined: job zone, toolpath strategy, tolerance, interpolation, approach and retract, links, feeds and speeds, toolpath transformation etc Machining operations sequence

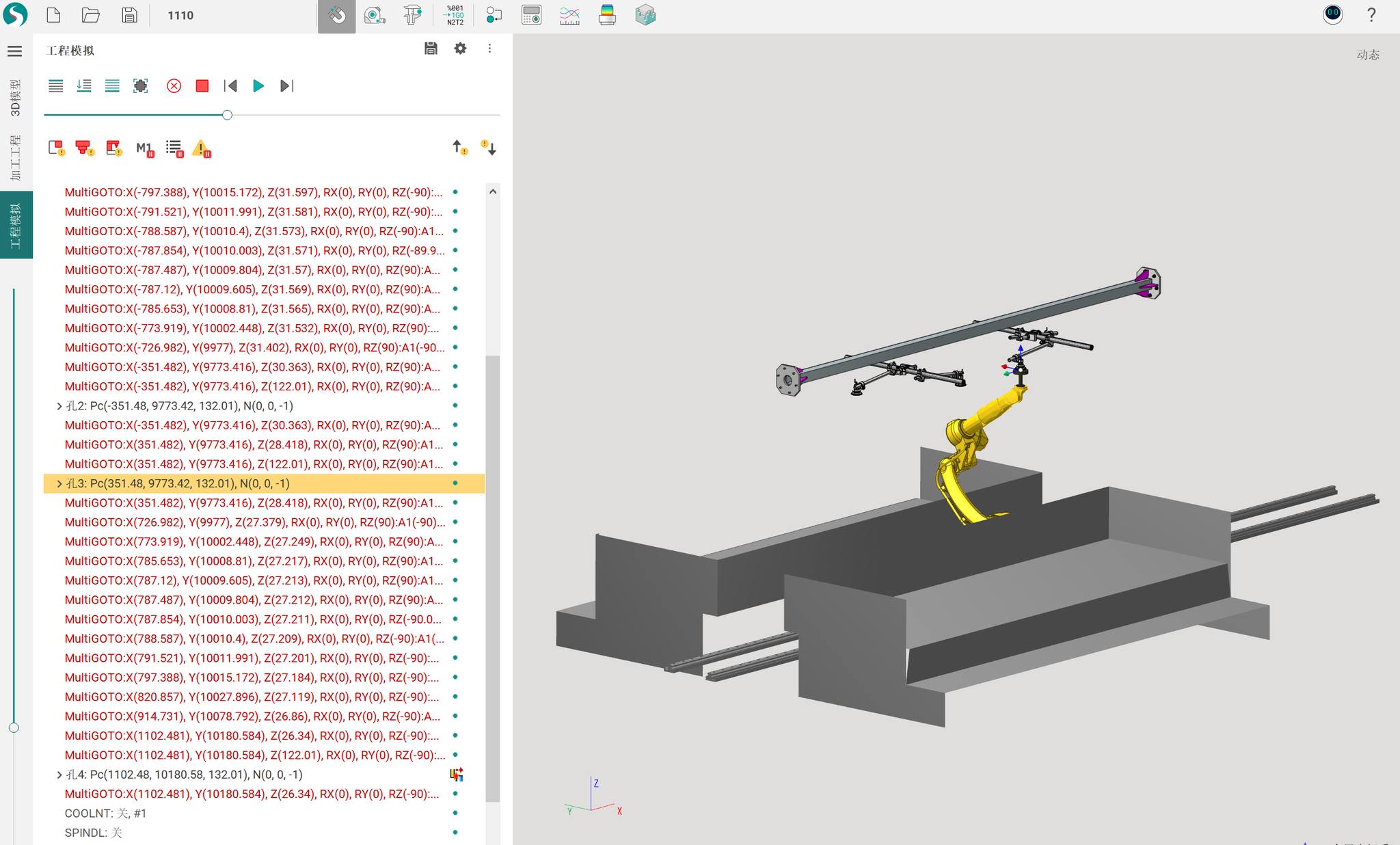

Machining operations sequence Useful tools for everyday work: virtual machine pendant, tape measure, postprocessor, machining report, tool management, verify and compare tool, tool reach inspector, axes graph and 3d model transformation tools.

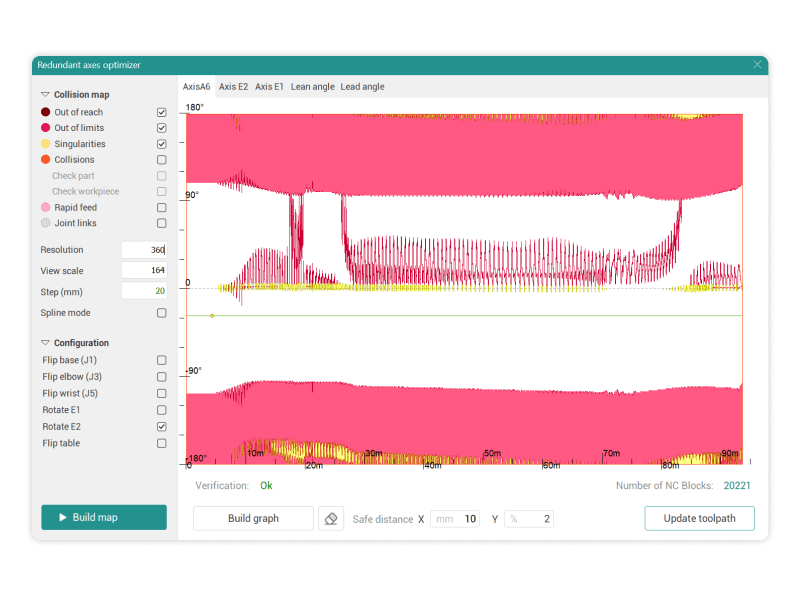

Useful tools for everyday work: virtual machine pendant, tape measure, postprocessor, machining report, tool management, verify and compare tool, tool reach inspector, axes graph and 3d model transformation tools. Gain full control over singularities, collisions, reach zone limits, and redundant degree of freedom provided by 6th axis using a dedicated and powerful tool: the robot axis map

Gain full control over singularities, collisions, reach zone limits, and redundant degree of freedom provided by 6th axis using a dedicated and powerful tool: the robot axis map

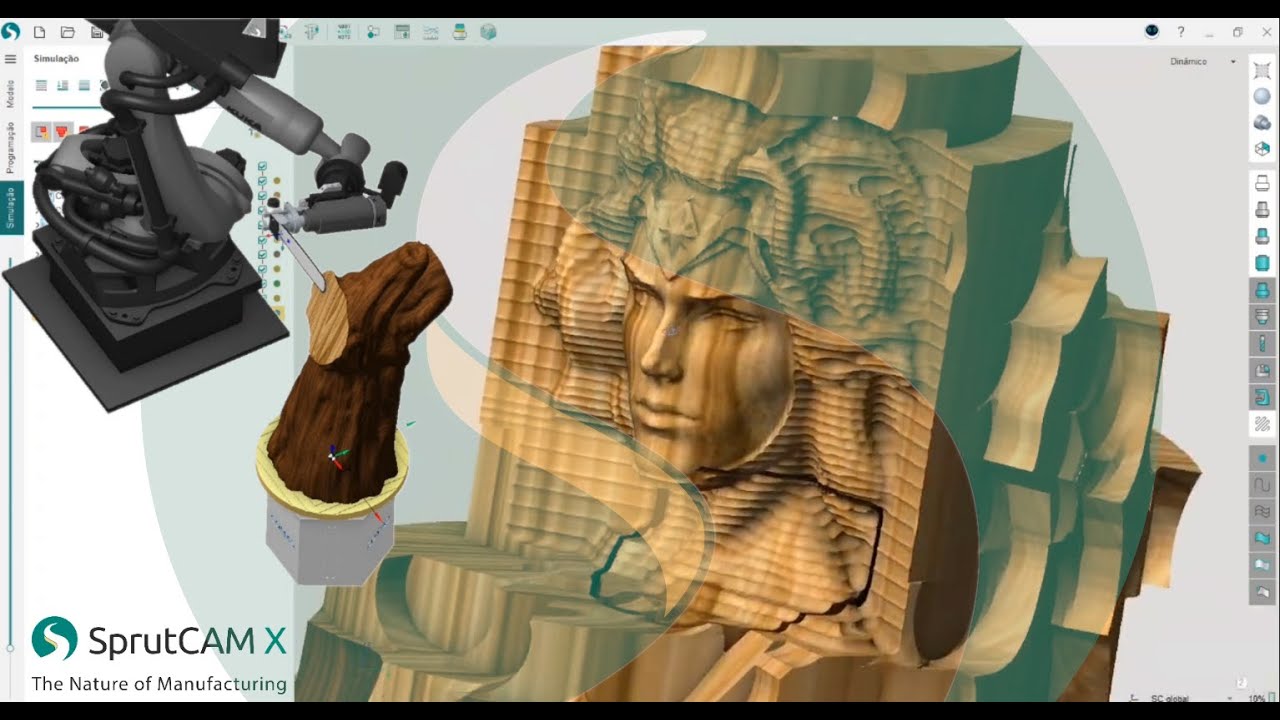

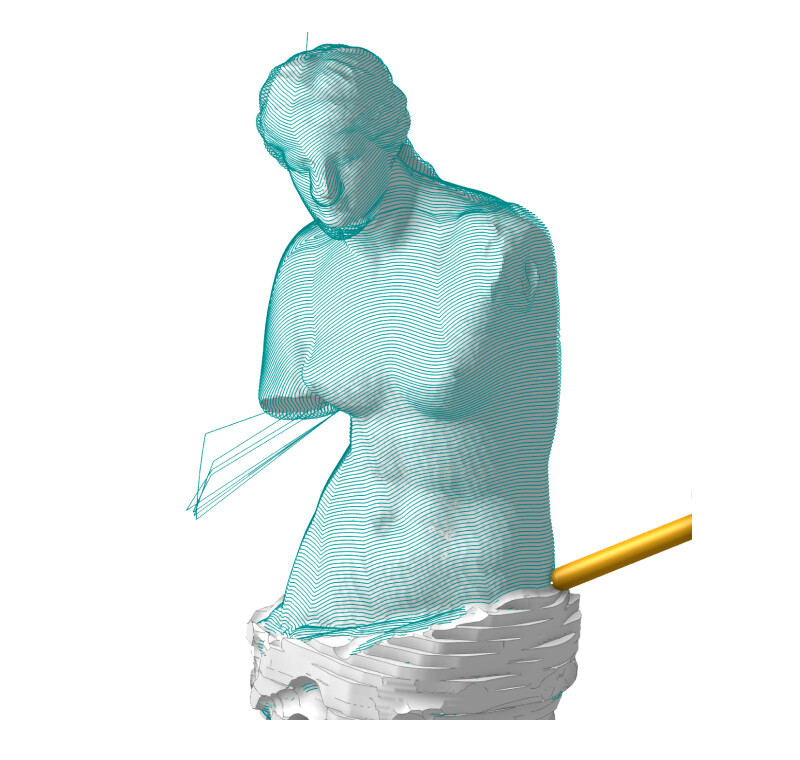

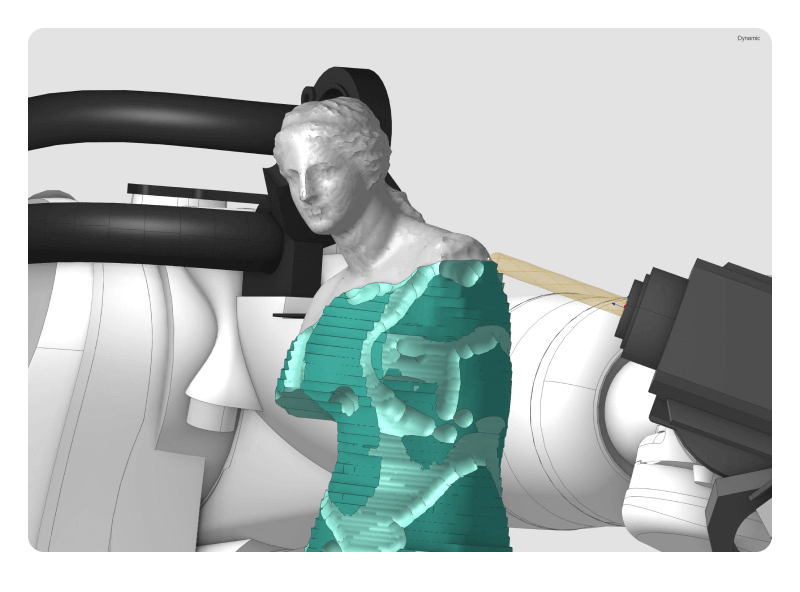

Precise and smooth simulation of workpiece evolution through the machining process. Either for machining or for additive processes

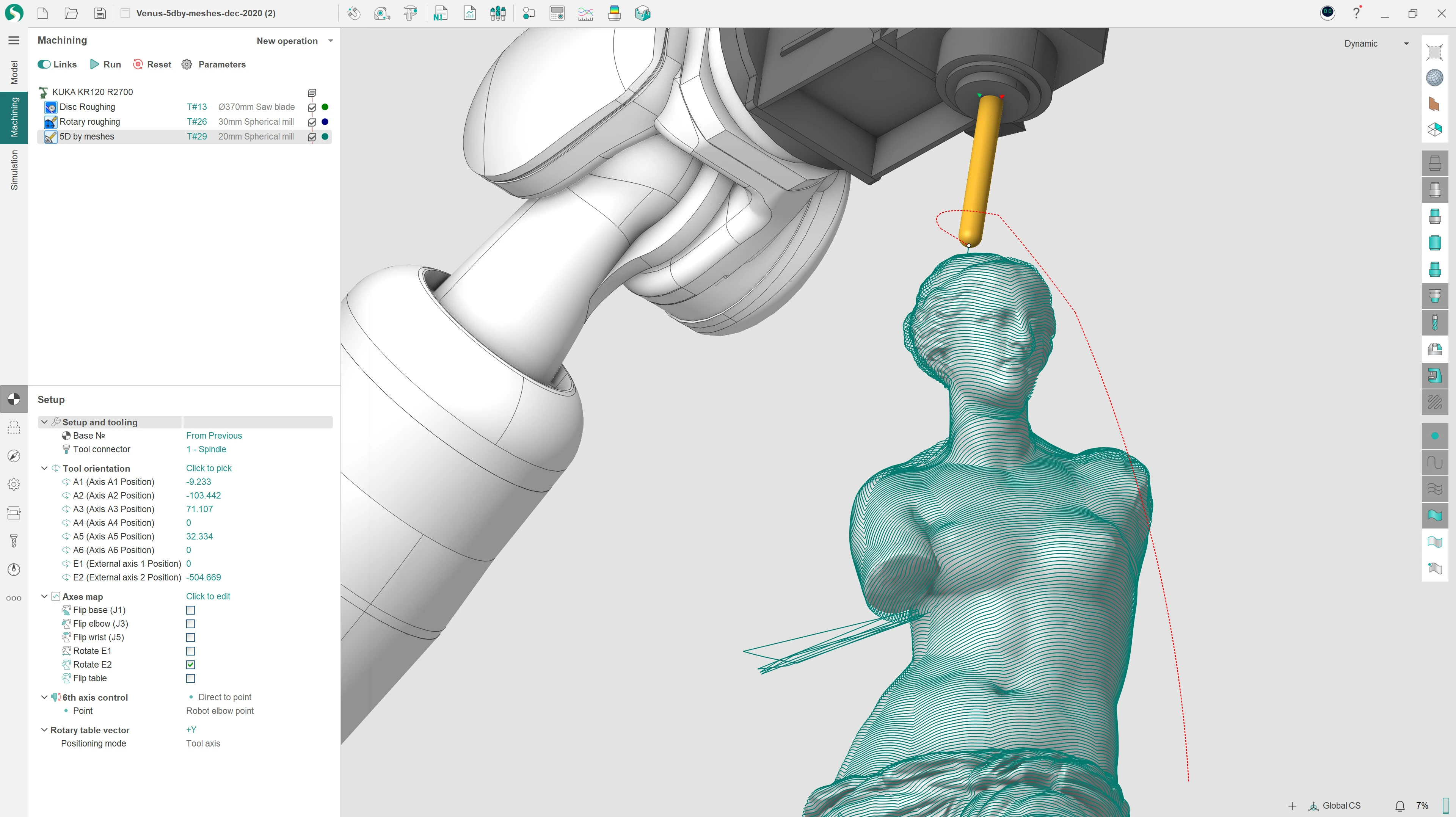

Precise and smooth simulation of workpiece evolution through the machining process. Either for machining or for additive processes The main working area. Here are machine digital twin, part, workpiece, tools are shown. SprutCAM X Robot shows the interactive elements and simulation in this area

The main working area. Here are machine digital twin, part, workpiece, tools are shown. SprutCAM X Robot shows the interactive elements and simulation in this area

Go beyond

traditional robot simulation software

SprutCAM X is an all-in-one solution for offline

programming that includes:

Toolpath calculation for any application

Simulation

Optimization for singularity and collision free movements

Post-processing

Offline robot programming workflow

CAD

CAD

Design with integrated CAD or import 3D models

CAM

CAM

Generate toolpath

Generate the optimal toolpaths for robotic milling coming from the advanced CAM software, SprutCAM X, customized for robots. As well as robot-specific toolpaths.

OLP

OLP

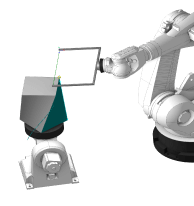

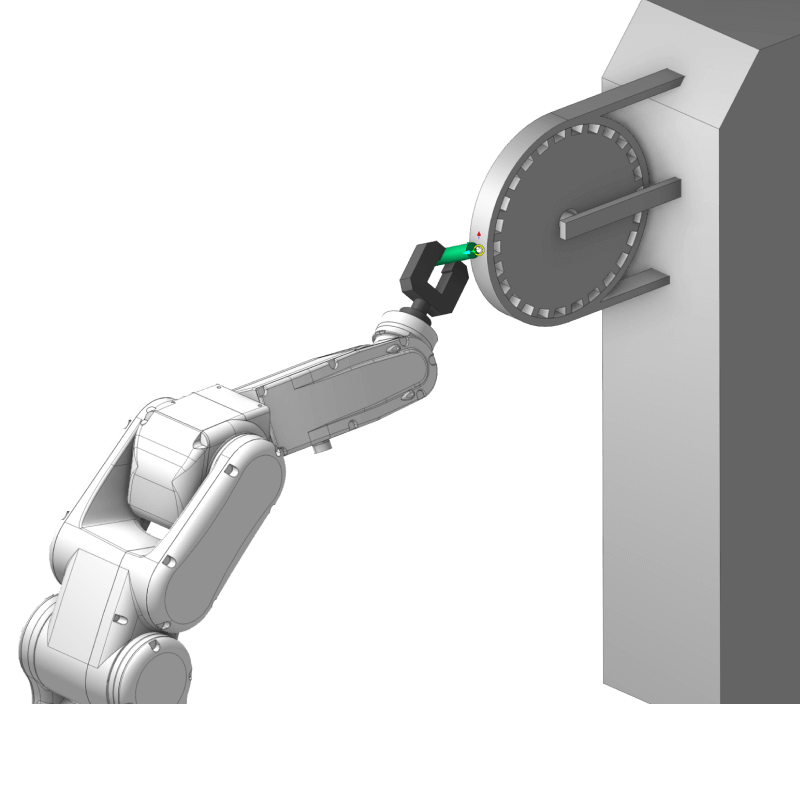

Manage robot kinematics

Handle singularities, collisions, reach zone limits and control redundant axes movements with dedicated tools

Simulation with Digital Twin

Simulation with Digital Twin

Simulate a robotic cell of any complexity with high resolution and smoothness

Post-processing

Post-processing

Generic and tailor-made postprocessors

Pre-Launch Verification

Pre-Launch Verification

Leverage the power of G-code verification

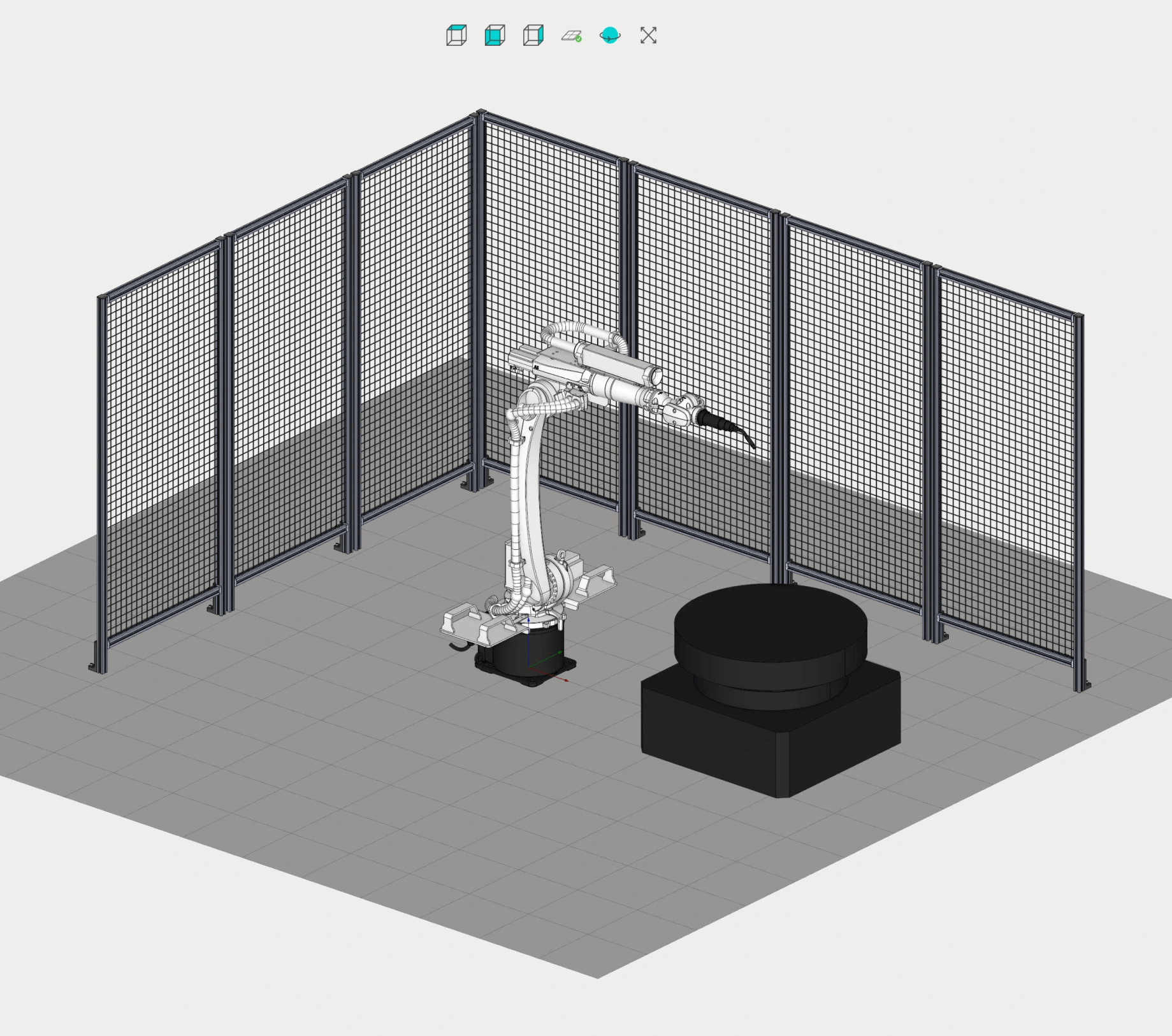

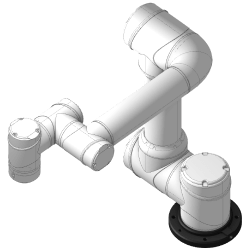

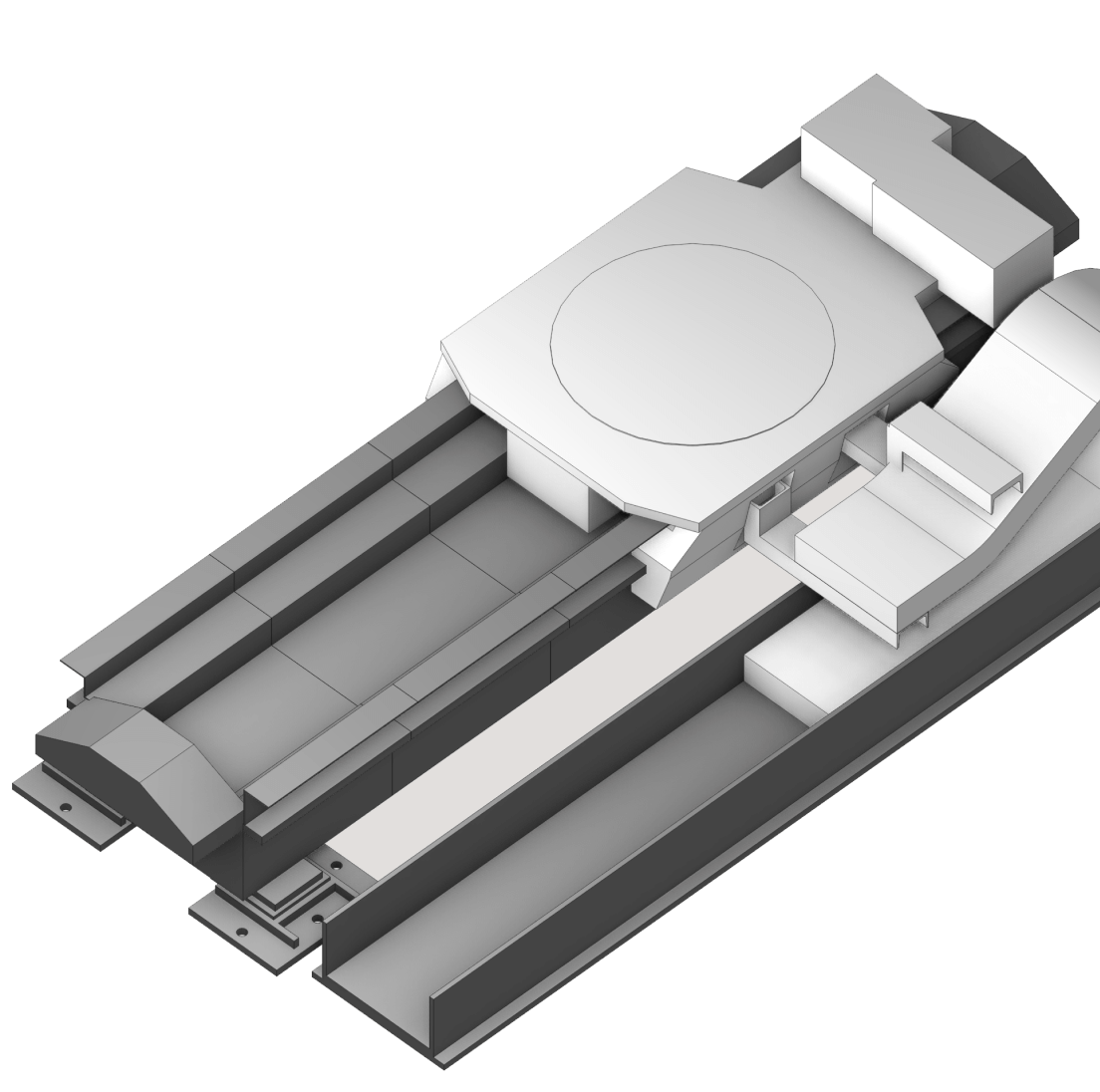

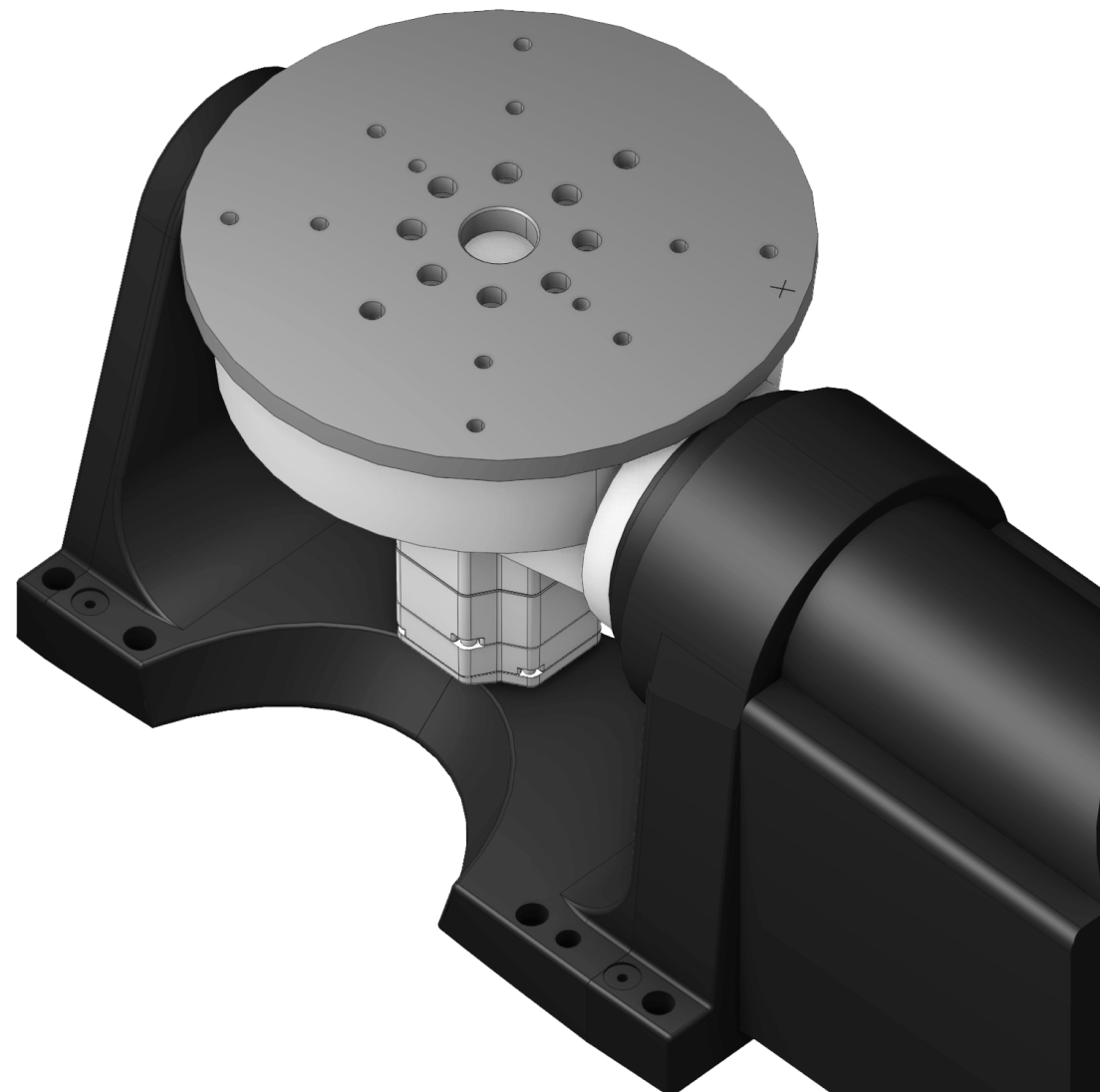

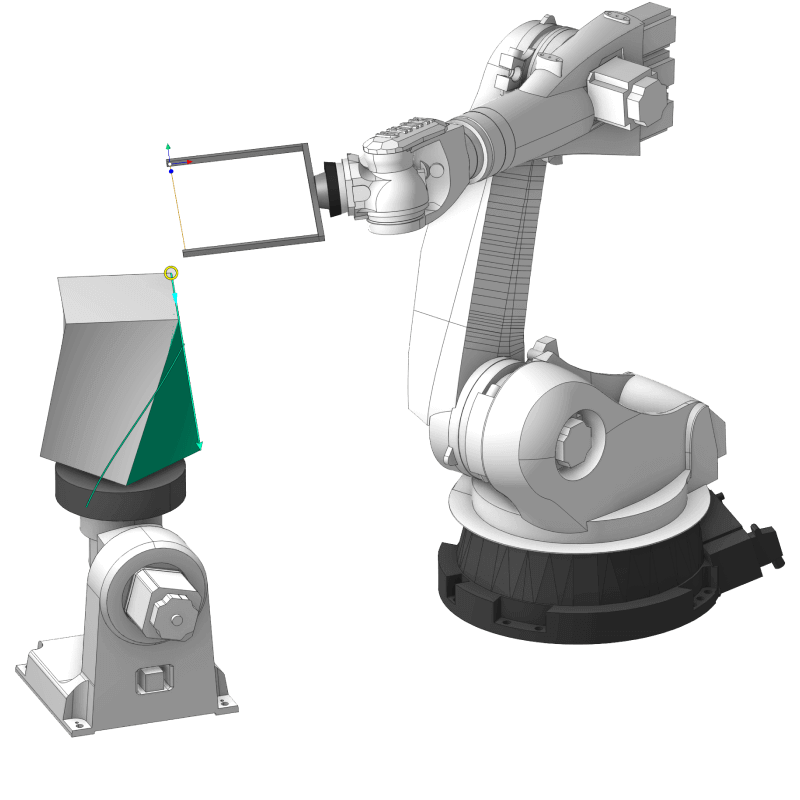

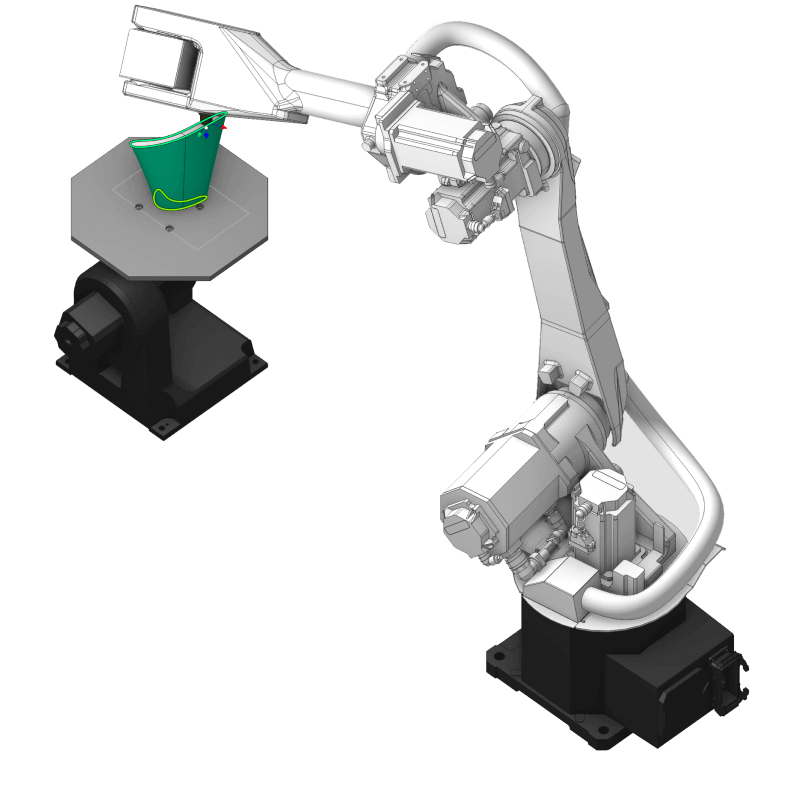

MachineMaker: zero code digital twin builder

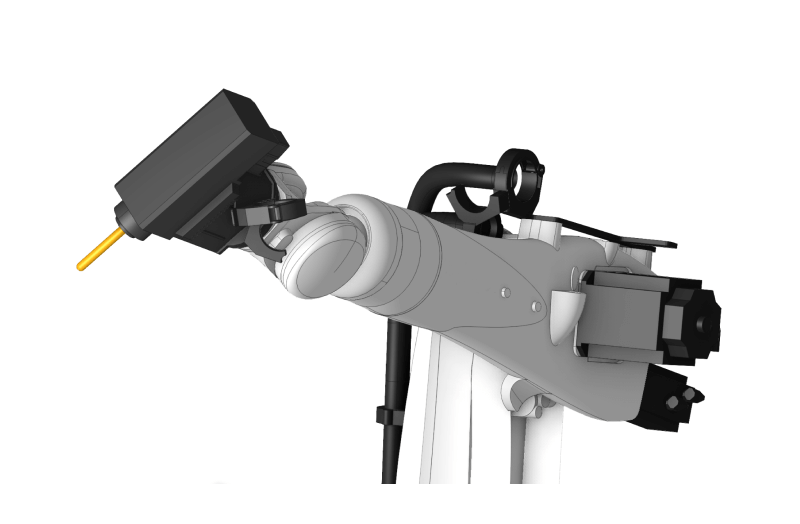

SprutCAM X Robot allows manufacturers and integrators to create an accurate real-world cell with equipment and production components in a virtual environment, as well as simulate all robot functions on the screen.

The quality of simulation and detailing of digital twins in SprutCAM X Robot is second to none.

A wide range of certified post processors for most makes and models of robots guarantee error-free code. SprutCAM X Robot library of kinematic diagrams supports the largest selection of industrial robot brands. And with the MachineMaker app, you can quickly create an accurate kinematic model of any robotic cell.

Supported machinery

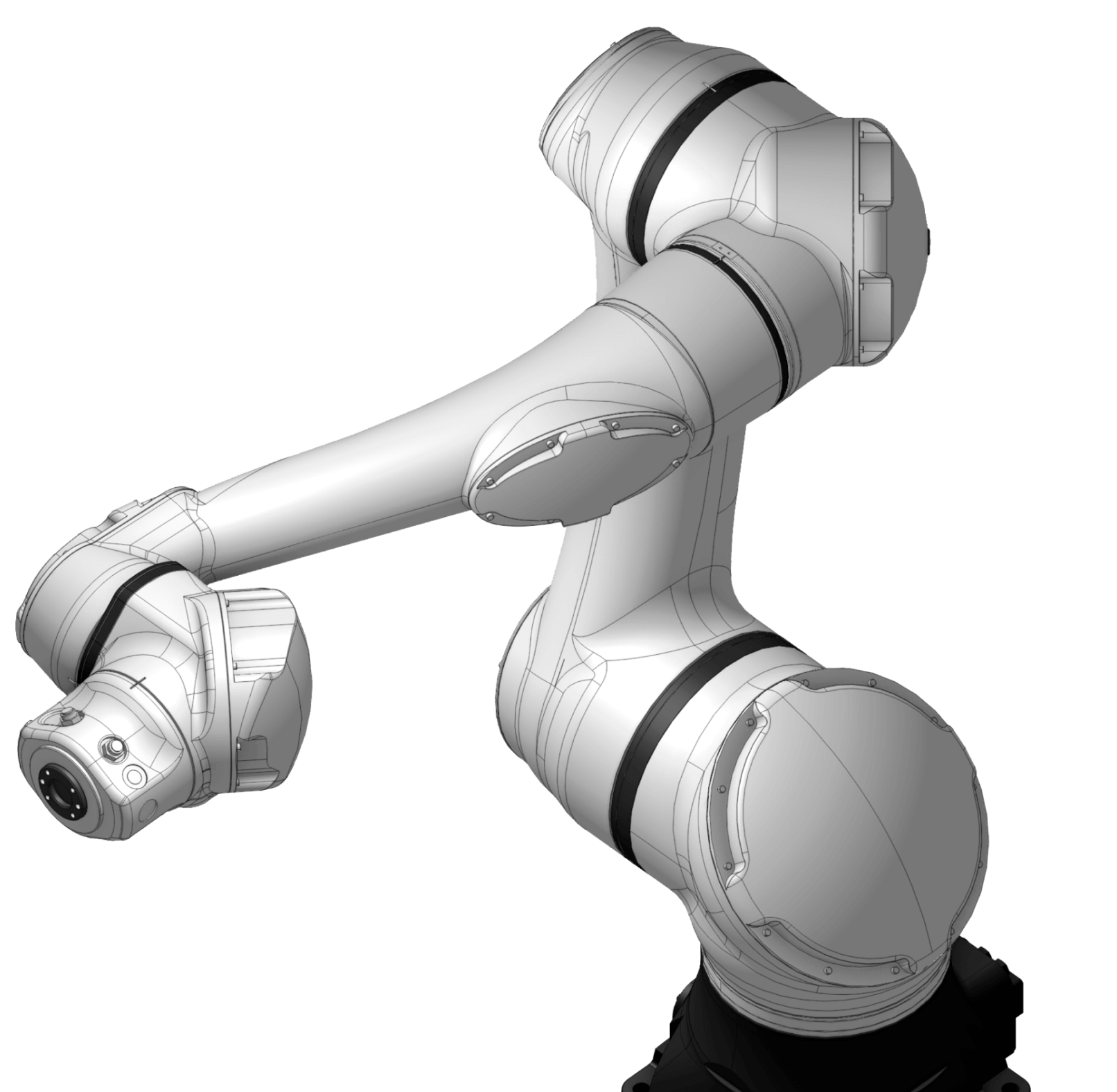

Industrial robots

Heavy-Duty

Robots

Cobots

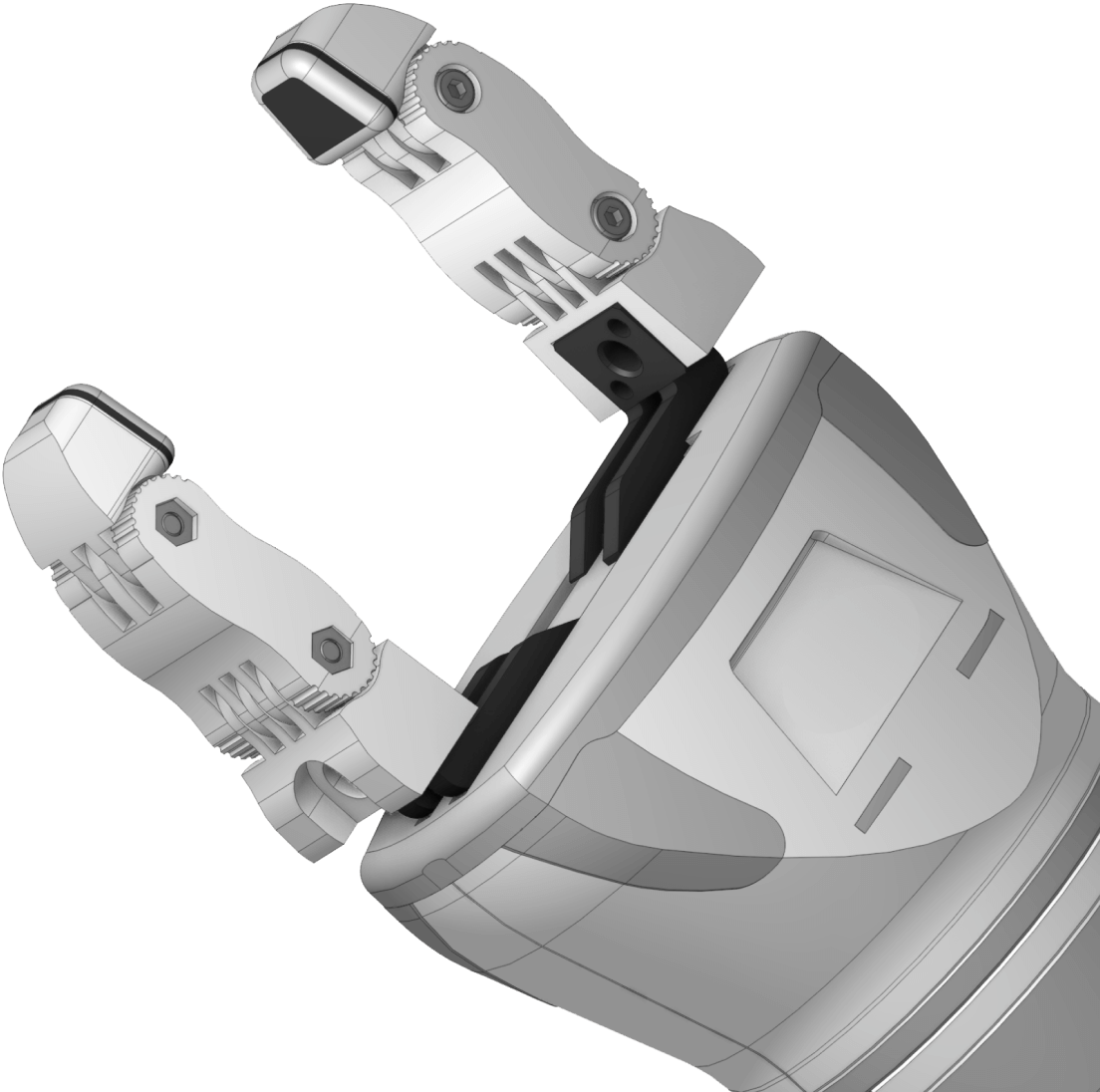

End effectors

Rails

Rotary tables

Stationary objects

Applications

Take advantage of offline robot programming:

Go beyond traditional simple applications such as pick-and-place.

Discover new possibilities with enhanced milling, multiaxis cutting, additive and hybrid manufacturing technologies.

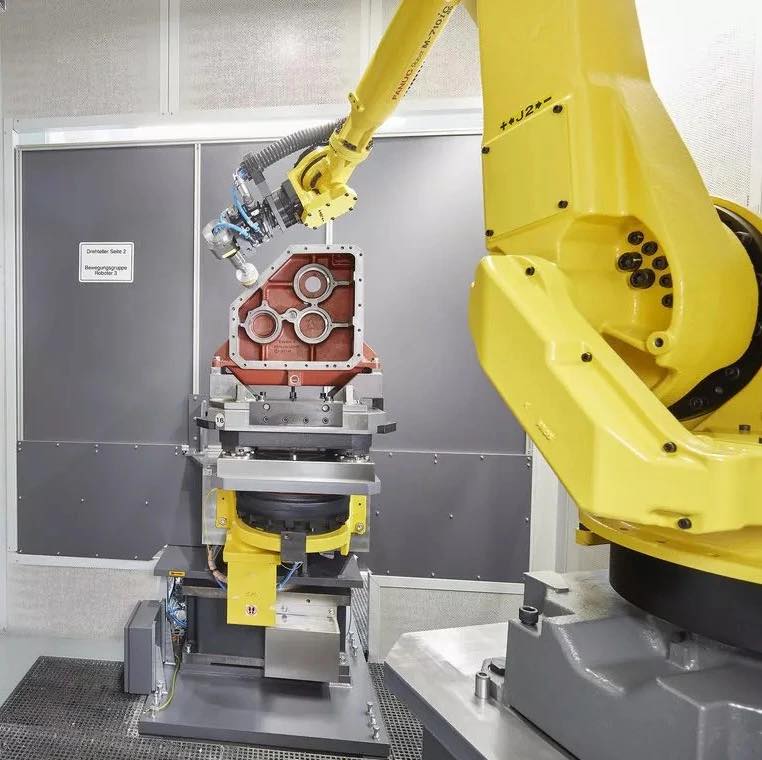

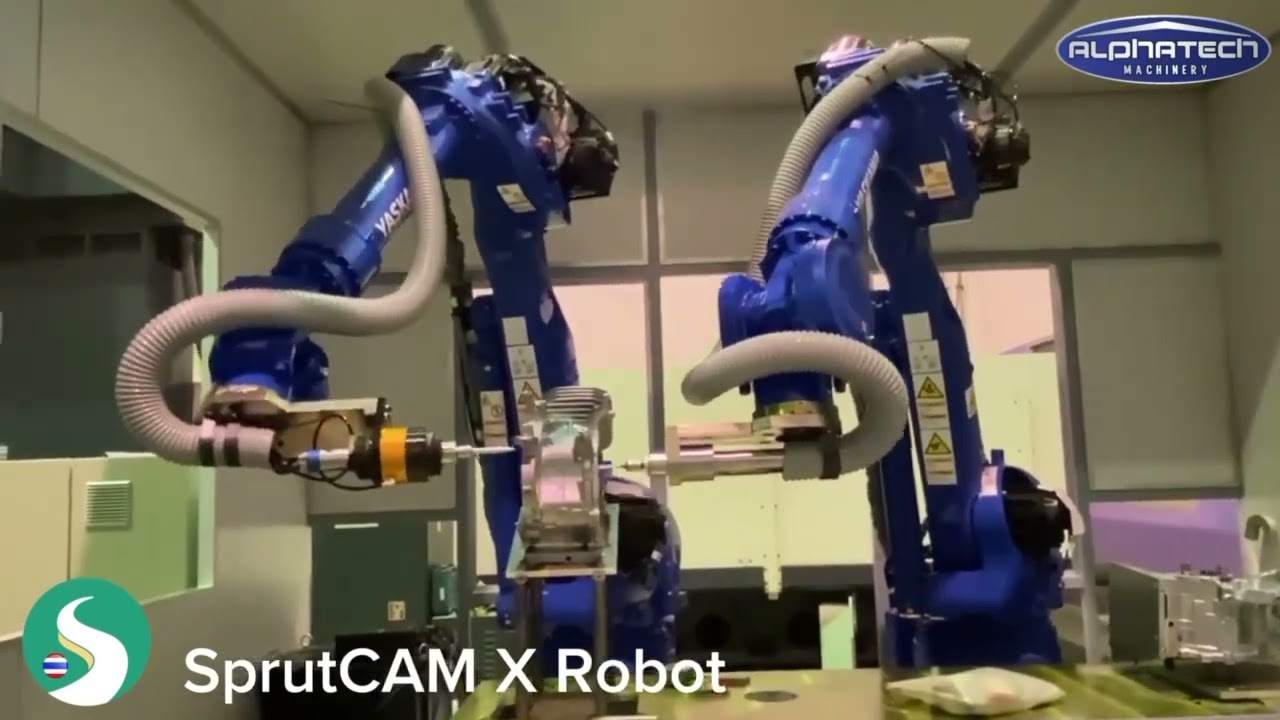

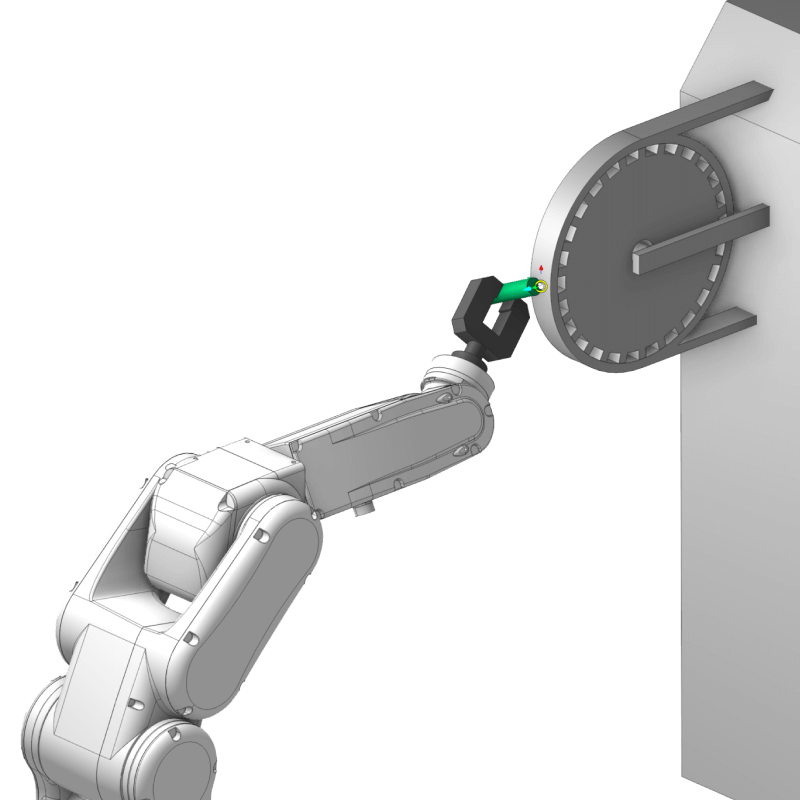

Robot milling

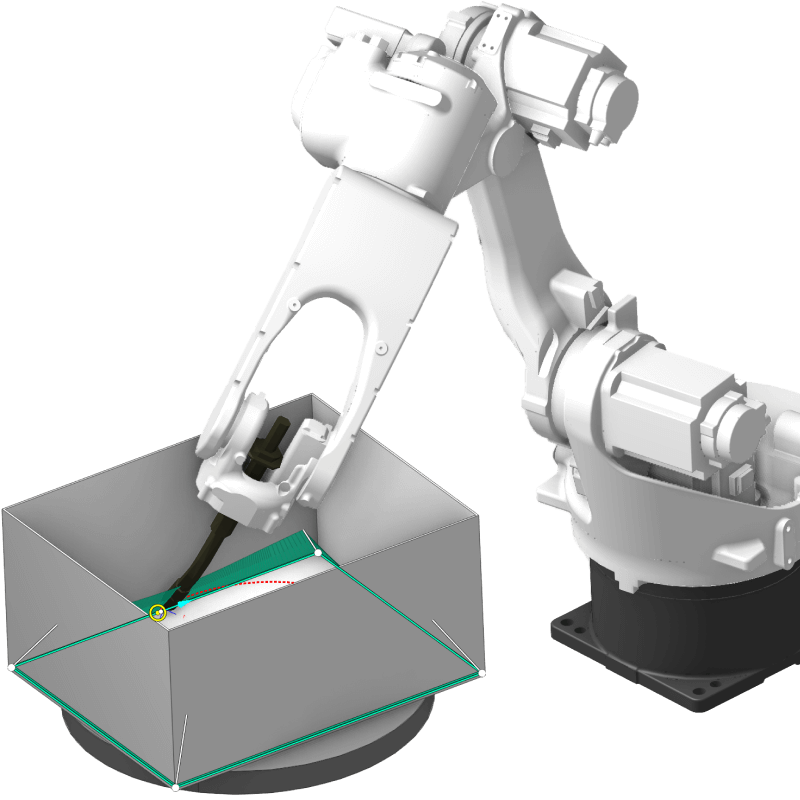

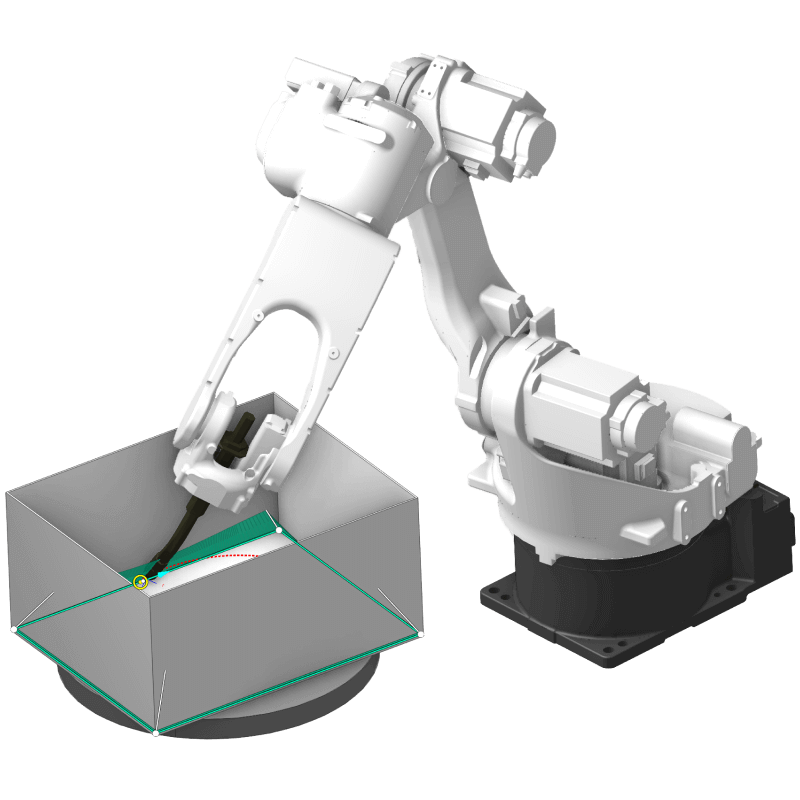

3—5D milling with redundant axes support

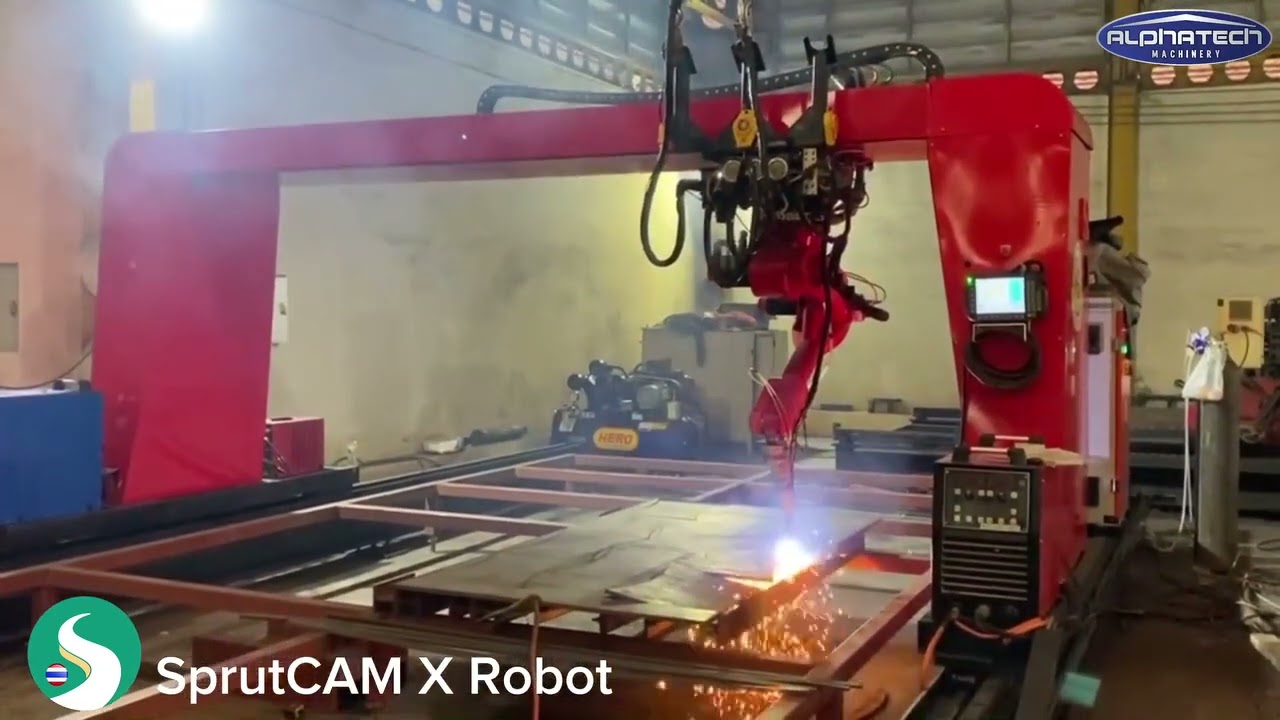

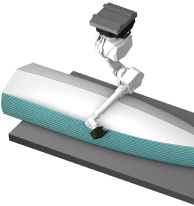

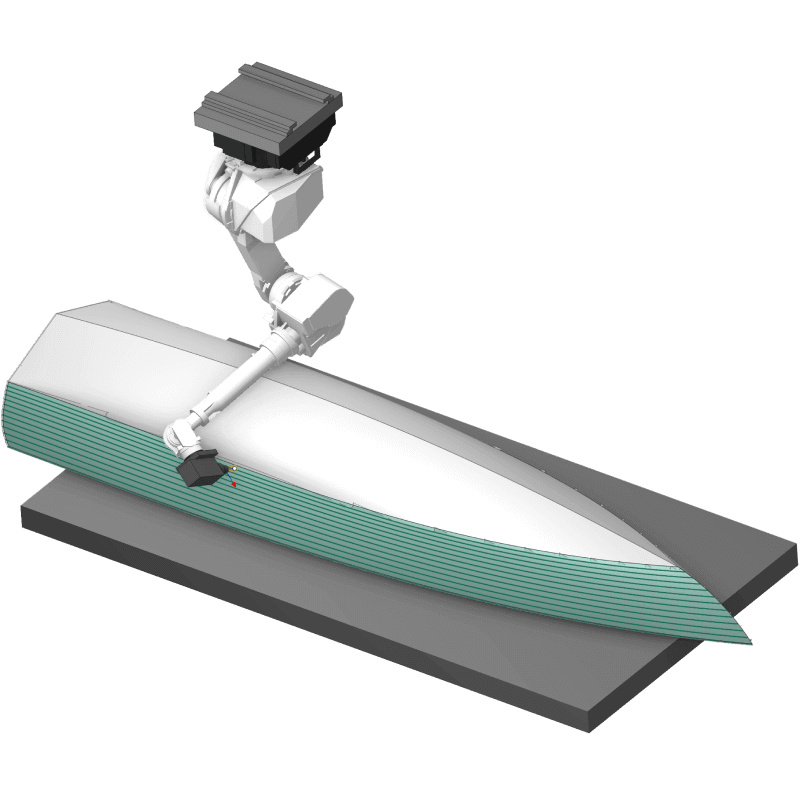

Robot cutting

Miltiaxis cutting with precise tool vector control

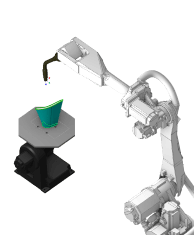

Additive

3—5D cladding with advanced layer thickness control

Robot welding

Simple easy-to-use solution for welding programming

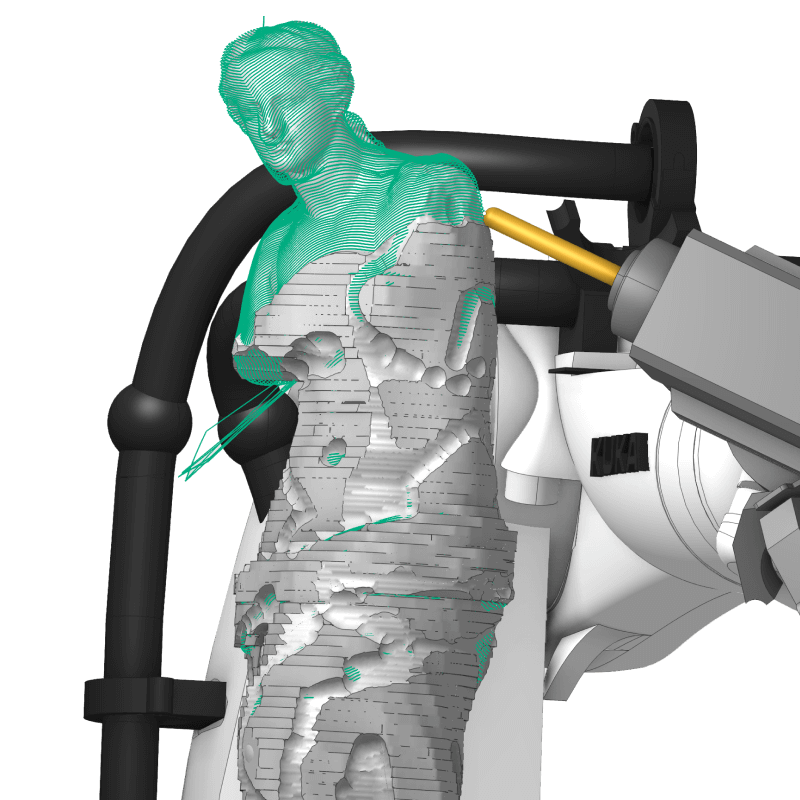

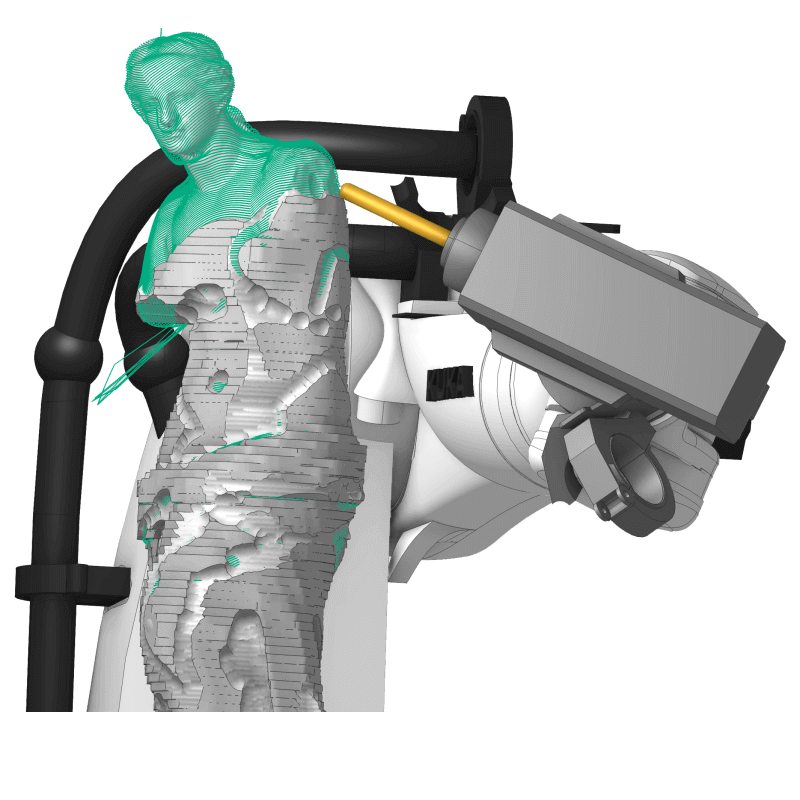

Sculpture/Stone

Stone roughing, disk tool, advanced 5D finishing for mesh models

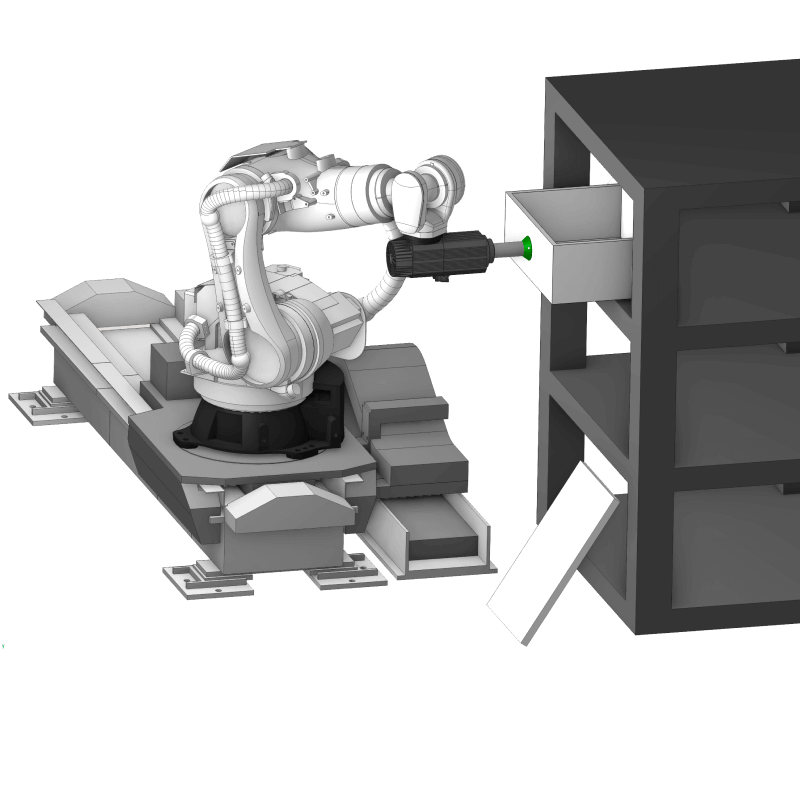

Pick and place

Collision-free automatic pick-and-place

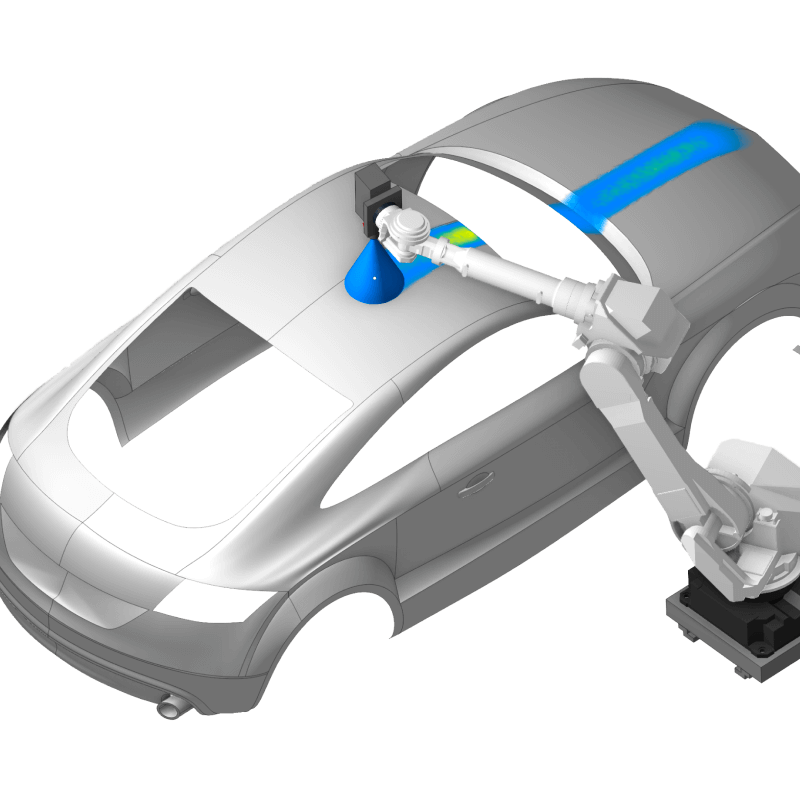

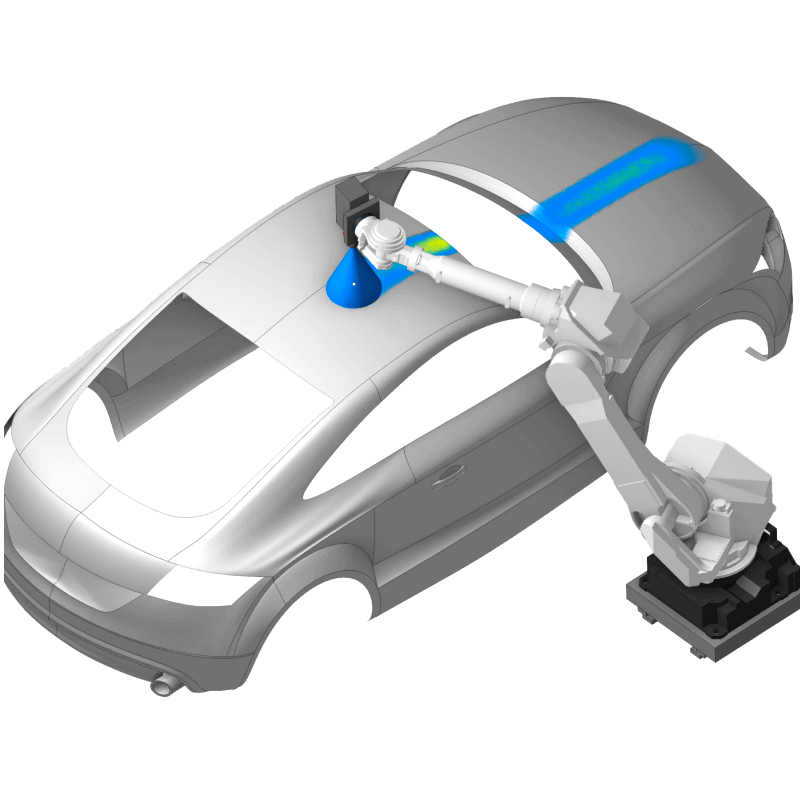

Spray painting

Simulate and test your painting on your PC

Polishing

Tool-to-part and part-to-tool supported

Technology highlight:

additive and hybrid

Cutting‑edge and in‑demand technologies for additive and hybrid manufacturing using robots

Applications

Take advantage of offline robot programming:

Go beyond traditional simple applications such as pick-and-place.

Discover new possibilities with enhanced milling, multiaxis cutting, additive and hybrid manufacturing technologies.

3—5D milling with redundant axes support

3—5D milling with redundant axes support

3—5D cladding with advanced layer thickness control

3—5D cladding with advanced layer thickness control

Stone roughing, disk tool, advanced 5D finishing for mesh models

Stone roughing, disk tool, advanced 5D finishing for mesh models Collision-free automatic pick-and-place

Collision-free automatic pick-and-place Simulate and test your painting on your PC

Simulate and test your painting on your PC Tool-to-part and part-to-tool supported

Tool-to-part and part-to-tool supportedTechnology highlight:

additive and hybrid

Cutting edge

high demanded technology for additive and hybrid manufacturing with robots

#PoweredBySprutCAM

#PoweredBySprutCAM

Daily posts from our clients all over the world

Ready to embark on your SprutCAM X journey?

Select your preferred path

Get a trial version

Download a free 30-day trial version of SprutCAM X or SprutCAM X Robot. Take online courses and get a certificate.

Request a quote

Find a local SprutCAM X dealer and get a quote for the turnkey solution.