Here is how SprutCAM X helps # 1 Italian kart bodywork manufacturer with drilling

At the beginning of 2024 we visited KG, a renowned Italian manufacturer of kart bodywork and spare parts. Here is the story of their successful use of SprutCAM X CAM software for drilling and more, as told by the company’s CEO, Davide Gaggianesi.

Table of contents:

- Davide Gaggianesi, CEO at KG, Italy, sitting next to a SprutCAM X workstation.

- The KG, Italy choice of CAM software for drilling

- CAM software for drilling on 5 axis CNC machines:

- What SprutCAM X offers as CAM software for drilling:

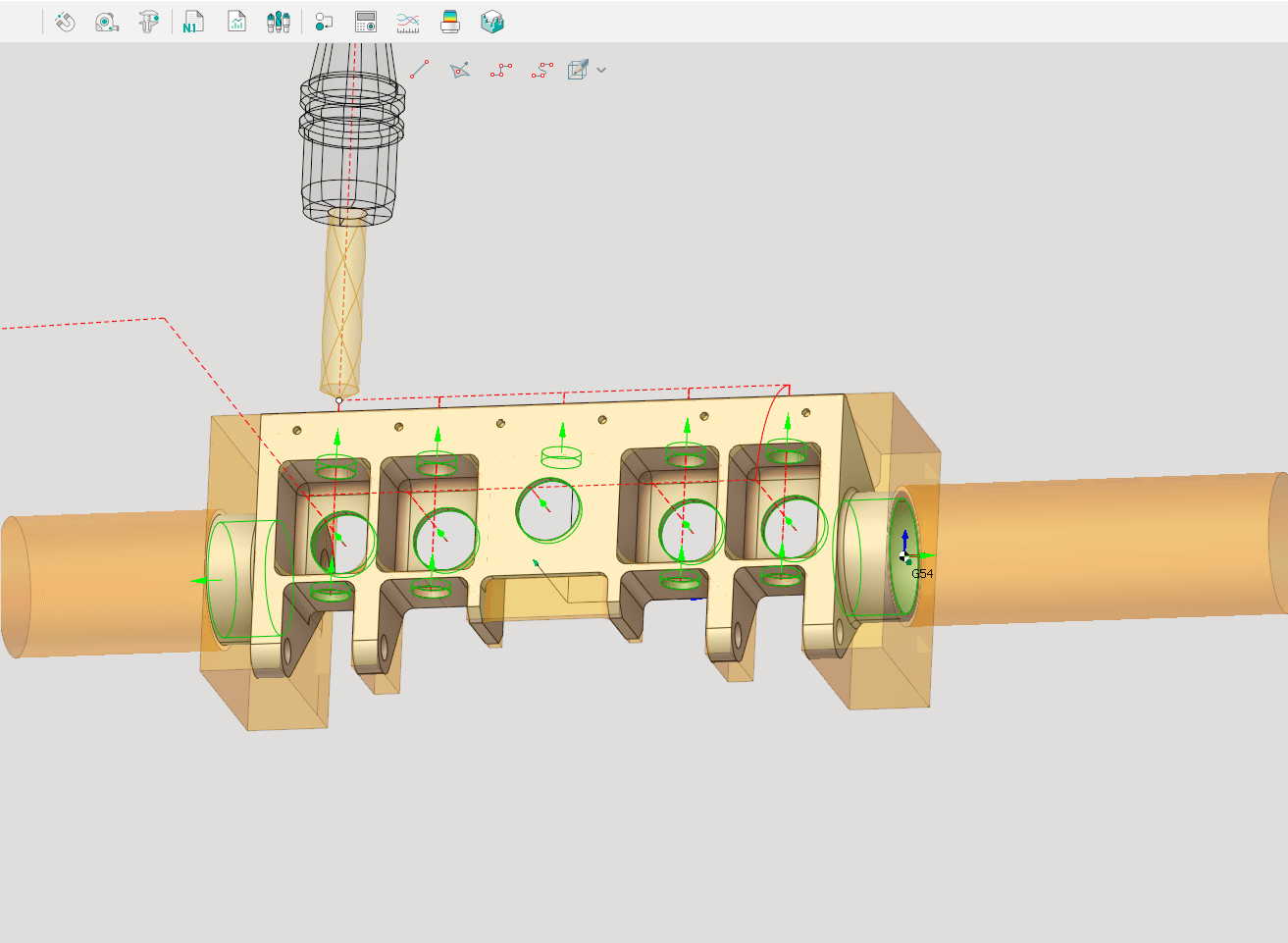

- SprutCAM X: CAM software for drilling. Screenshot of working area of SprutCAM X interface, 5 axis drilling operation programming.

The KG, Italy choice of CAM software for drilling

Davide Gaggianesi, CEO of KG, Italy:

“KG is an Italian company leader in the production of karting bodies and we don’t have much experience in drilling but now there is the necessity to drill plastic parts for our products and we decided to invest in the sector and with the CAM we started with SprutCAM X and we are really happy of this product because even for not so experienced people it is so easy to use and it is really easy to program and also the simulation it is perfect with the real drill so we are really happy of that. I would say that the ability to be so easy is the main point that we appreciate.

So we use SolidWorks. I don’t design, there’s a guy that designs here in the company and we use SolidWorks. We are absolutely at the beginning because we started in November, so at 3-4 months, so, short period.

And that’s it. At the end we don’t have big training, just experimenting by ourselves, we find the real solution and so it’s so happy because the training was only one day, probably, not more.

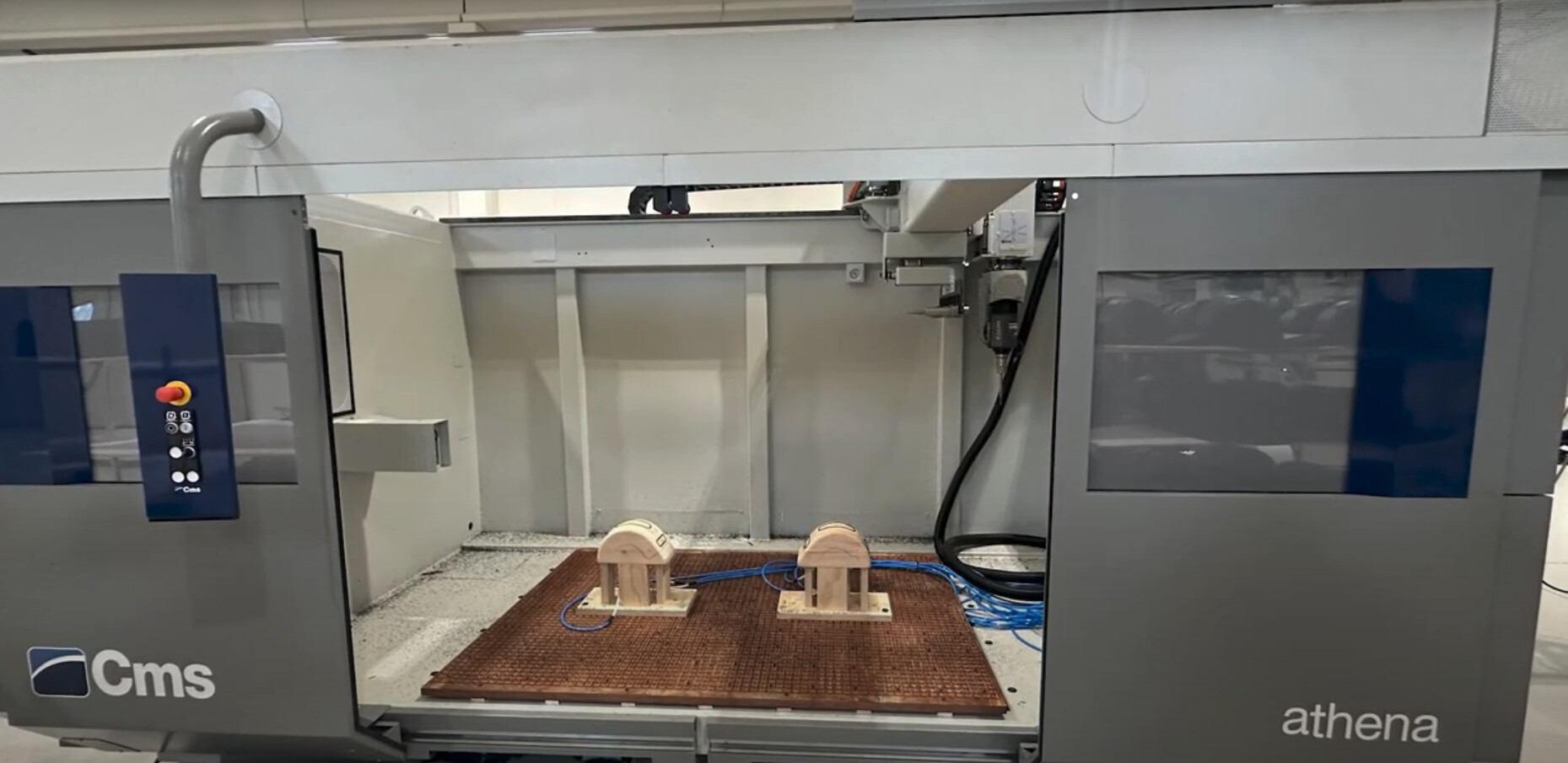

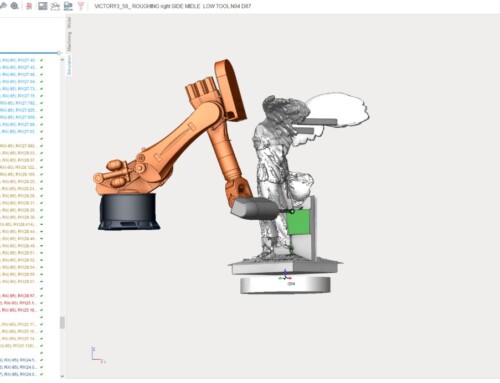

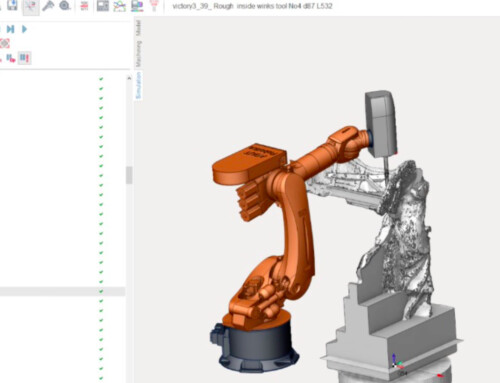

We use SprutCAM X to program a 5-axis drilling machine and the company name of this machine is CMS and we are also happy with this machine. So we also have another robot that we used in the beginning and this is a 6-axis with the table that has the possibility to rotate and we also use SprutCAM X.

Honestly, we have no experience because as I told you before we are starting now, but we see other CAM and what was our first feeling was that it is so difficult to program. The main difference is the ability to be simple. This is the main advantage for which we decide to use SprutCAM X. I think that the simulation of SprutCAM X is really perfect because when we simulate, we are always sure that this is what really happens when we go to drill on the machine.”

Here you can watch the video version of this story:

CAM software for drilling on 5 axis CNC machines:

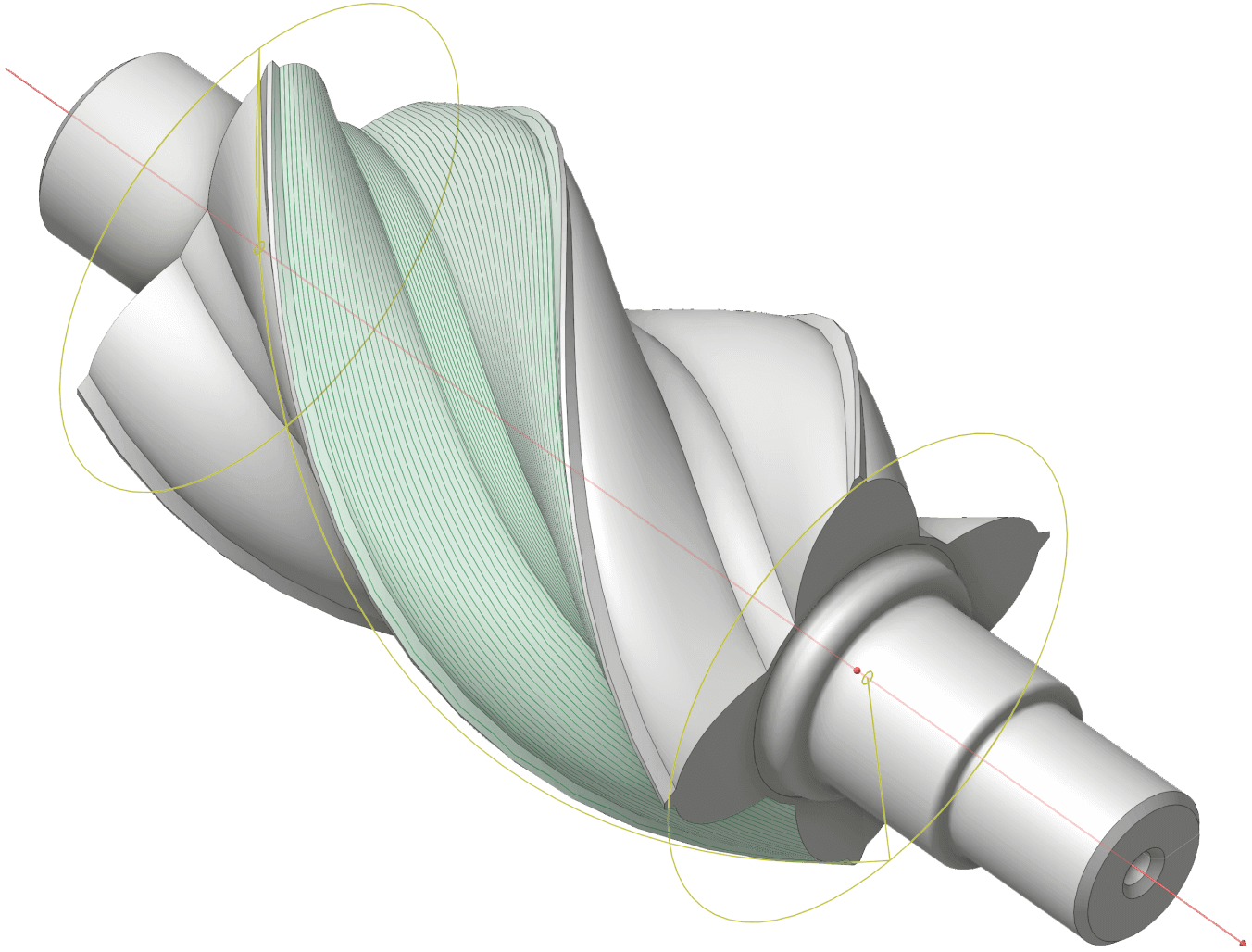

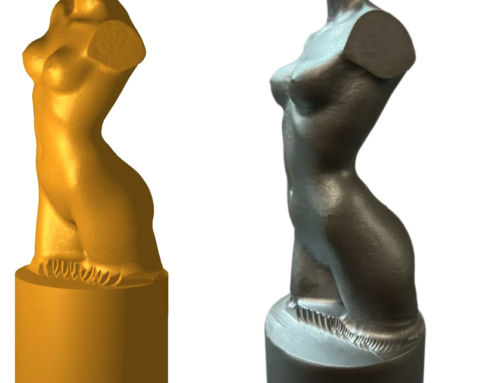

CAM software is utilized to program drilling operations on 5-axis CNC machines. It provides a user-friendly interface for creating toolpaths and generating G-code instructions that control the movement of the machine. The process typically involves creating a 3D model of the part that needs to be drilled. CAD software is used to create the model, which is then imported into CAM software. In the CAM software, the user selects the drilling operation and specifies parameters such as drill diameter, cutting speed, feed rate, and depth of cut. The software generates a toolpath that shows the path the drill bit will take to create the desired holes. Finally, a simulation is run. Before sending the program to the CNC machine, it is crucial to simulate the toolpath to ensure there are no collisions or errors. The CAM software usually includes a simulation feature that enables the user to visualize the toolpath in a virtual environment. After verifying the toolpath, the CAM software generates the G-code instructions that will be sent to the CNC machine. These instructions provide information on tool changes, spindle speed, feed rates, and other parameters required for the drilling operation. The G-code program is then transferred to the CNC machine, and the operator sets up the workpiece and tooling based on the program’s instructions. Finally, the drilling operation is executed. The CNC machine follows the program to move the cutting tool along the specified toolpath and drill holes in the workpiece. CAM software streamlines the programming of drilling operations on 5-axis CNC machines by automating manual tasks involved in generating toolpaths and ensuring accurate and efficient machining processes.

What SprutCAM X offers as CAM software for drilling:

In SprutCAM X drilling operation is part of the subgroup of operations called Holes machining. This group includes:

– Drilling cycles G81, G82, G83, G73, G86, G87, G88, G89,

– Drilling with chip removal cycle

– Tapping cycle, tapping with chip breaking and removing, G84

– Hole pocketing cycle