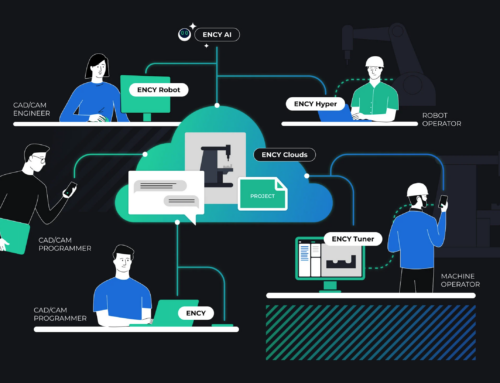

SprutCAM X CAD/CAM in the automotive industry: a variety of use cases

Here is a collection of SprutCAM X CAD/CAM use cases in the automotive industry from all over the world

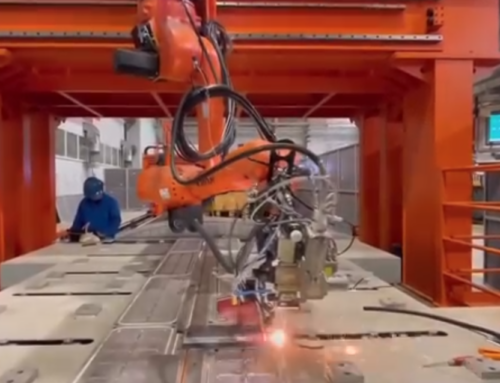

BMW plant chooses SprutCAM X CAD/CAM: Germany

BMW has selected SprutCAM X Robot, distributed by Datentechnik Reitz, for 3D printing with KUKA robots at its Landshut plant. The plant’s Lightweight Construction and Technology Center is developing innovative additive manufacturing processes for producing large components, which traditional 3D printers cannot handle due to size or motion limitations. SprutCAM X Robot enables efficient programming of KUKA robots for both 3D printing and milling, offering advanced control, flexibility, and the ability to slice parts in all axes. The software’s seamless integration with various robots and its ability to handle large-scale, complex tasks were key factors in BMW’s decision, supported by Datentechnik Reitz’s expertise in CAM systems and ongoing technical support.

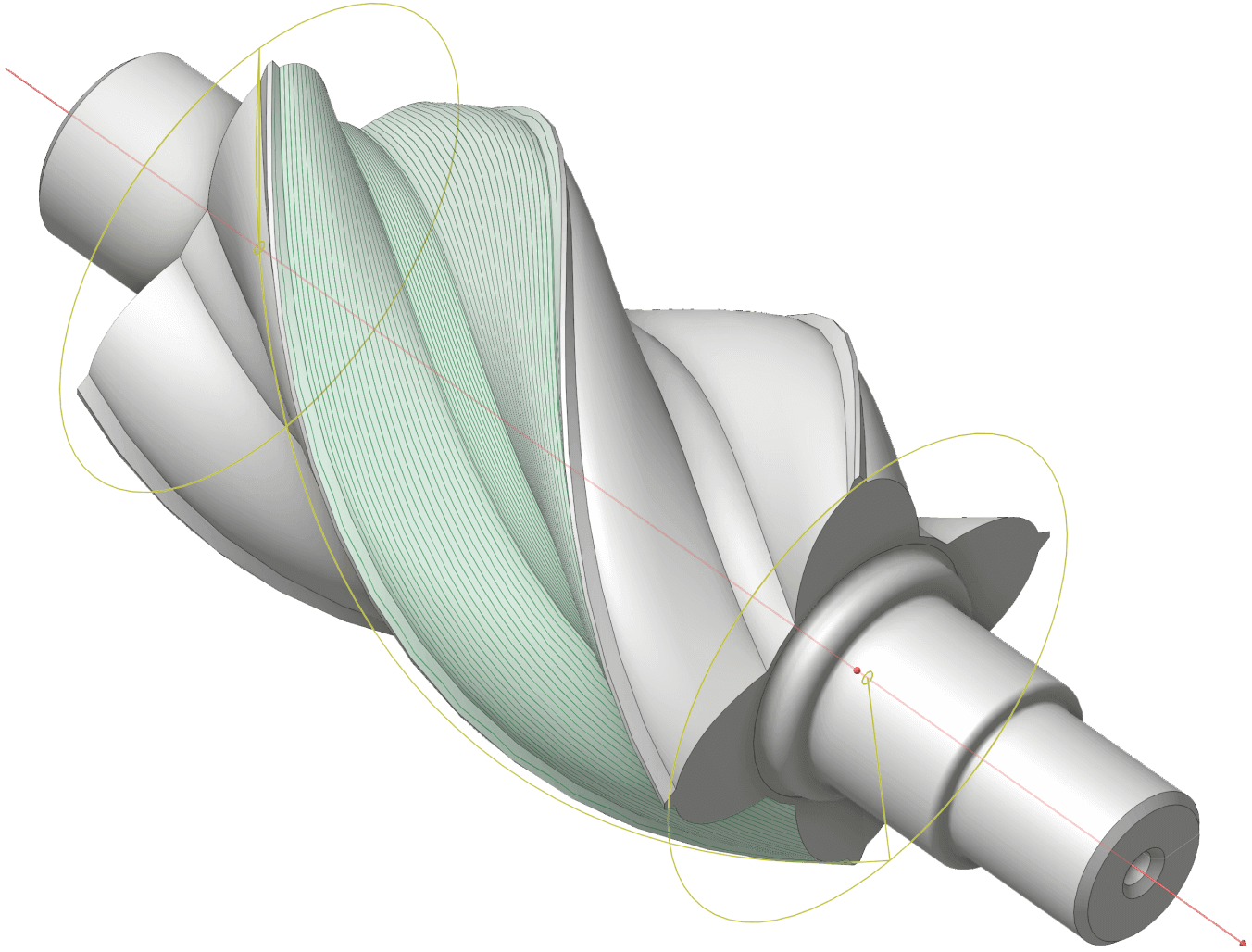

SprutCAM X CAD/CAM used for gearbox production: Germany

Kordel Antriebstechnik, a German gear manufacturer, has fully automated its gearbox production with the help of a 6-axis Fanuc robot for deburring heavy parts, supported by the SprutCAM X CAD/CAM system supplied by Datentechnik Reitz. The robot performs fully automated deburring after machining, which is more efficient than using a milling machine, especially for parts with dimensional variations. The system is designed for ease of use, allowing operators to program deburring tasks by simply selecting edges and tools from a 3D model. The integration of SprutCAM X has streamlined the production process, increasing flexibility and minimizing setup times, crucial for maintaining consistent quality and meeting delivery demands.

Custom motorbike made with SprutCAM X: UK

Jordan Hicks and Larry Houghton, engineers from Lamb Engineering in Salisbury, UK, used the SprutCAM X CAD/CAM system to design and build a custom motorcycle, which won Best in Show at the prestigious Bigtwin Bikeshow competition in the Netherlands in November 2022. The project, a collaboration between the two, saw Jordan, a design engineer and machinist, use SprutCAM X to machine all components of the bike, except for the tires and engine internals, while learning to apply advanced 3D CAD and CAM techniques, including 4th axis machining. This innovative project marked a significant learning milestone for both engineers and showcased the power of SprutCAM X in creating complex, custom designs.

SprutCAM X used for programming CNC machines to make wheel rims: Spain

Braid Wheels, a Spanish manufacturer of high-performance wheels for sports cars, selected SprutCAM X to program CNC milling for their wheel rims. After evaluating various systems to address a bottleneck in their 5-axis milling process, Braid chose SprutCAM X for its ease of use, versatility, and ability to handle essential operations like roughing, scallop finishing, 5D surfacing, pencil milling, and corner cleanup. The software’s ability to program independently from the design department has streamlined their production process, ensuring efficiency and speed in completing jobs. Braid has praised SprutCAM X for its high-quality operations and fast calculations, making it a recommended solution for CNC wheel rim milling.

SprutCAM X CAD/CAM used for kart bodywork parts manufacturing: Italy

KG, a leading Italian manufacturer of kart bodywork, began using SprutCAM X for drilling operations on a 5-axis CNC machine, despite having little prior experience in drilling. The company’s CEO, Davide Gaggianesi, highlighted the software’s ease of use and effectiveness, noting that even with minimal training, the team was able to independently program the drilling machine. SprutCAM X’s simple interface and accurate simulation made it the ideal choice for their needs, ensuring the real drilling process aligned with the virtual simulation. The software’s ability to handle various drilling cycles, such as chip removal, tapping, and hole pocketing, streamlined their operations and improved productivity.

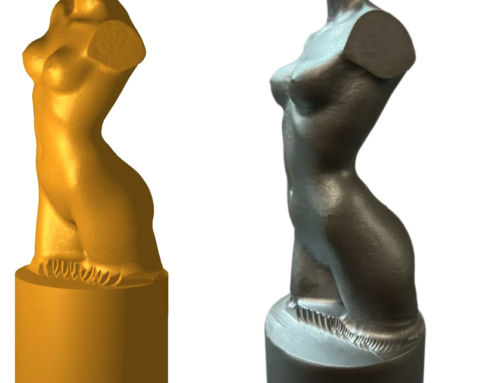

SprutCAM X used for manufacturing of the 1st EV in Brazil

In April 2024, SprutCAM X was showcased as a key tool for Ângulo Protótipos, a Brazilian company involved in various automotive projects, including the development of parts for buses, motorhomes, and the first Brazilian electric car, Lecar. The company uses SprutCAM X for precise machining, improving the speed, quality, and consistency of their parts. This shift from manual processes to CNC machining with 3D model files has resulted in significant cost reductions and better final products. Lecar, an electric car with a range of 400 kilometers, utilizes advanced materials like Sheet Molding Compound (SMC) for its body, ensuring performance and safety. SprutCAM X has enabled Ângulo Protótipos to meet these high standards efficiently.