Robot Calibration mobile app now features 14 leading industrial robot brands

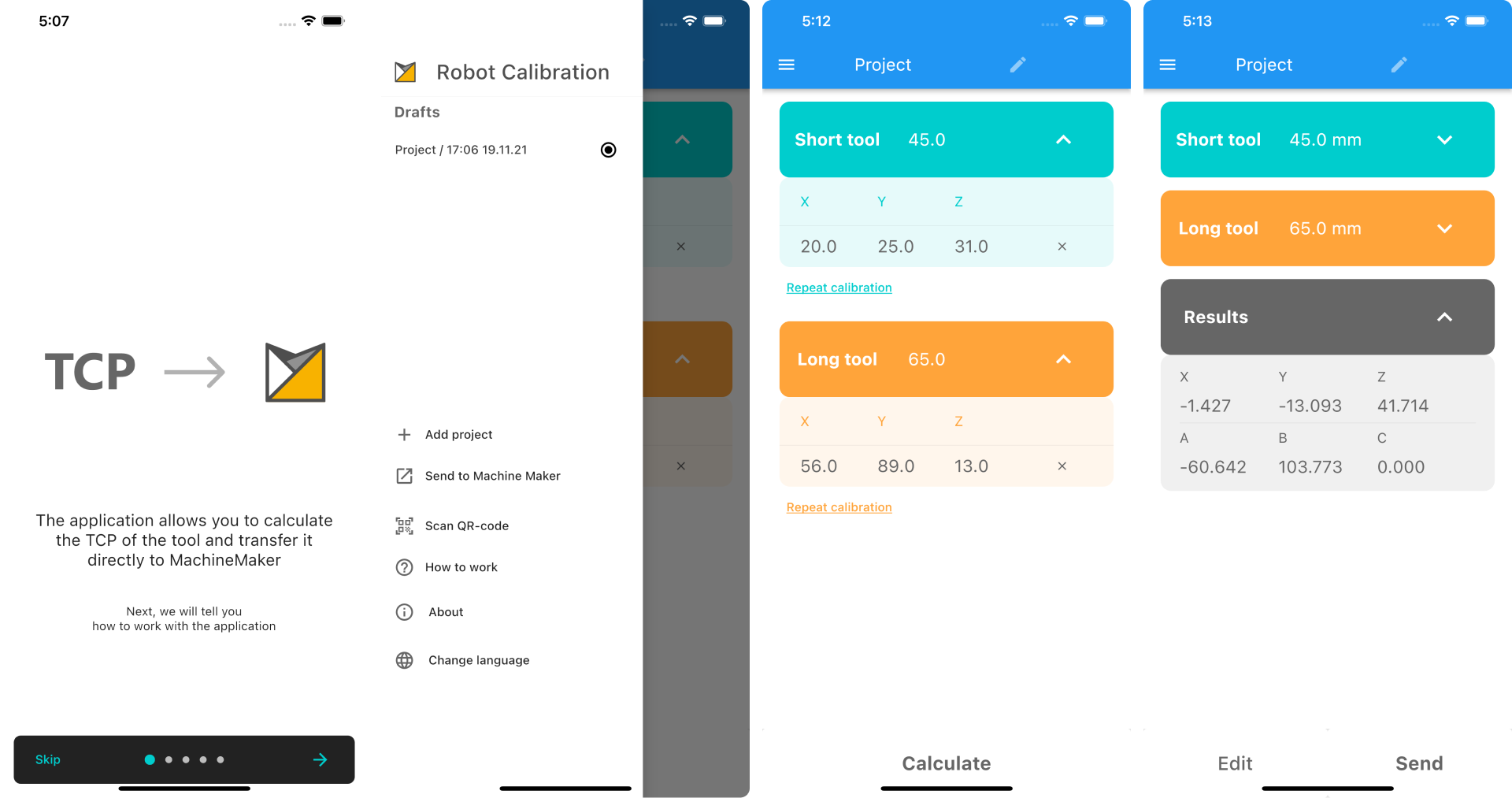

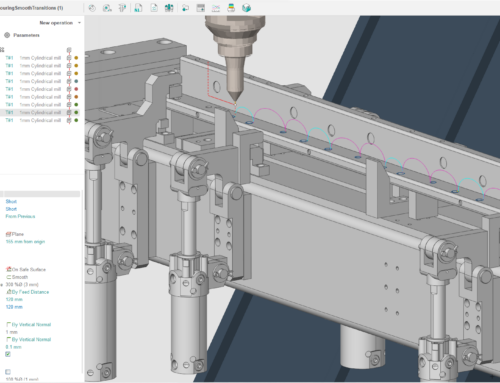

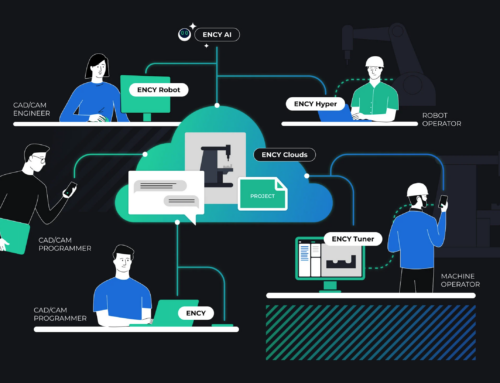

SprutCAM Tech’s Robot Calibration mobile app is designed to accurately calibrate the Tool Center Point (TCP) and automatically transfer the data to SprutCAM X Robot via a smartphone.

What is TCP calibration?

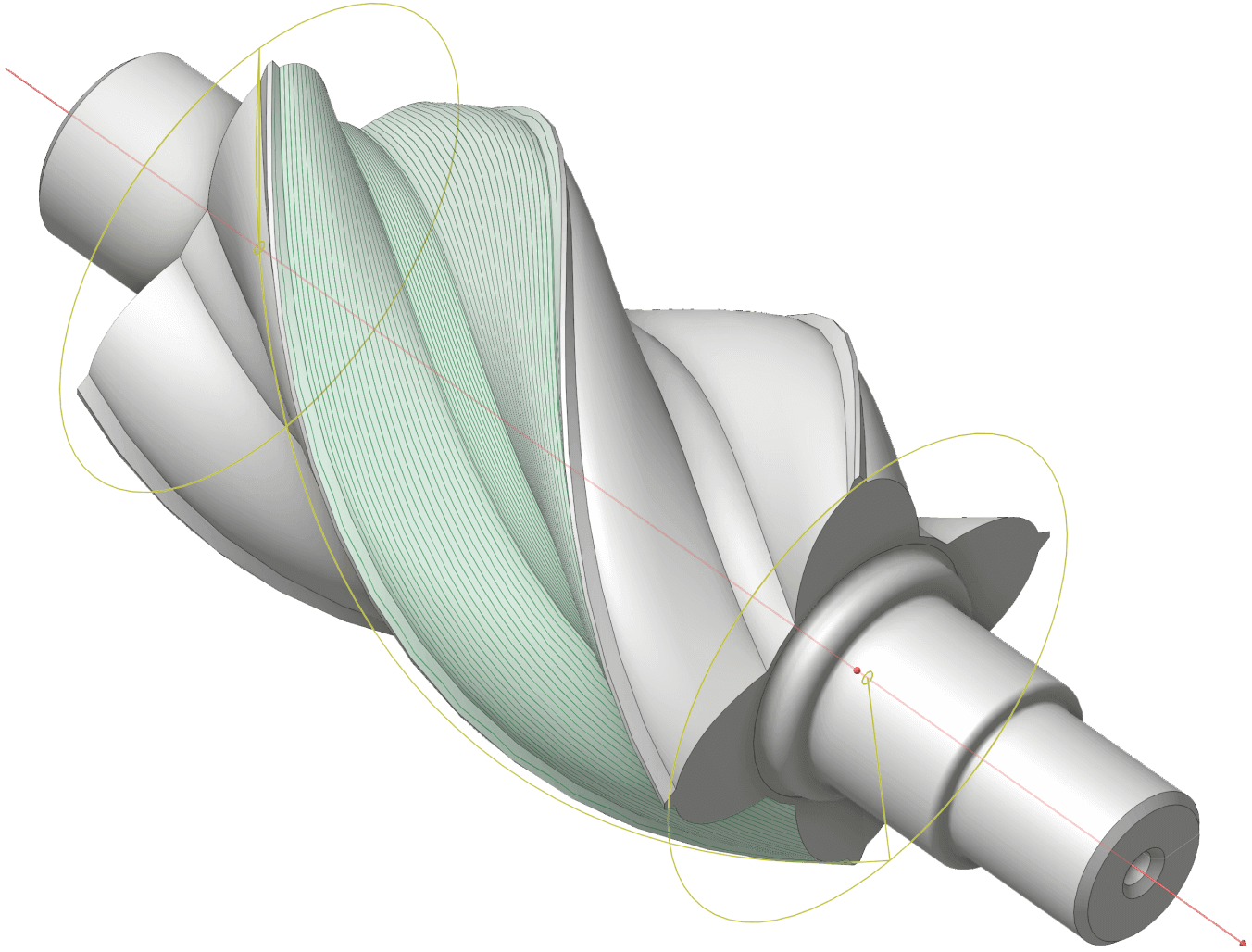

Tool Center Point (TCP) calibration is a process used in robotics to determine the position of a tool relative to the robot’s arm or body. This information is critical to ensuring the accuracy of the robot’s movements and the precision of its tool operations. The goal of TCP calibration is to find the exact position of the tool tip, which can then be used as a reference point for the robot’s motion control system. This allows the robot to consistently and accurately perform tasks such as cutting, drilling and welding in the correct location. As a rule the calibration process consists of measuring the positions of various points on the tool and using these measurements to calculate the position of the TCP.

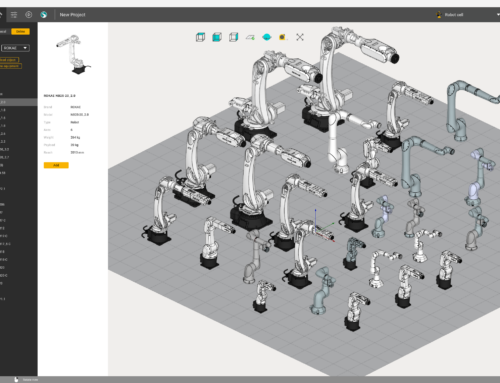

Robot Calibration app supports leading industrial robot brands

The original version of the application only worked with robots from three well-known manufacturers, but the latest version now supports TCP calibration for the following robot brands FANUC, Kuka, CRP, Denso, Dobot, Estun, Hiwin, Hyundai, Motoman, Newker, Manutec, Nachi, OTC Daihen and Turin.

SprutCAM Tech’s app uses the double spike method for calibration:

- 1st step. Measurement of the position of the long tool. The position of the tool is measured at different joint angles or at different positions along the robot path.

- 2nd step. Measurement of the short tool position and automatic determination of the tool orientation.

- 3rd step. Automatic recognition with OCR and reading of the data by the Robot Calibration application and calculation of TCP coordinates.

- 4th step. Transmission of TCP coordinates to MachineMaker using a QR code.

Scanning values from the robot

Transfer values from TCP from SprutCAM X Robot

The double spike method is a TCP calibration method used in robotic and machine tool applications. It consists of measuring two points on a probe and calculating the position of the tool center point based on these measurements. The purpose of TCP calibration is to determine the location of the TCP with respect to the robot’s base coordinate system so that it can be accurately positioned for machining or other operations. In general, the double spike method can be useful in situations where the probe is unable to measure the tool position at the exact TCP.