CAD/CAM for Aerospace & Aviation

CAD/CAM for Aerospace. Let’s start with the basics.

The Aerospace and Aviation industry epitomizes the merger of human ambition with cutting-edge technology. Encompassing commercial airliners, military jets, drones, and spacecraft, this industry continually evolves. Current trends spotlight the advent of electric propulsion, an enhanced emphasis on eco-friendly designs, and the integration of robust AI-driven safety mechanisms.

CAD/CAM for aerospace: intricacies behind the flight

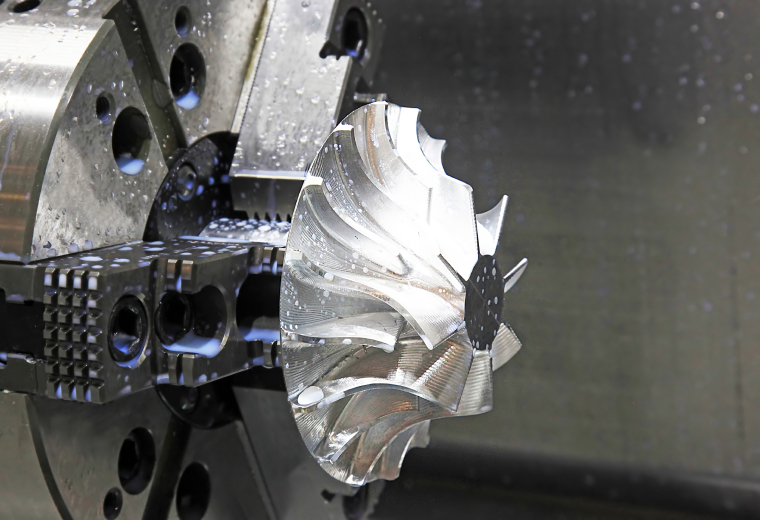

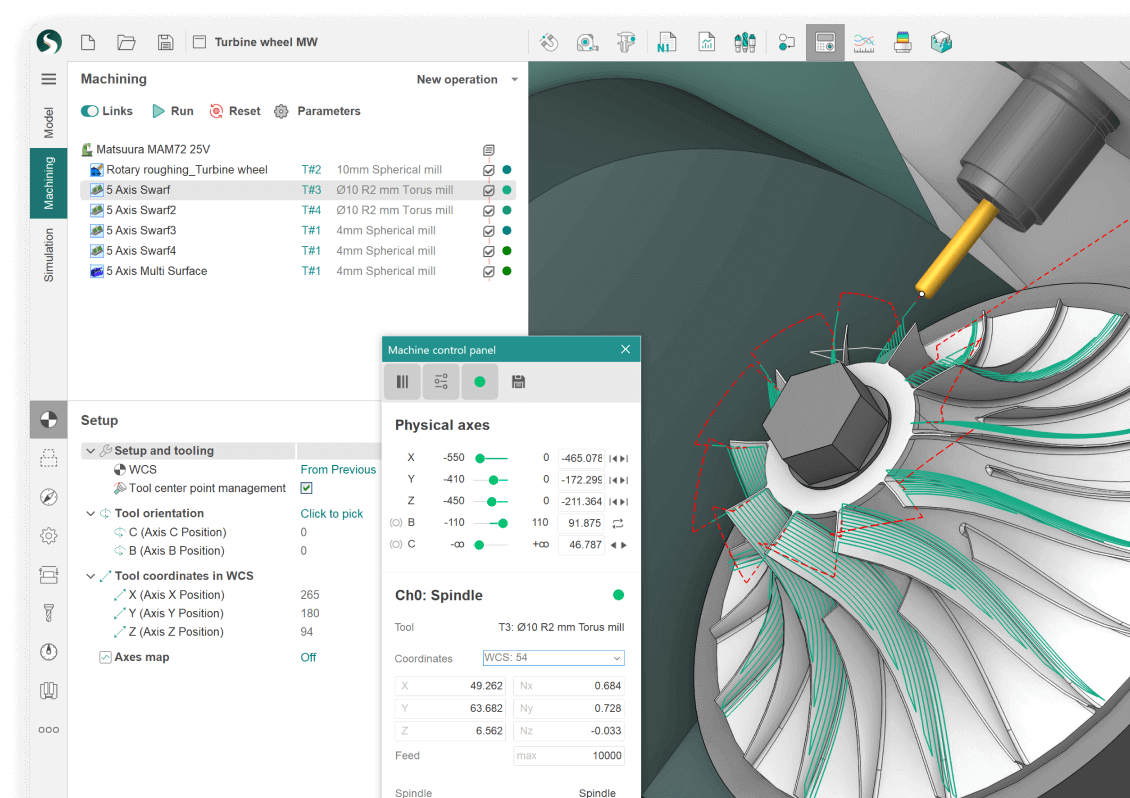

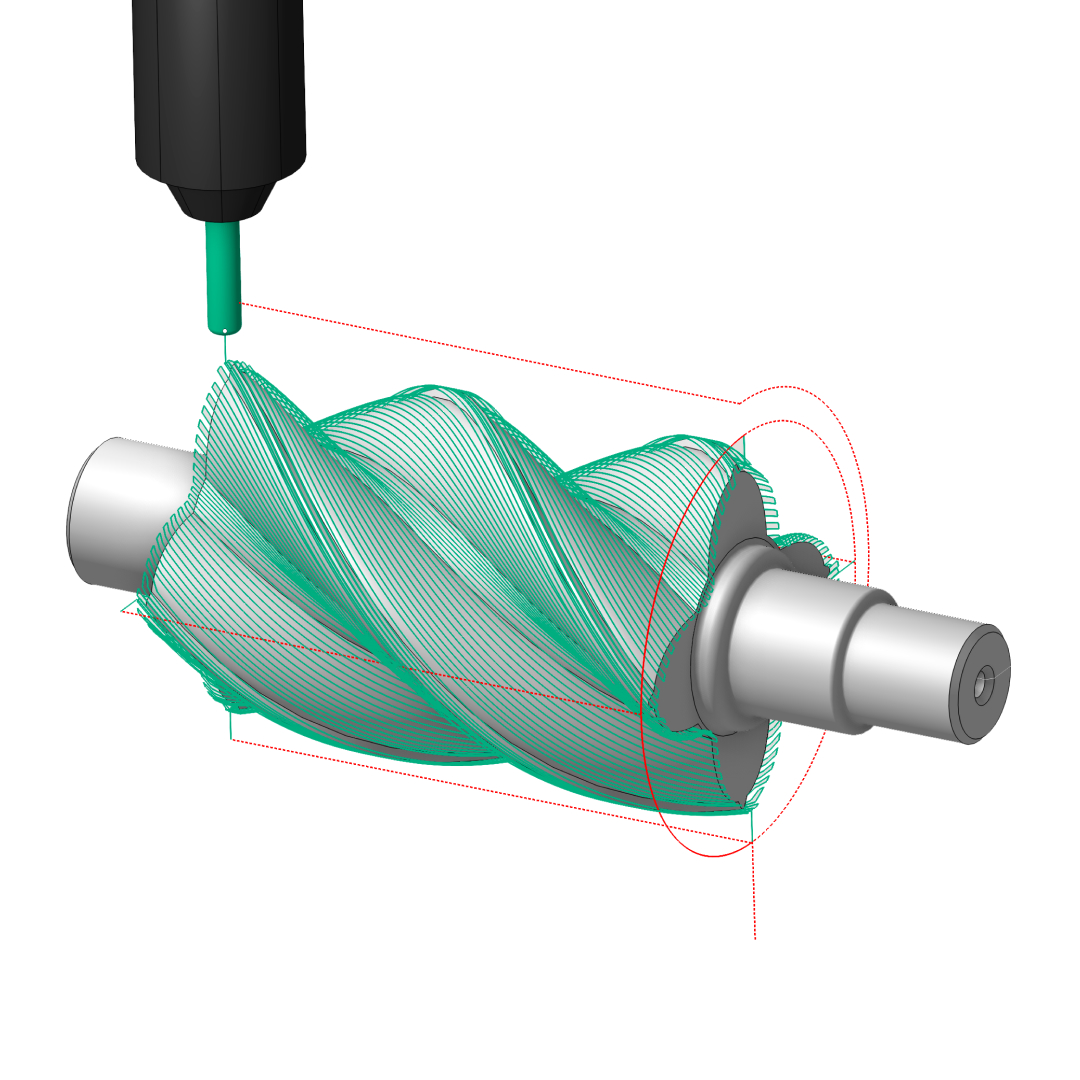

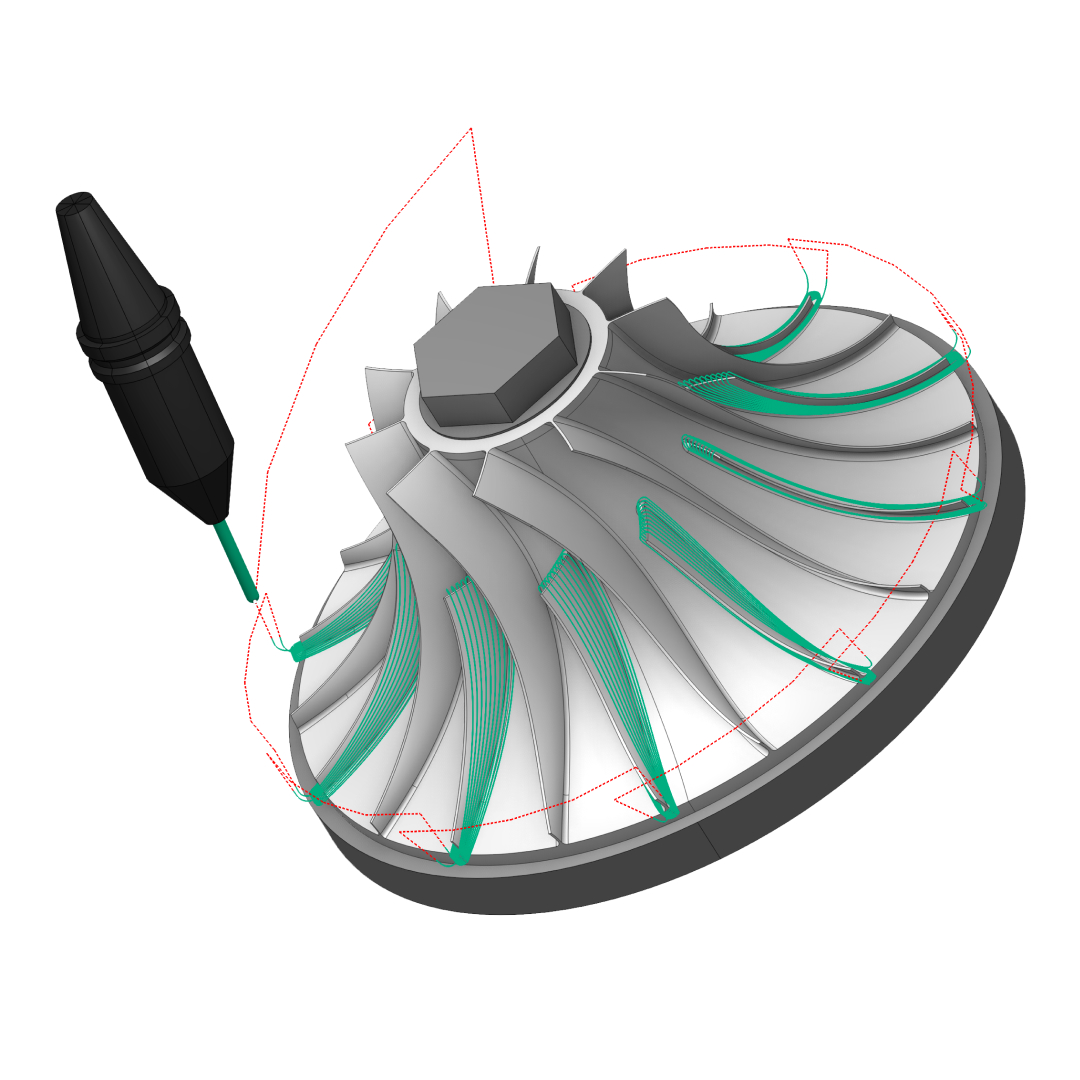

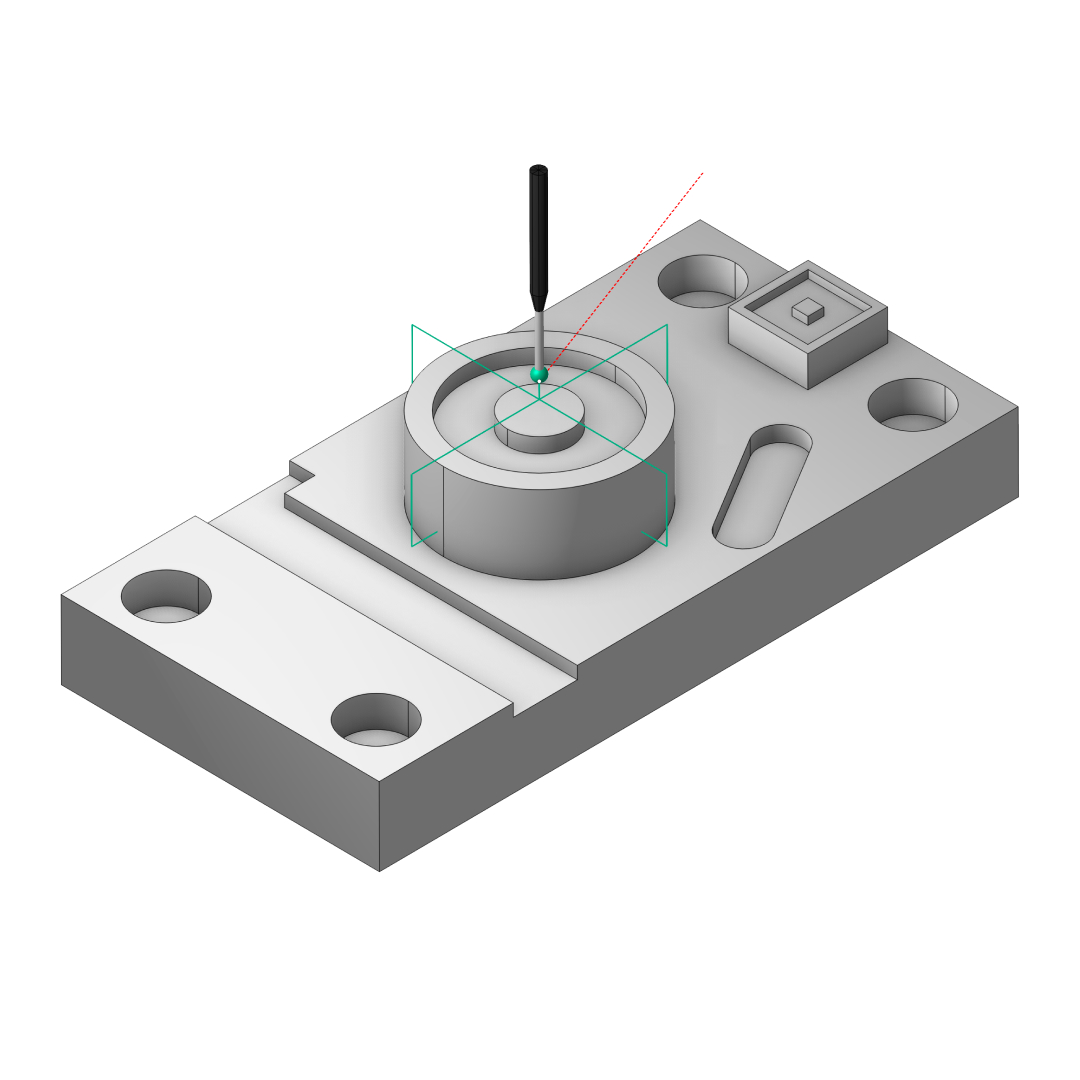

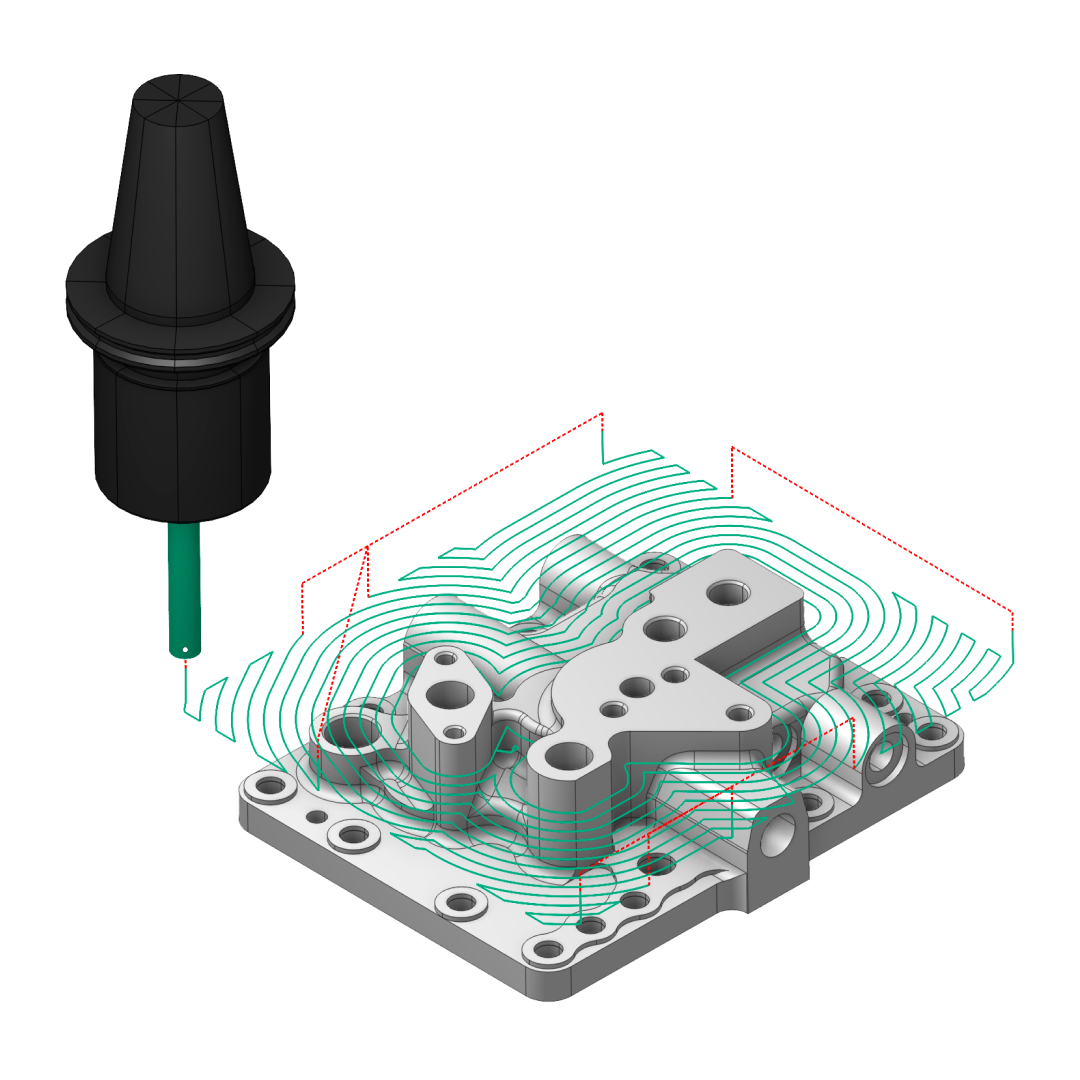

With SprutCAM X, CAD/CAM for aerospace, aerospace manufacturers can confidently tackle these challenges and produce the high-quality components required for safe and efficient flight. Its advanced machining techniques and simulation capabilities make it an essential tool for modern aerospace manufacturing, helping to ensure that each component is produced with the utmost precision and accuracy. Whether creating complex turbine blades or lightweight structural components, SprutCAM X is the go-to CAD/CAM for aerospace manufacturers looking to stay at the forefront of their industry.

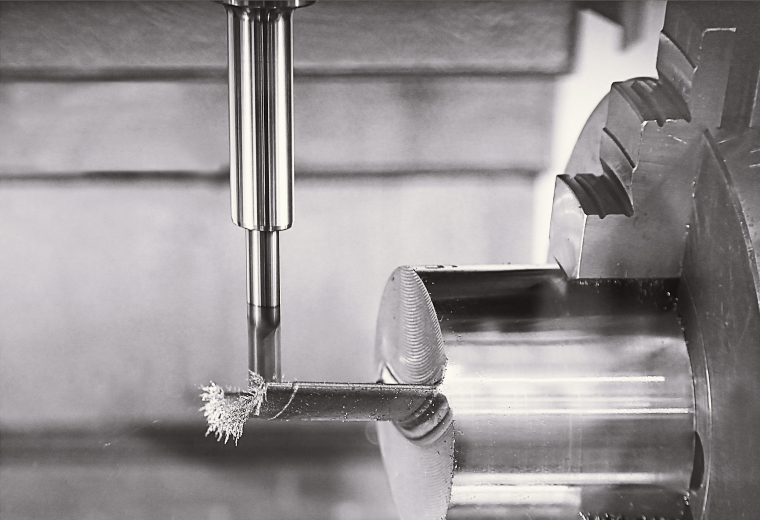

Behind every aircraft lies a labyrinth of meticulously designed parts, each playing a crucial role in its operation. Turbine blades, with their unique curves, ensure engines operate efficiently. The aircraft’s skeletal framework, made of lightweight yet durable materials, provides the necessary structure, while intricate cockpit instruments guide pilots through every flight phase. These components, among many others, underline the vast complexity and precision inherent in aerospace design and engineering.

We specialize in precision mechanical machining, the pieces made are for the aerospace industry. The machine used is a Doosan DNM 5700. We have become SprutCAM X customers this year. We decided to choose SprutCAM X for its ease of use particularly for the speed of calculation and the quality of the finishes. We use the scallop machining on 3d surfaces.

Marcello Ciuffetelli

Costruzioni Meccaniche s.n.c.

We’ve recently moved over from Visual Mill Pro to SprutCAM X. SprutCAM X is lightening fast compared to our older CAM and infinitely more flexible. We’ve created our specific CNC machine in CAD format and imported it in SprutCAM X, then using the built in postprocessor generator, we create the postprocessor for our machine. The most remarkable thing in SprutCAM X is speed. Previously for many models VMPro would take over a night to read in a complex CAD model. Whereas for exactly the same model SprutCAM X does it in a blink.

Dr. Naresh Sharma

NASHERO s.r.l. Italy

The world of CAD and CAM software continues to change with the end result of giving users more value and capabilities for less money. When I first used CAM software the cost was over .25 million for the system. With SprutCAM X, I could literally and figuratively cut circles around those first accomplishments in far less time. I have been pleasantly surprised to find that SprutCAM X not only has proven to be very reliable in its output, the value for the costs are outstanding. Every CAM system has its pros and cons, but I have found that SprutCAM X has very few cons which is a great accomplishment for all involved in its creation. Thanks.

Loyd May

WAYPOINT engineering