Robotic sculpting with SprutCAM X Robot: FHL KIRIAKIDIS

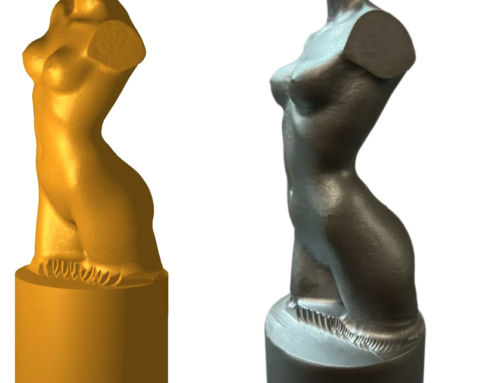

We have previously written about the Nike of Samothrace statue project that won the prestigious Pinnacle award. Here is an interview with Angelos Pappos, CAD/CAM engineer from FHL, the company behind this project that makes art come true in marble. If you are interested in other cases where SprutCAM X Robot has been used for artistic purposes, please follow this link.

FHL KIRIAKIDIS GROUP: SprutCAM X Robot CAD CAM for arts

Please describe in as much detail as possible the process of creating a sculpture, in which SprutCAM X Robot is involved, from selecting and preparing the stone workpiece to the finishing touches.

The initial and pivotal step of creating a sculpture is the careful selection of a suitable stone block—one that is free from structural and color issues. After transporting this block to our facility, we perform a comprehensive quality check and sketch the sculpture’s orientation on the marble.

Afterwards, we begin the process of removing excess material and cutting the block to rough dimensions, utilizing our wire machines. Meanwhile, our 3D modelers and CNC programmers start the demanding task of programming.

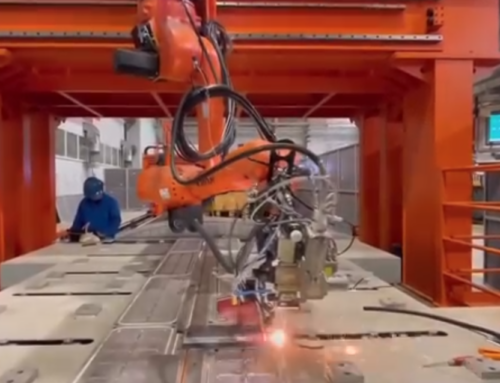

Once the initial batch of programs is complete, our CNC programmers, in collaboration with operators, coordinate the start of the production. The robot operates methodically, always under the supervision of the programmers until the job’s completion.

Upon concluding the robot-assisted phase, our skilled Sculptors take charge, meticulously attending to all final detailing and executing the polishing process to perfection.

Specifically, what tasks does the SprutCAM X Robot perform during this process?

SprutCAM X Robot proves to be an invaluable tool in our production process, granting us exceptional control and significantly enhancing our capabilities. This boosts our confidence to tackle even the most challenging projects. The main tasks related to SprutCAM X robot are:

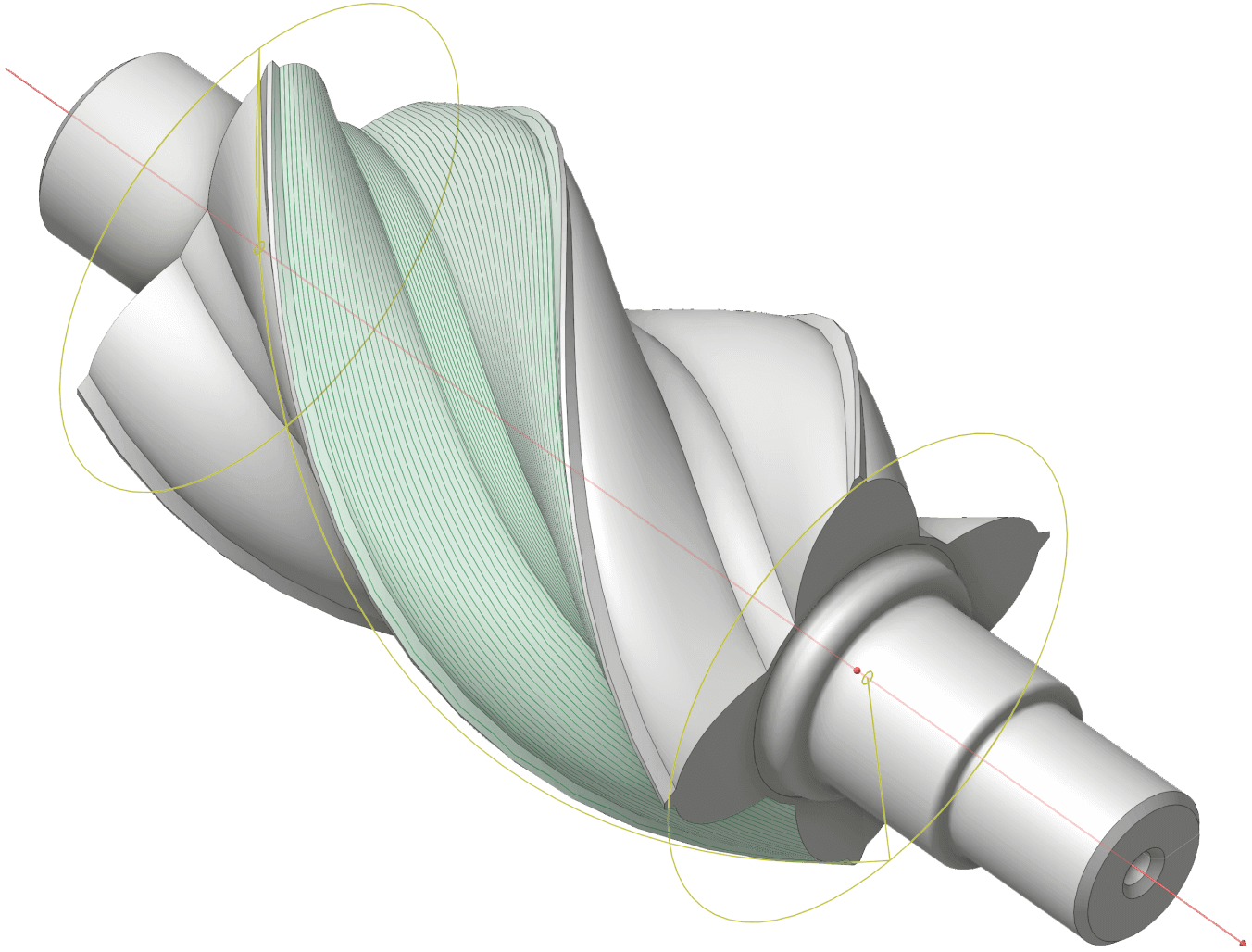

In the pre-production phase, we begin by determining the dimensions of the raw material and the optimal positioning on the robot work area, ensuring the robot’s reachability. We also create templates for the strategies we plan to use, sometimes even crafting a test object.

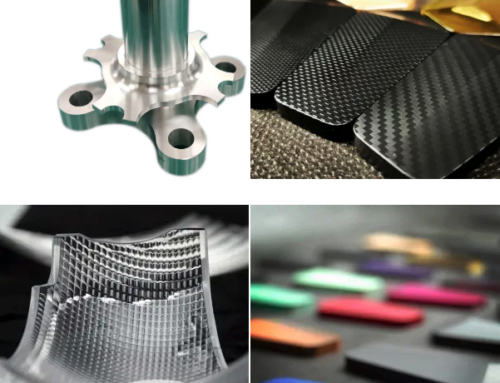

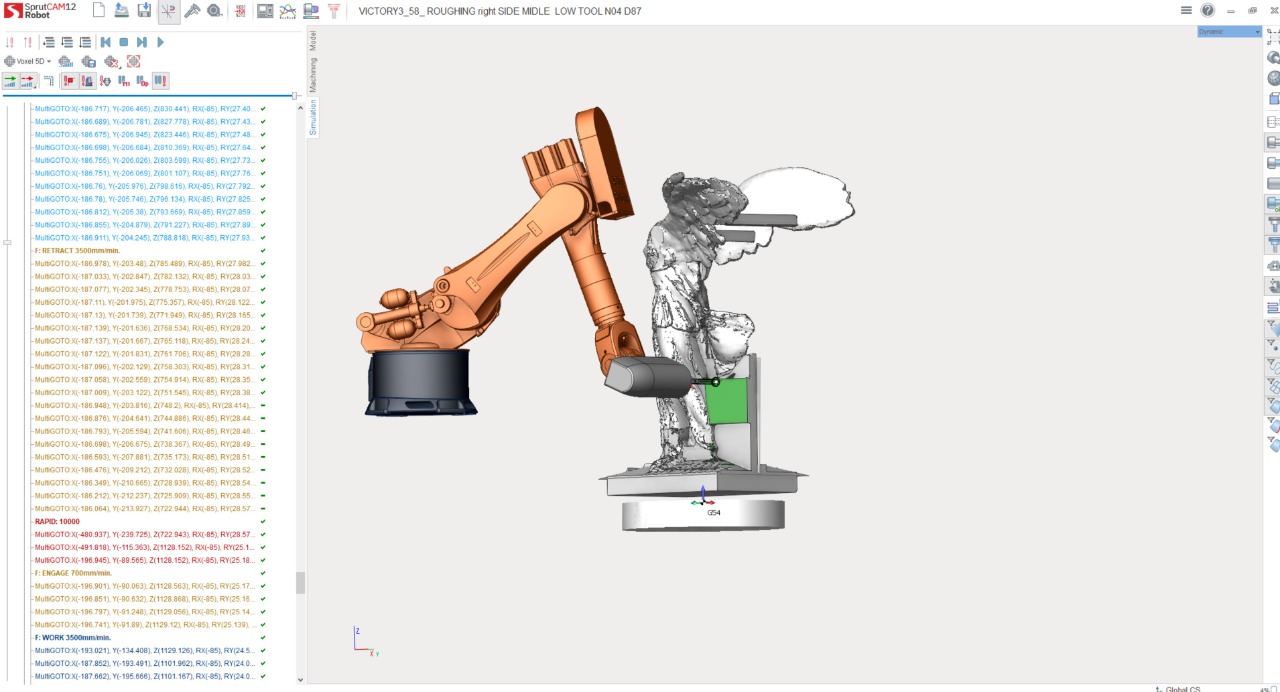

During the production phase, the robot’s primary task is to efficiently remove excess material, prioritizing safety, and speed. Subsequently, we transition to the finishing stage, carefully selecting the appropriate tools based on each surface’s nature. We utilize a range of different strategies provided by SprutCAM X Robot. The software also plays a crucial role in verifying the completion of the sculpture by visualizing the remaining stock material on the workpiece.

How were the sculptures created before the use of SprutCAM X Robot and why was the decision made to incorporate robots and robot programming software?

Crafting sculptures has always been a challenging endeavor. Prior to incorporating robots, our company faced the choice of either turning down such projects or outsourcing them to third parties.

The introduction of new hardware and software technologies has unleashed a lot of transformative capabilities for us. We can now craft complex pieces with high precision, achieving surfaces of remarkable quality. Today, thanks to our robots and, notably, SprutCAM X Robot, our company can tackle any project with confidence.

What equipment does the SprutCAM X Robot operate on?

Currently, we use SprutCAM X Robot to program our articulated robots (5x KUKA KR420 Robots, AGUT HERCVLES PRO and QD Robotics).

How was the decision made to choose the software for programming the robots?

It’s a straightforward answer to an interesting question – it’s all about staying ahead in a fiercely competitive industry. We’ve always been pioneers in our field, constantly in pursuit of the best solutions. During our search for robotics solutions, we came across AGUT Robotics, from whom we acquired our robots. They introduced us to SprutCAM X Robot, and after our initial experience, it became clear that we had made the right choice.

What truly set SprutCAM X Robot apart for us is its user-friendly visual controls on the model, a wide array of diverse strategies, and great simulation capabilities.

How was the training for the software carried out and how was it implemented?

AGUT Robotics provided on-site training at our factory. Our instructors guided us through a comprehensive training program, covering everything from the fundamentals of hardware operation, 3D model preparation and simple contouring strategies to advanced topics such as the programming of complex sculptures. This hands-on approach ensured a seamless implementation of the software into our workflow. Furthermore, we continuously aim to educate ourselves in even more complex strategies that we may not be familiar with yet.

What are the plans for the continued use of SprutCAM X Robot in the company?

Our company is committed to producing sculptures and architectural elements, and SprutCAM X Robot remains an indispensable component of our operations. We’re looking forward for the addition of new features, especially the integration of AI, which holds the promise of providing more innovative tools for us to explore.