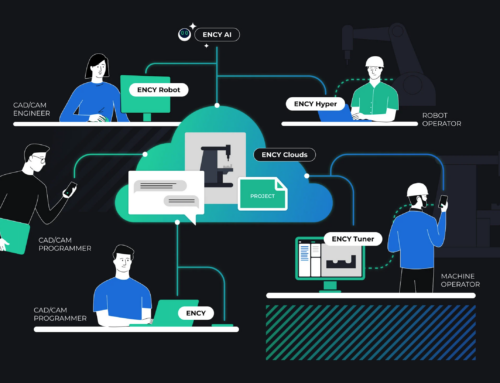

4 axis CNC machining in SprutCAM X CAM system

4 axis CNC machining from our partner in Spain, MecData:

4 axis sculpting with SprutCAM X

Introduction

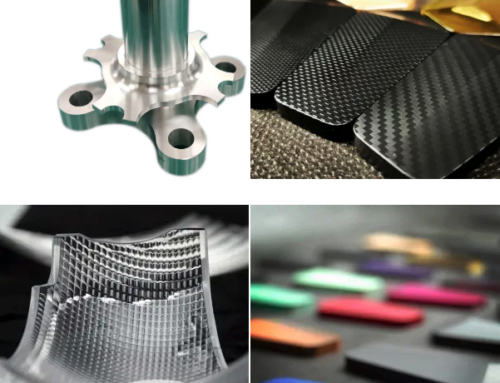

SprutCAM X CAD CAM software is an excellent tool for 4 axis sculpting tasks. It is widely popular all over the world.

In the era of automation, 4-axis machining has become a common feature in various manufacturing processes. It is a process that requires a thorough understanding due to its complexity and importance. 4-Axis machining, also known as 4-axis CNC machining, is a multi-axis process that uses CNC machines equipped with an additional rotary axis.

4-Axis machining sculpting

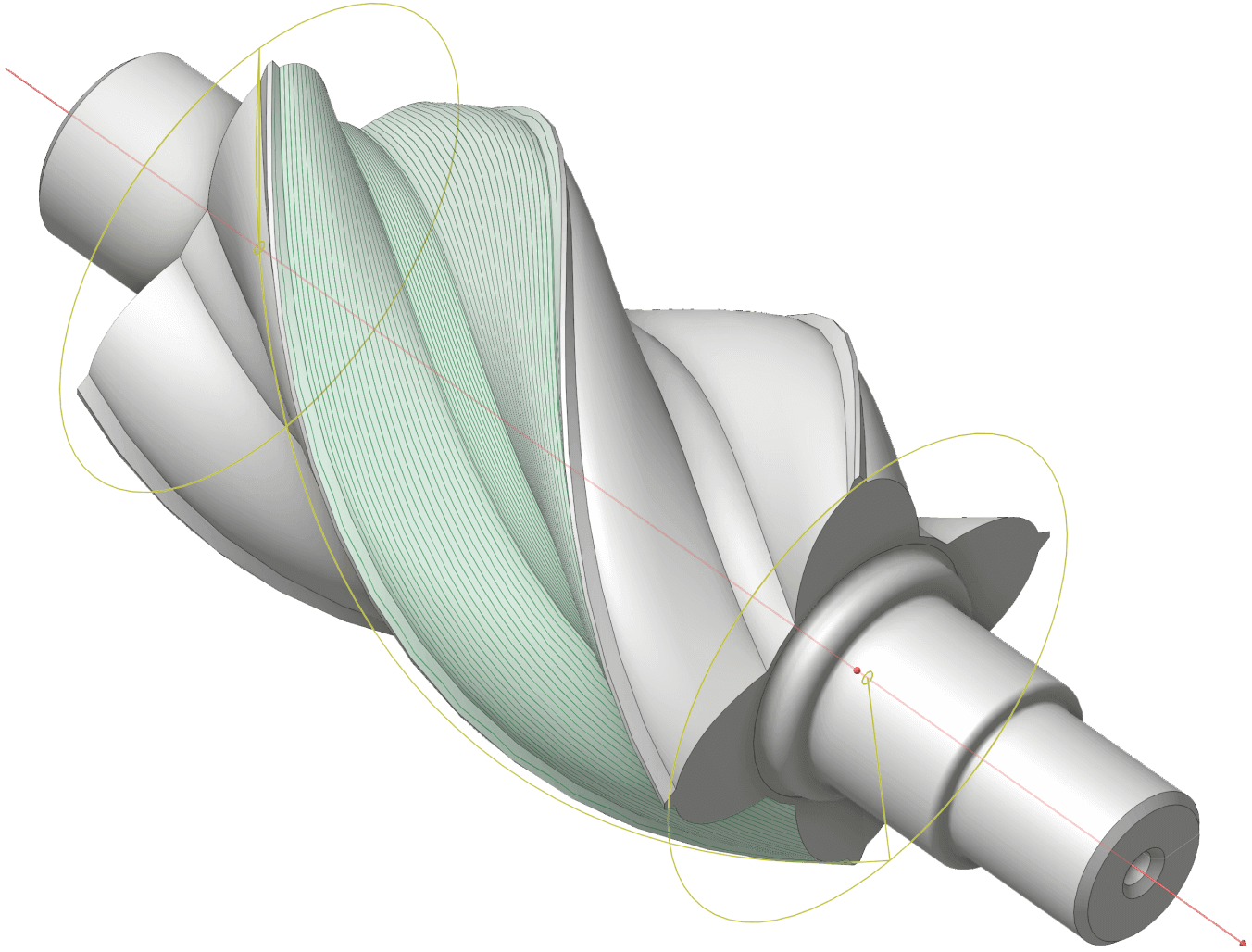

This process utilises a CNC machine that operates in four different axes simultaneously. It typically includes the X, Y, and Z axes, which are the three linear axes, and an additional rotational A-axis around the X-axis. This unique characteristic enables the machining of complex parts and milling at odd angles, which is not possible with 3-axis machining.

– CNC stands for Computer Numerical Control.

– The X, Y, and Z axes refer to three mutually perpendicular directions.

– The A axis facilitates the rotation of the workpiece around the X axis during the 4-axis CNC machining process.

The process of 4-axis CNC Machining

A comprehensive understanding of this process necessitates a focus on the movements and capabilities of CNC machines. These machines move the cutting tool along the X, Y, and Z axes while simultaneously rotating the workpiece on the A axis. This additional axis enables the machine to work on the workpiece from various angles, facilitating the creation of intricate parts with accuracy.

CAD Design involves designing a product using Computer-Aided Design (CAD) software on a Windows PC. After the design is complete, Computer-Aided Manufacturing (CAM) software generates a toolpath for the CNC machine to follow during setup. The workpiece is mounted by the CNC machine operator and the machine is set up with the appropriate cutting tools. The machining process can then commence. The workpiece is able to rotate on the A axis while the tool moves in the X, Y, and Z directions, allowing for continuous machining at various angles. Following the machining process, any necessary finishing operations, such as cleaning or deburring, are then carried out.

Different Varieties of 4-Axis CNC Machines

There are various types of 4-axis CNC machines, each with unique capabilities that are suited for different applications.

Milling machines are the most commonly used among these. They are ideal for creating complex parts with features such as angled cuts and holes. The additional A-axis allows the cutting tool to approach the workpiece at an angle, enabling it to mill slots and holes at any required angle.

On the other hand, 4-axis CNC lathes are used for turning operations. The lathe tool can approach the workpiece at any angle thanks to the added axis, allowing for the manufacture of complex geometries. Lathes are versatile machines that can work on a variety of materials, including metal, wood, and plastics, making them a valuable asset in manufacturing industries.

Additionally, 4-axis CNC routers, primarily used in the woodworking industry, offer precision and the ability to work on large parts. Furthermore, their robust construction and easy setup make them a valuable asset in any production line.

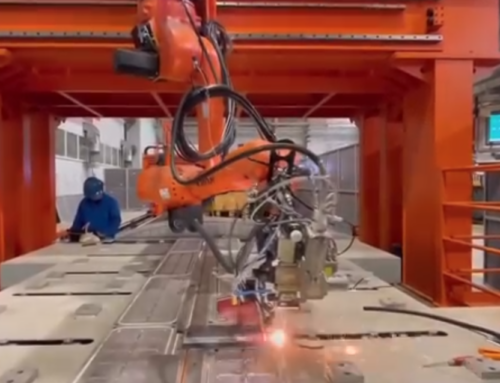

Applications of 4-Axis CNC Machines

4-axis CNC machines have proven to be highly versatile and have made a significant impact in various sectors, including the aerospace industry. Their precision and ability to work on complex geometries make them ideal for this industry, where the creation of complex parts and components is often required. This technology is particularly useful in the manufacturing industry for producing turbine and airframe components, as well as in the automotive industry for engine components and body parts. This technology is particularly useful in the manufacturing industry for producing turbine and airframe components, as well as in the automotive industry for engine components and body parts. This technology is particularly useful in the manufacturing industry for producing turbine and airframe components, as well as in the automotive industry for engine components and body parts. The electronics industry also benefits from the precision and efficiency of 4-axis CNC machining. 4-axis CNC machining is widely used in various industries due to its ability to produce intricate and complex parts with great precision and efficiency.

The production of electronic components requires a high degree of precision. 4-axis CNC machines are capable of achieving this by manufacturing components such as circuit boards and casings.

Similarly, in the oil and gas industry, parts that can withstand extreme conditions are essential. 4-axis CNC machines can produce high-quality and durable components to meet these requirements.

Benefits of 4-Axis CNC Machining

4-axis CNC machining is known to offer several benefits that can improve efficiency and provide cost-effective solutions for various manufacturing industries. One of the significant advantages is enhanced capabilities. The inclusion of an additional A-axis can enable the production of intricate components that may be challenging to manufacture with only three axes. This can expand the design and manufacturing possibilities.

Furthermore, it may lead to an increase in efficiency. 4-axis CNC machining allows for continuous machining from different angles without the need for manual adjustment, significantly reducing production time.

Furthermore, the added axis provides greater control over the machining process, resulting in improved precision and accuracy. This method is highly versatile and has proven to be a valuable tool in various industries. 4-axis CNC machines are considered to be versatile tools in any manufacturing setup, as they are capable of handling a variety of materials and part sizes, ranging from small electronic parts to large aerospace components.

Disadvantages of 4-Axis CNC Machining

While the advantages of 4-axis CNC machining are undeniable, it is important to consider some of its drawbacks. One of the primary concerns is the cost associated with purchasing and setting up a 4-axis CNC machine, which can be a substantial investment for any company. Nevertheless, it is crucial to take into account the initial investment required for CNC machines, despite their potential long-term benefits.

Furthermore, the operation of these machines can be complex and costly due to the need for skilled operators for setup, programming, and supervision. It is also important to note that CNC machines may have limitations based on geometry.While the additional A-axis does provide greater flexibility, it is important to note that there may still be certain geometries and angles that a 4-axis machine could struggle with. In these instances, it may be worth considering a 5-axis CNC machine as a potentially more appropriate choice.

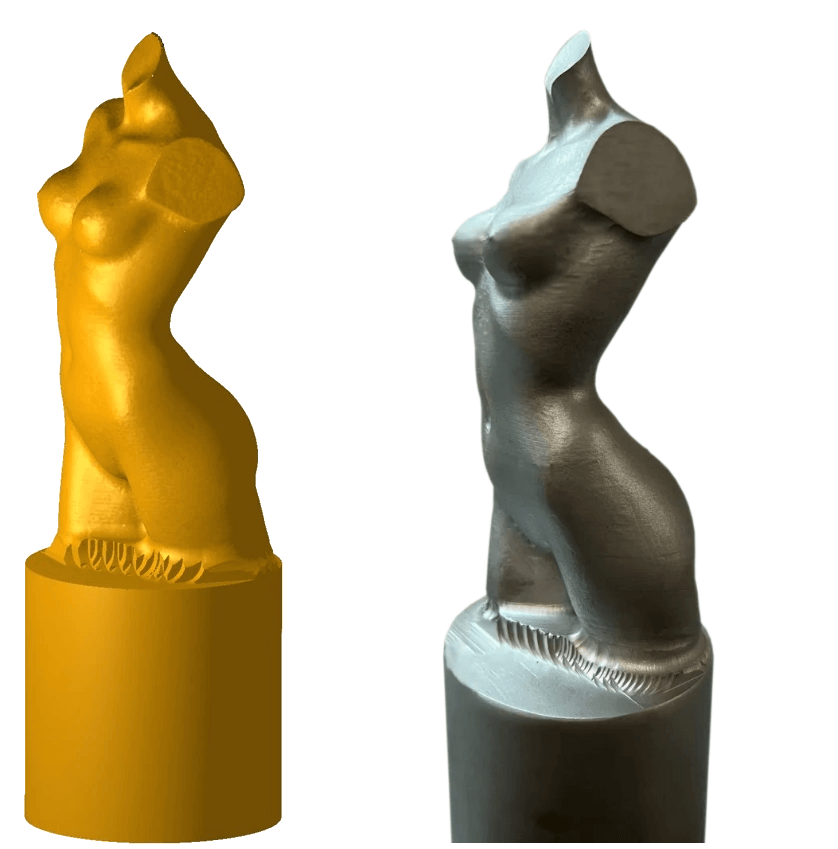

Mecdata company sculpting project

For example Mecdata company (SprutCAM dealer in Spain) used SprutCAM 4 axis sculpting software recently for statue sculpting in following way.

Project details:

CNC Machine: Mori Seiki SV50

Controller: Fanuc 0i

Material: Aluminium

Workpiece: Cylinder diameter 50 x 100