From CAD to CAM

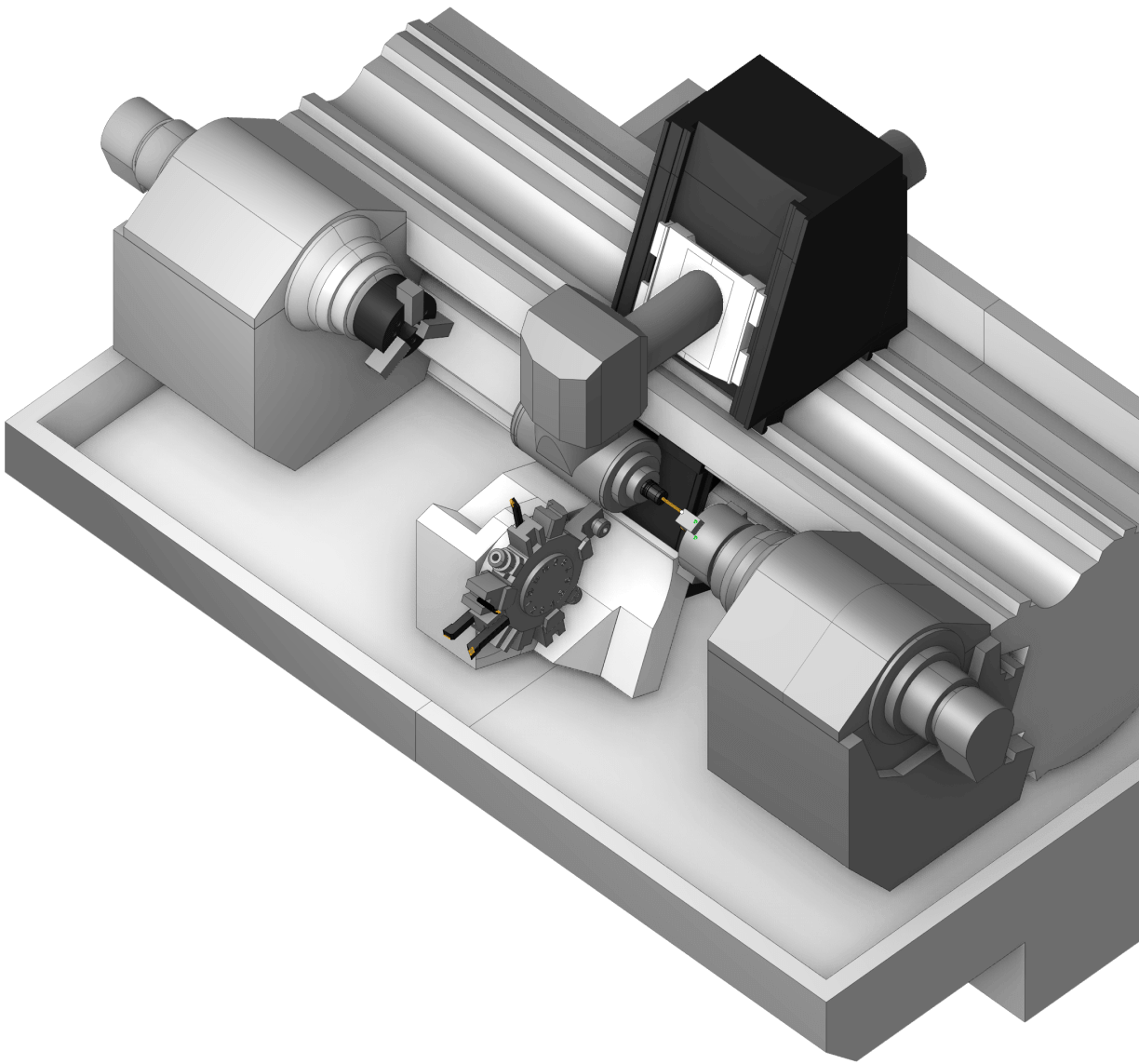

A lot ща our customers use IronCAD. It is important to have a good response and accurate transfer of the part from CAD to CAM.

Here is feedback from cncbuilt from the USA.

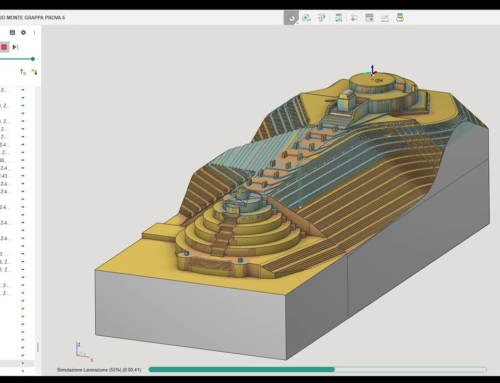

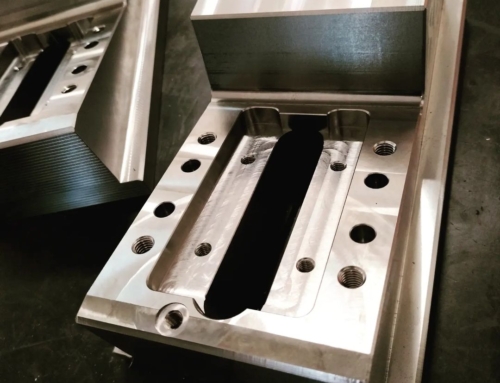

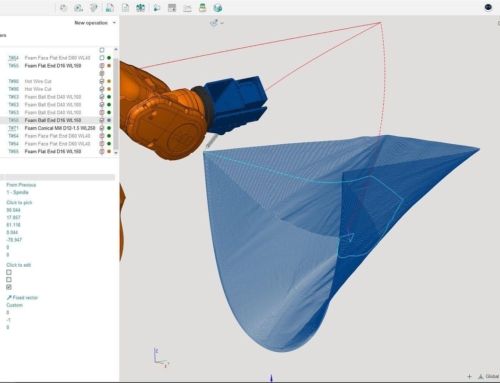

“Moving more parts to the fadal this morning which requires an updated ironcad CAD model with repositioned parts (which the triball makes a trivial effort) that allows me to proceed with an import of the native ironcad file directly into a CAM #sprutcam project file. In the sprutcam project, I proceed quickly in creating all the required CAM operations and generate the gcode file to feed to my mill. I have found over the past year the seamless import of native ironcad files into a predefined cam tree structure in sprutcam v14 including all work offsets (g54,55&56) positions to be a huge game-changer. Thanks for the tips roguetoolpath !!! It would have been easy to knock these parts out on the tormach / flexarm like I have been doing for years but little by little the fadal migration is happening. The investment of time spent this morning moving this effort over to the fadal will quickly pay off being able to run a double pallet of parts and having all the tapping done by the mill. The 2nd pic is of me doing a quick sanity check on physical part positions on the pallet”