Job Shop

The Job Shop industry, characterized by its adaptability and diverse range of manufacturing processes, plays a crucial role in meeting specialized production needs. Job shops offer customized solutions, manufacturing parts and components in small to medium quantities, catering to a variety of sectors including automotive, aerospace, electronics, and more. As production demands become increasingly specific, trends within the industry are leaning towards advanced automation, digitalization, and agile production techniques. Embracing Industry 4.0 principles, job shops are incorporating IoT-enabled machinery, data-driven decision-making, and real-time monitoring to enhance efficiency and reduce lead times, ensuring they remain competitive in an ever-evolving market.

Innovative Components and Technologies that Drive the Industry

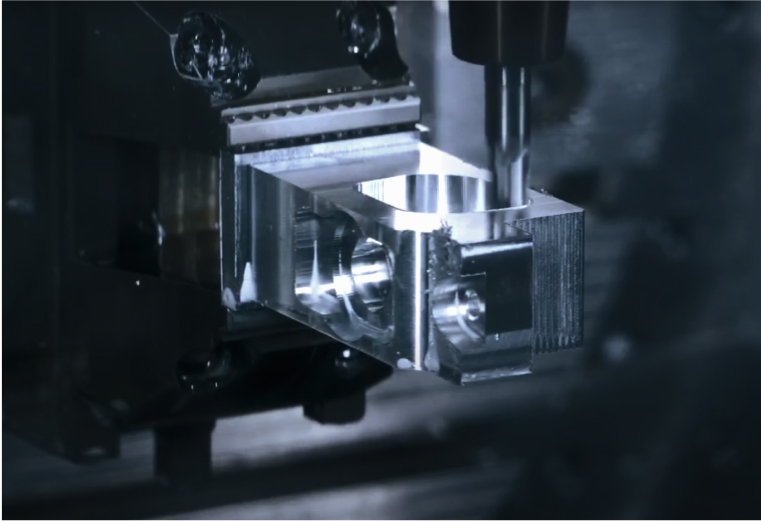

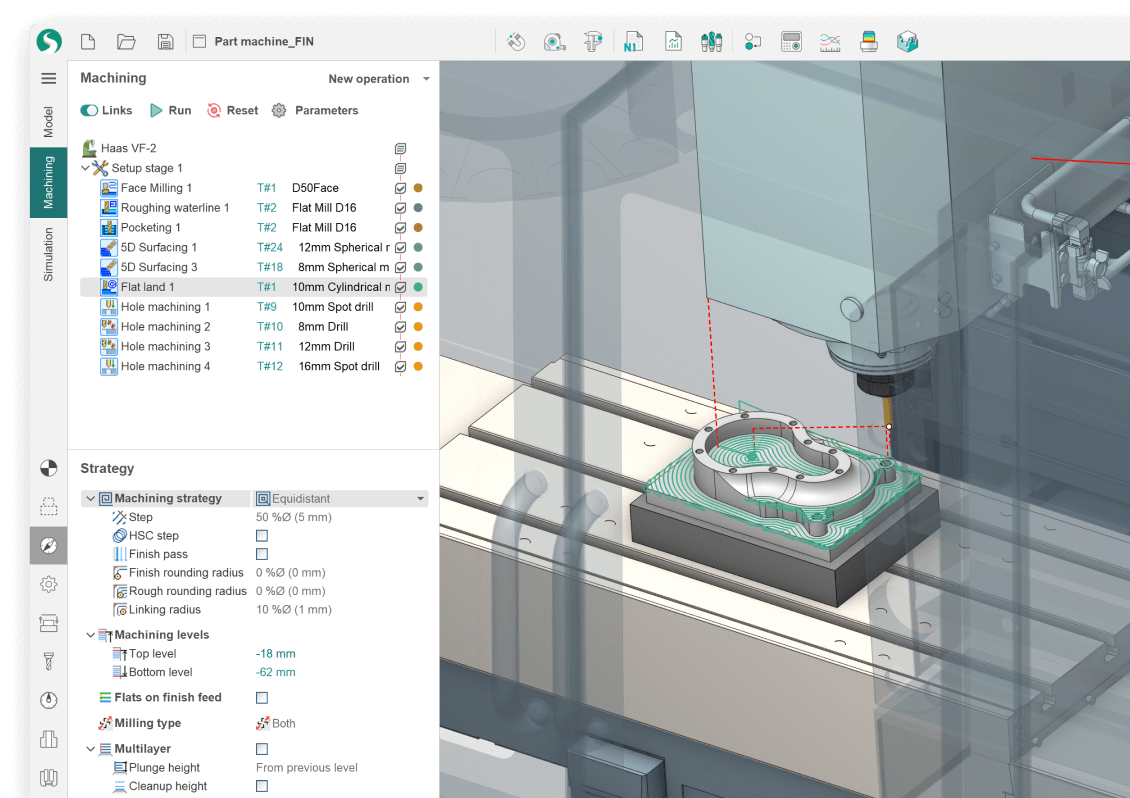

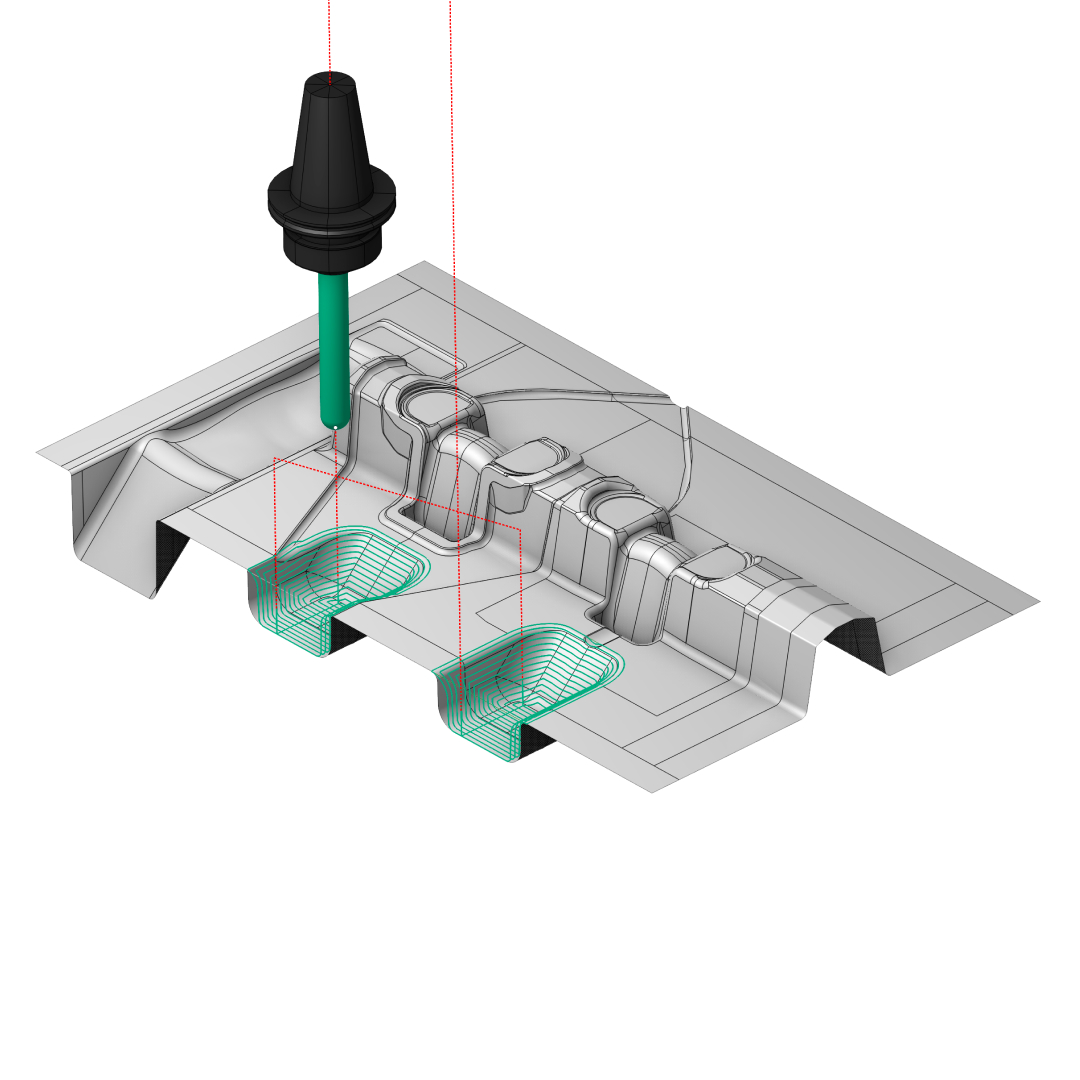

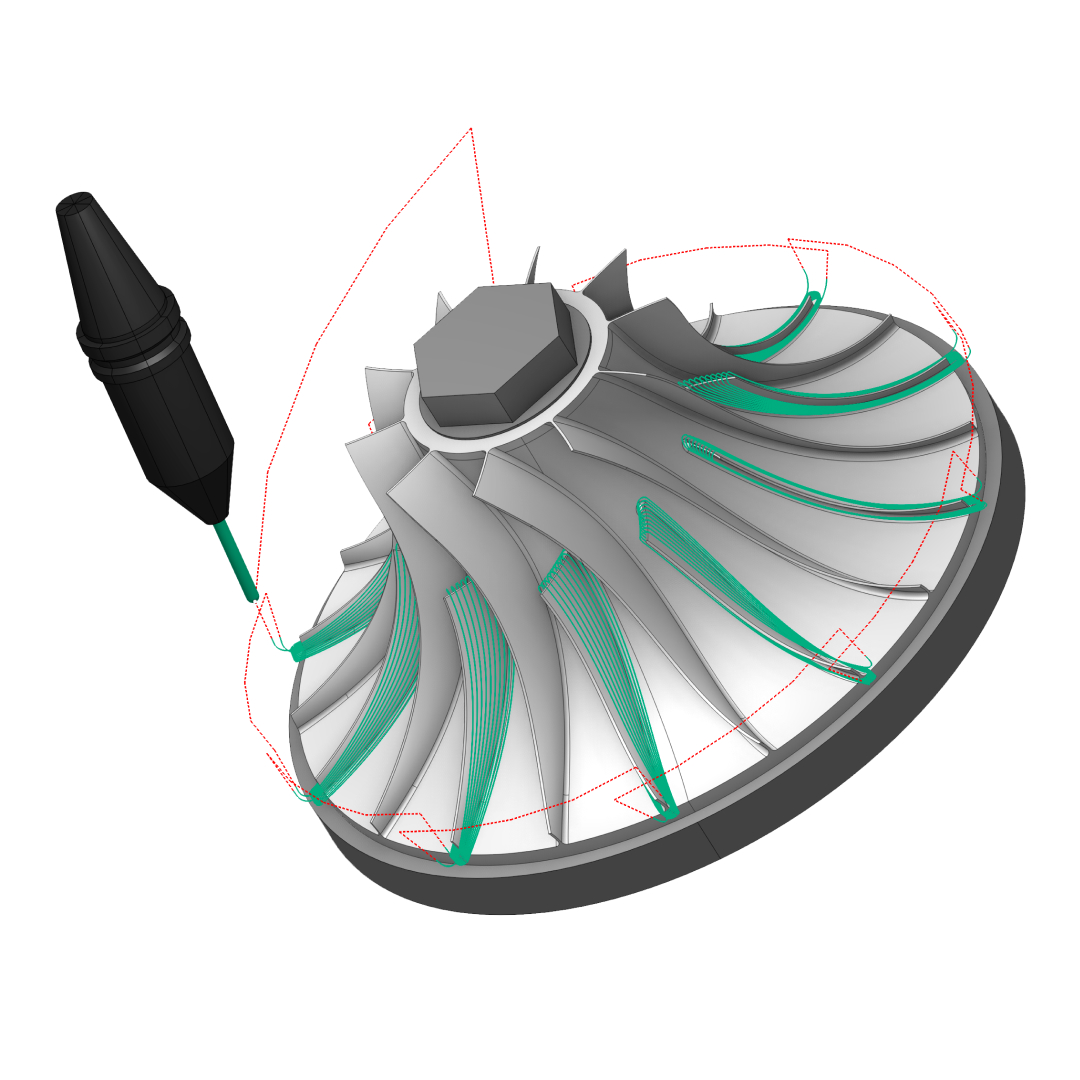

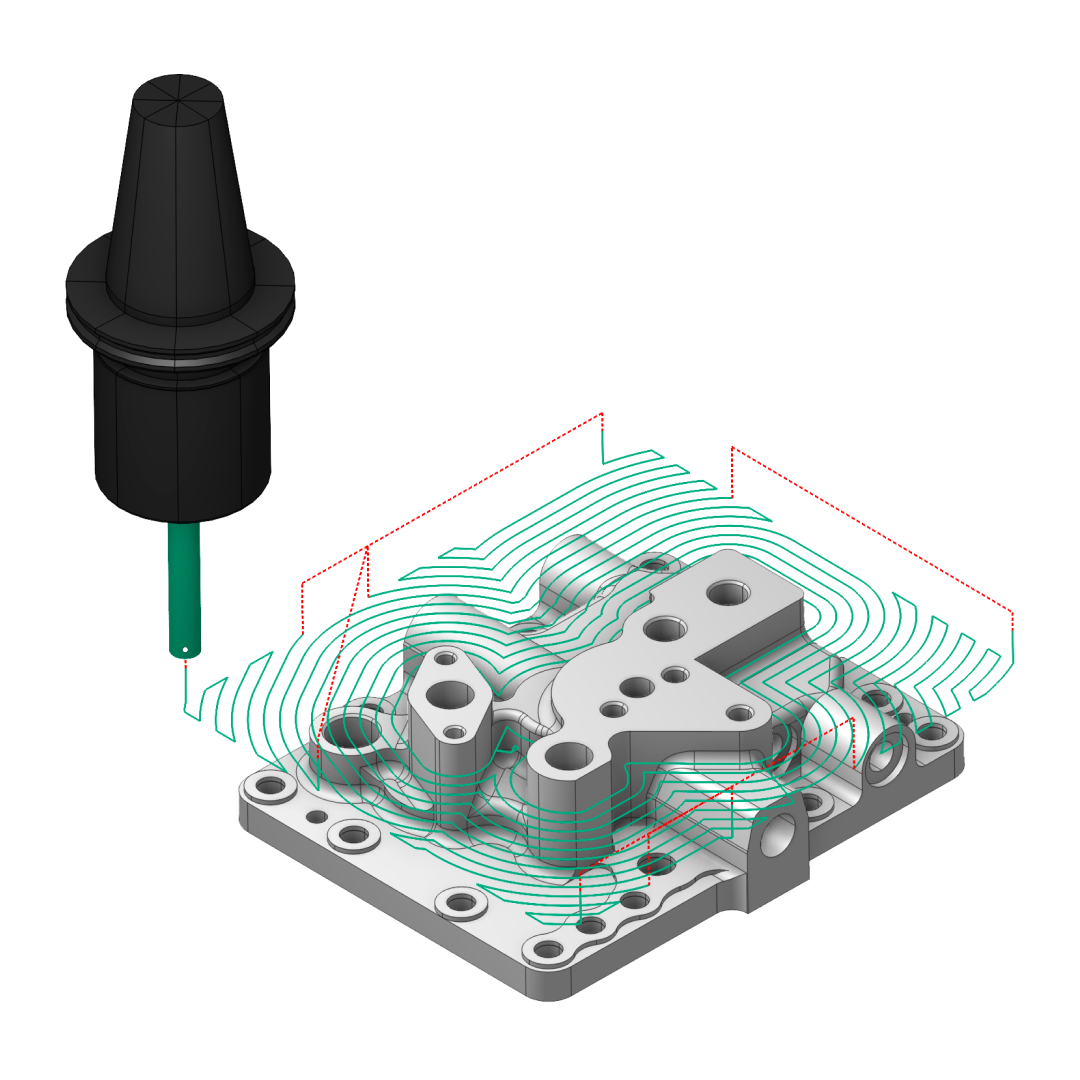

In the dynamic world of job shops, an array of components and technologies underpins the precision and adaptability that defines the industry. CNC machining centers are the backbone of manufacturing, providing the capability to produce intricate and accurate parts. 3D printing is revolutionizing prototyping and short-run production by rapidly creating complex designs. CAD/CAM software streamlines design and programming processes, enabling efficient production and minimizing errors. Additionally, collaborative robots, or cobots, are becoming more prevalent in job shops, working alongside human operators to optimize tasks and improve production efficiency. The amalgamation of these technologies enables job shops to maintain their versatility, delivering tailored solutions to meet the unique needs of their clients.

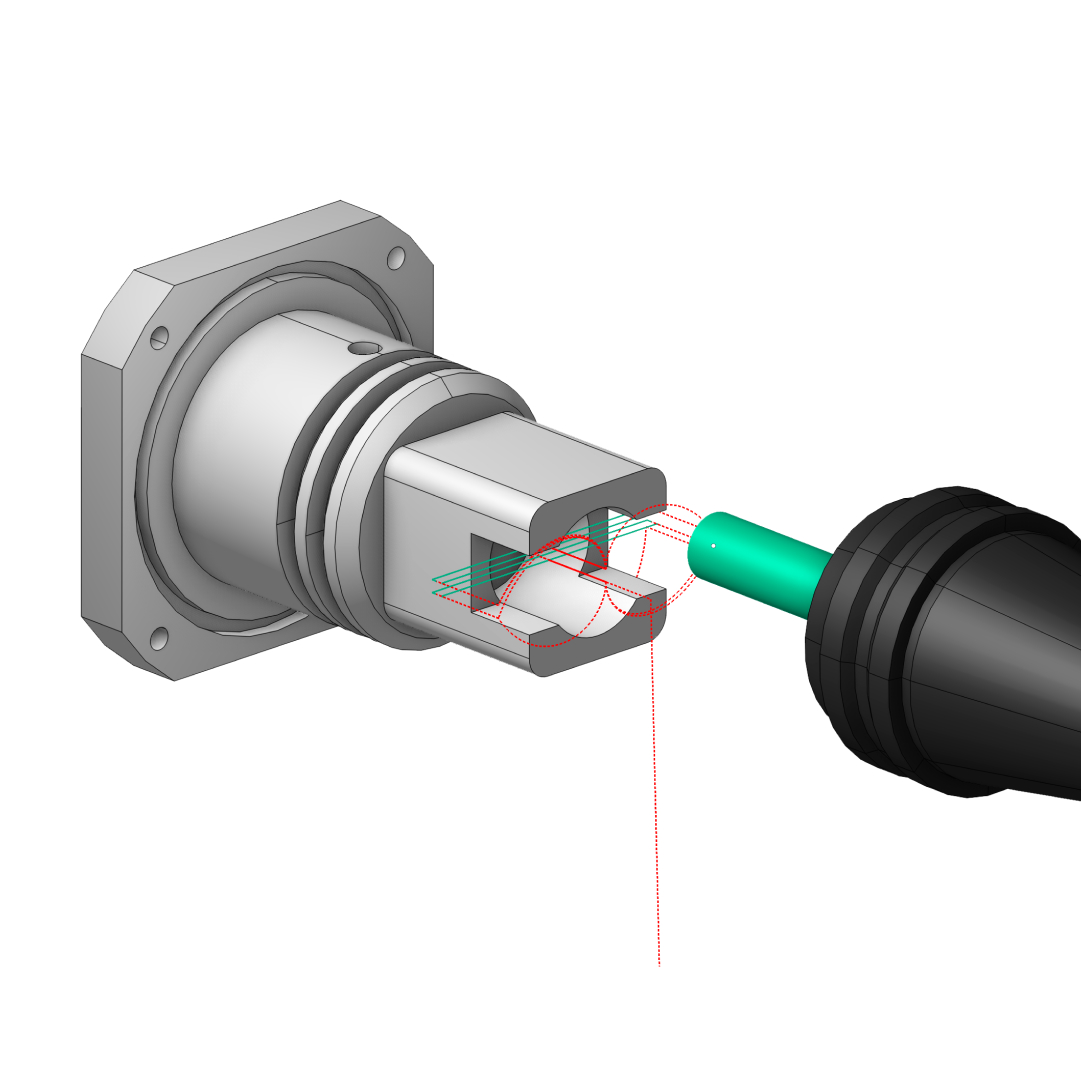

We are users of CAD/CAM systems for 20 years. In this period, we tested more than 6 valued brands. Recently, we performed research with 5-axis milling. The prototype of a trunnion table with zero backlash was developed and tested with SprutCAM. The SprutCAM was the best acquisition for our 5-axis applications. Featuring the ability to compute and simulate nontrivial kinematics. The SprutCAM postprocessor only defines the syntax of CNC program, without performing geometric calculations as inverse kinematics and linearization. The postprocessor is seen here, as a kind of translator. This new approach reduces the possibility of errors in postprocessing.

Felicio Jose Gesser

Instituto Federal de Educação