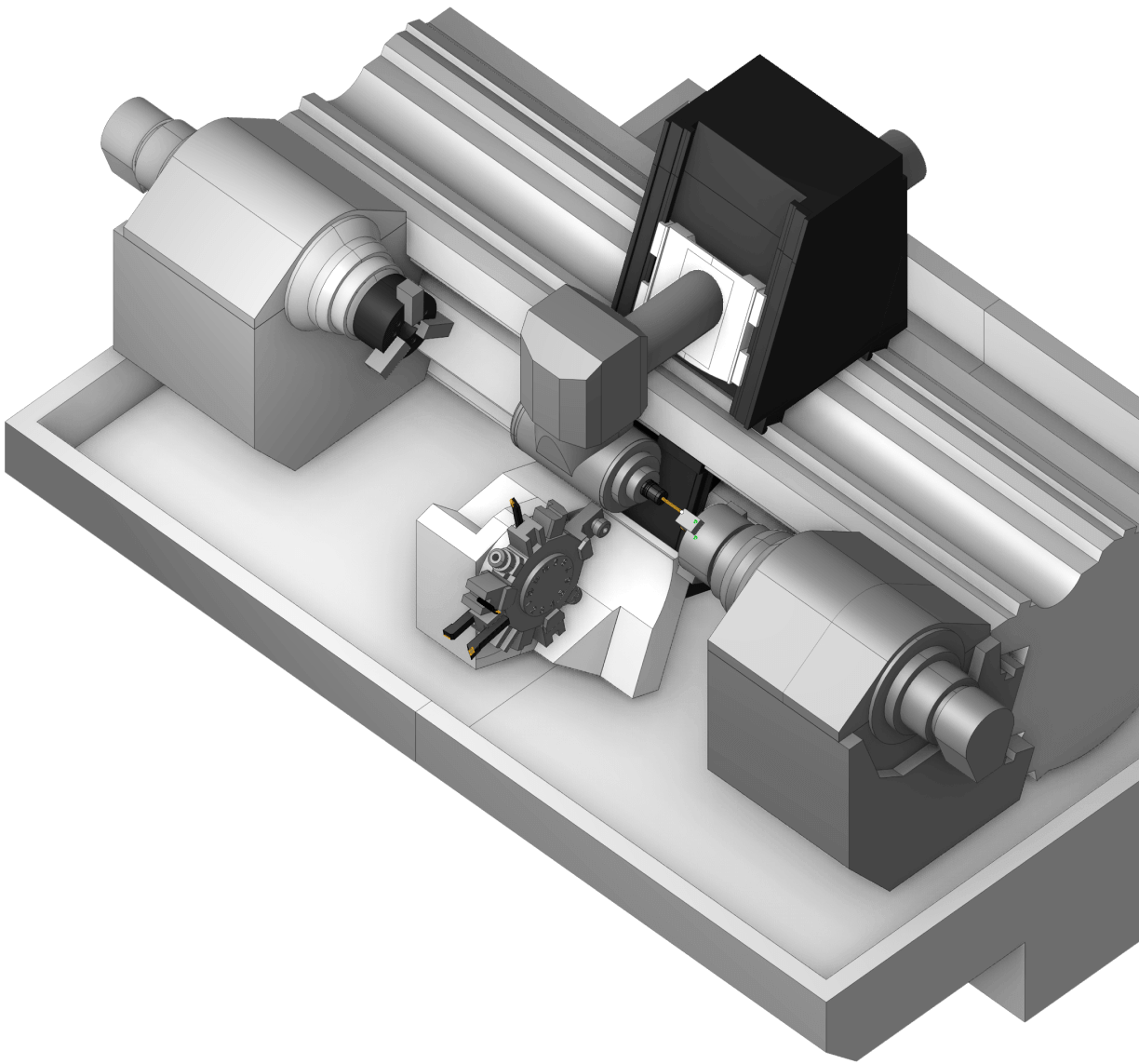

5-axis milling with side tool on CNC machine

Are you looking to enhance the industrial production of your CNC machines and robots? Look no further than SprutCAM X! With its advanced programming capabilities, SprutCAM X allows you to streamline your manufacturing process and achieve higher efficiency.

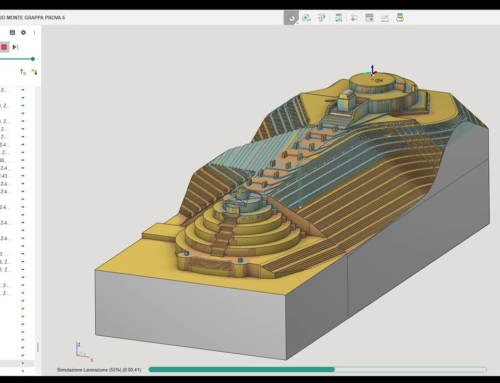

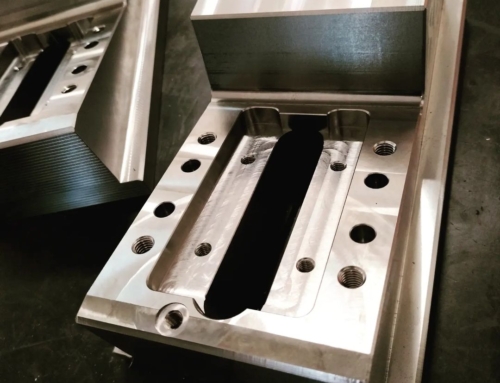

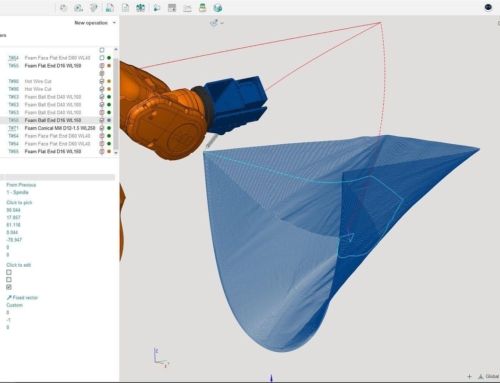

One of the key features of SprutCAM X is its support for 5-axis milling machining with the tool side on a CNC machine. This machining on the video, also known as “swarf” mchining, involves removing material using the tool flank while following the surface of a 3D solid. By utilizing this toolpath, you can achieve precise and intricate cuts, resulting in high-quality finished products. Video is created by our Italian reseller Magister.

What sets SprutCAM X apart is its exceptional level of customization. You have the flexibility to tailor the machining process according to your specific requirements. With SprutCAM X’s fast and interactive interface, you can quickly program your CNC machines and robots from a PC before starting production. This not only saves time but also minimizes errors and optimizes movements, ensuring a smooth and efficient manufacturing process.

So, if you’re aiming to boost your industrial production, SprutCAM X is the ideal solution. Take advantage of its powerful programming capabilities, enhance your CNC machines and robots, and enjoy the benefits of improved productivity and accuracy. Say goodbye to costly errors and hello to a more efficient and streamlined manufacturing process with SprutCAM!