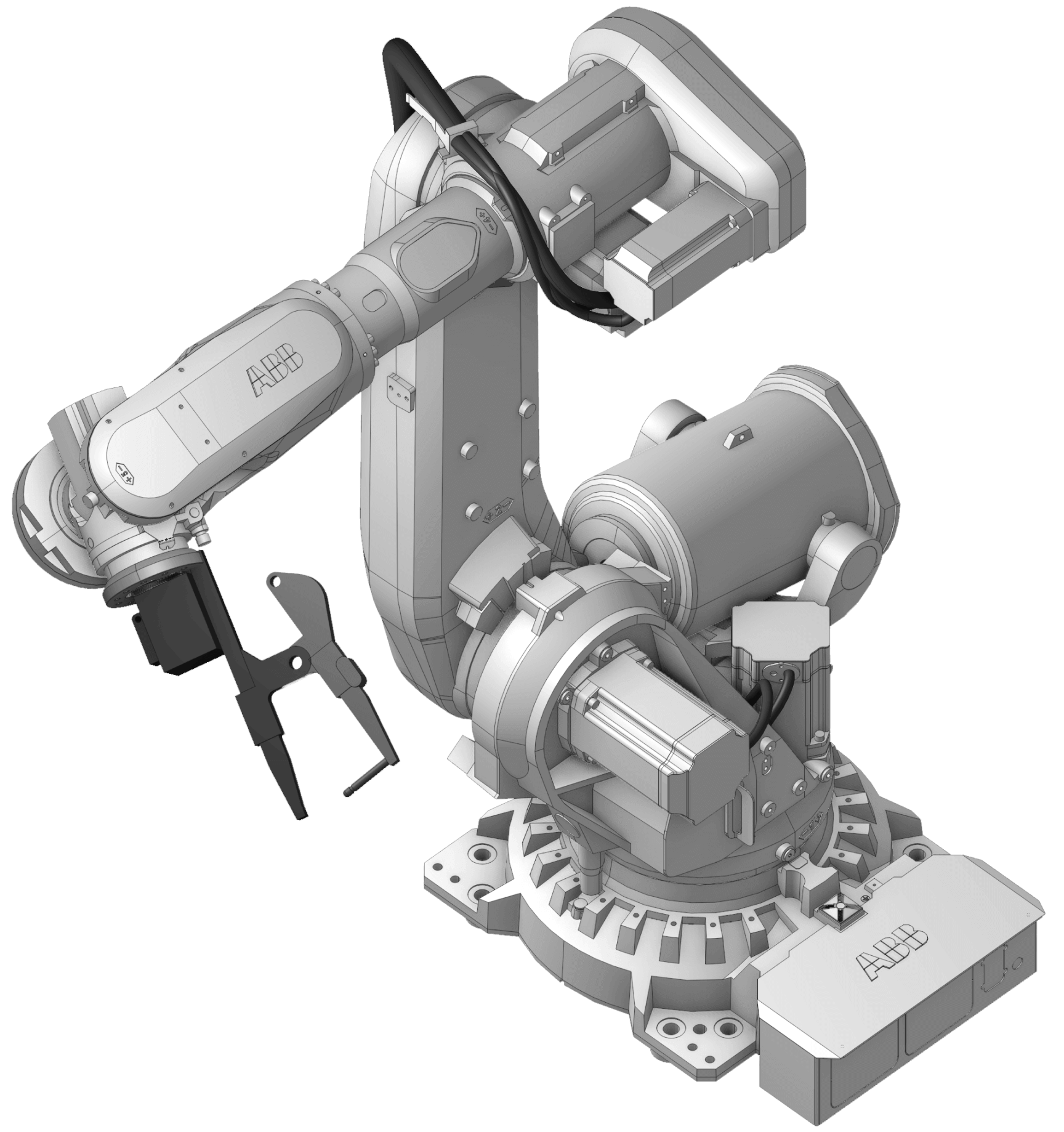

Robot welding

Here you can see the welding operation by SprutCAM Robot.

Created by Ubaldo Garcia Zaragoza from XMART PLM.

We're inviting robot integrators to collaborate with us.

Buy SprutCAM X online in the USA and Canada.

Here you can see the welding operation by SprutCAM Robot.

Created by Ubaldo Garcia Zaragoza from XMART PLM.

Download a free trial version of SprutCAM X or SprutCAM X Robot to explore the capabilities of the software. Take online courses to learn SprutCAM X and get a certificate upon completion.

9, Aiolou and Panagioti Diomidous

3020, Limassol, Cyprus

© 2021 – SprutCAM Tech. All rights reserved.

This website uses cookies and third party services. Privacy policy

Ok