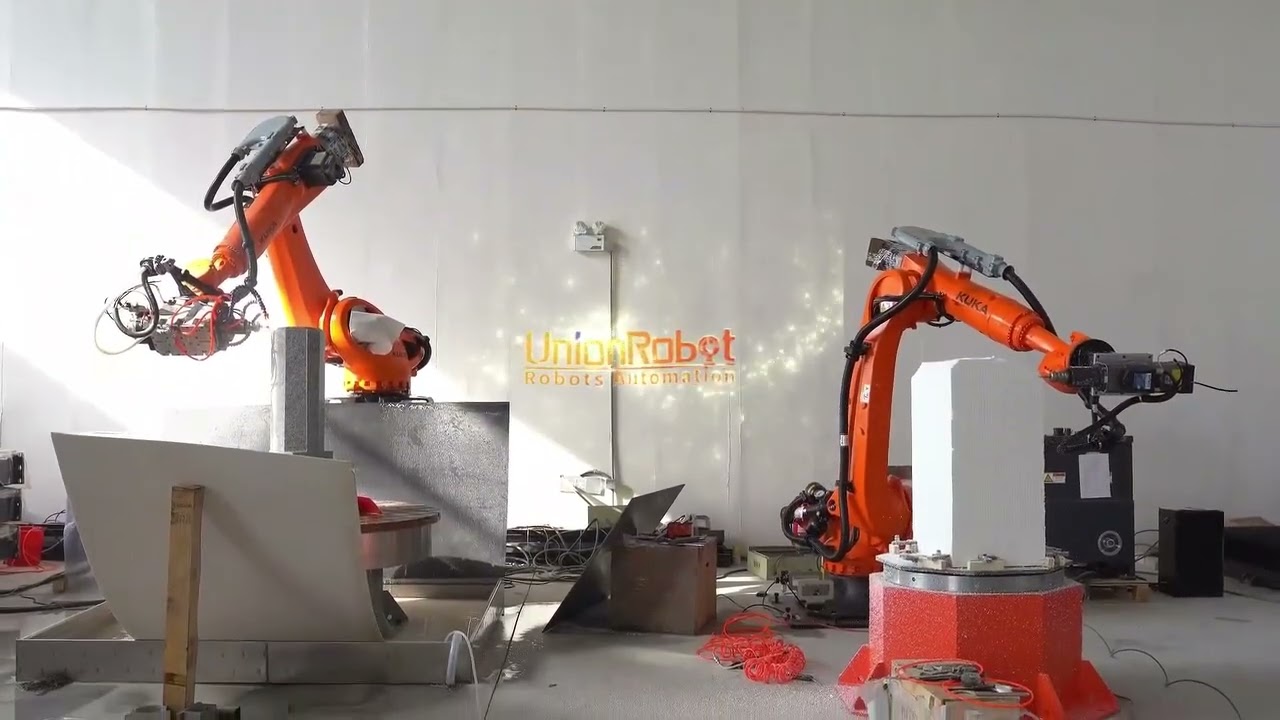

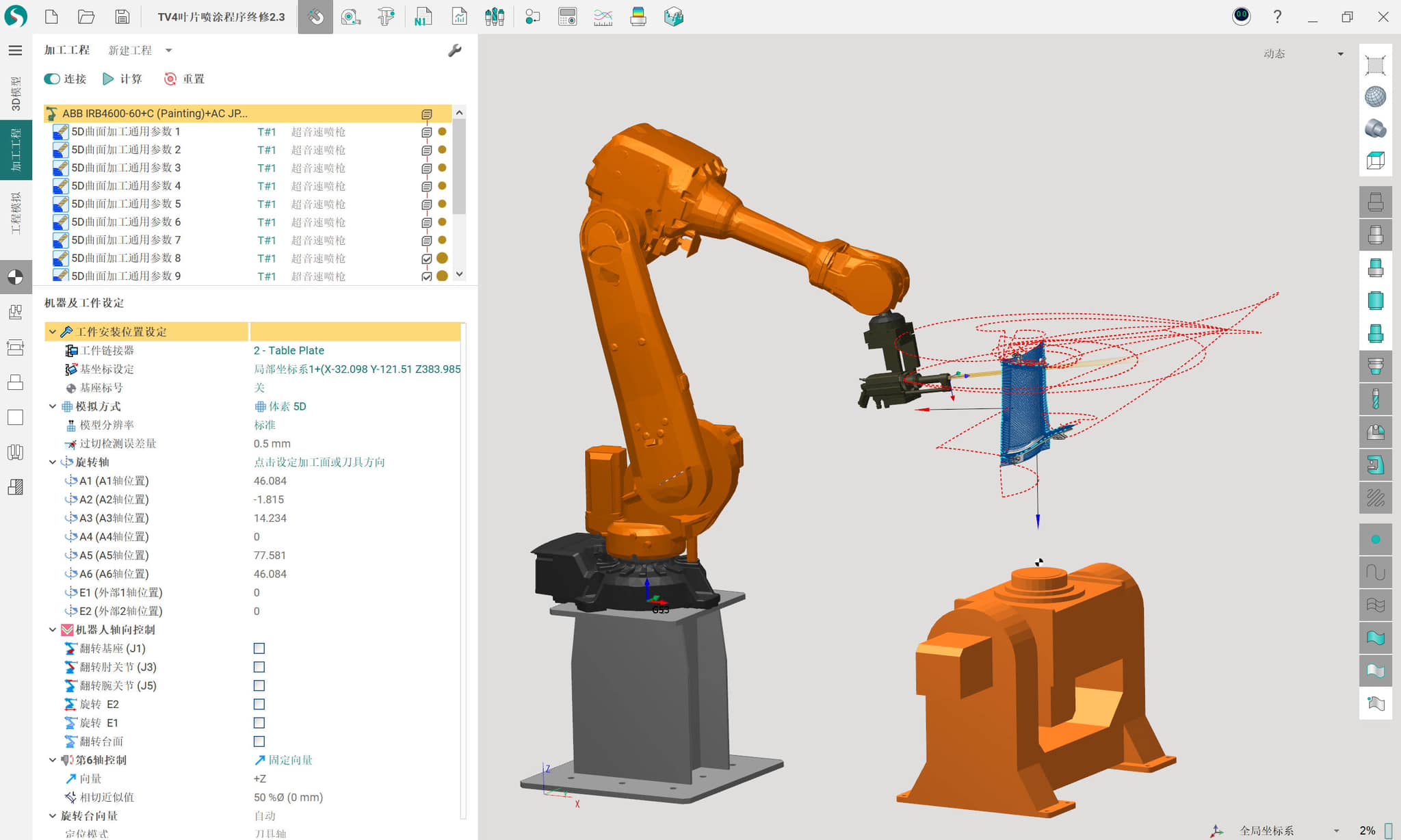

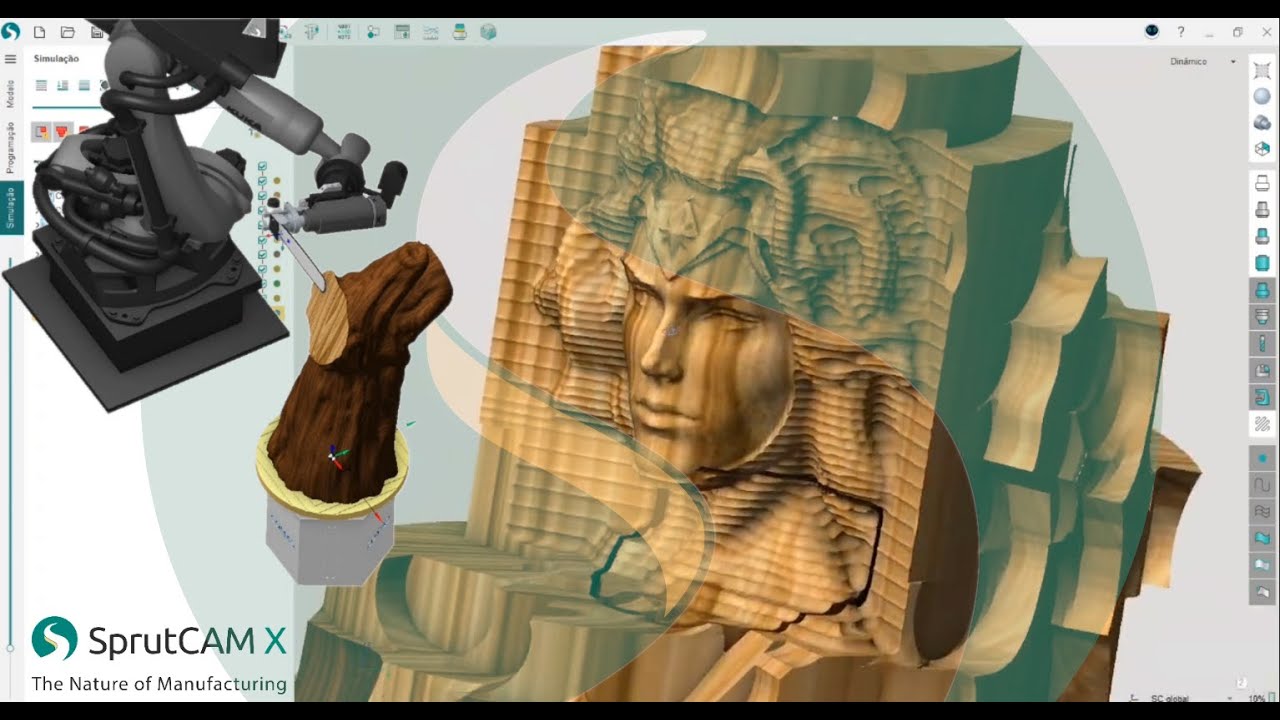

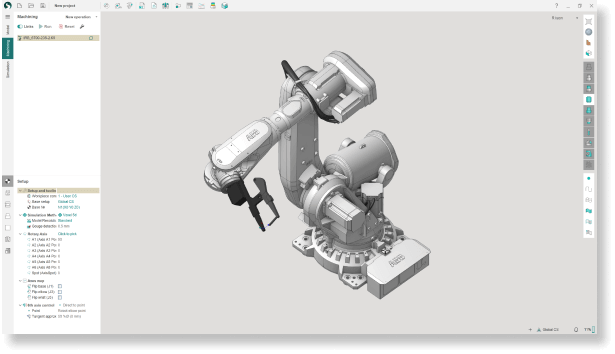

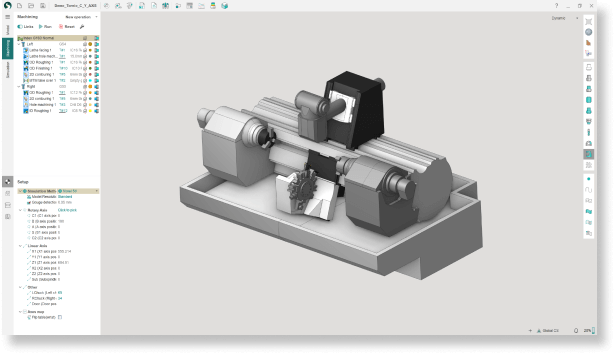

One platform for both worlds

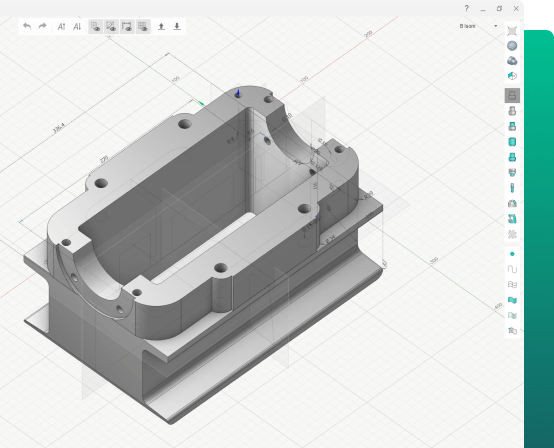

With a single technology solution, programming both CNC machines and industrial robots becomes effortless. With a crisp, crystal-clear interface that supports 4K displays, the previously separate worlds of CNC and industrial robotics are now tightly and seamlessly united for the first time.

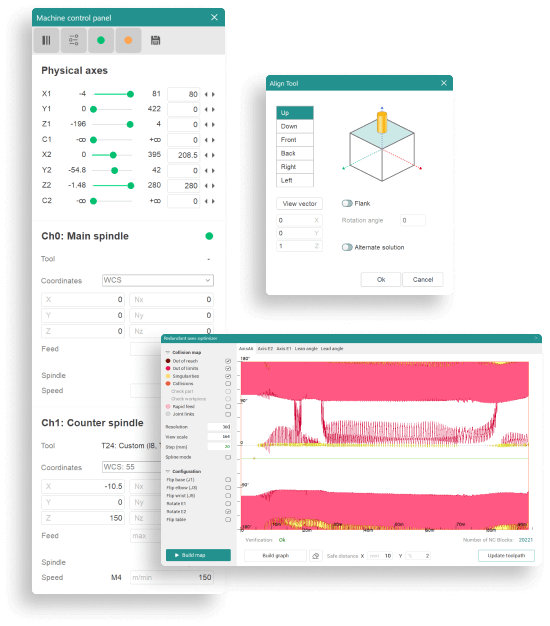

Unique user experience and interface

We strive to create a workflow that is intuitive and effortless for users. UI/UX designers play a crucial role in the development of SprutCAM X software, as they are responsible for creating intuitive and user-friendly interfaces for the software. They work closely with the development team to ensure that our products is easy to use, visually appealing, and meets the needs of the users. As a result, you will find yourself in an environment that feels natural and familiar to a production engineer while using your PC.

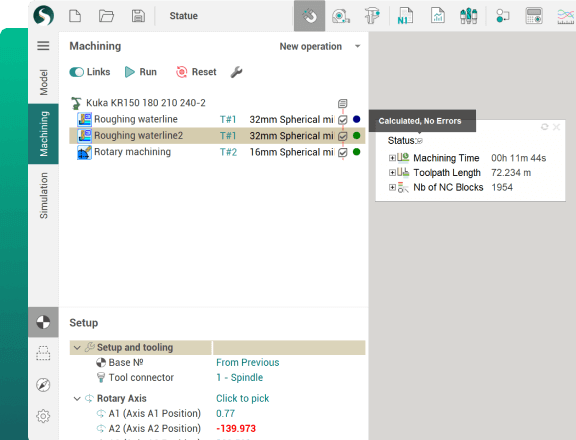

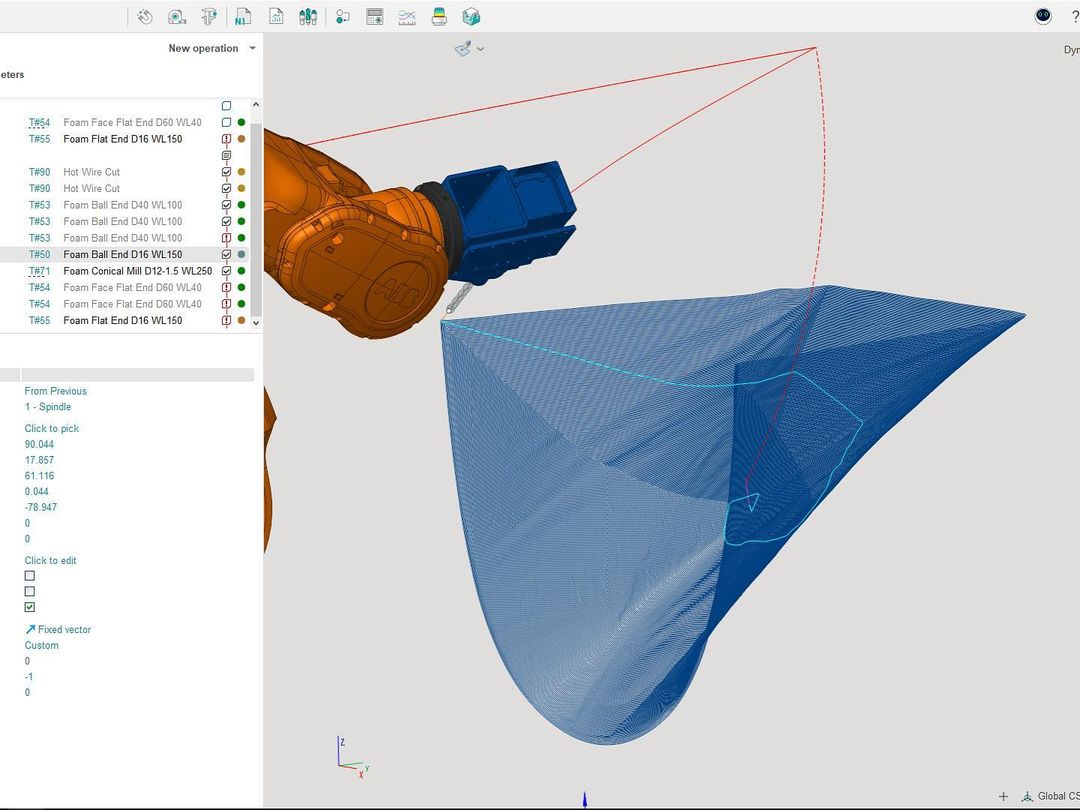

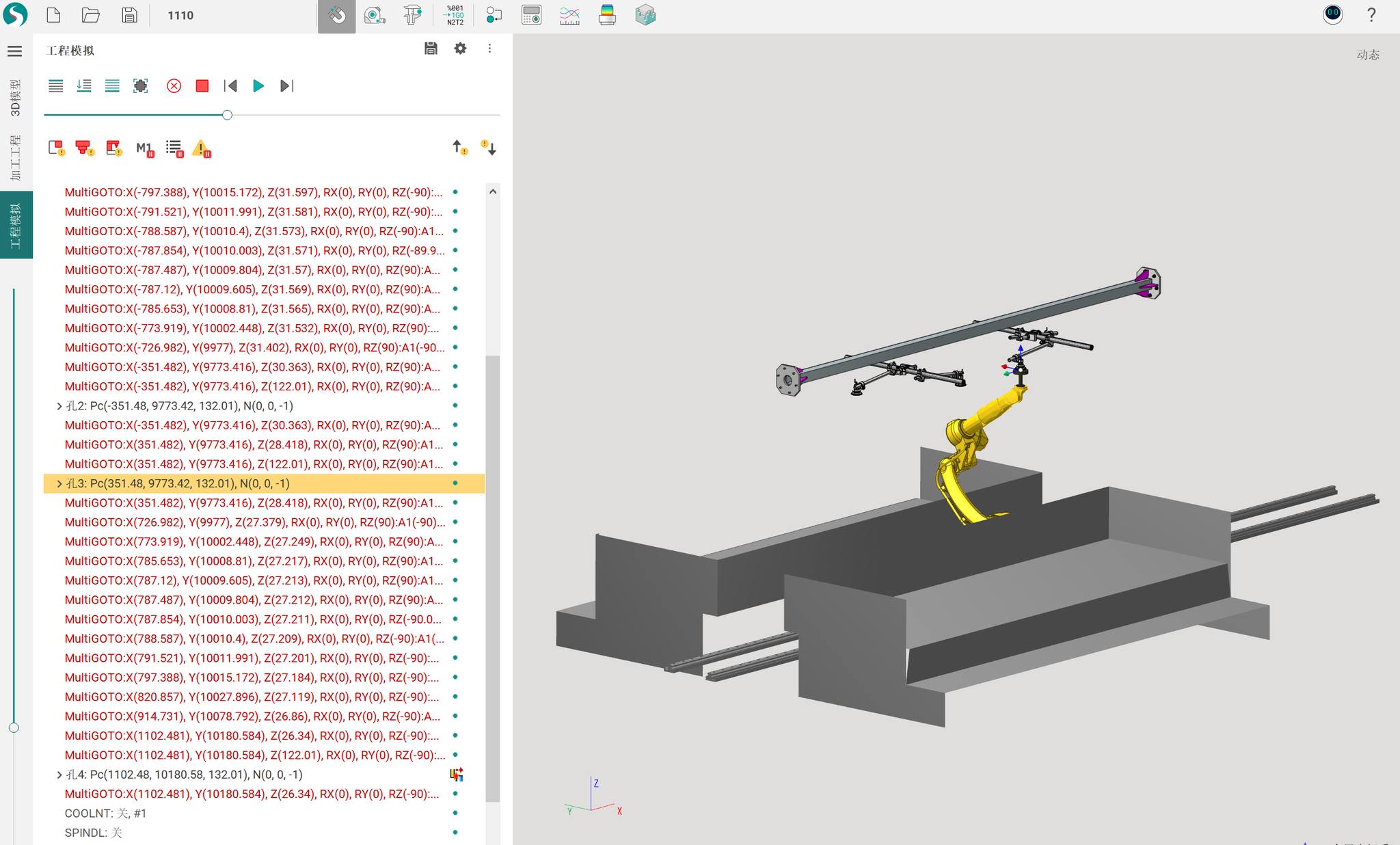

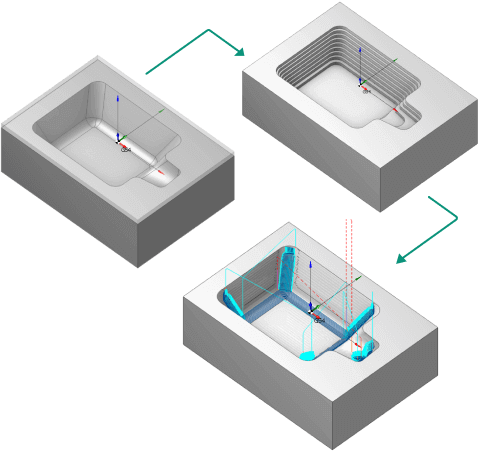

Phenomenal interactivity

Easily adjust the number of passes, direction, or depth, and change the machining strategy on the fly using the familiar drag-and-drop technology. You can also visually evaluate the result before even starting the calculation of the technological operation.

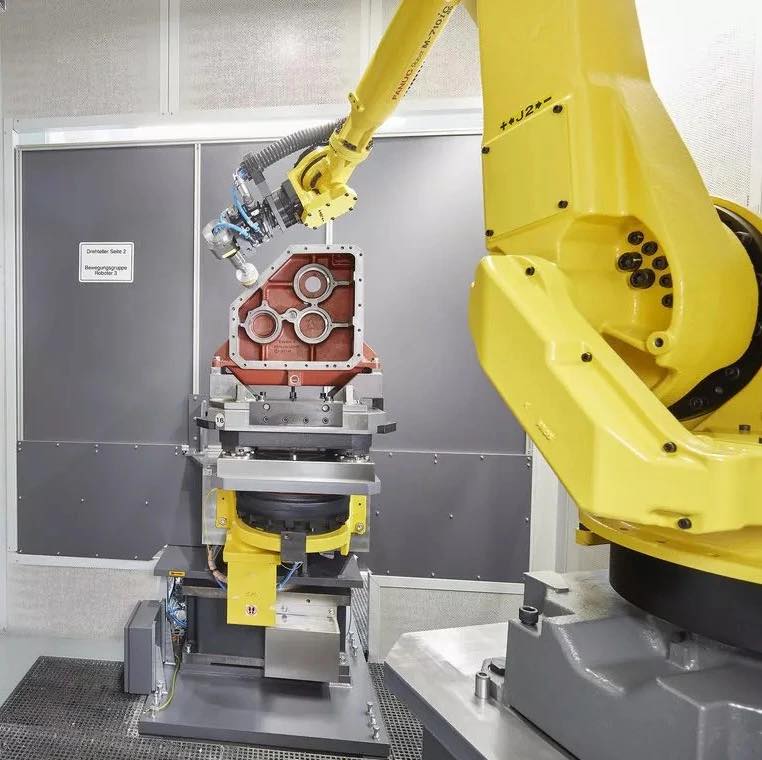

Efficiency and Safety

SprutCAM X optimizes toolpaths in real-time based on the current state of the material (stock), reducing unnecessary movements and cutting time for improved efficiency. The platform’s engine automatically generates safe rapid positioning between cutting cycles, optimized for the specific machine, tools, and setup being used.

Open to integration

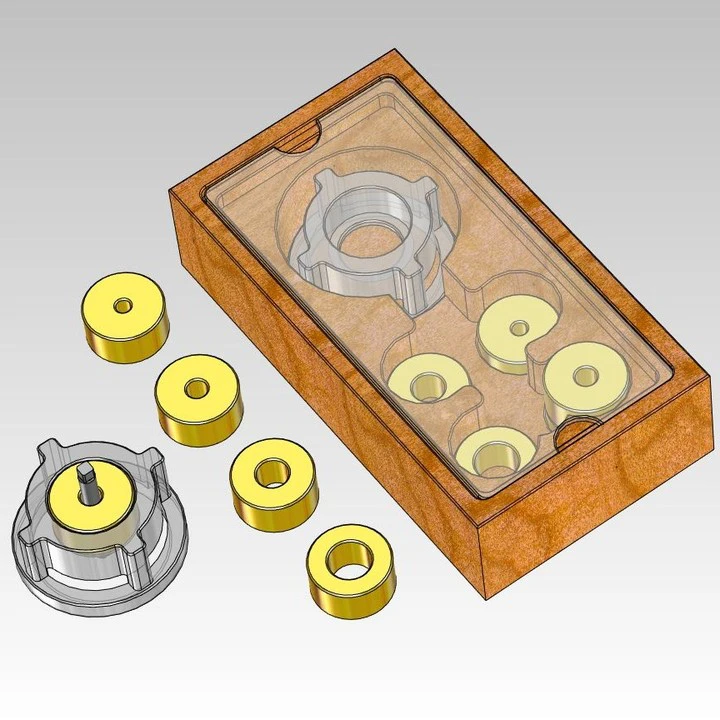

SprutCAM X for Developers is a set of APIs that enables the creation of custom applications for SprutCAM X through an open architecture, using widely-used programming languages. With it, you can automate intricate and repetitive tasks, integrate with third-party applications, and personalize the SprutCAM X interface to your liking, all in your preferred programming language.