Machine Tool Industry

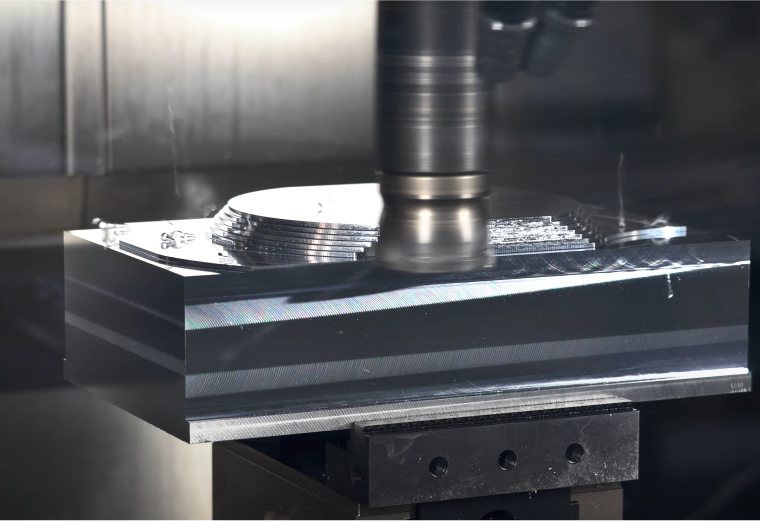

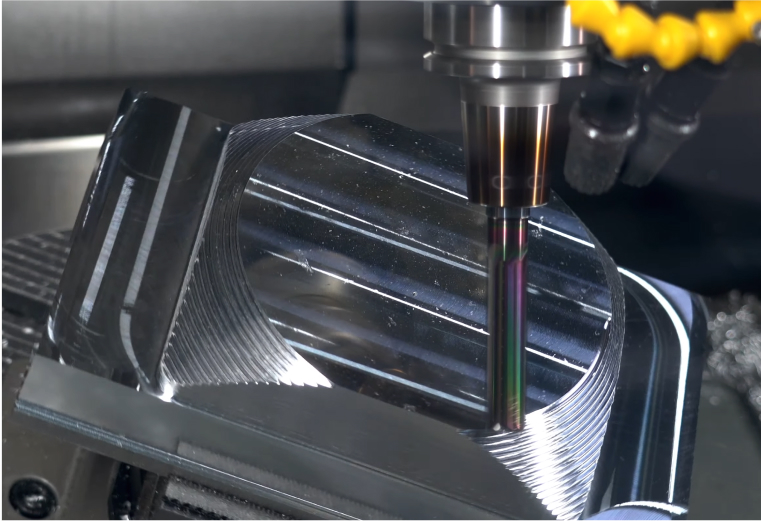

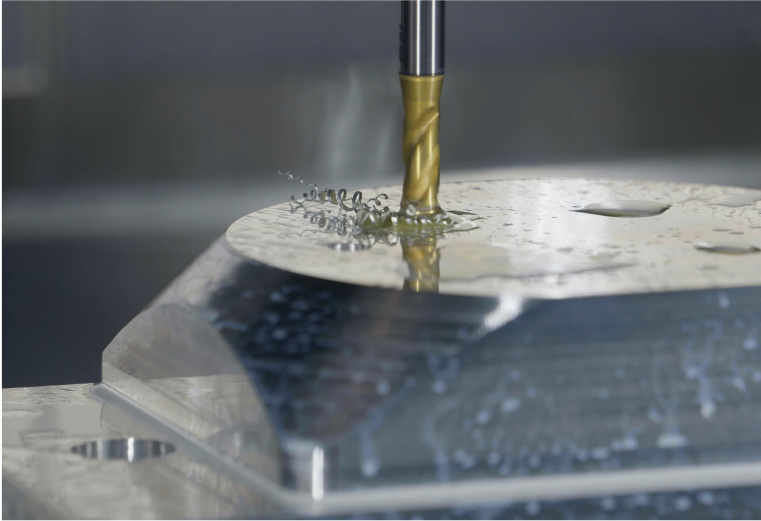

The Machine Tool Industry stands as a cornerstone of manufacturing, supplying the machinery necessary to shape and fabricate precision parts across sectors. This industry encompasses the design, production, and distribution of a vast array of machine tools, ranging from lathes and milling machines to CNC machining centers. As manufacturing becomes more intricate, the industry is embracing trends like advanced automation, IoT integration, and smart manufacturing. Innovative techniques such as additive manufacturing are reshaping traditional processes, while predictive maintenance and real-time monitoring optimize efficiency, reduce downtime, and enhance overall productivity.

Pioneering Technologies that Define the Industry

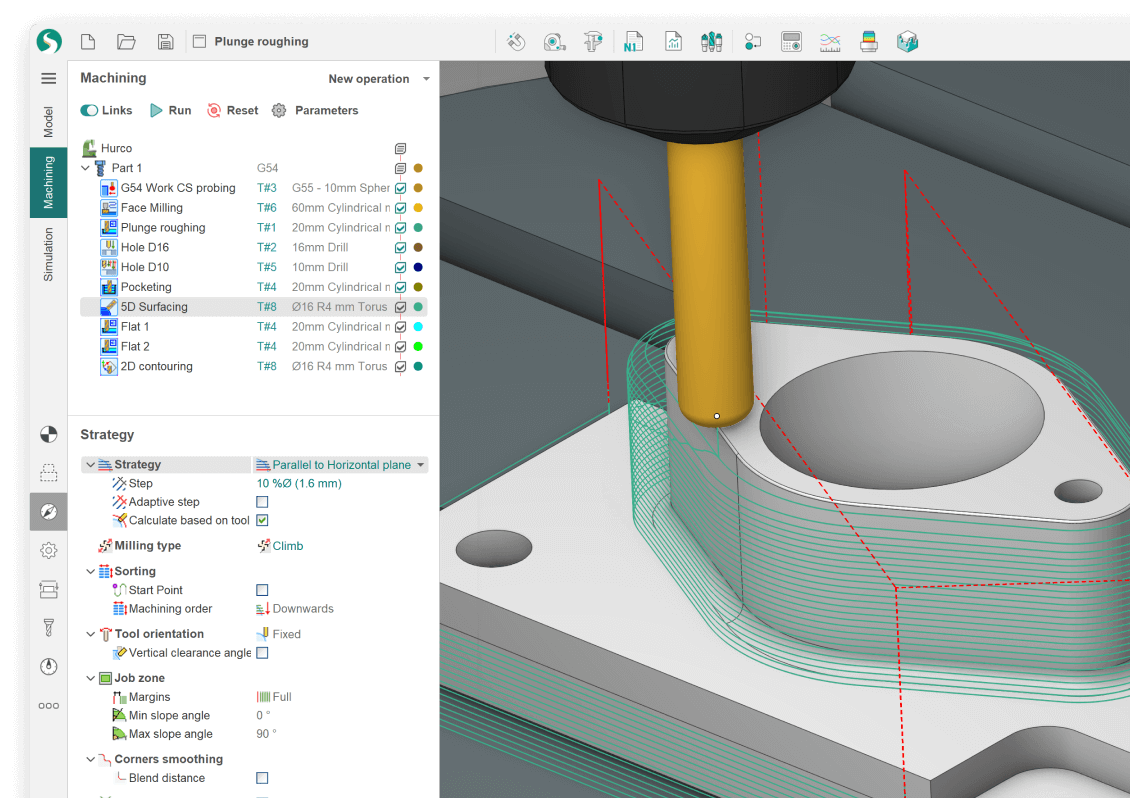

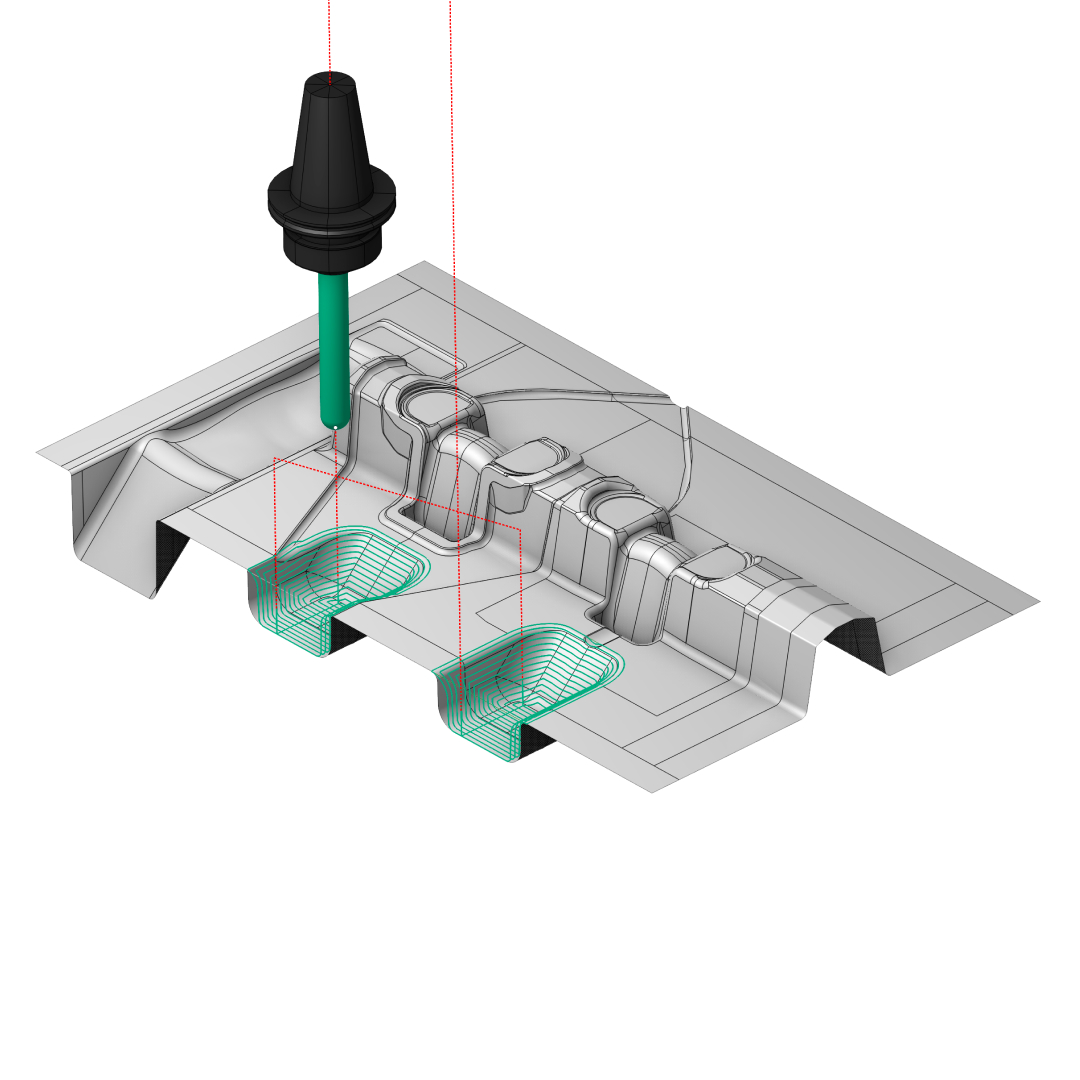

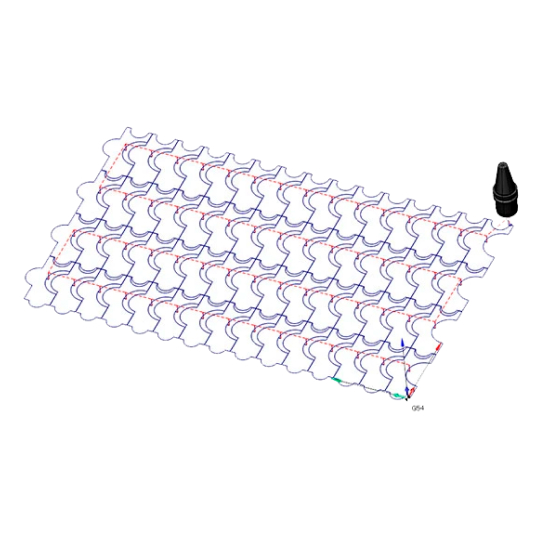

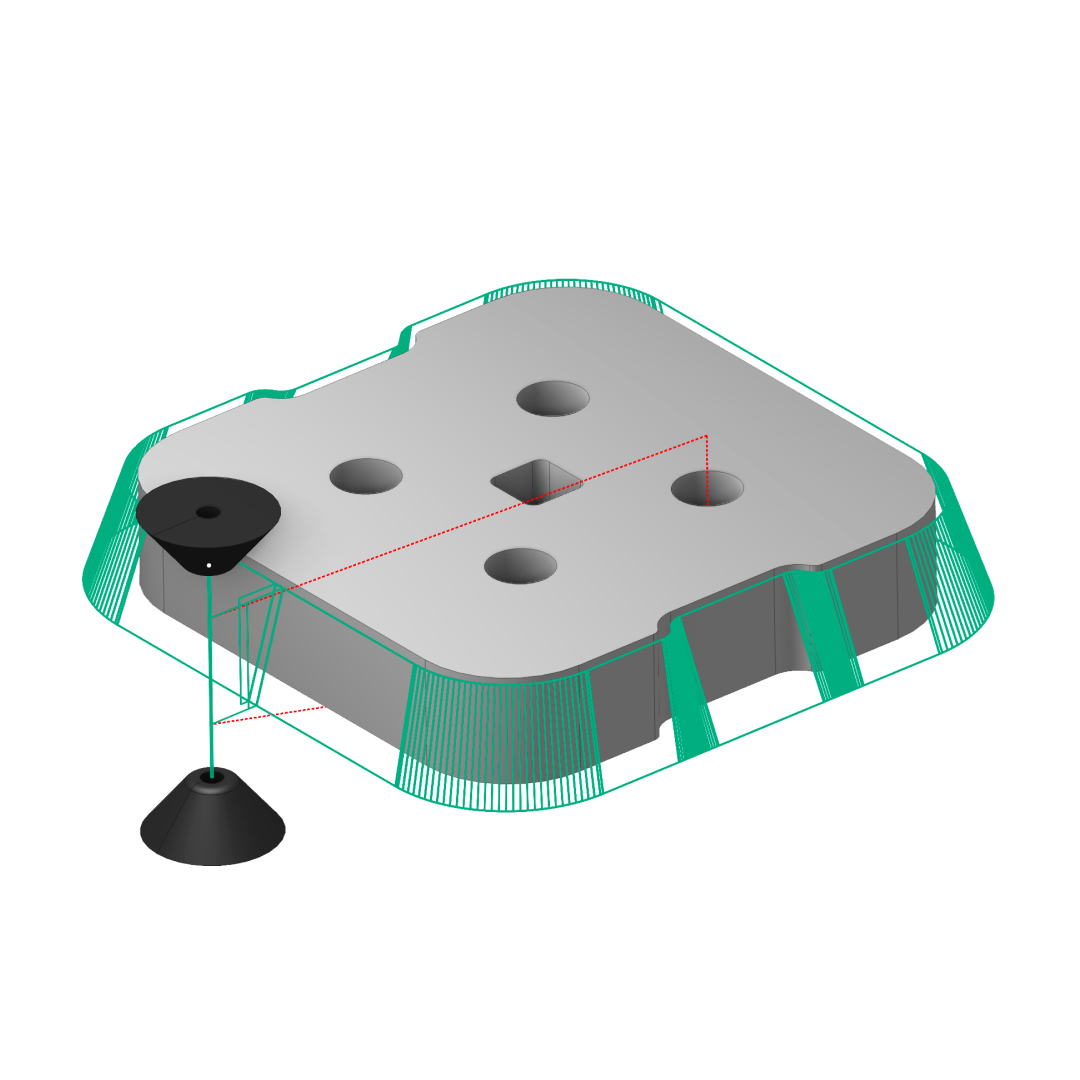

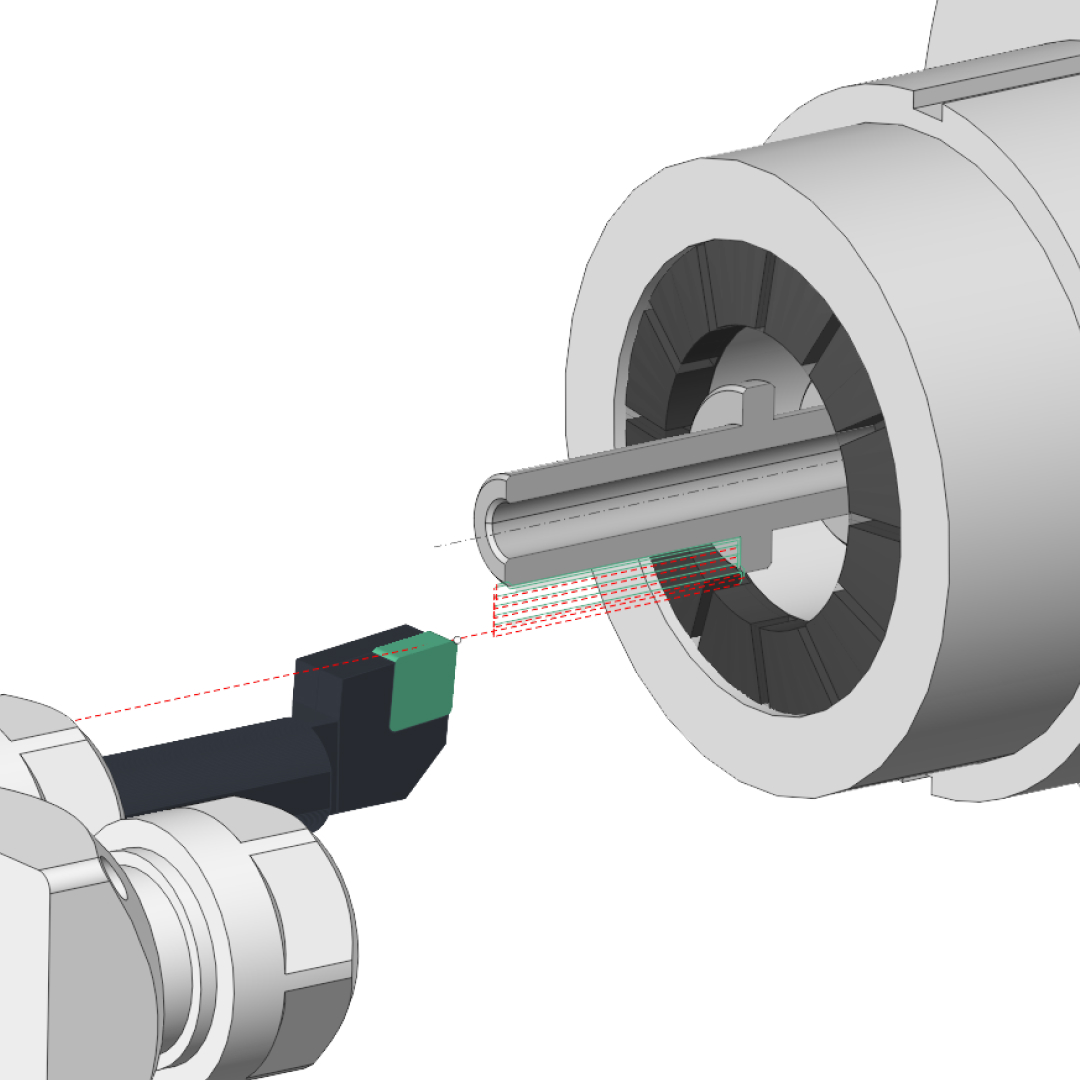

At the heart of the Machine Tool Industry lies an array of technologies that define its capabilities. CNC (Computer Numerical Control) systems drive precision and complexity in machining operations. Cutting tools, ranging from drills to end mills, ensure the accuracy of material removal. Advanced software, including CAD/CAM solutions, streamline design and programming, facilitating seamless production. Smart sensors and IoT connectivity enhance data-driven insights for predictive maintenance. Robotics and automation systems optimize processes, while 3D printing augments prototyping and customization. The integration of these technologies underscores the industry’s commitment to innovation and precision in modern manufacturing.

The world of CAD and CAM software continues to change with the end result of giving users more value and capabilities for less money. When I first used CAM software the cost was over .25 million for the system. With SprutCAM X, I could literally and figuratively cut circles around those first accomplishments in far less time. I have been pleasantly surprised to find that SprutCAM X not only has proven to be very reliable in its output, the value for the costs are outstanding. Every CAM system has its pros and cons, but I have found that SprutCAM X has very few cons which is a great accomplishment for all involved in its creation. Thanks.

Loyd May

WAYPOINT engineering