Die & Mold

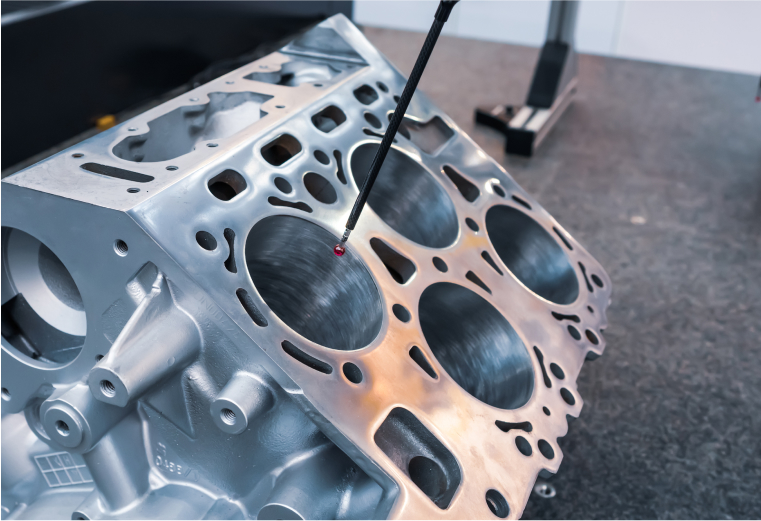

The Die & Mold industry is a cornerstone of modern manufacturing, responsible for creating the tools and dies that shape a multitude of products we use daily. Recent trends indicate a growing demand for precision and complexity, driven by sectors like aerospace, automotive, and consumer electronics. With the rise of automation and Industry 4.0 technologies, the need for quicker mold production and adaptability has surged.

Key Components & Technologies

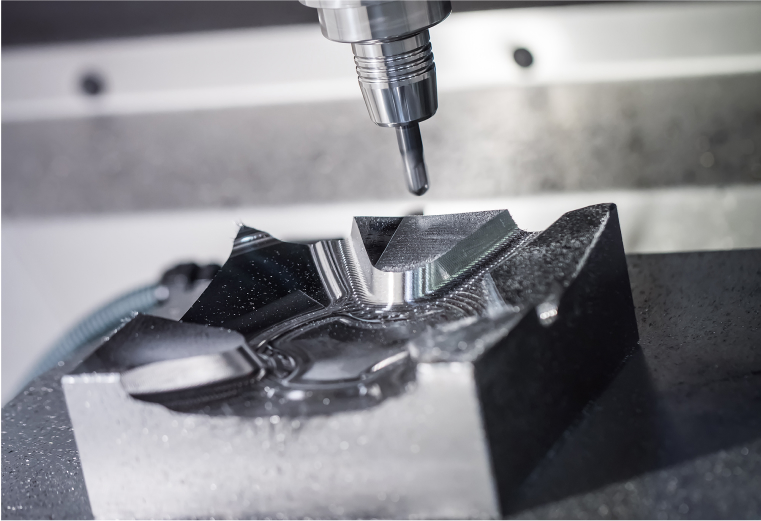

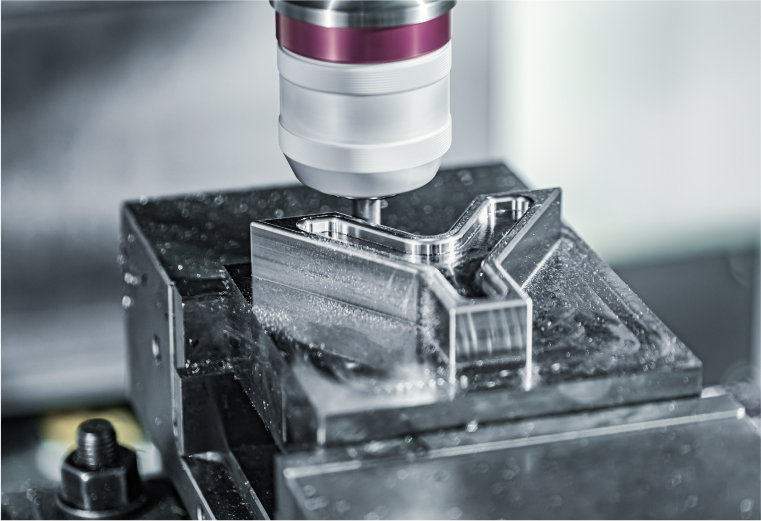

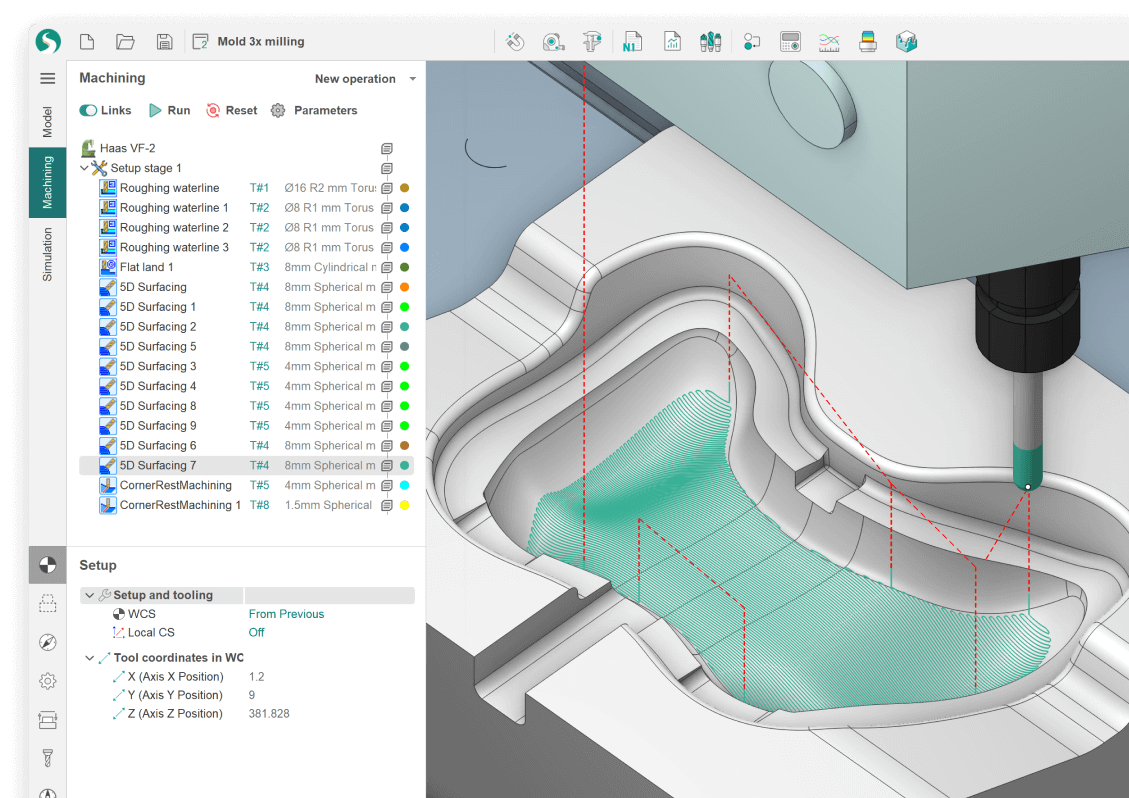

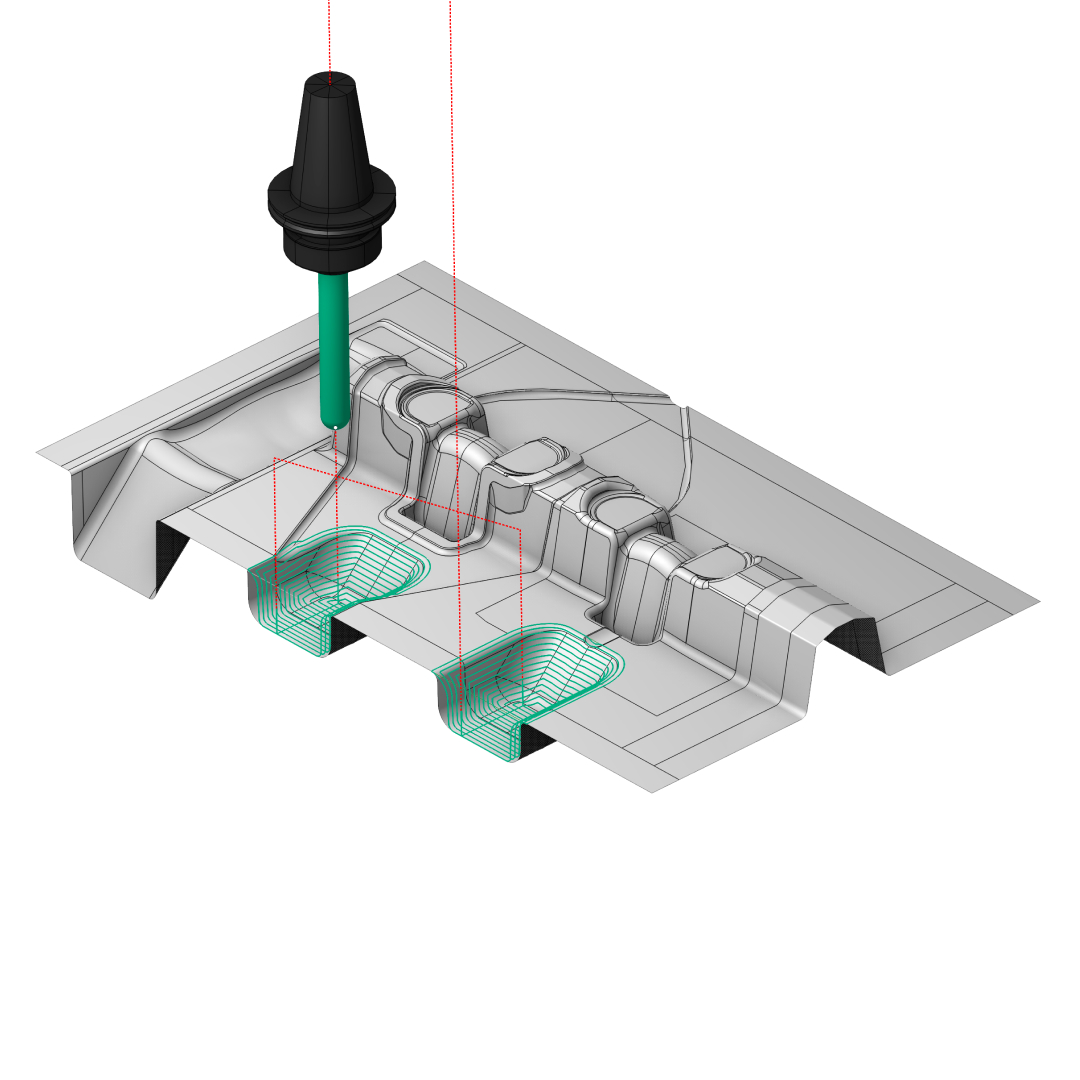

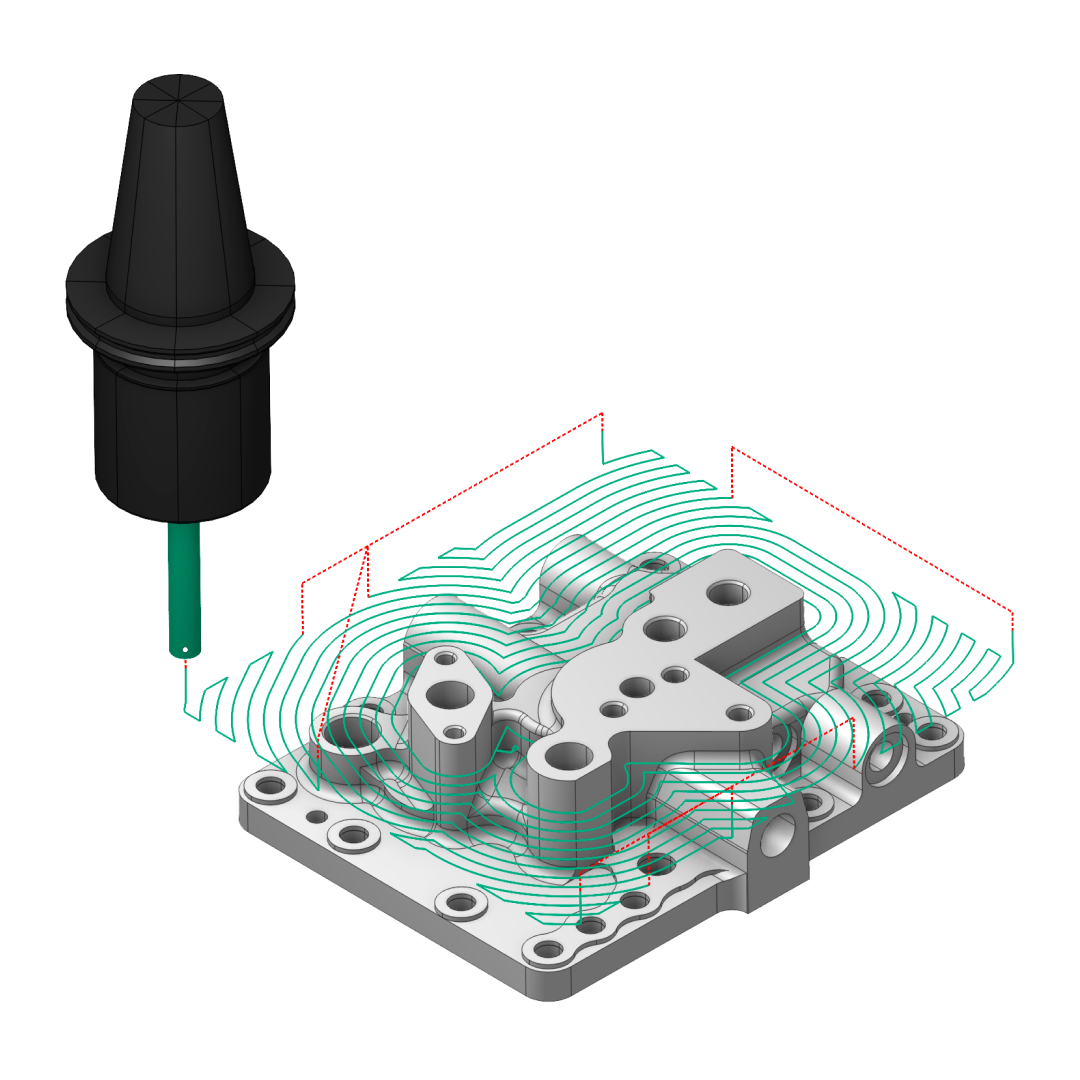

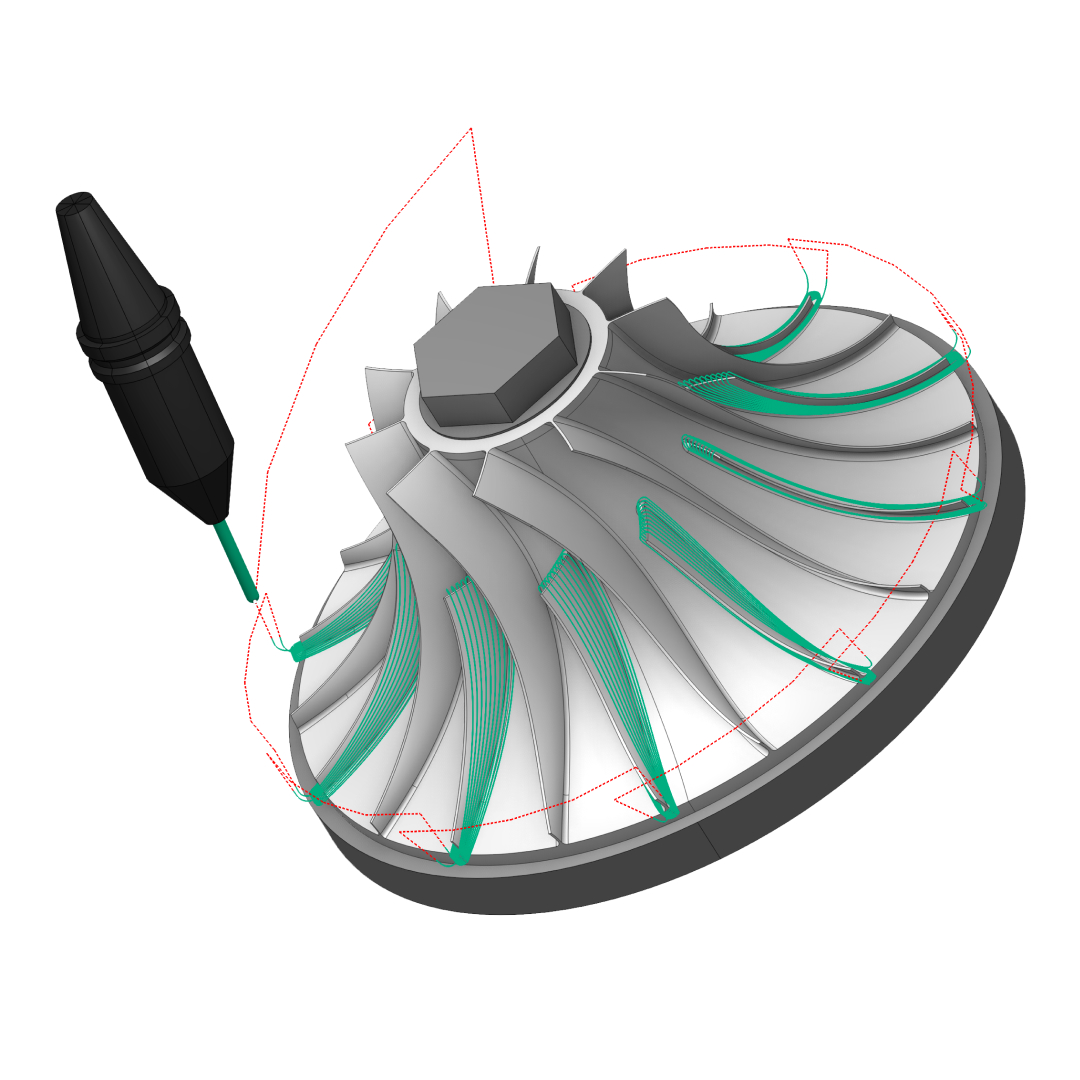

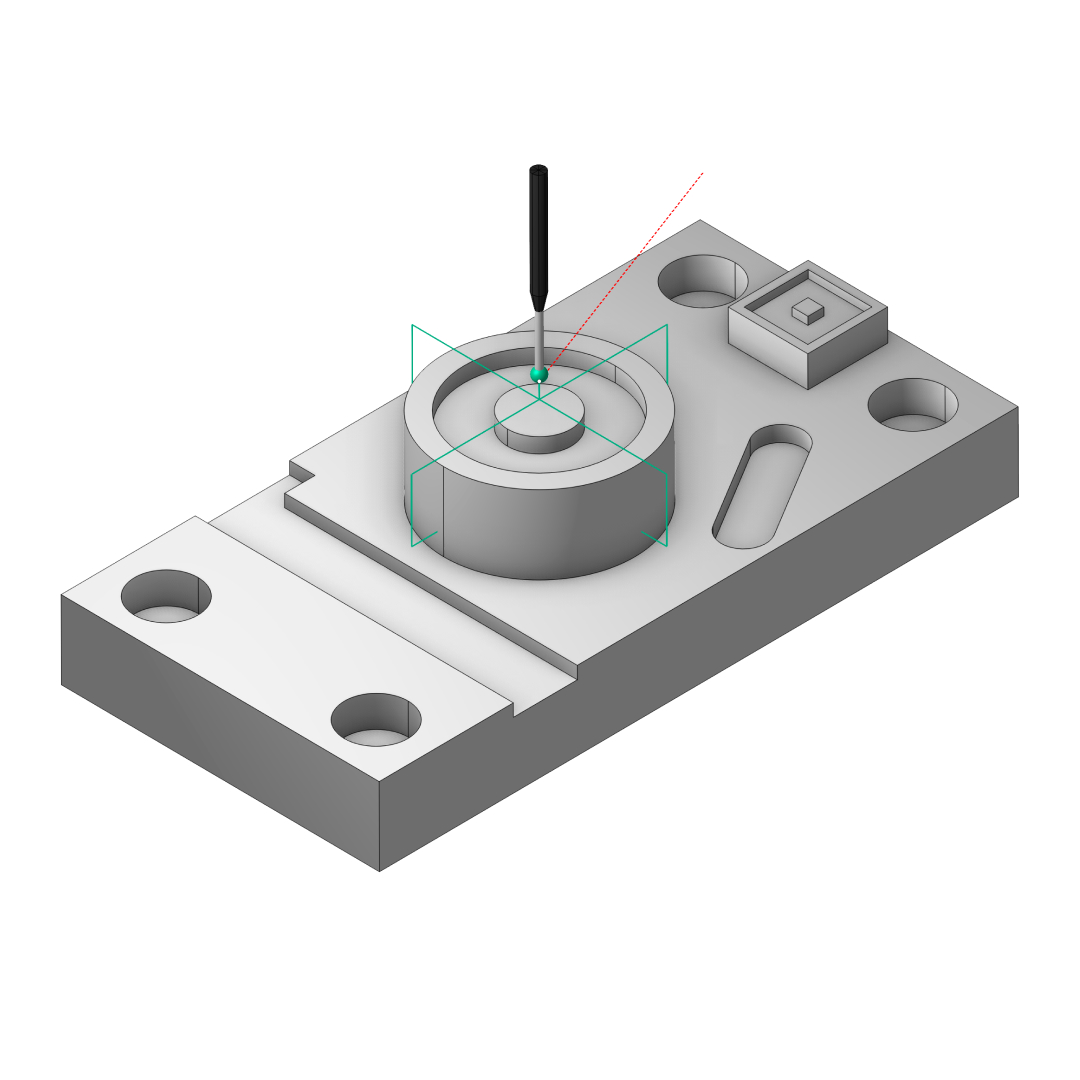

Intricate cavities, cores, and ejection mechanisms are quintessential parts in mold-making, requiring impeccable accuracy. Advanced Computer Numerical Control (CNC) machining, Electrical Discharge Machining (EDM), and 3D printing have emerged as vital technologies. Their ability to achieve tight tolerances and incorporate complex geometries solidifies their significance in today’s Die & Mold industry.

We had looked at several different 3D systems, but decided on SprutCAM X because of its ease of use. In fact, it is so easy that we didn’t require any formal training! In our line of business, which is the manufacture of specialized automation equipment, our designs are call for very complex 3D machining, and SprutCAM X has allowed us to do the work in-house, at a fraction of the cost of other systems we had looked.

Mr. John Roberts

TF Automations