Lathe project by roguetoolpath

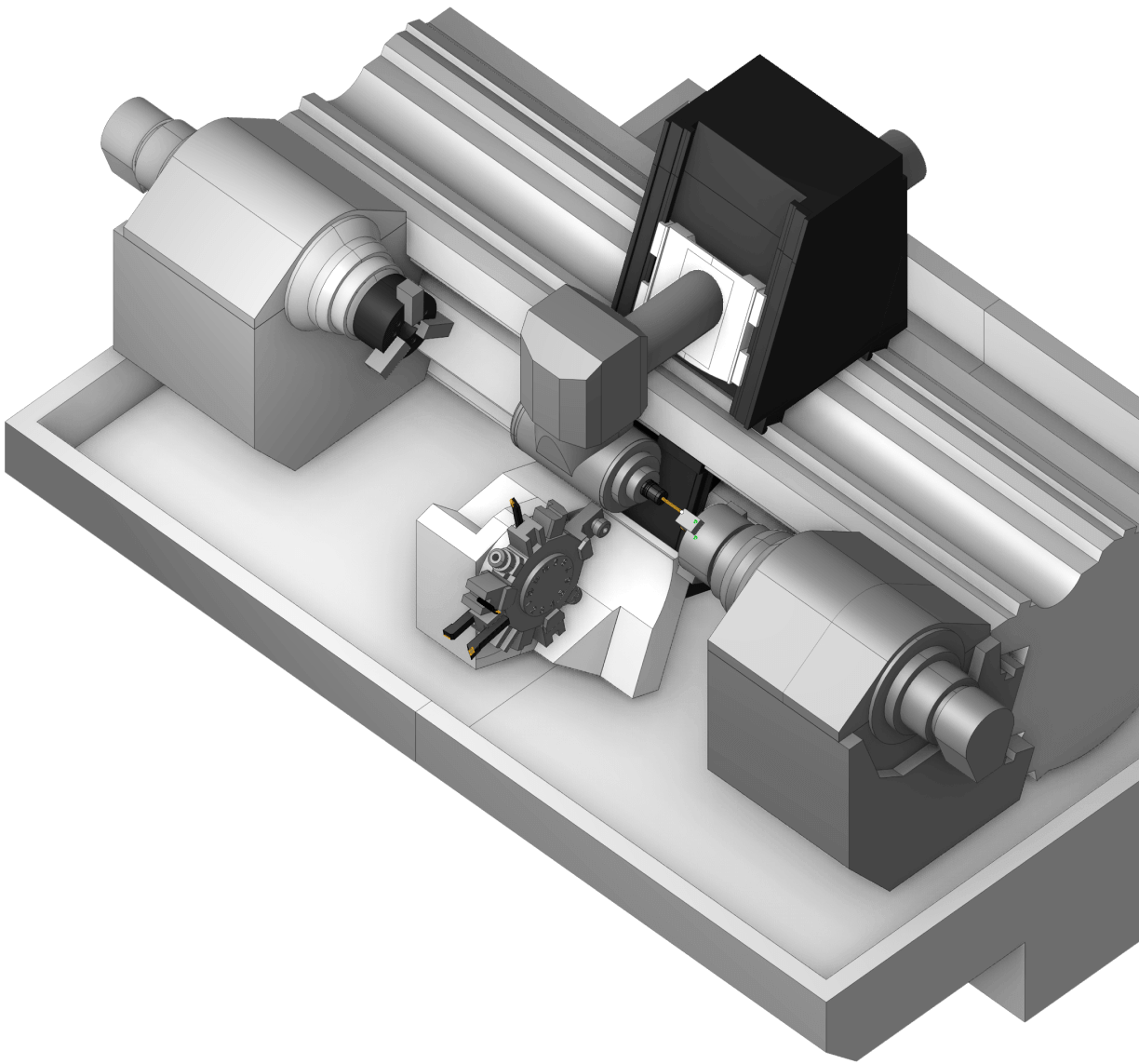

Do you like to play chess? We want to show you an amazing lathe project created by our customer roguetoolpath on a Tormach CNC machine. You can see what can be done by using lathe operation and just a piece of metal.

“Project for lathe to run now and then and make something cool at same time. A chess set design that can be made mostly with a lathe.”

“CNC lathes are often considered a solution in need of a problem! I must say I would find it hard to do anything like this without one.

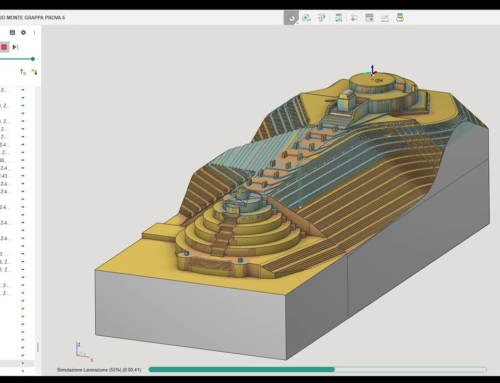

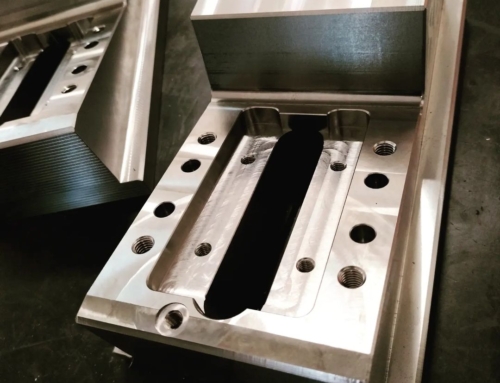

First set of pawns and rooks. Note finish and profile of rook on left. Default tool paths thinned out center area before finish of end and material flex effected the profile and finish. Easy to spot this problem if I had run the simulation. No problem to fix and control with different tool paths. Run simulation = less scrap – in this case anyway! Next 2 pictures show simple change. Back to the drawing board!”

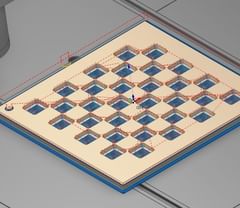

“Basic chess board design. Over the years I have made a few of these. They are labor and time intense project of glue up, cut and glue up again followed by surfacing and finish. Taking a page out of @laneymachinetech textbook Tuesday posted just a few days ago. Design for make ability :) chapter 1:3 Reduce number of parts by 32+! Then leverage the precision of cnc tools to perform most of the work. Shown is the board made from 1 piece or slab. Cnc Router is then used to mill out inlays for the squares. The 32 inlay squares are also milled out on cnc router to correct size and tolerance for a press fit or whatever you desire. Using this strategy, I can then make a wide range of boards if desired, using a wide range of wood, plastic, and metal materials. Chess piece storage can also be designed in same style. In this case it gives projects a handmade look, that I can’t do with my hands. The very reason I use cnc tools.”

Please, see the whole project on roguetoolpath Instagram page.

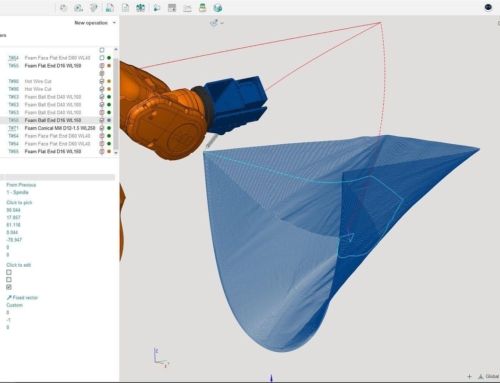

You can find out more about SprutCAM and how our customers use it on this page.