Making 3D Neptune with SprutCAM X

Scanning in 3D: Neptune

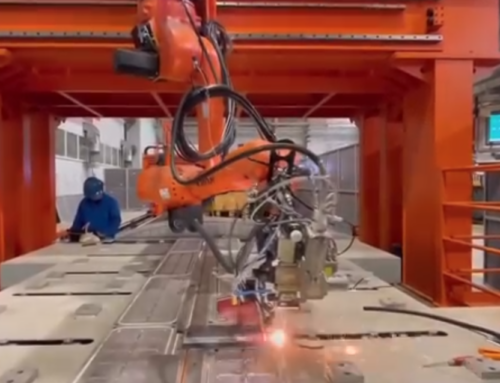

Robots are often disvalued in manufacturing circles as being inaccurate. This is despite the fact that precise and reliable cutting is not often used to describe industrial robot arms. Robots are capable of much more than just welding or pick and place applications. Robots are often dismissed as only suitable for welding or pick and place applications.

With improved initial accuracy and calibration methods robots are no longer uncommon in machining-type applications. As the level of robot technology increases, new applications for robots in manufacturing are constantly being created. Robots are now being addressed for tasks once thought to only be capable of being performed by CNC machines. In response to the emergence of new mechanical challenges, software solutions are being developed to enhance control and efficiency in automation. While CNC operations have plenty of established software suites for programming, robot operators have often relied on manual teaching of robot movement. Manual teach methods are often time-consuming and inaccurate. Off-line programming is a faster way of producing robot trajectories. Robot path programming can occur on a computer, while the robot can continue to operate with a current program. Off-line programming is not a novel idea; robot simulations have been available for decades. What is currently becoming available is new software with features that can take advantage of improved robot features, such as the production of robot trajectories from CAD/CAM data.

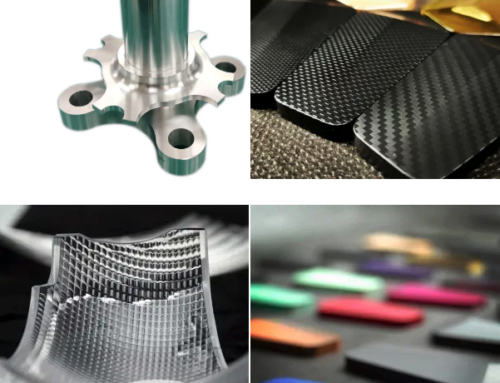

Project details:

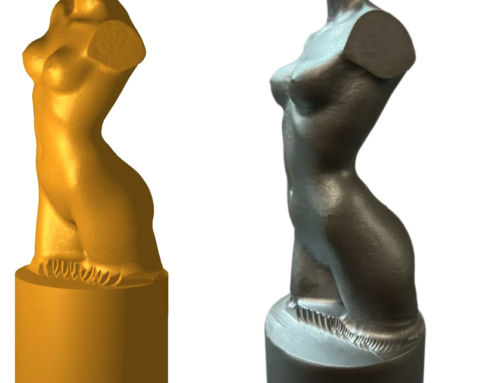

Original 50cm figure made of resin and painted with glossy paint. The aim is to make a copy in polystyrene (porex) 3.5 metres high.

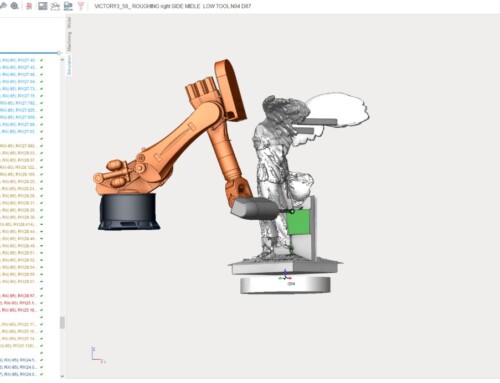

The mesh generated after scanning has been processed by modifying some parts to suit the customer’s tastes and then split into several parts to facilitate fabrication.

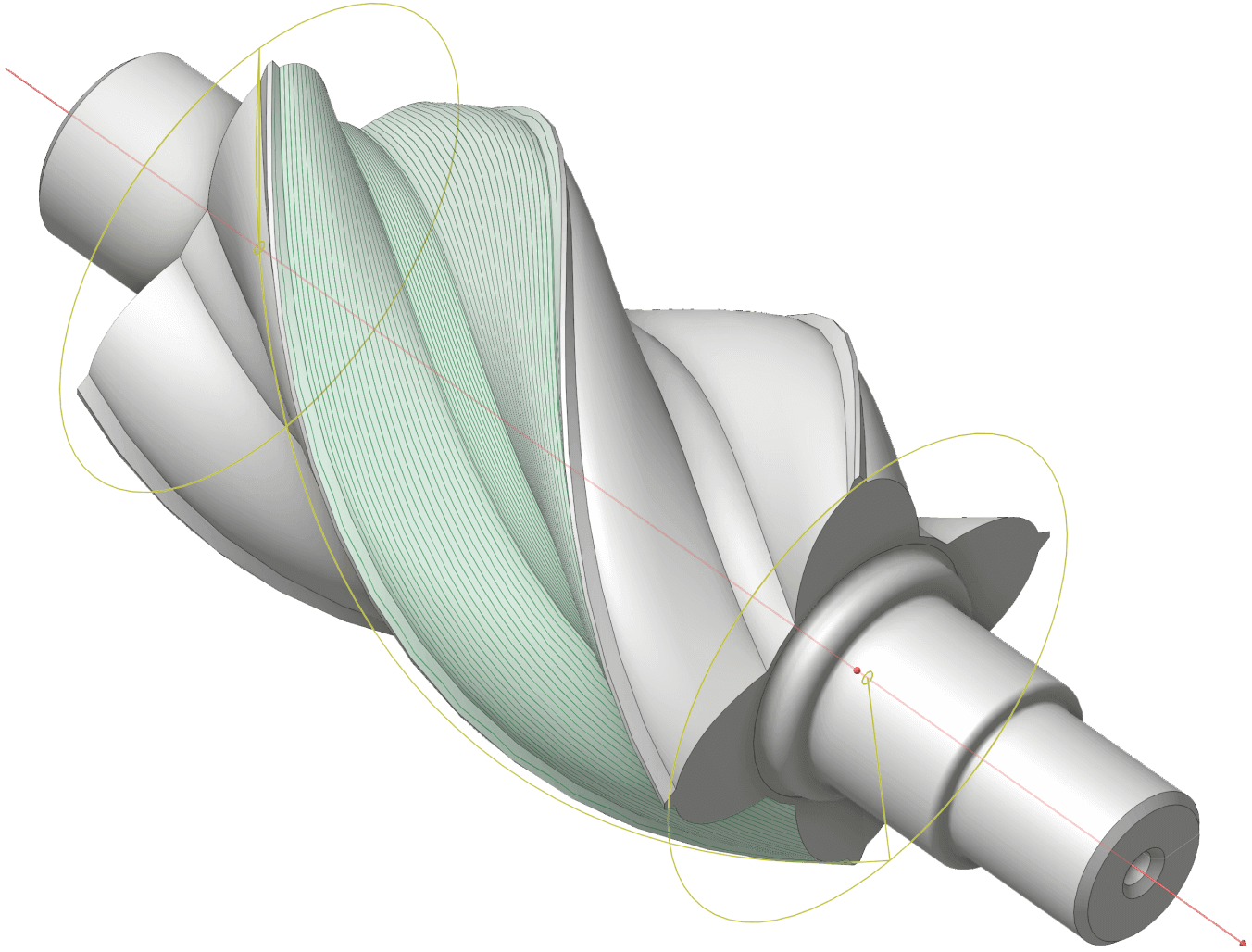

With SprutCAM Robot, the paths have been programmed to produce each part with a milling robot.

The resources savings obtained by SprutCAM software provide new economically efficient robotic solutions. The use of SprutCAM software significantly reduces barriers such as programming time, thus enabling companies to integrate robotic solutions into their processes with greater confidence. Employees already experienced with programming CNC machines t can be educated to operate a robot in a same way. Those without prior CAD/CAM experience can take special SprutCAM training. Expert-level robot operation requires years of experience, but SprutCAM offers great increase in productivity, reducing the need for operators to program the robot manually.