SprutCAM X Robot cuts cycle times by 50%

Villeroy & Boch, founded in 1748, needed a CAM system for offline programming of a robotic cell for finishing bathtubs. The German manufacturer chose SprutCAM X Robot. As a result, cycle times for the company’s most complex products were cut in half.

Villeroy & Boch bathtubs are bulky, yet sophisticated products that require a high degree of precision and care in finishing. That is why SprutCAM X Robot was the right choice. The company liked the perfect price-performance ratio, state-of-the-art simulation, which is very important for the company’s fine products, and the functionality of the axis map feature.

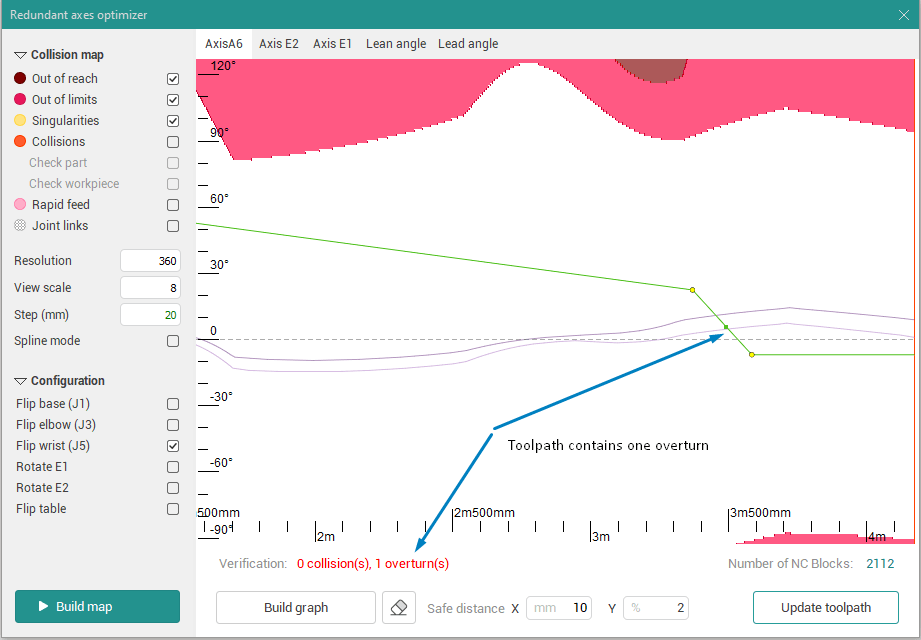

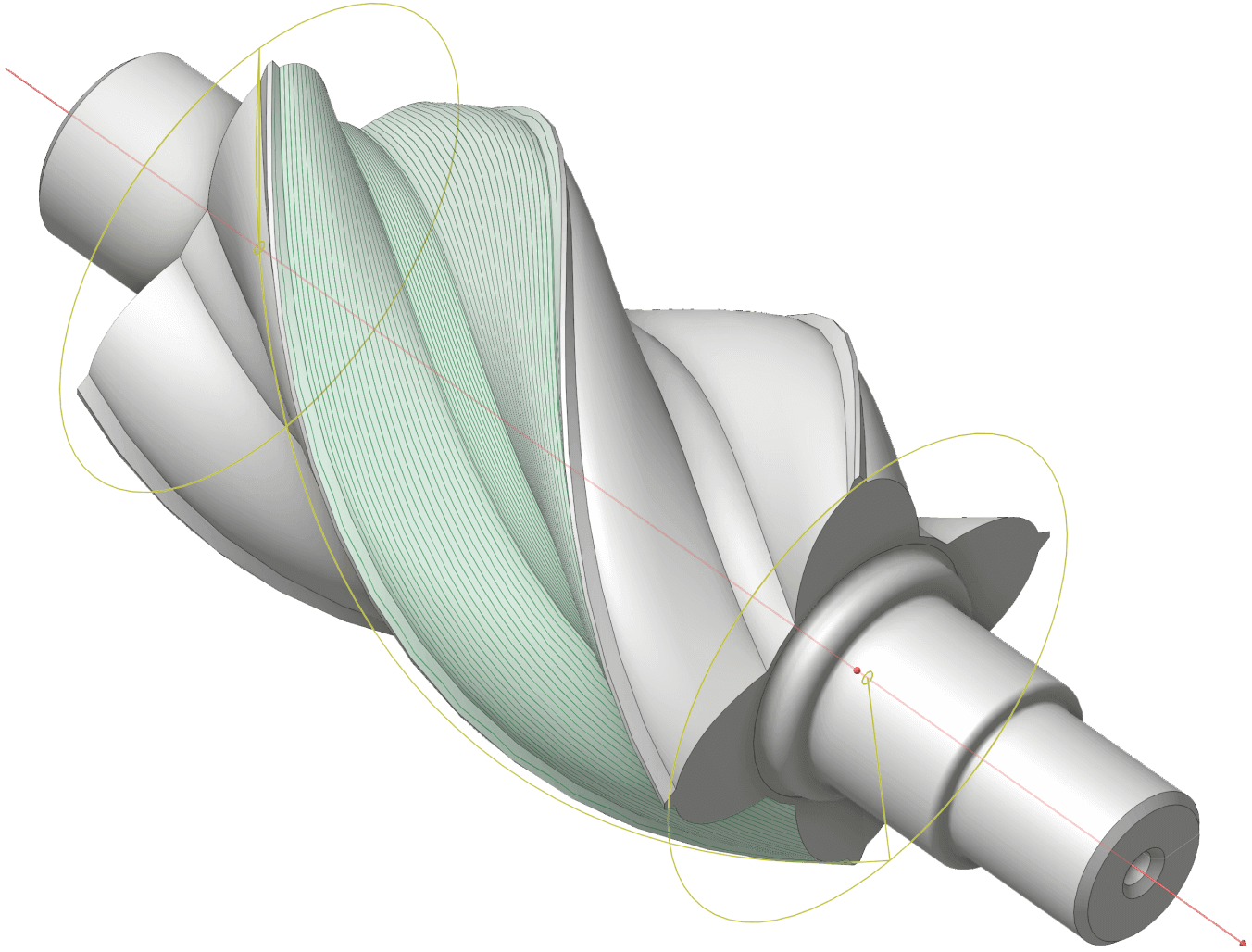

Robot Axis Map function enables manually setting and fine-tuning the automatic control rules for the excessive degrees of freedom of a robot (the 6th axis, the rail axes, the rotary table axes).

It was also very important for Villeroy&Boch that CNC Solutions, our partner in Belgium, acted as a one-stop shop, providing the robotic cell, the CAM system for Offline Programming, the post processor and the digital twin of the robotic cell as a turnkey solution.

Here is the customer’s testimonial in detail:

Jan van Vooren, Process Engineer Villeroy&Boch.

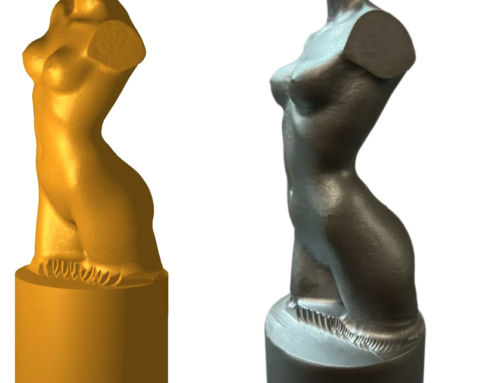

“We used to need 3-5 days development time for our most complex projects, with SprutCAM X we can completely finish the process in one day.”

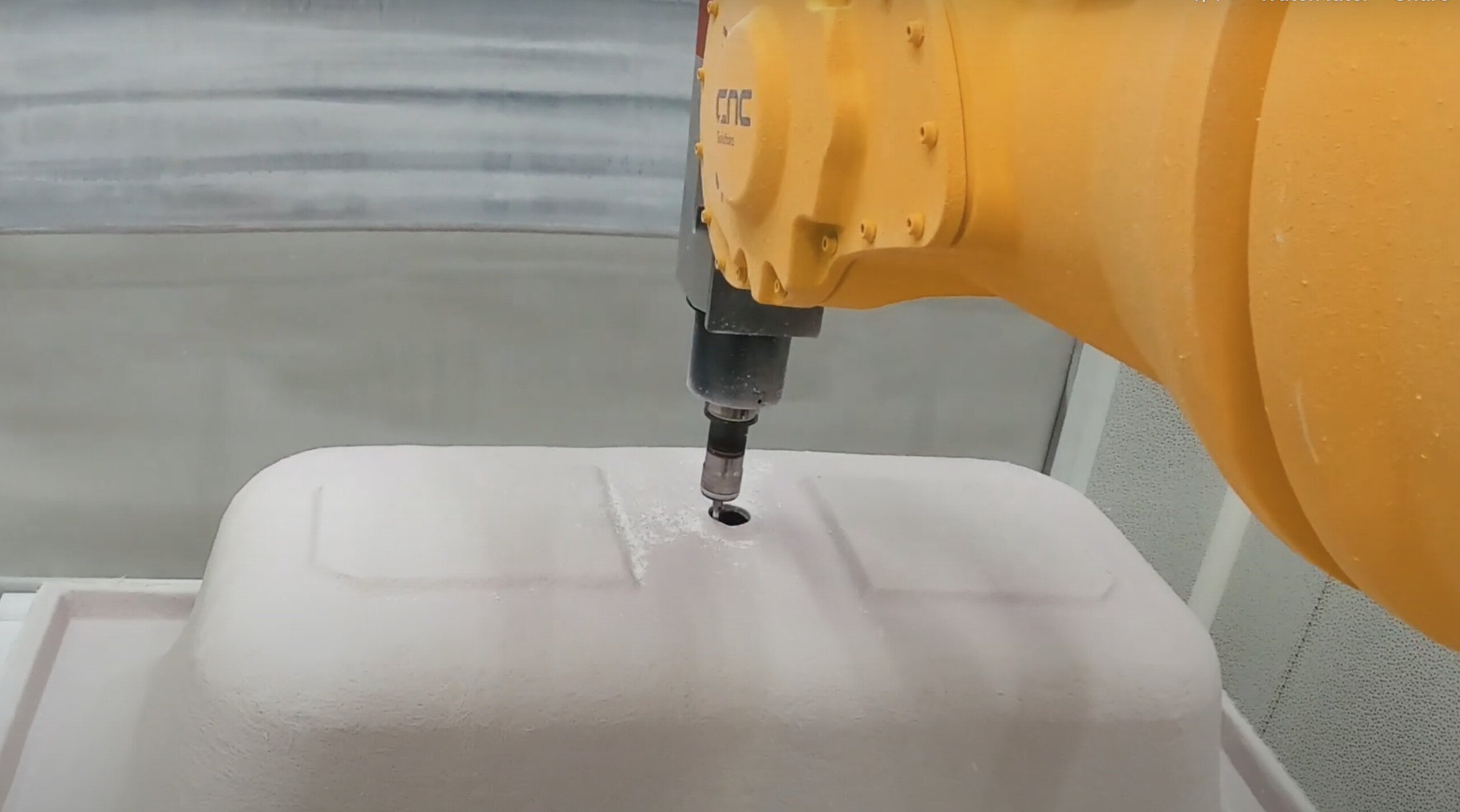

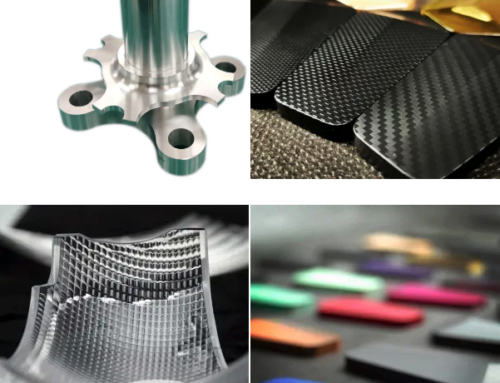

“We use SprutCAM X for the final treatment of the baths when we mill the openings for drains and overflow in various sizes.”

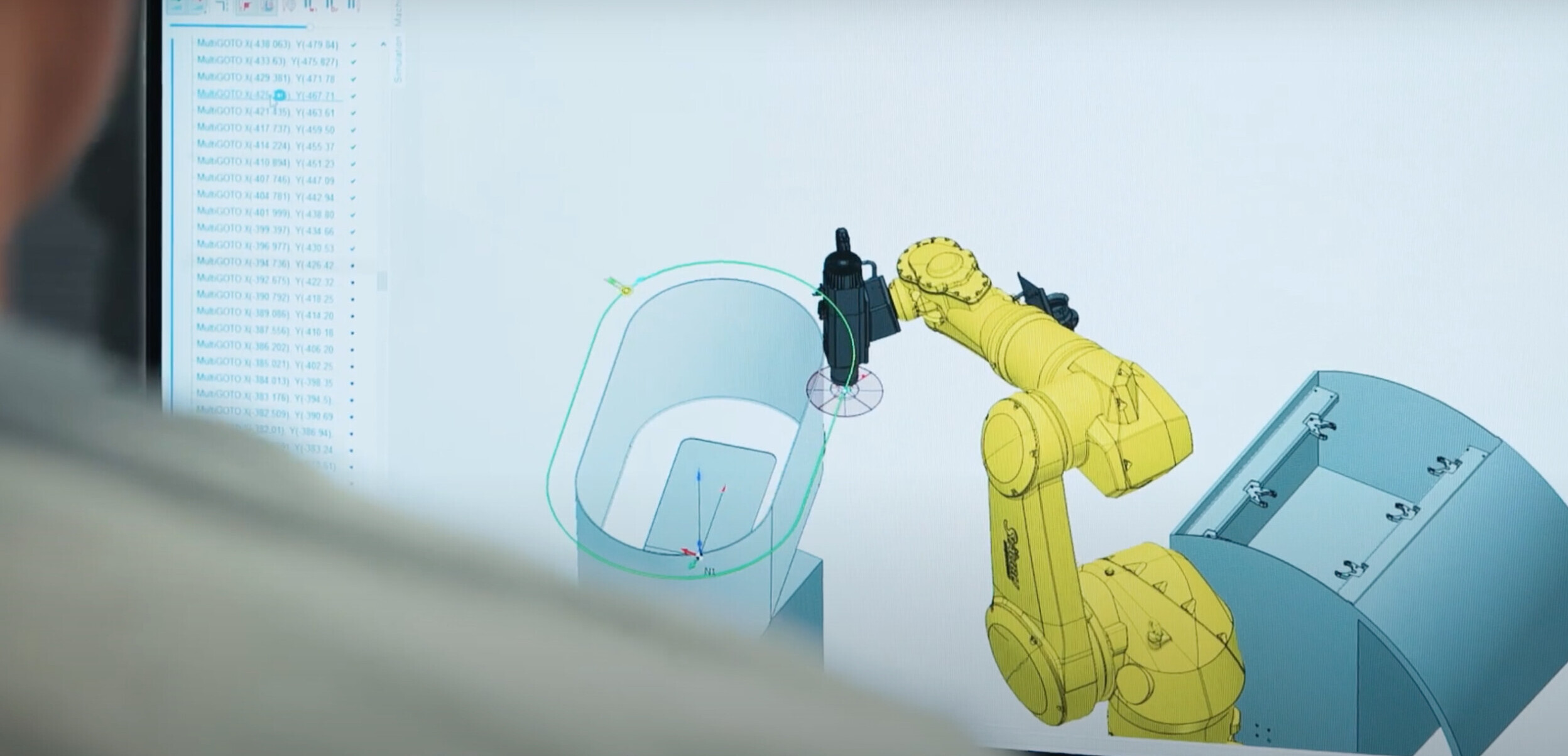

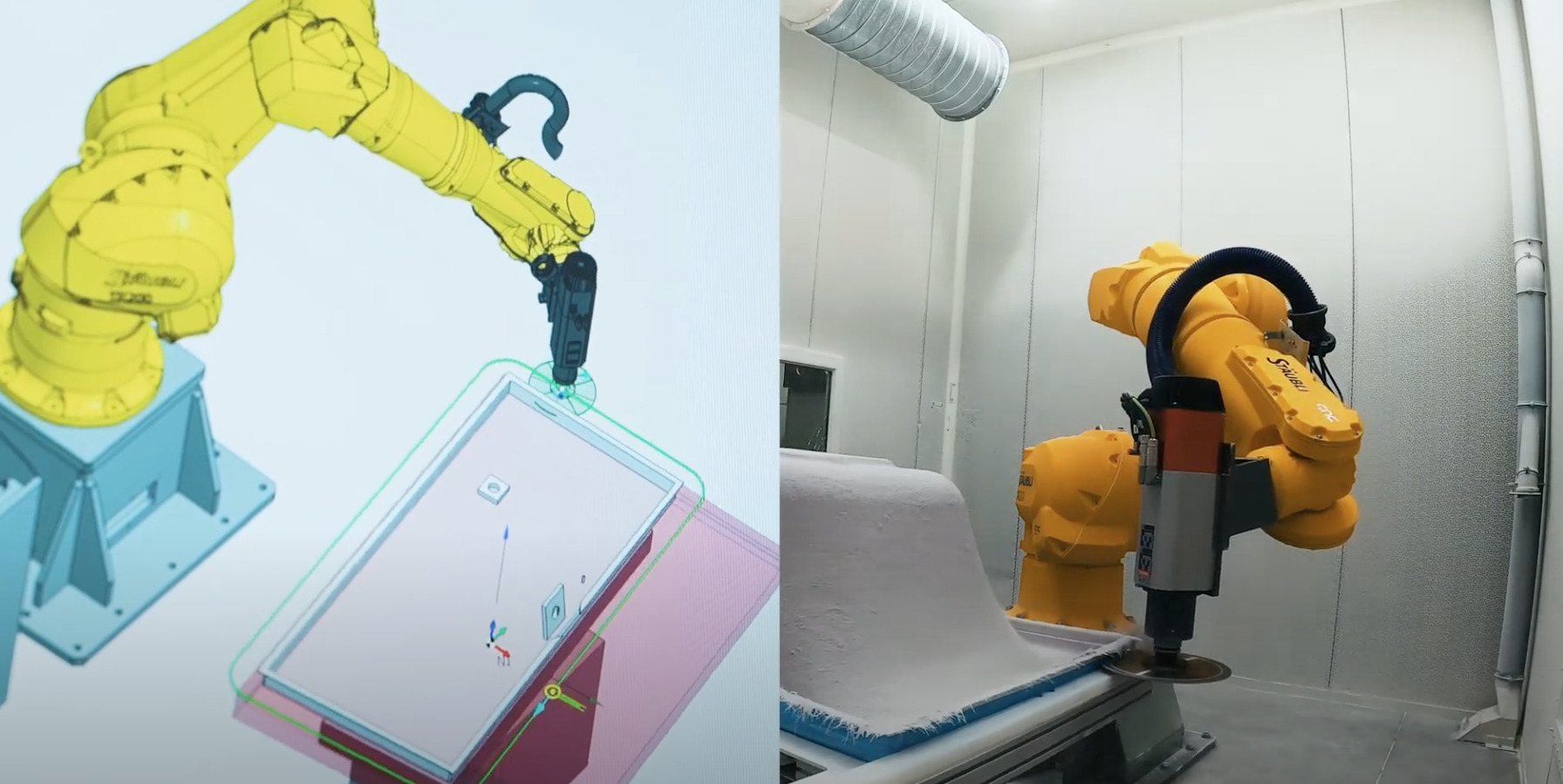

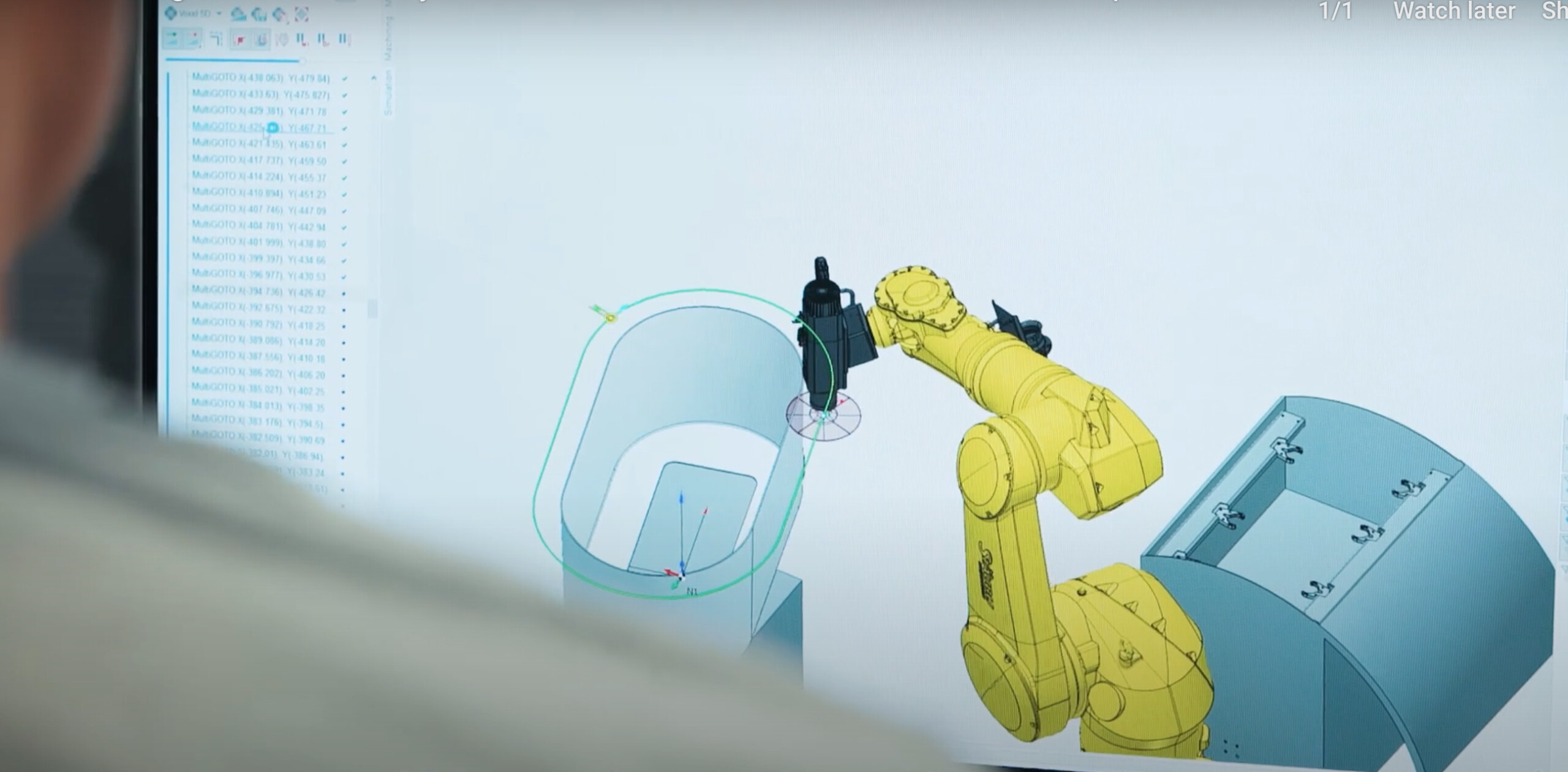

SprutCAM X enables us to develop programs for the robot. First I upload the drawing of our own robots into SprutCAM X. Then I select certain contours or openings. Then I can apply milling operations on those contours and openings.

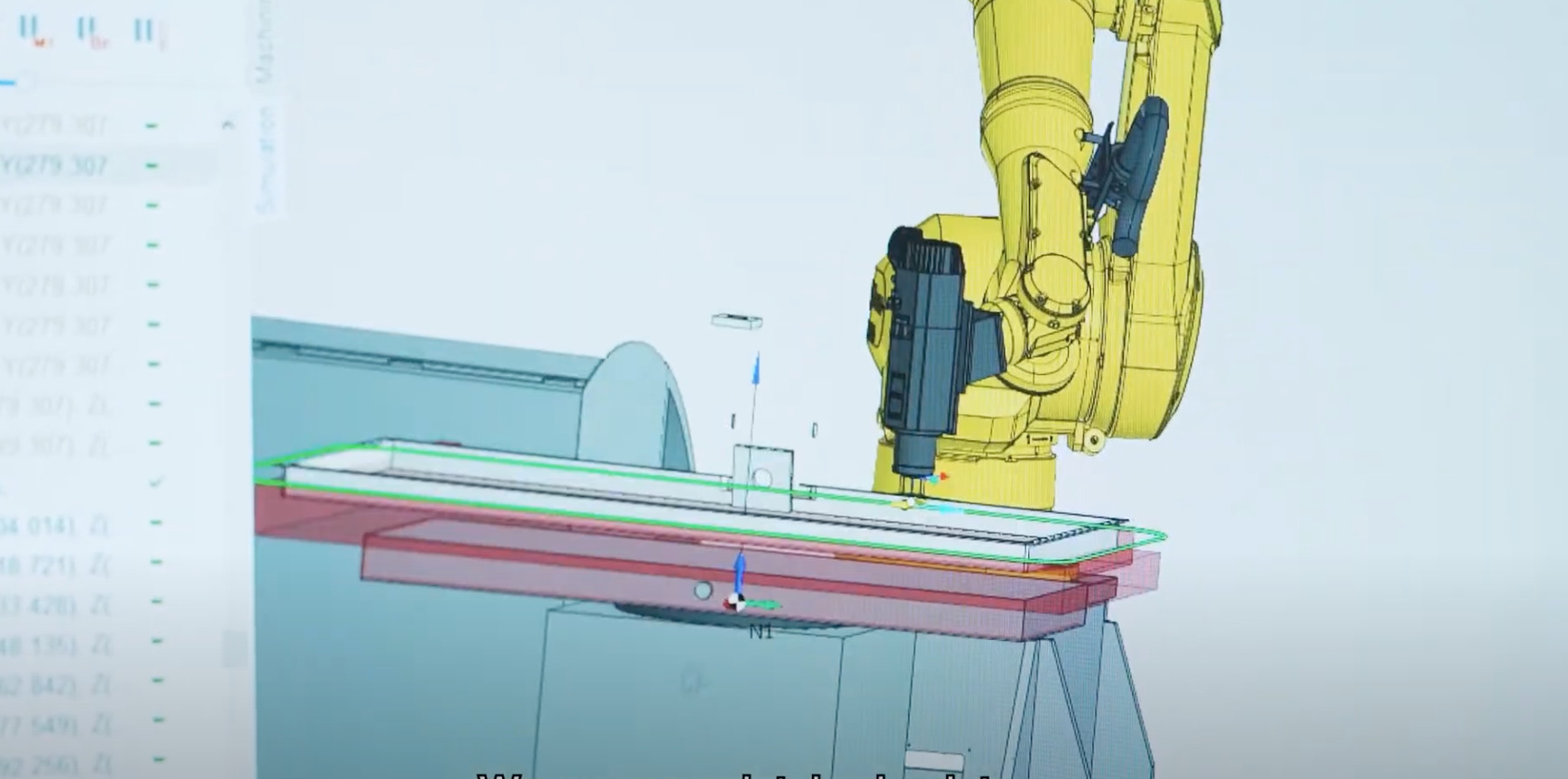

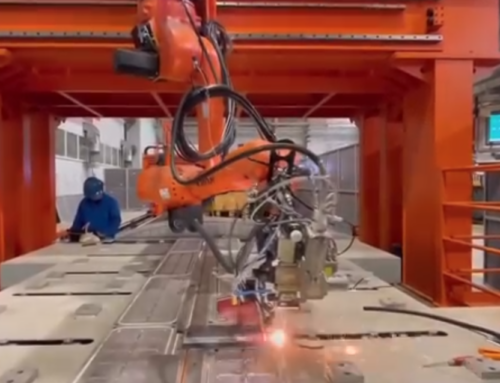

We can completely simulate the program in such a way that both the robot cell and our robot are outlined. Our product then runs along. Afterwards a post processor translates the trajectories in machine code which can then be executed by the robot.

CNC solutions provided the complete turnkey solution consisting of:

- Staübli robot

- Electric control cabinet

- Robot foot

- Milling motor

- Controls

And of course, SprutCAM X Robot all together with the post processor, digital twin of the robotic cell.

See the gallery below: