SprutCAM X for mold and die manufacturing: MCT S.r.l, Italy

Here is a story about the Italian company MCT using SprutCAM X CAM software for mold and die manufacturing.

Daniela Actis Dato, general manager:

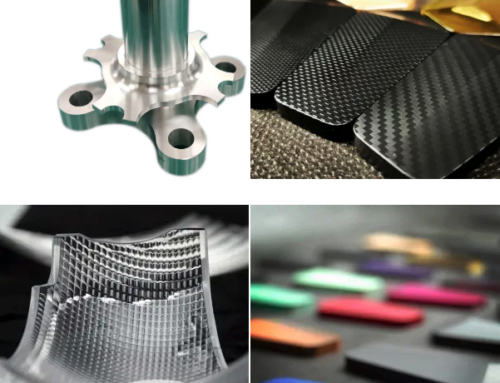

MCT was founded in 1994 and it was an individual company. Now MCT is a company with 34 employees and now the owners are me and my brother. These are our products. We make products for the medical, for electronic parts, for safety, passive safety and also for sports. Our goal is to satisfy customers. Our main customers are Impeco, Matica and Brother that make printers and Panini that makes money counters.

Silvio Scapino, production planner:

The core business of MCT is injection and molding of the parts, of plastic parts, but also we allow to give the service to the customer to the assembly of the plastic parts. This is the kind of two assembly process and also we have to program the parts in according to the customer with the tools that are certificated every year. Quality is mandatory, and to allow us to have a good quality, we have to start with the production, with the mass production, only if we have a Green Dot from the quality department.

So the first is the identification of the raw material with the label, so you can see in our Warehouse if we have the raw material adapted to the requirement of the customer and so we very quickly prepare the tools for the production time. Environment for us is to be sure that the parts that we have to produce also produce a waste of the parts. So to be sure that these parts are also recycled, we have to divide in different kinds of raw material the waste of the parts.

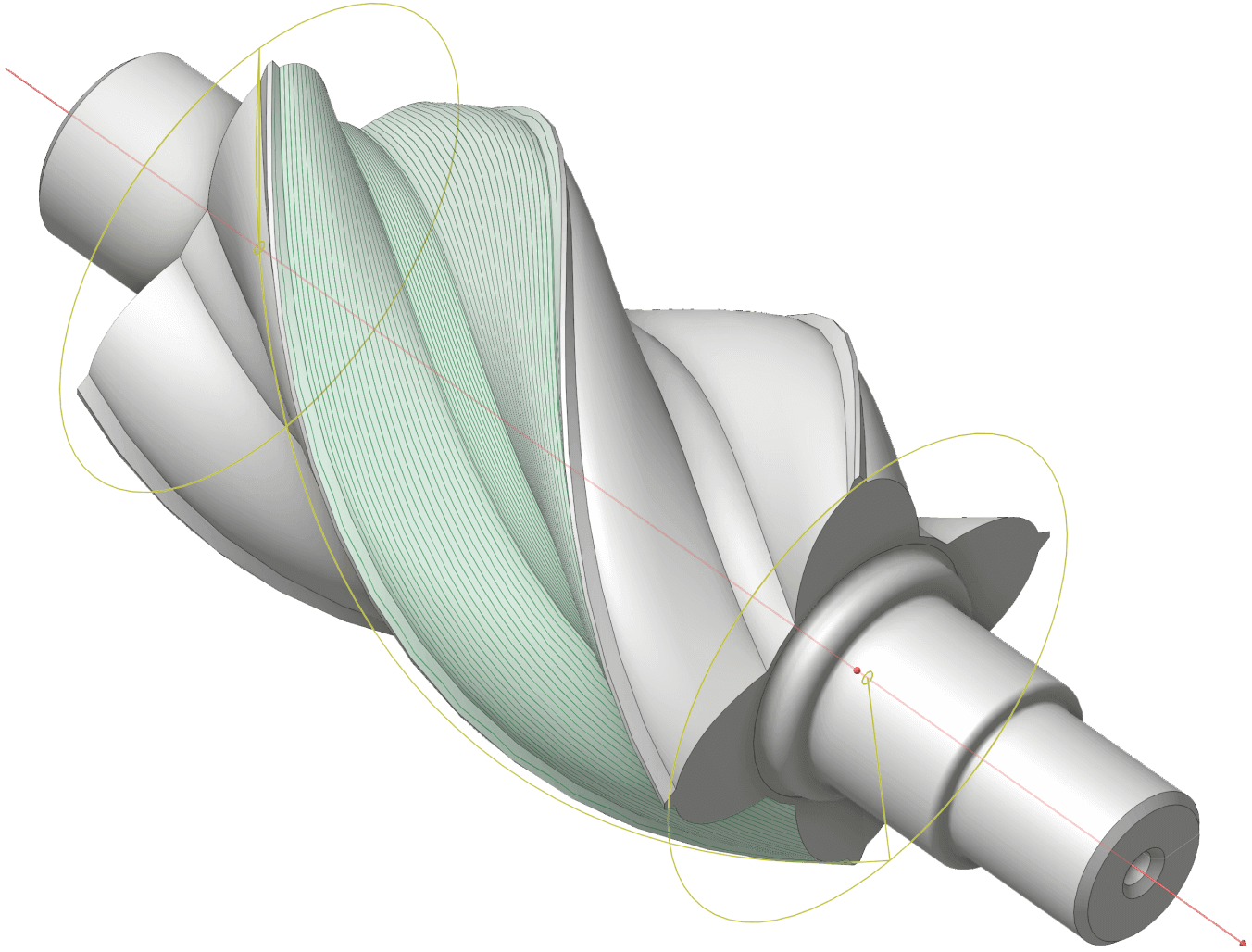

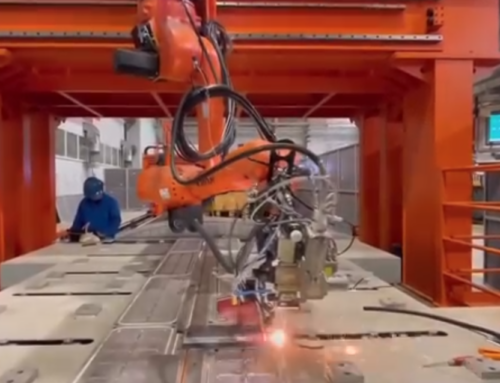

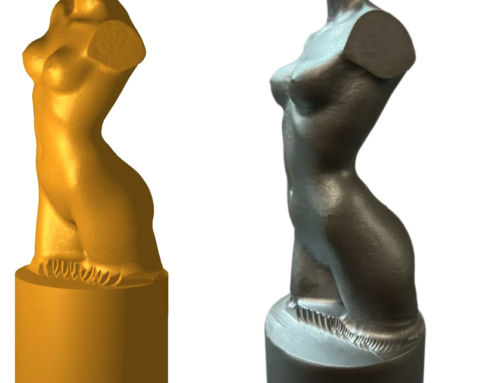

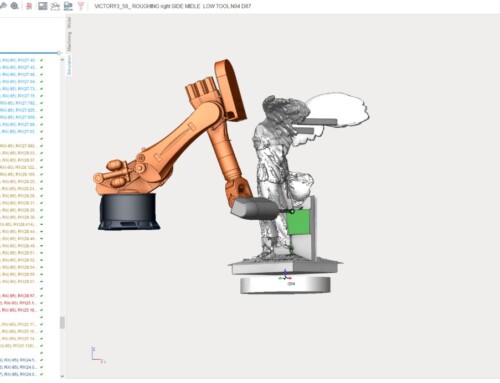

Andrea Manzo, Technical product manager: We got SprutCAM eight years ago. Our supplier for SprutCAM is Sintesi. We use SprutCAM for making the program for our machine in the workshop, so we have Makino and Haas and Okuma and the language of all the machines is Fanuc. This machine is a Makino and we use it to work the base mold. This is a wire machine, we use SprutCAM also with this machine. With this machine we cut all steel hardened.

Livio Pettiti, Sintesi:

First of all we thank very much the MCT team for the Trust In Sintesi. We are working with this company since maybe 15 years, maybe more. So they have followed us in all this time. Now they are using three SprutCAM seats and I believe that they are very satisfied of the products and also of our support.

CAM software for mold and die manufacturing: SprutCAM X

Livio Pettiti, Sintesi, SprutCAM X dealer in Italy

Here you can watch the video version of this story:

If you are looking forward to learn more how CAM software for mold and die manufacturing is working, you can check out a case from Greece here. We also have a dedicated page for Mold and Die which you can check out here.