Adaptive CNC milling by SinteSi

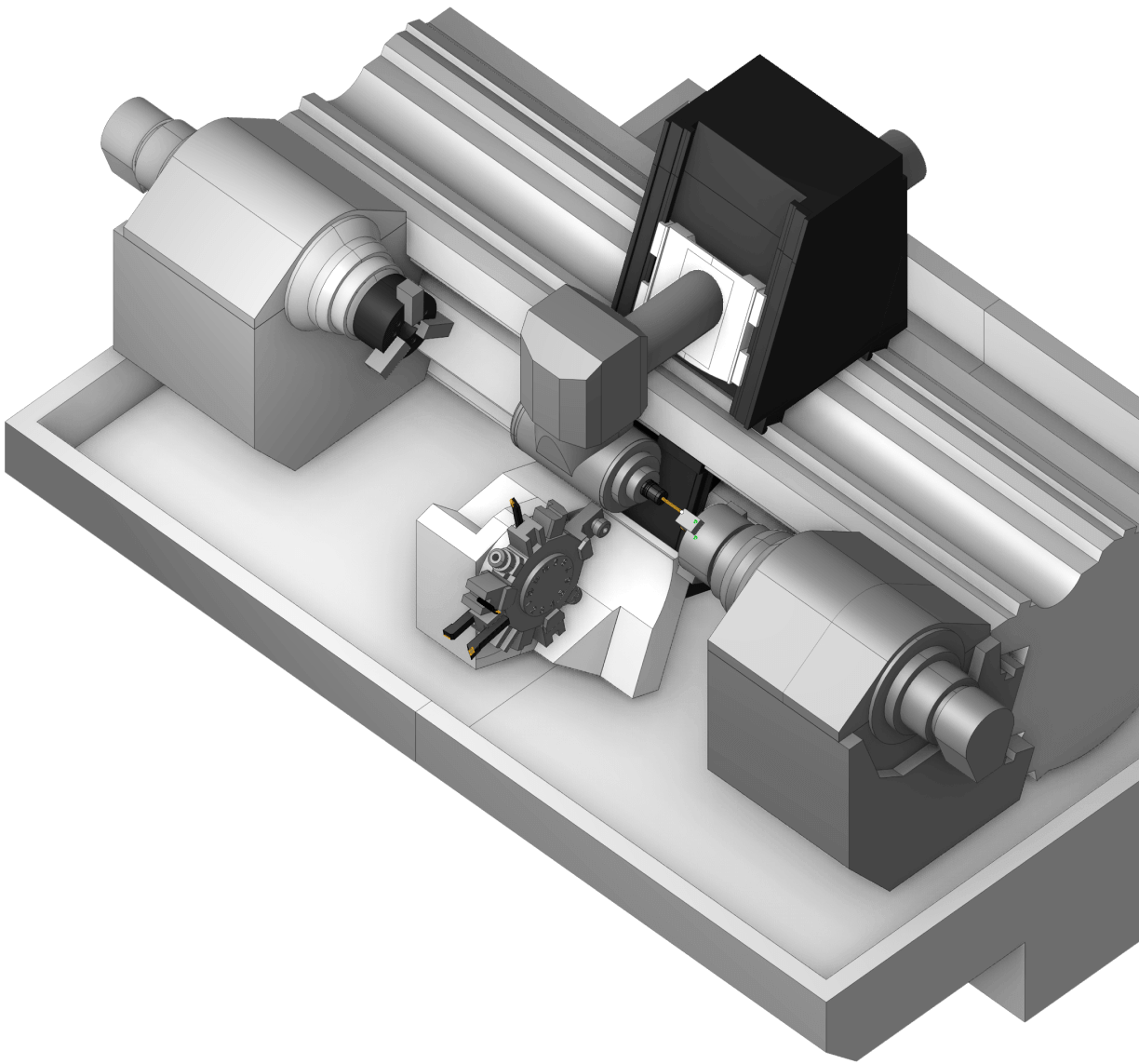

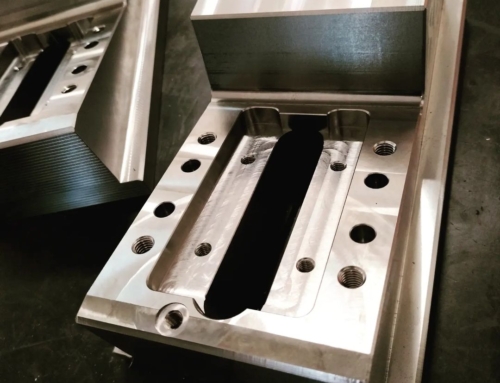

Manufacturers commonly use CNC milling to produce intricate shapes and components with high precision. This involves the use of computer-controlled machines that shape the workpiece by cutting away material. However, some milling operations require adaptive techniques to achieve the desired outcome.

SinteSi, an Italian partner, provides a video demonstrating adaptive milling operation.

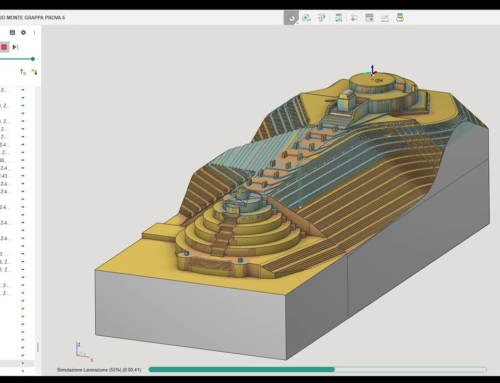

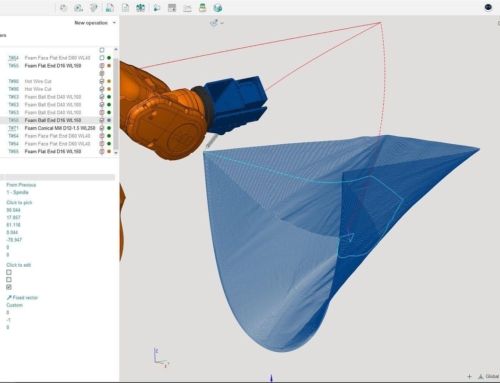

To improve efficiency and quality, CAD/CAM software like SprutCAM X offers adaptive milling capabilities. This technique optimizes the milling process by adjusting the toolpath based on real-time feedback from the machine and workpiece. Adaptive milling can adapt to the milling environment by compensating for unexpected resistance, preventing tool breakage and reducing the risk of workpiece damage.

Optimizing the toolpath in real-time during milling operations improves efficiency and productivity. Adaptive milling can minimize material removal, reducing machining time, and waste. This is particularly beneficial when working with expensive or challenging-to-machine materials.

SprutCAM X provides various adaptive milling strategies such as 2D adaptive clearing, 3D adaptive roughing, and adaptive finishing. These strategies optimize milling operations for a broad range of applications, including intricate geometries.

To conclude, adaptive CNC milling is a valuable technique that can enhance milling operations’ efficiency and quality. SprutCAM X provides various adaptive milling strategies, reducing waste, saving time and money, and improving the overall quality of products when manufacturers incorporate adaptive milling into their workflows.