5 Axis Laser Cutting programmed in SprutCAM X Robot: a case from China

5 axis laser cutting programmed in SprutCAM X CAD CAM software

5 axis laser cutting is widely used for cutting parts of all types of shapes from various materials. It is used in a variety of industries as it is characterized by high precision.

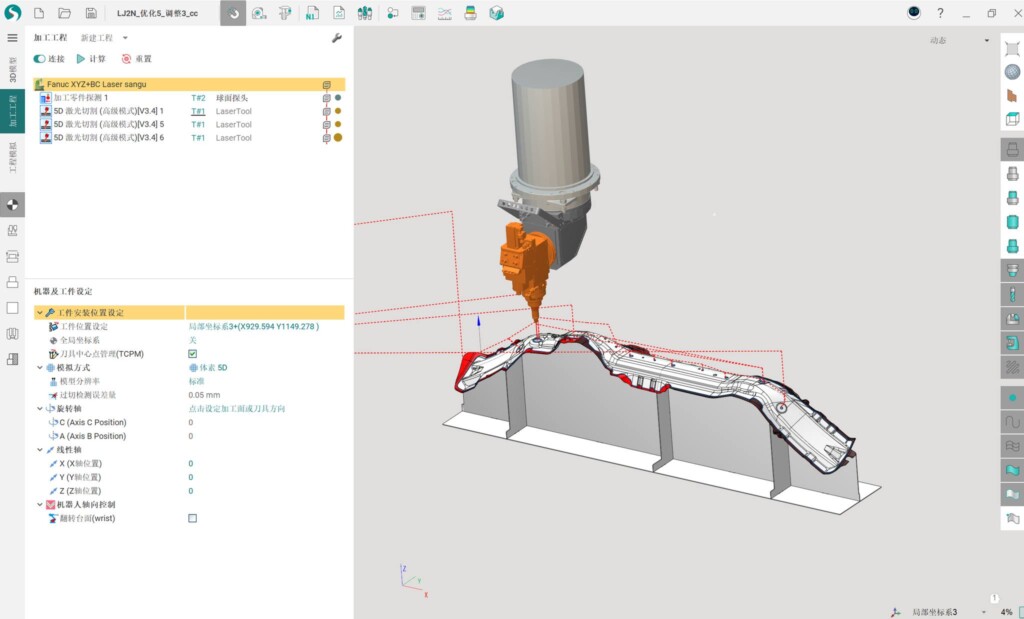

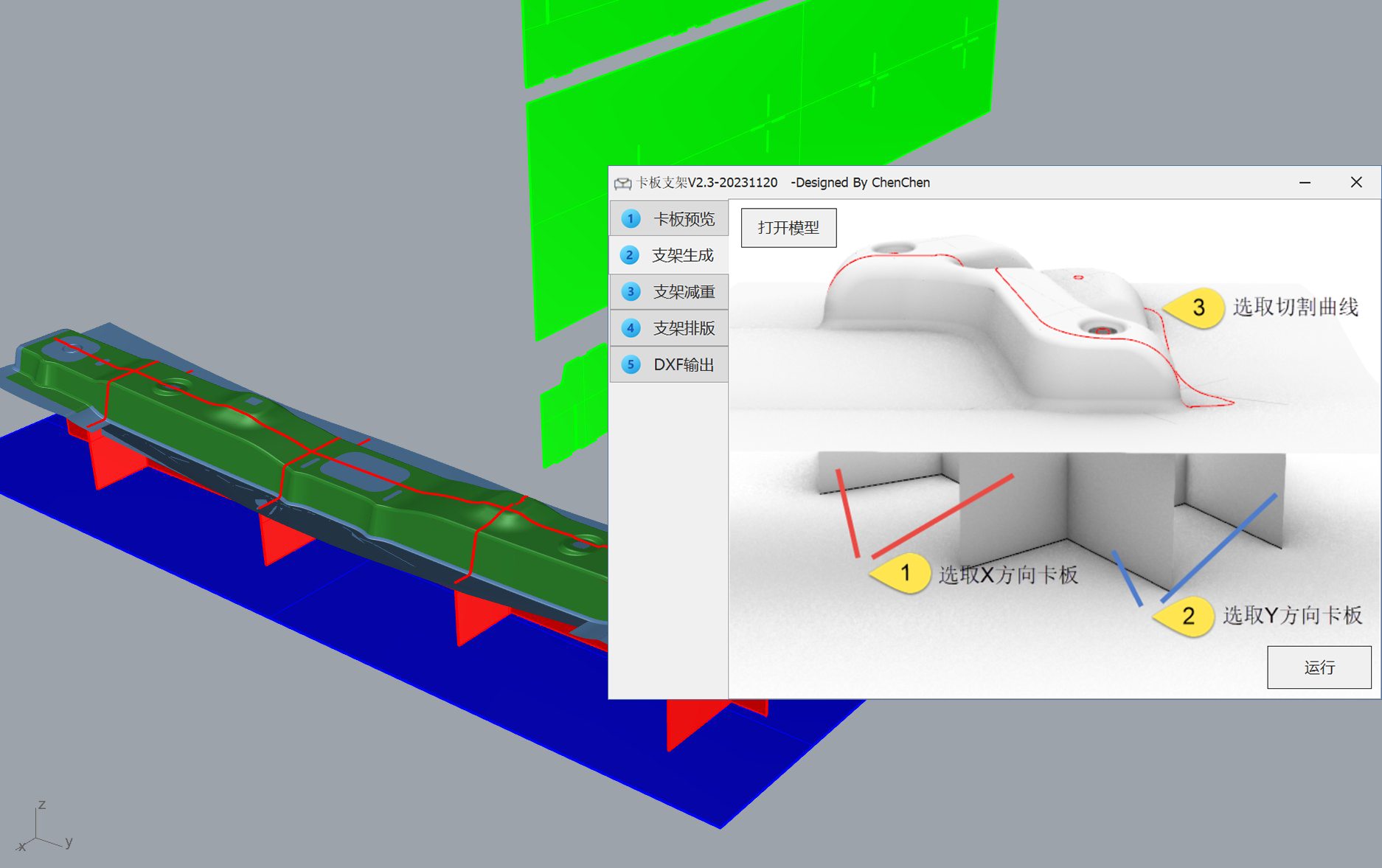

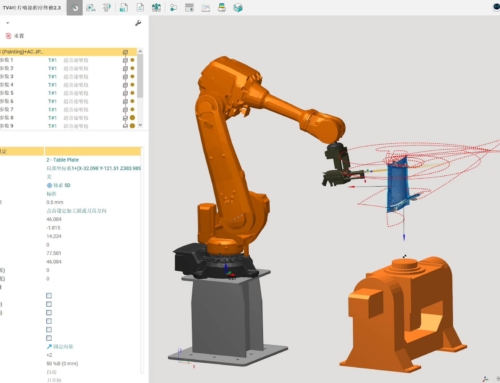

Our dealer Sprut Software Technology (Kunshan) Co., Ltd. China, shared a video of 5-axis laser cutting programmed in SprutCAM X Robot. This is a car body part being machined on a 5 axis laser cutting machine. By the way, for more info on using CAD CAM in the automotive industry, please visit this page.

5 axis laser cutting: advantages of industrial robots

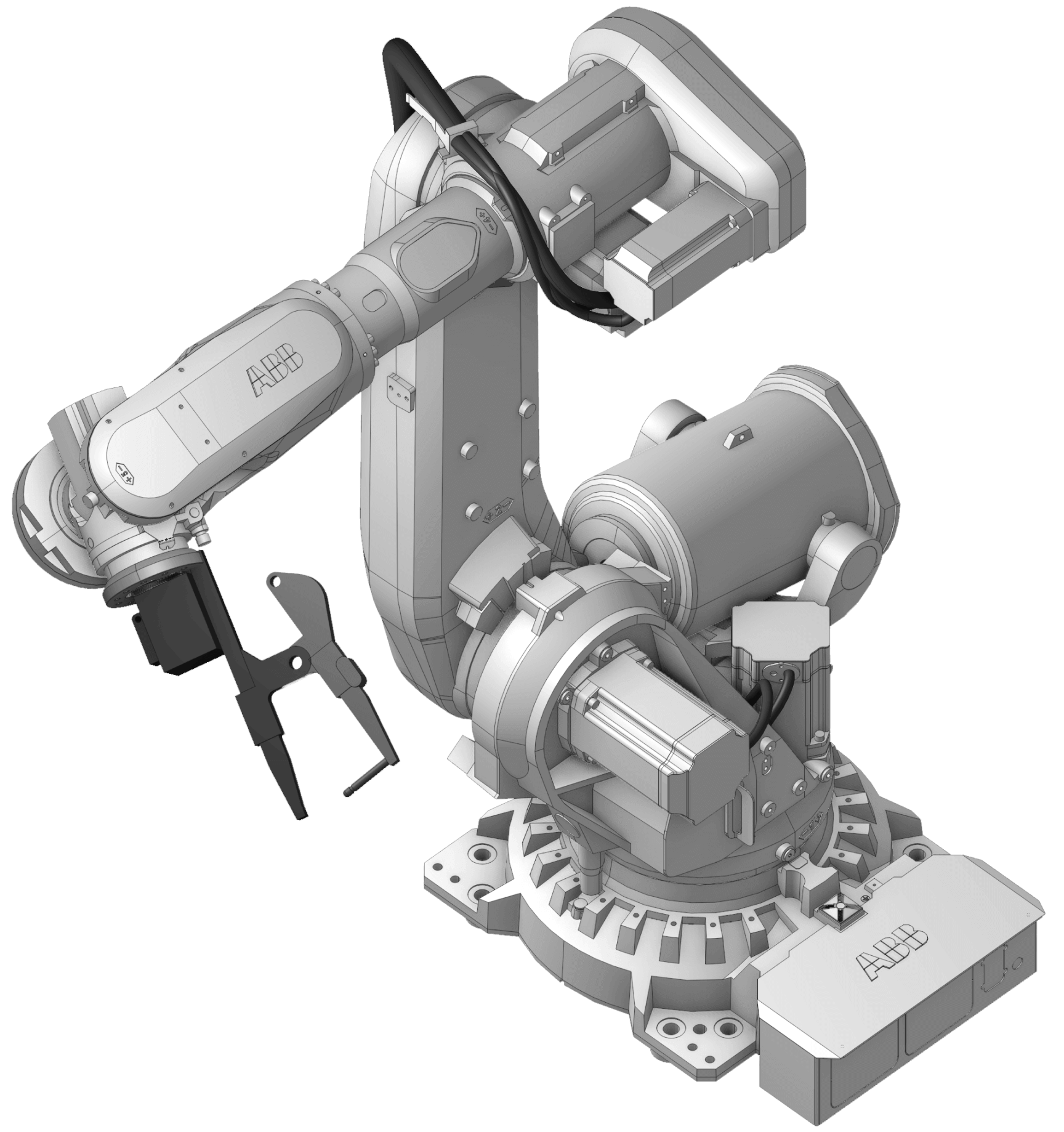

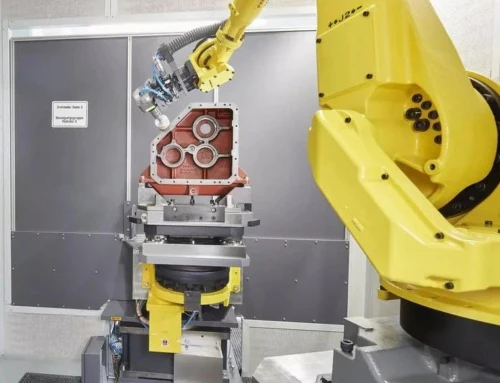

Laser cutting has become an increasingly popular method of cutting materials for industrial purposes. It offers a high level of accuracy, speed, and efficiency that other cutting methods simply cannot match. However, traditional laser cutting machines have limitations when it comes to the complexity of the cuts they can make. This is where industrial robots come in. By using 5-axis robots, laser cutting becomes even more versatile and precise.

5-axis robots are able to move in five different directions, allowing them to reach areas that traditional laser cutting machines cannot. This means that they can cut materials from any angle, making it easier to create complex shapes and designs. Additionally, 5-axis robots are able to work faster than traditional laser cutting machines, which means that production times are reduced.

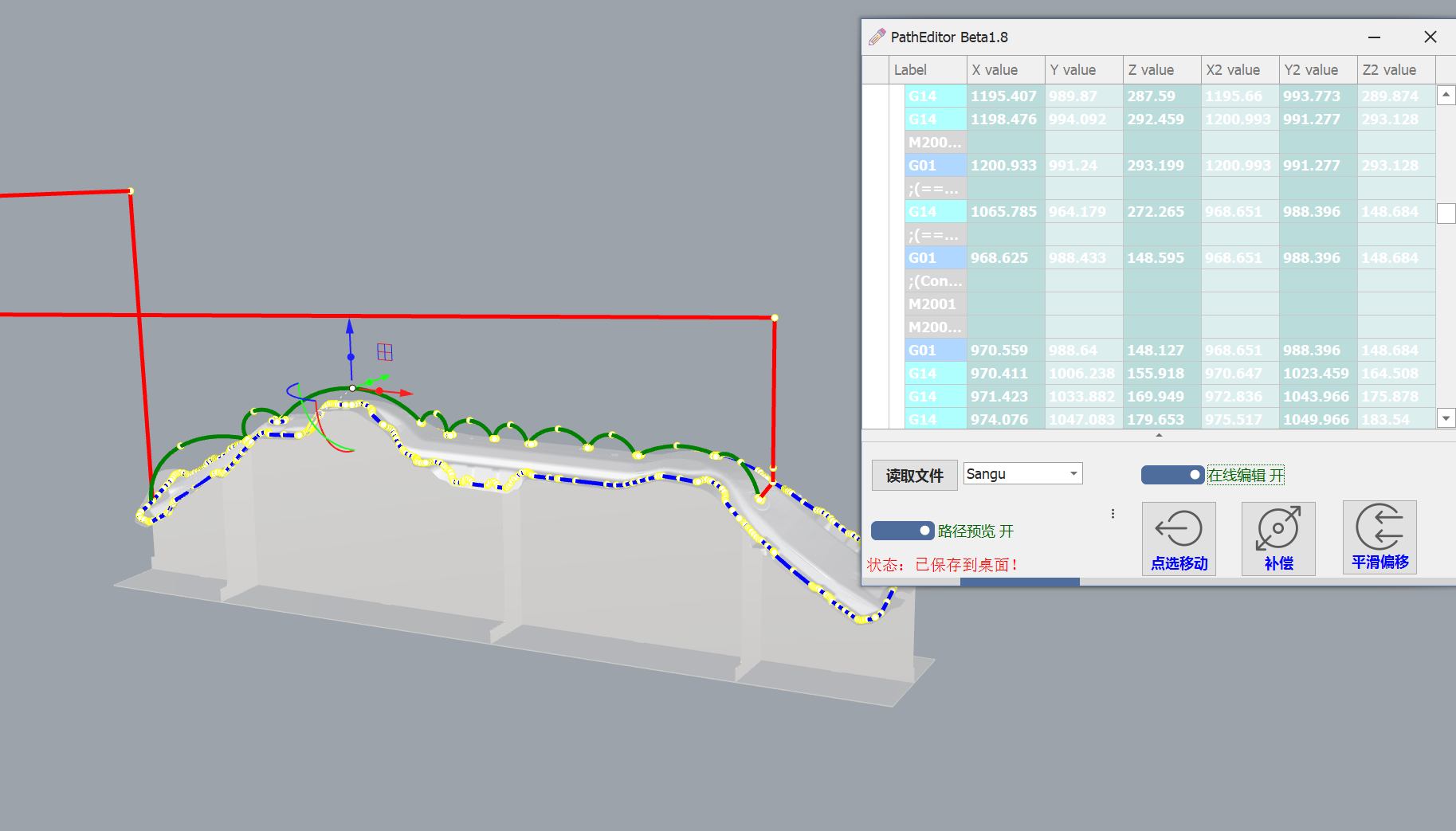

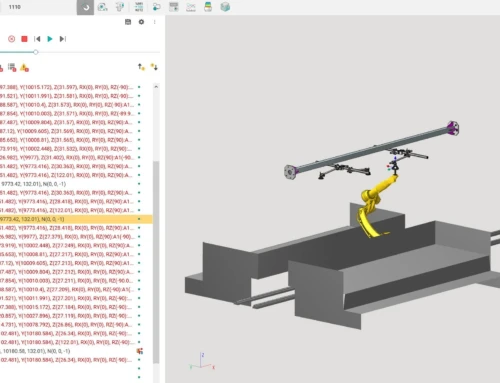

To program these robots, CAM systems are used. CAM (Computer-Aided Manufacturing) systems take the design created in CAD (Computer-Aided Design) software and convert it into instructions that the robot can follow. These instructions include details such as the path the robot should take, the speed it should move at, and the power of the laser beam.

5 axis laser cutting with SprutCAM X Robot

One popular CAM system used for programming 5-axis laser cutting is SprutCAM X Robot. This software is designed specifically for multi-axis machining and offers a range of features that make programming complex cuts easier.

SprutCAM X Robot CAD CAM software offers a range of simulation tools that allow users to test their programs before running them on the robot. This means that any errors or issues can be identified and corrected before they cause any damage to the machine or the material being cut.

Overall, using 5-axis robots for laser cutting offers a range of advantages over traditional laser cutting machines. They are able to cut more complex shapes and designs, work faster, and offer greater precision. By using CAM systems such as SprutCAM X, programming these robots becomes even easier and more efficient. As technology continues to advance, it is likely that we will see even more innovative uses for laser cutting with industrial robots in the future.