Cutting plastic panels with SprutCAM X Robot

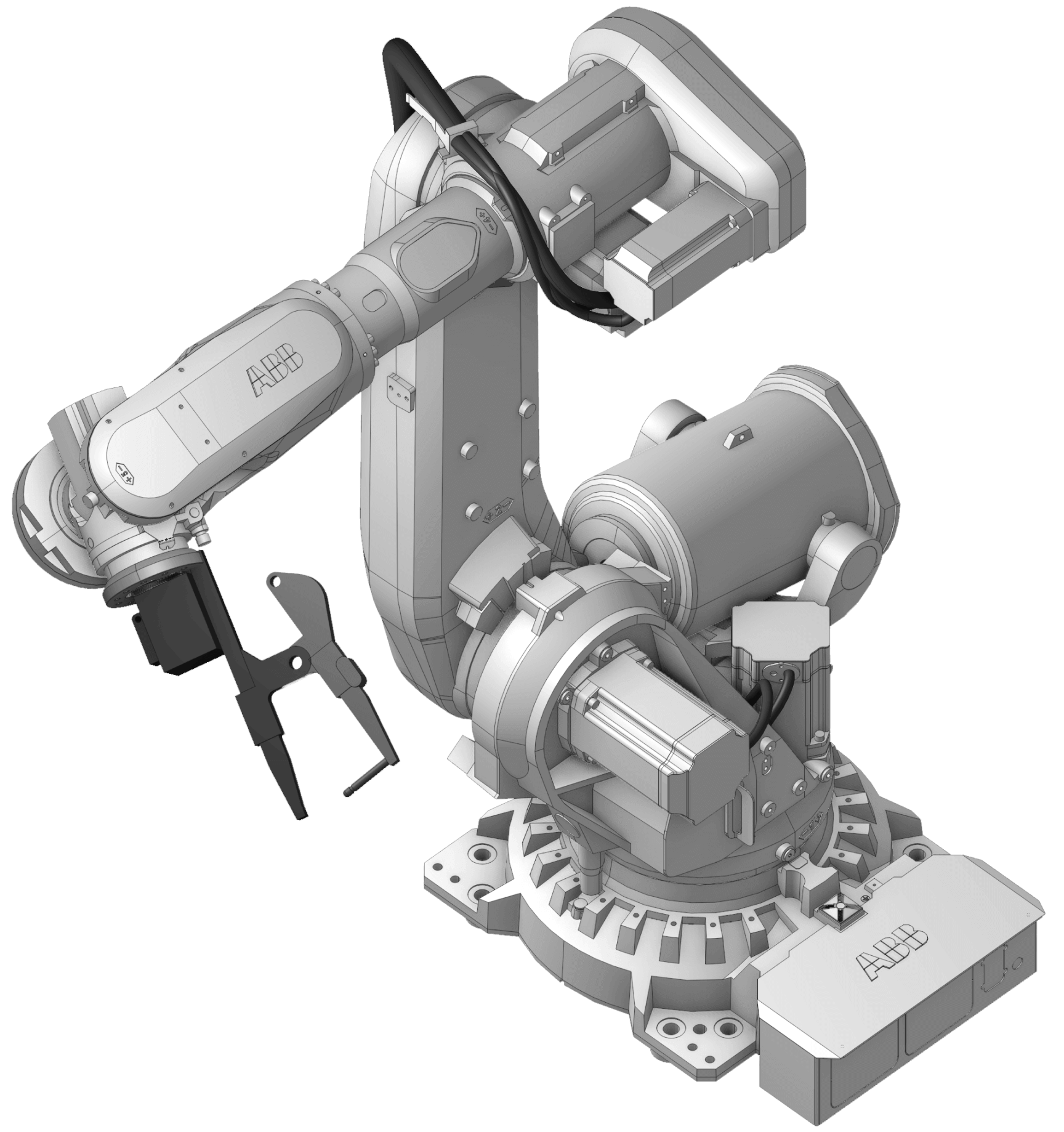

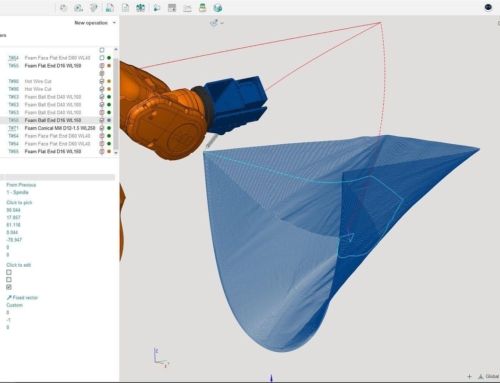

We already posted video of Nordica Sterling Robotics using SprutCAM X Robot for milling. This video demonstrates their prowess in cutting plastic panels with their robotic milling cell.

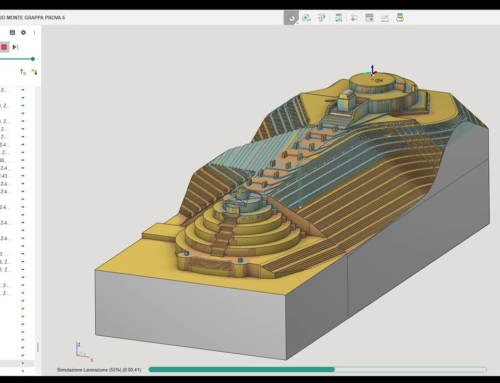

The video showcases the robotic milling cell in action, cutting and shaping plastic panels with precision and accuracy. The SprutCAM X Robot software allows for complete control and programming of the robotic arm, ensuring that every cut and movement is exact.

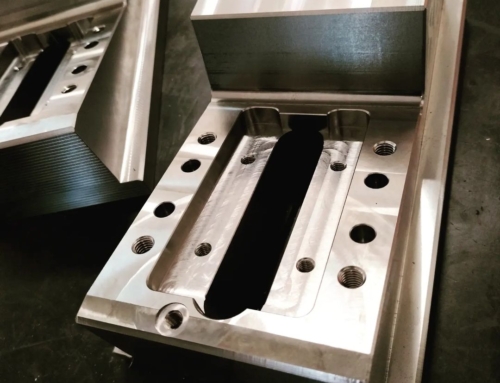

Using a robotic milling cell for cutting plastic panels offers consistency and repeatability in the process.

The robot can perform the same cuts and shapes with precision every time, ensuring that the final product meets the desired specifications. This level of consistency is difficult to achieve with manual cutting methods, which can be prone to human error and variability.

The robotic milling cell can operate for extended periods without requiring breaks or rest, unlike human operators. This allows for greater efficiency and productivity in the manufacturing process, as the robot can work continuously without interruption.

In addition, Nordica Sterling Robotics’ use of the SprutCAM X Robot for milling plastic panels has environmental benefits. The robot produces less waste than traditional cutting methods, as it cuts more precisely and with less margin for error. This means that less material is wasted in the manufacturing process, leading to a more sustainable and eco-friendly operation.

Overall, Nordica Sterling Robotics’ use of the SprutCAM X Robot for milling plastic panels showcases the innovative and transformative capabilities of robotics in manufacturing. The precision, efficiency, and sustainability benefits of the robotic milling cell make it a popular tool for cutting and shaping a wide range of materials in the manufacturing industry.