BMW chooses SprutCAM X Robot

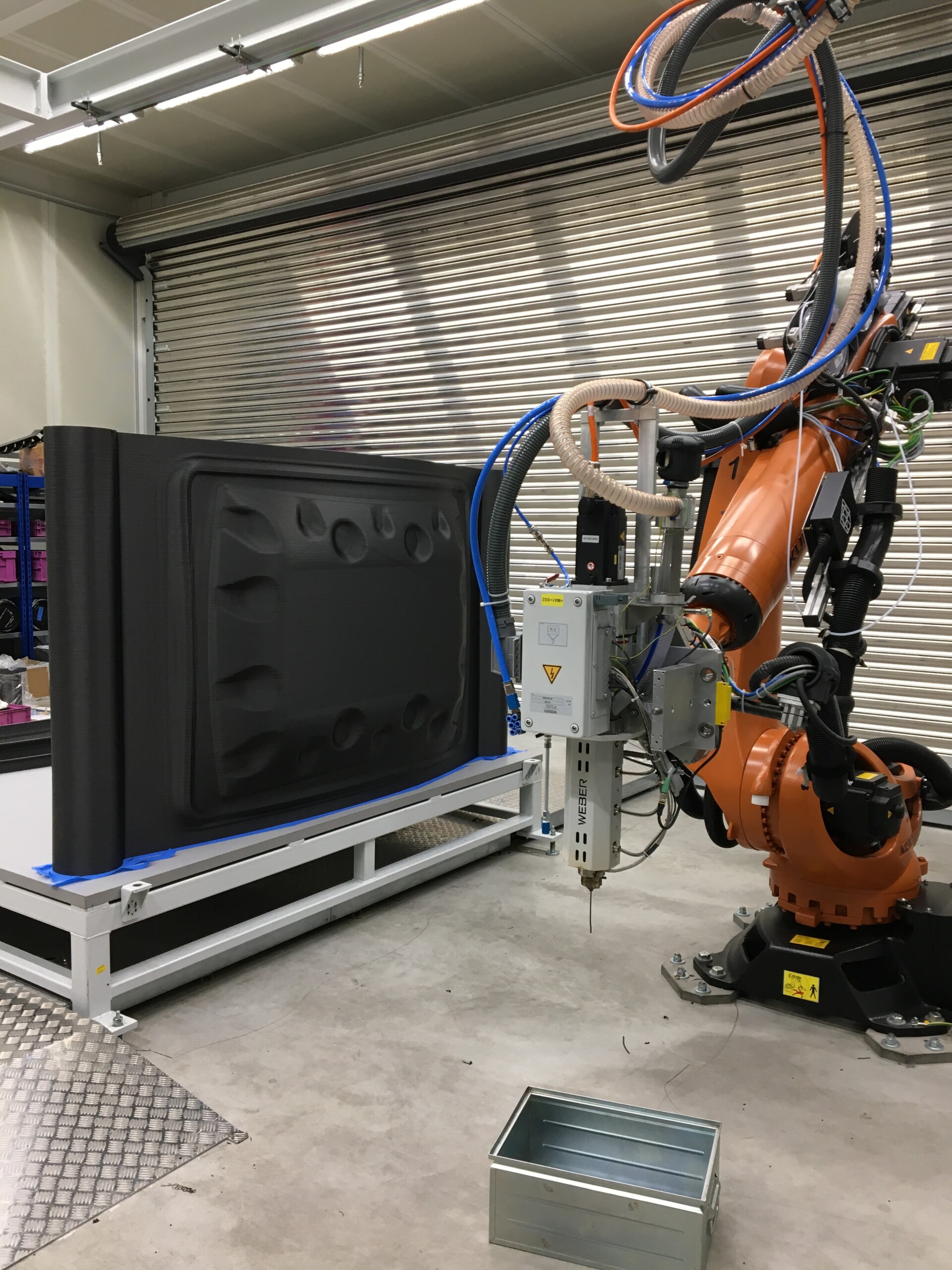

The renowned Bavarian automobile manufacturer has chosen SprutCAM X Robot distributed by Datentechnik Reitz, Germany for 3D printing with KUKA robots.

3D printing with industrial robots

BMW Group’s Landshut plant has innovative processes being developed and put into the manufacturing pipeline. The company’s Lightweight Construction and Technology Center (LuTZ) is working on ways to manufacture components using additive technologies. In particular, the company’s R&D center is using 3D printing to manufacture large parts and components. Most of the current additive manufacturing machines are not suitable for the production of such components because they are either too small or do not have the sufficient axis motion range for the tasks.

However, the 3D printing of these parts can be completed by industrial robots due to their large range of motion. The goal of this project, which now came to fruition, was to have industrial robots do 3D printing in a simple and short process chain. Besides, the carmaker needed additional degrees of freedom to position an extruder in 5-axis.

KUKA robots were already in house

The BMW Landshut plant had already been using Kuka robots which were performing their tasks perfectly. The working area of these robots is sufficiently large and can be expanded almost indefinitely with the possible use of so-called linear axes. The challenge was all about the programming of the robots.

SprutCAM X Robot is decisive for the success of the operation

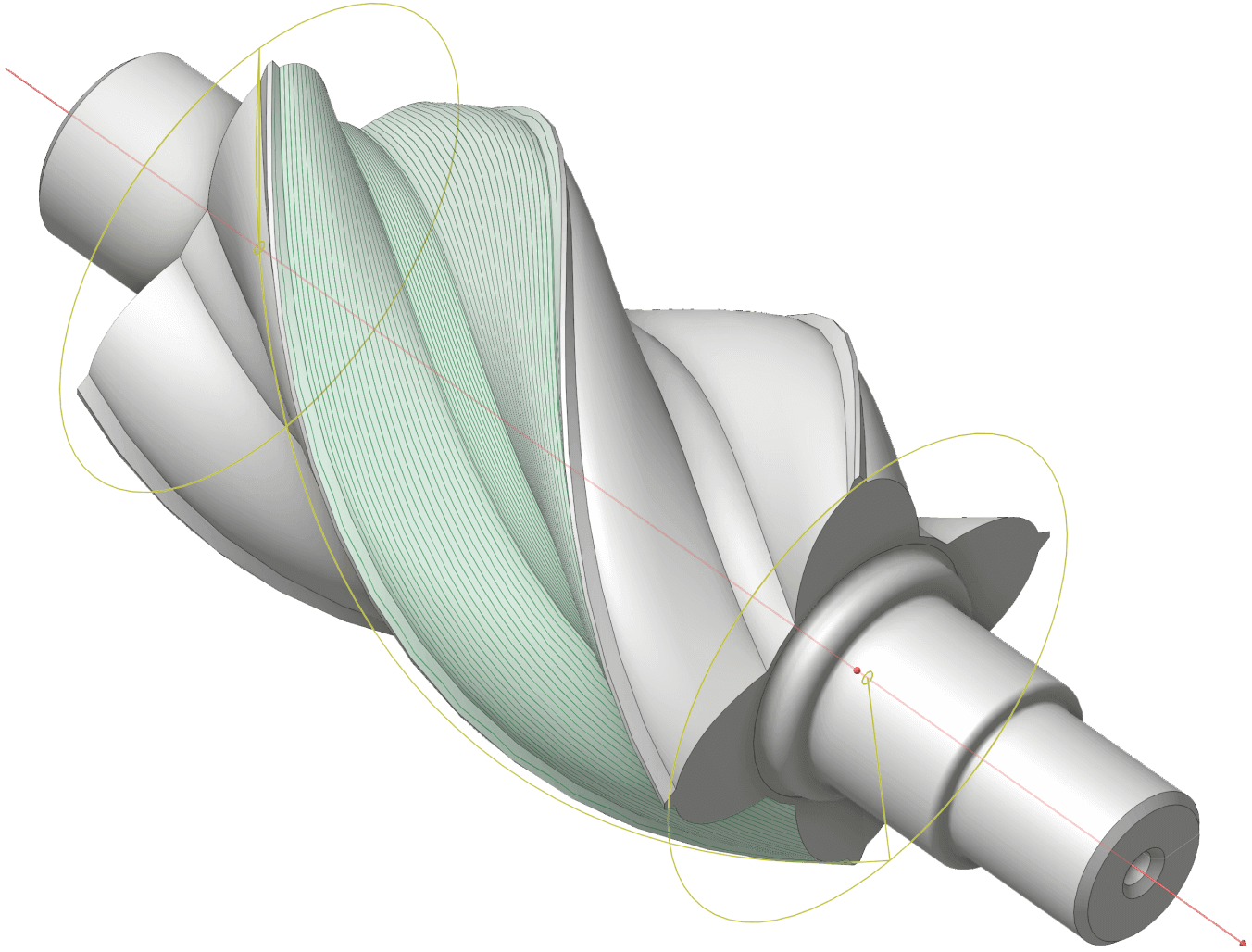

BMW had to look for a software package which supports both milling and 3D printing in equal measure. Moreover tool reach zones, collision areas and singularities had to be shown in the software. The output code had to be generated natively for different robots.

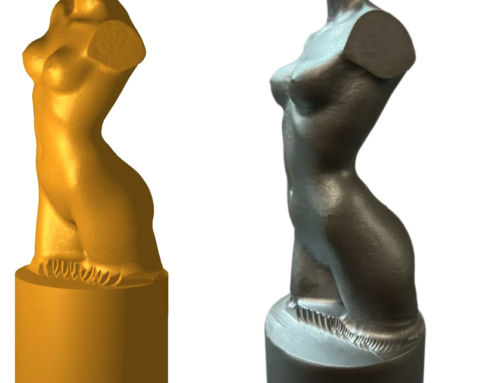

After some tests, the decision was made in favor of SprutCAM X Robot distributed by Datentechnik Reitz from Breidenstein, Marburg area. SprutCAM X Robot allows users to create free-form surfaces and program their 3D printing and milling. The control of robotic systems has been part of SprutCAM’s daily routine for a long time and different robot models can be controlled in the system without any trouble. Additionally SprutCAM X Robot offers a method to slice parts in all axes, i.e. not only in 3-axis. This means that machined parts can also be printed laterally. Whether the extruder is mounted on the robot or the additive part is attached to the robot, makes no difference.

Training and technical support of the project are handled by Datentechnik Reitz. The company has been offering CAM systems for this industry for more than 25 years and its expertise spoke to BMW for itself. Also in the subsequent support stage, the customer’s suggestions and feedback can be introduced in the software on a win-win basis.

SprutCAM X Robot is all-in-one software for industrial robots offline programming. It provides an innovational, convenient and natural robot programming environment, where the engineer’s interaction with the robot, tool and product is as close to reality as possible. For more information go to: https://sprutcam.com/sprutcam-robot/.

Download the PDF version

Publication of this material is possible only with the written permission of BMW AG, Datentechnik Reitz GmbH and SprutCAM Tech Ltd.