3D printing by additive

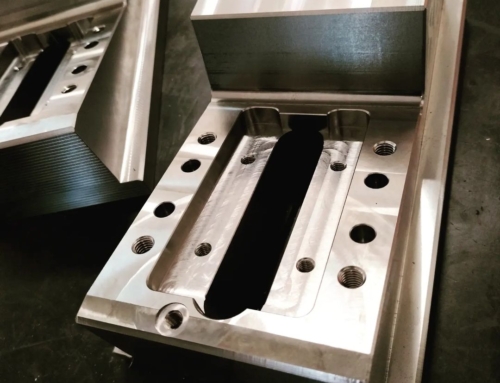

3D printing has become more popular our days. This method allows you to obtain geometry. That is impossible or problematic to obtain using classical cutting methods. Low weight and high material utilization are the main advantages of 3D printing parts. Such parts can have completely or partially closed cavities that are difficult to access for the cutting tool.

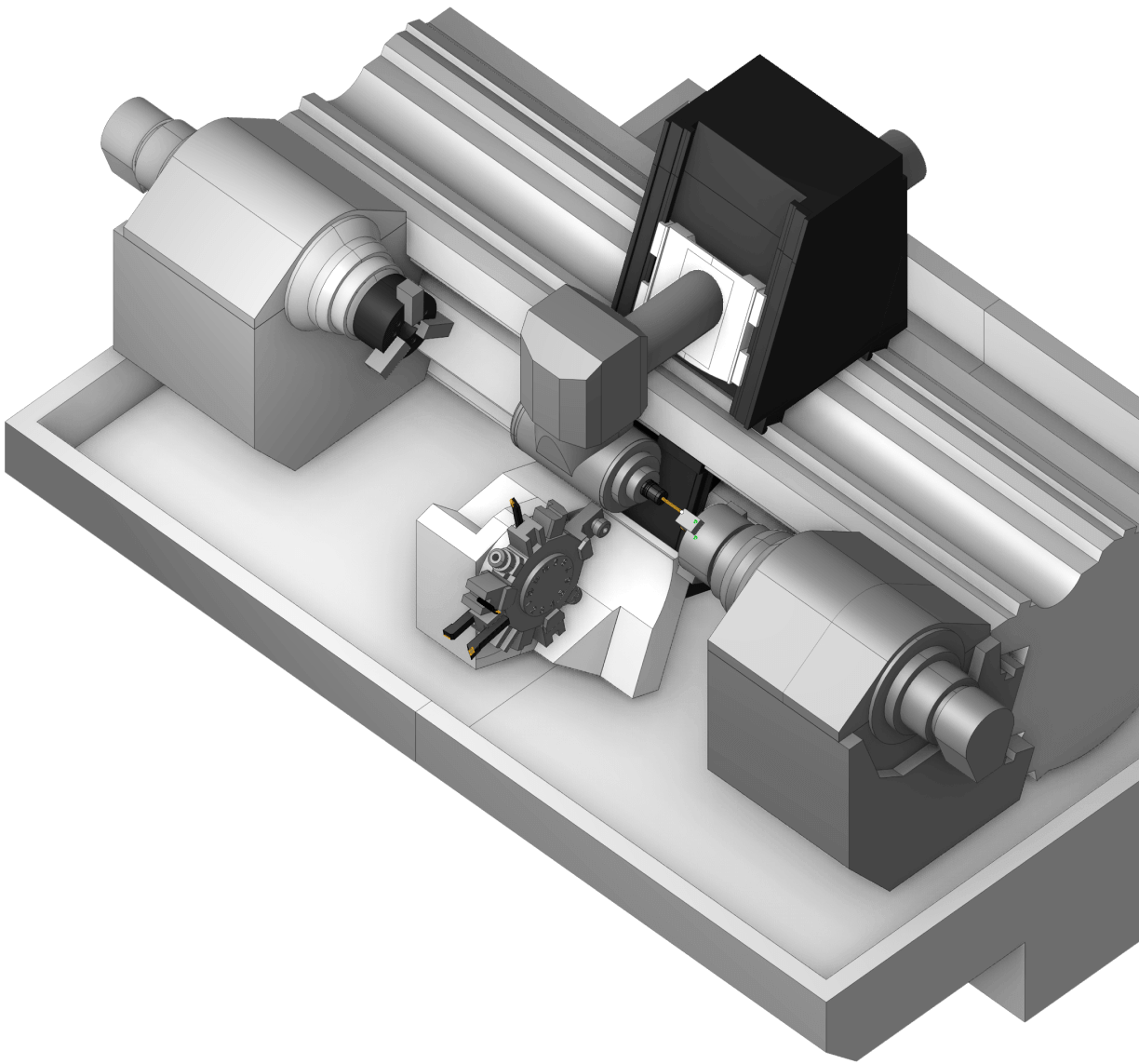

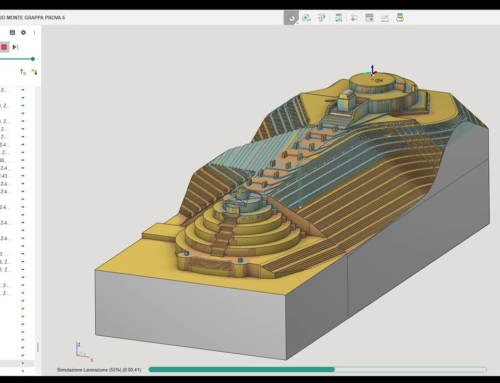

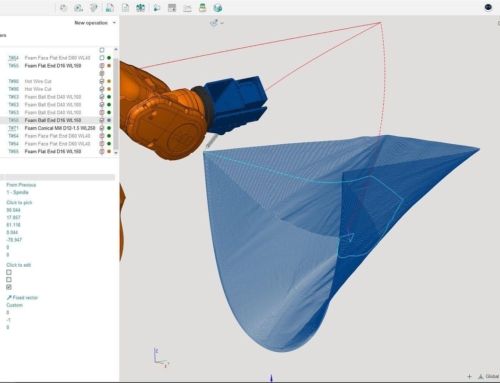

When calculating the toolpath, SprutCAM takes into account the peculiarities of machining: transfer of tool entry points, providing gaps to eliminate overlap, changing the angle of filling the area. Several printing modes are available in the system: by curves (only model walls), with full or partial filling of the model. The use of industrial robots in this process makes it possible to obtain large-sized models and change the orientation of the extruder during printing, providing optimal processing conditions at every point.

Video created by SprutTP.

See more videos on their YouTube channel.

See more information