SprutCAM X CAD/CAM for automotive: first Brazilian electric car

SprutCAM X CAD/CAM for automotive: 1st Brazilian EV, buses, motorhomes

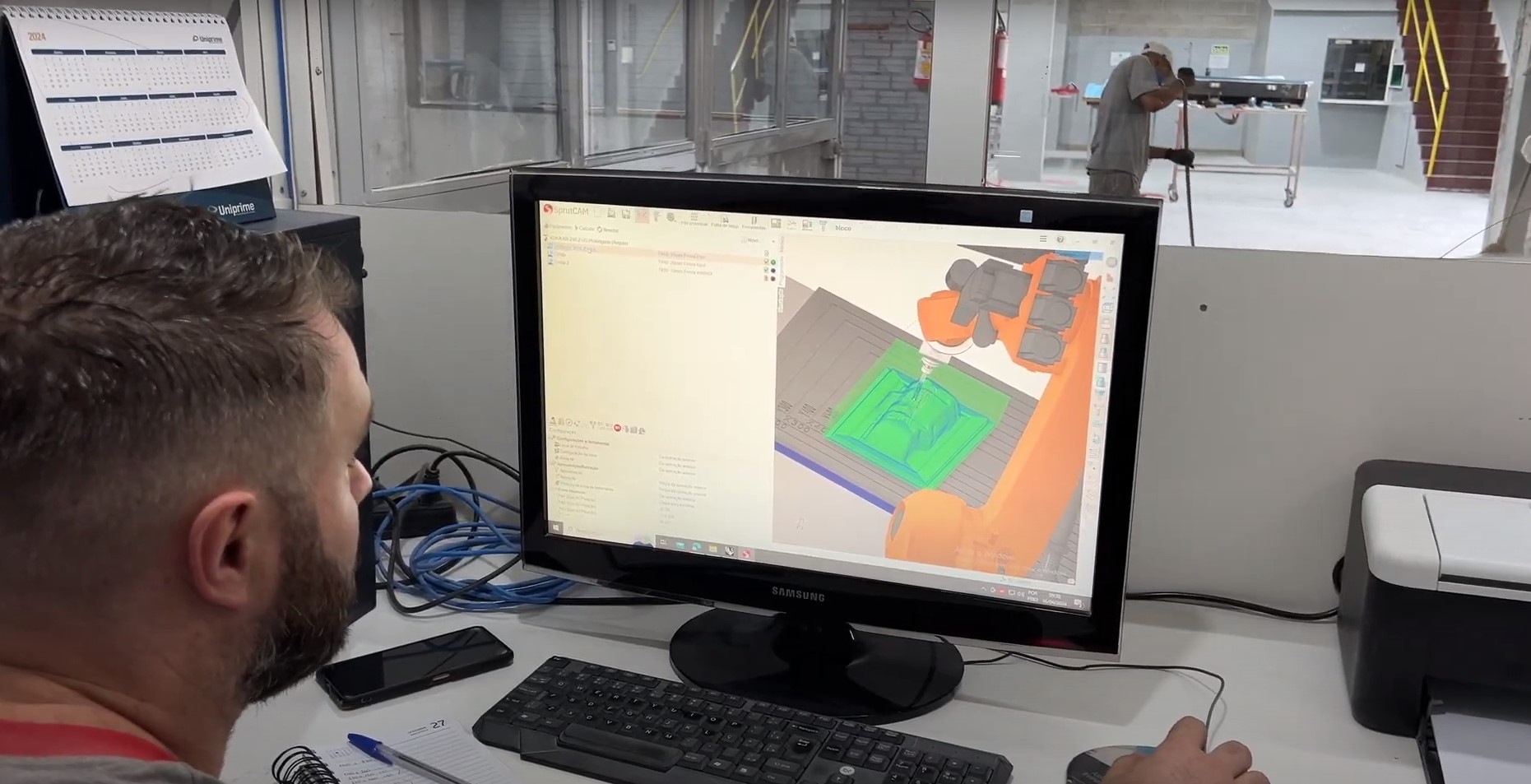

In April 2024 we visited some of our customers in Brazil and filmed them give their opinion on SprutCAM X CAD/CAM system. Here is Nivaldo, owner of Ângulo Protótipos speaking (full video will be available later):

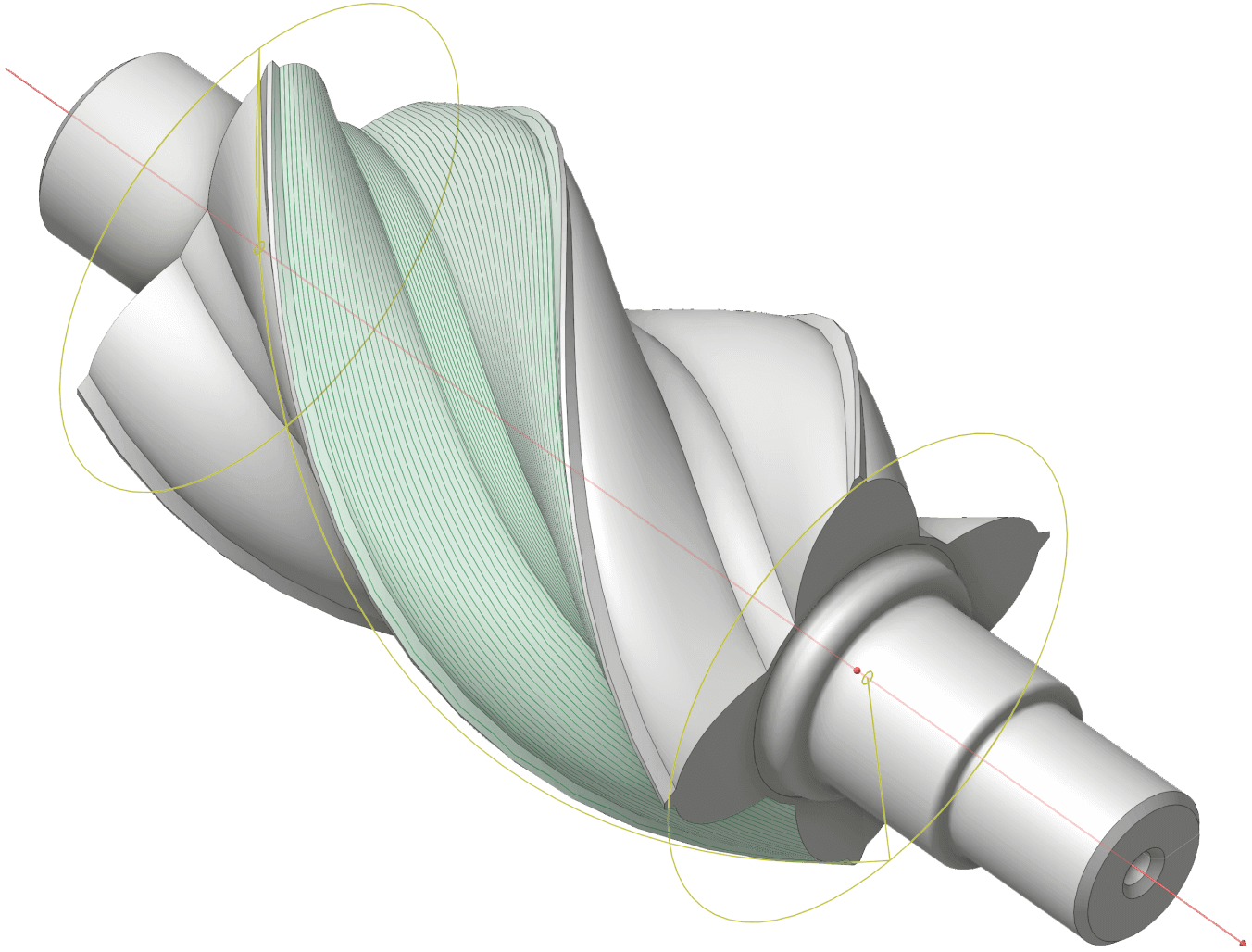

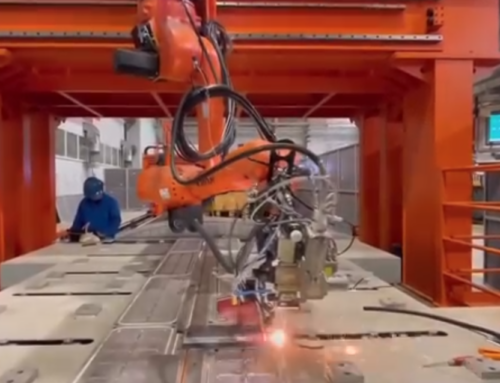

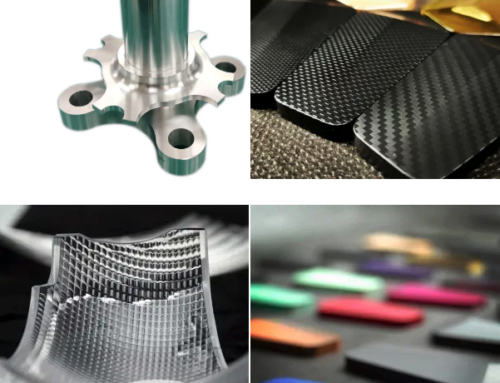

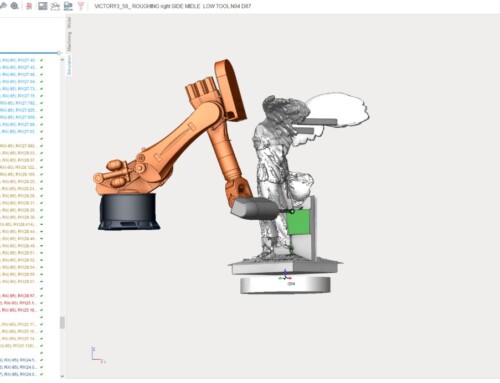

“My name is Nivaldo. I’m the owner of the Angulo Protótipos company. We do development of projects for third parties. We have a number of projects: 3D, Solidworks, machining, which we are doing using Sprutcam X. Our main client is Marco Polo, the bus manufacturer. We develop parts for buses for the aftermarket: fiberglass, plastic. We build and make prototype models and molds. Now we have other clients, for instance, Santo Inácio, a motorhome builder from Gramado. National reference in quality. We do the molds development for them and supply parts for assembly of motor homes. And we also have a new client, Lecar: we participate in the development of the first Brazilian electric car.”

About Lecar:

Safety is the most important aspect of the LECAR MODEL 459 project. The technology used in its structure is called Sheet Molding Compound (SMC), with international application awards and best product of 2016 by the Society of Plastics Engineers (SPE), in Germany.

The project is characterized by the ideal position of the engine and the traction, the low and favorable weight x performance, the safety and stability in curves and, finally, the power delivered immediately by the ideal electric motor selected for the project

With a range of 400 kilometers (equivalent to an average week’s driving), it can be recharged overnight.

Charging is also possible using a 110V/220V household outlet.

The body has been adapted to Brazilian climatic conditions. Made of Sheet Molding Compound (SMC), the same technological, resistant and flexible material used in Formula 1 cars, SMC is lighter, five times stronger than steel and is the material used by major brands in the construction of their cars. (such as Ferrari and Porsche).

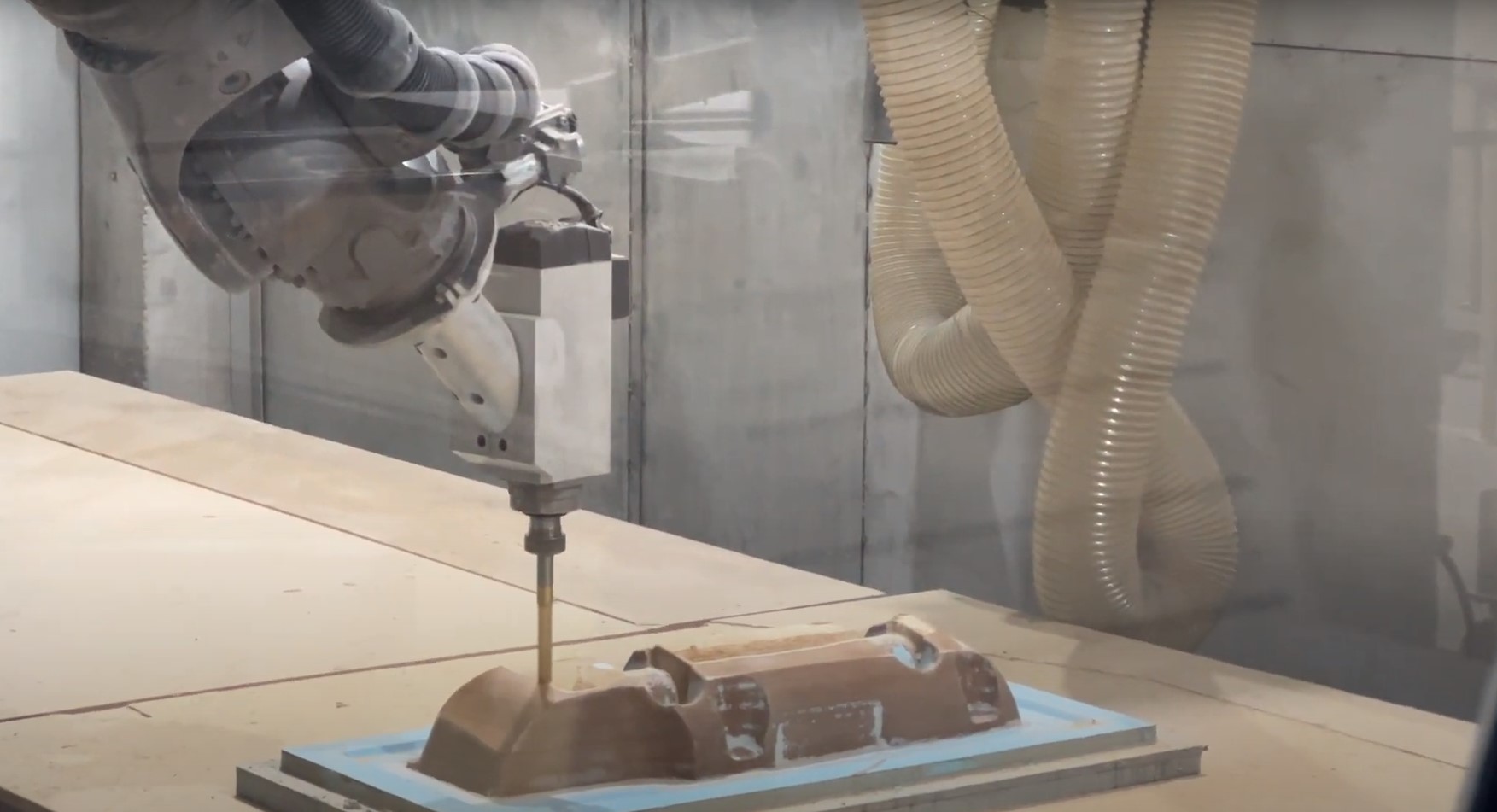

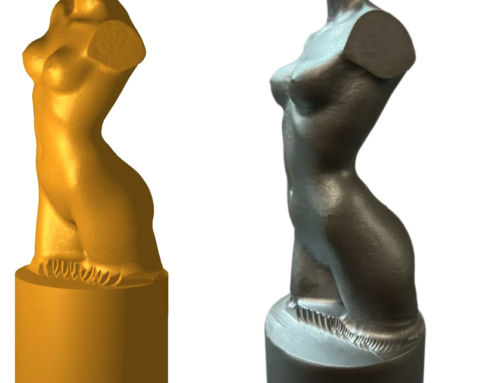

“So all of this is machined using SprutCAM X, then the finish is given. Before we used to do all the processes manually: the plastic, wood, and sanding. It took a lot of time and the quality was not satisfactory. We came to the conclusion that apart from the quality issue, there was no consistency in parts because all was done manually. So with the implementation of SprutCAM X for machining we just use the 3D model file, do the milling and the accuracy is perfect. We have a lot of gain in speed and quality and we reduced the cost a lot and the final price for the customer. So everything works faster, with better quality, better final price and at lower cost.”

This video was made possible with the help of Comac Brazil, our distributor in that country.

To learn more on SprutCAM X CAD/CAM for automotive, please visit this page.