Braid Wheels: SprutCAM X as CAM system for programming CNC milling of wheel rims

The Spanish company Braid Wheels selects SprutCAM X for programming CNC milling of its wheel rims.

What CNC milling task the CAM system needed to solve

BRAID Wheels is a company that has been producing high-performance wheels for competition and sports cars since 1978.

The BRAID brand has a wide international presence and is favored by racing teams and enthusiasts seeking optimal performance and distinctive style. Company’s wheels are used by winning DAKAR teams.

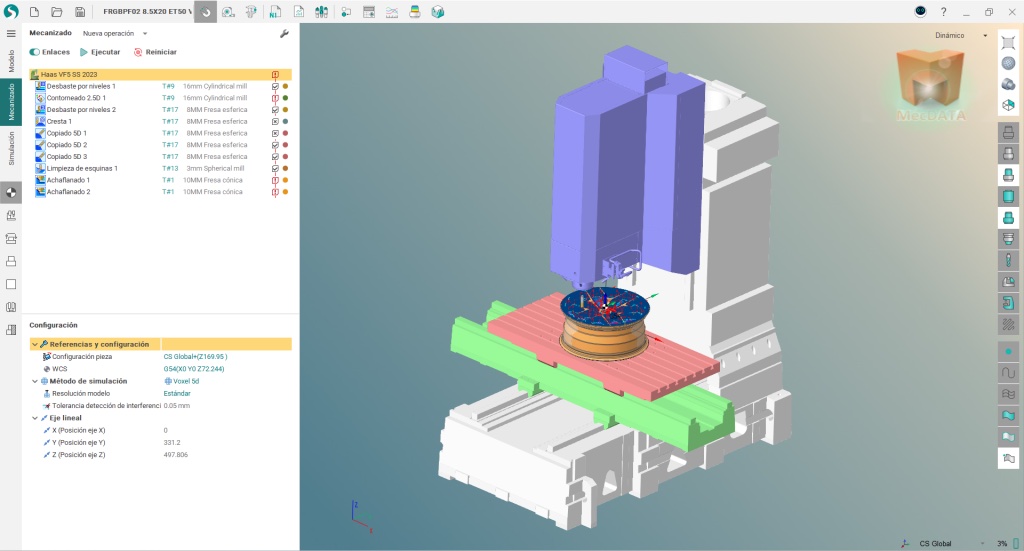

While Braid was evaluating various systems to overcome a bottleneck in the 5x milling programming process for CNC milling of their wheel rims, they contacted Mecdata, the distributor of the SprutCAM X CAD CAM software for CNC machines and robots offline programming. The application was found to be interesting due to its ease of use and versatility, which had been observed in online videos.

What Braid Wheels has to say about SprutCAM X

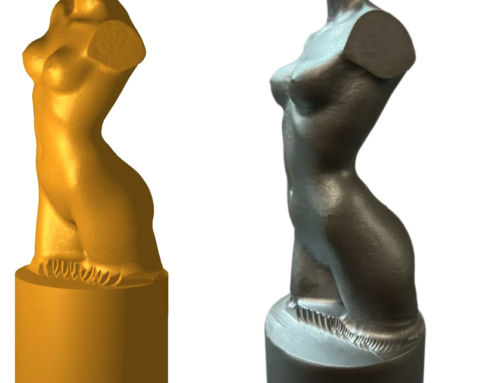

“After evaluating the application, a demonstration was requested using one of our parts. The demonstration met our requirements, and as a result, several licenses of the application were purchased.

This allows our technicians to program our machines independently. As a CAM application, we are not dependent on any changes in our design department, ensuring that our production process remains unaffected.

The adaptation to the new system appears to have been efficient, which has allowed us to complete pending jobs quickly. It is our belief that Sprutcam X is a highly recommendable option for CNC milling of wheel rims. We are satisfied with the quality of operations, variety of options, and speed of calculation.”

How SprutCAM X CAD CAM solves the task of CNC milling of wheel rims

SprutCAM X CAD CAM software really shines in the most important operations needed by Braid: Roughing waterline, Scallop, 5d surfacing, Pencil, Corners cleanup.

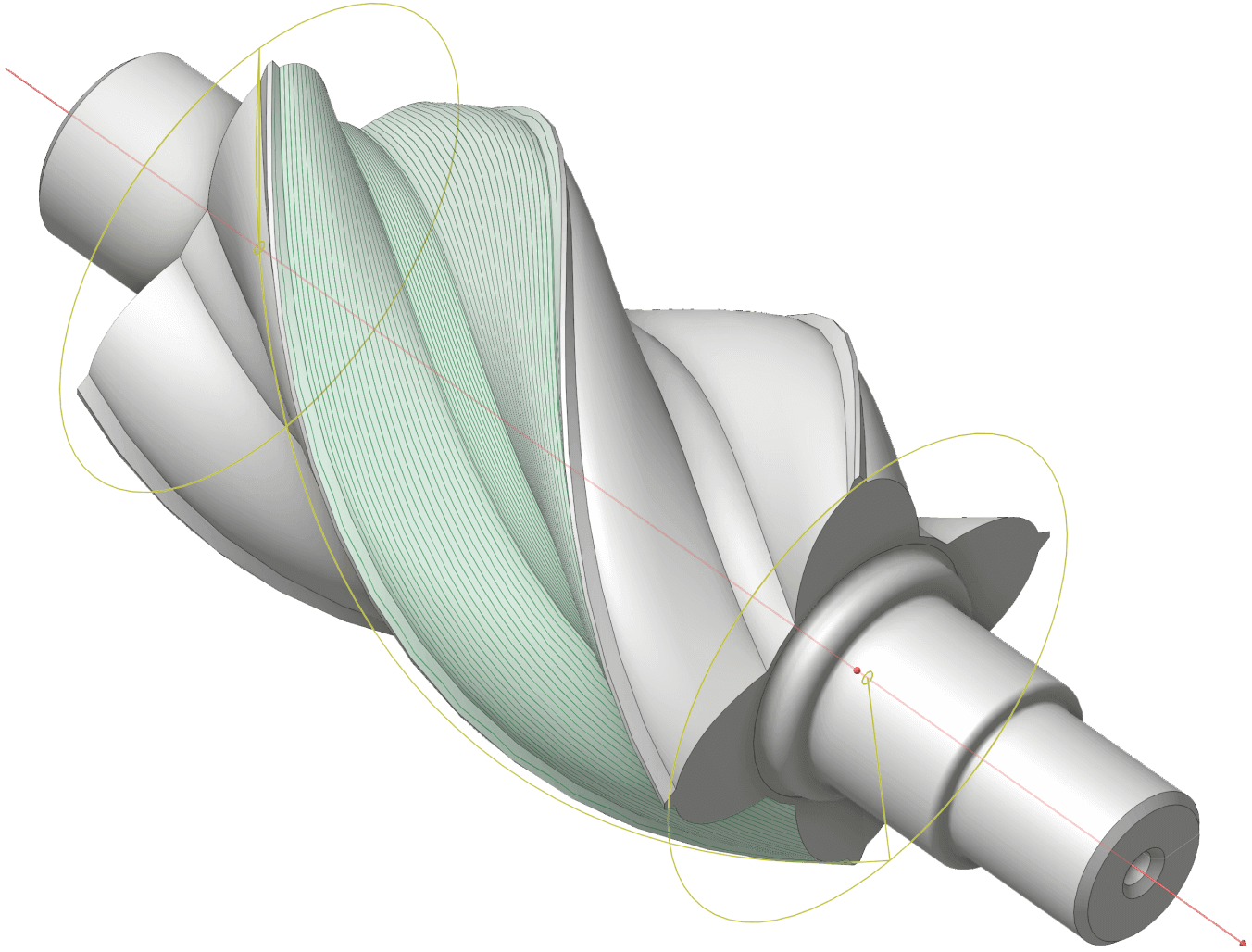

The waterline roughing operation in SprutCAM X software is a useful method for the initial rough machining of complex-shaped models that differ significantly from the workpiece. This operation is defined by a set of solid bodies, surfaces, and mesh objects that make up the model being machined. Additionally, an extra stock can be defined for each geometrical object or group of objects, which will be added to the main stock of the operation during machining.

The Scallop operation in SprutCAM X CAD CAM software is a finishing technique that can be used for various high-quality finishing applications. It generates a toolpath that maintains a constant true offset between passes along the surface of the geometry, ensuring a consistent scallop height across the entire surface, including steep regions.

5d surfacing operation in SprutCAM software allows for the surface to be machined using a variety of techniques, such as parallel to the plane, parallel to the curve, morph, and others, as well as tool axis orientation modes, including fixed, normal to the surface, to rotary axis, through point, through curve, etc.

The purpose of the Pencil milling operation in SprutCAM X CAD CAM software is to eliminate cusp marks that may be left from previous machining operations in corners. This technique is particularly useful when machining into corners where the surface radius matches the cutter corner radius. Single pass pencil milling produces a high-quality surface finish that is ready for polishing. The toolpath maintains climb milling as the default and can be used in conjunction with cutter contact angles. In all these operations SprutCAM X CAD CAM software outshines competitors.

We are pleased that Braid Wheels is one of our many satisfied customers.