Mastering the Most Common G-Codes: A Beginner’s Guide to Programming CNC Machines

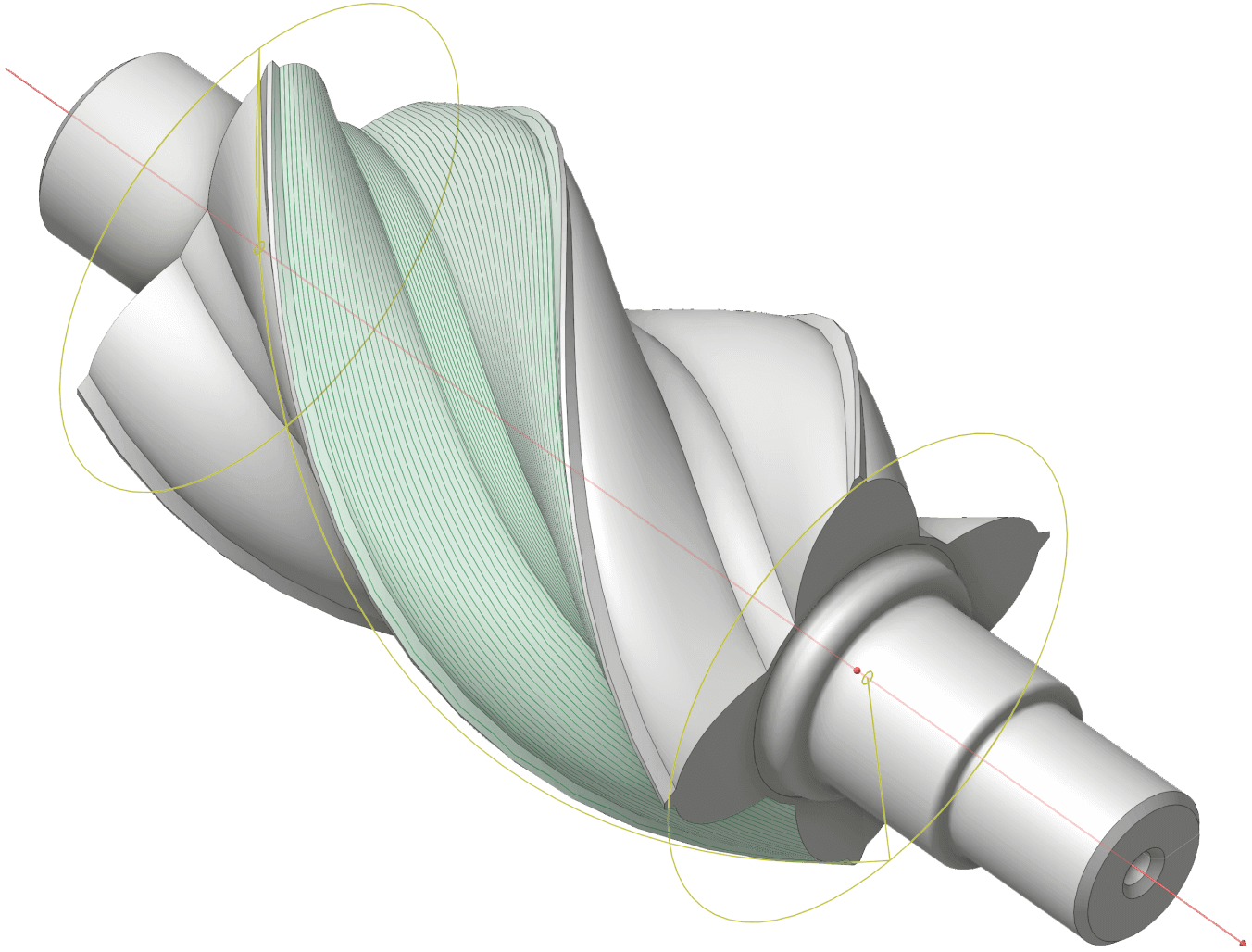

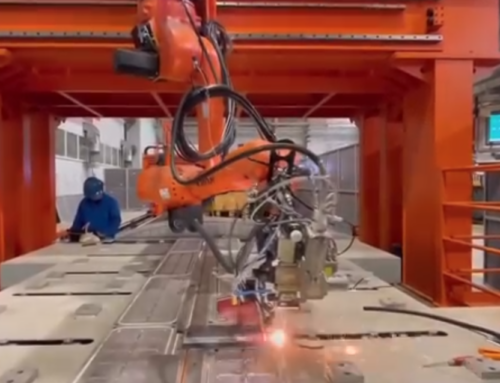

G-codes, also known as preparatory codes or modal codes, are a programming language used to control CNC (computer numerical control) machines such as mills, lathes, and routers. These machines are used to cut, shape, and form a wide range of materials including metal, plastic, and wood.

G-codes are used to specify the type of movement the machine should make, such as rapid movement (G00), linear movement (G01), or circular movement (G02 and G03). They also specify the location and speed of the movement, as well as the cutting tool to be used.

The most common G-codes include:

- G00: Rapid movement

- G01: Linear movement

- G02: Clockwise circular movement

- G03: Counterclockwise circular movement

- G04: Dwell (pause)

- G40: Cancel cutter radius compensation

- G41: Cutter radius compensation left

- G42: Cutter radius compensation right

- G90: Absolute positioning

- G91: Incremental positioning

In addition to G-codes, CNC machines also use M-codes, which are used to control non-movement related functions such as coolant control, tool changes, and program stops.

To create a CNC program, the user creates a text file with the appropriate G-codes and M-codes and sends it to the machine. The machine then interprets the codes and performs the specified actions.

In recent years, CNC machines have become increasingly advanced and user-friendly, with many machines now featuring built-in programming software that allows the user to create a program through a graphical interface, rather than manually writing G-codes.

Overall G-code is a powerful tool that can be used to program CNC machines to create precise and accurate parts with a high degree of automation. With the proper knowledge and understanding, G-code can be used to create complex and intricate designs that would be difficult or impossible to produce by hand.

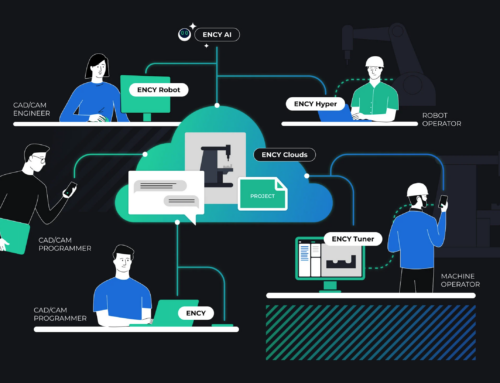

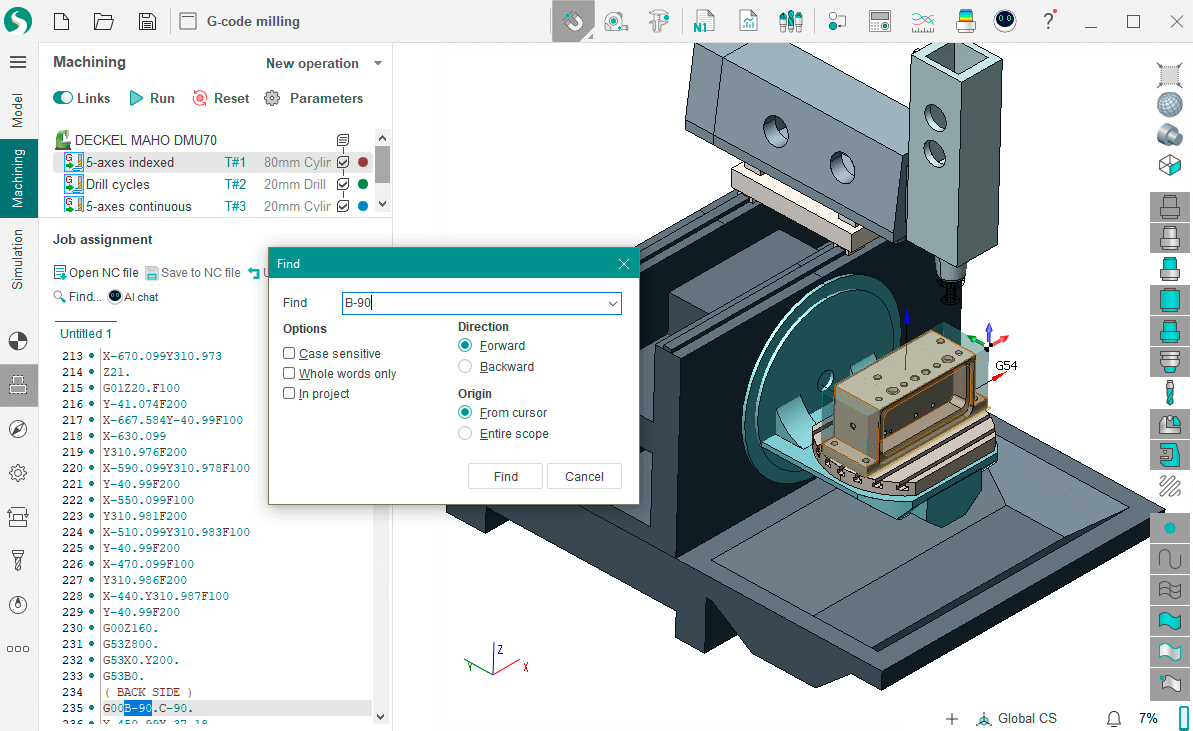

Why you need a CAD/CAM software for CNC machine programming

A CAM (computer-aided manufacturing) software is an essential tool for programming CNC machines. It allows the user to create a program by generating G-code from a 3D model or drawing, rather than manually writing the code. This makes the programming process more efficient and user-friendly, as the user can visually see how the machine will move and make adjustments as needed. Additionally, many CAM software programs include advanced features such as toolpath optimization, collision detection, and post-processing, which can help to improve the quality and accuracy of the finished product. In short, a CAM software makes the process of programming CNC machines much more efficient and precise, allowing for more complex and intricate designs to be produced with a high degree of automation.