Become a dealer

- Elevate your CAD/CAM offerings with the world-class software

- Join strong dealers community, backed by an independent vendor

- Dedicated channel sales team streamlines your success

- Comprehensive marketing and branding kits

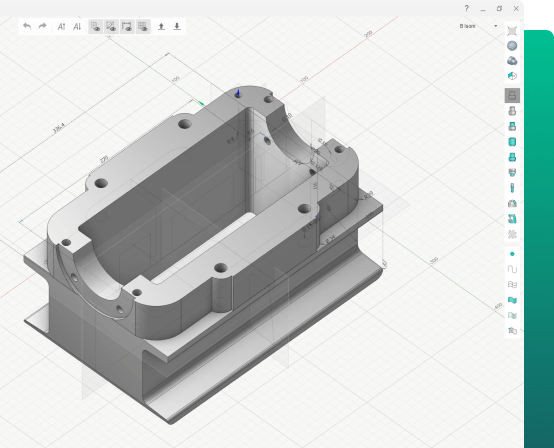

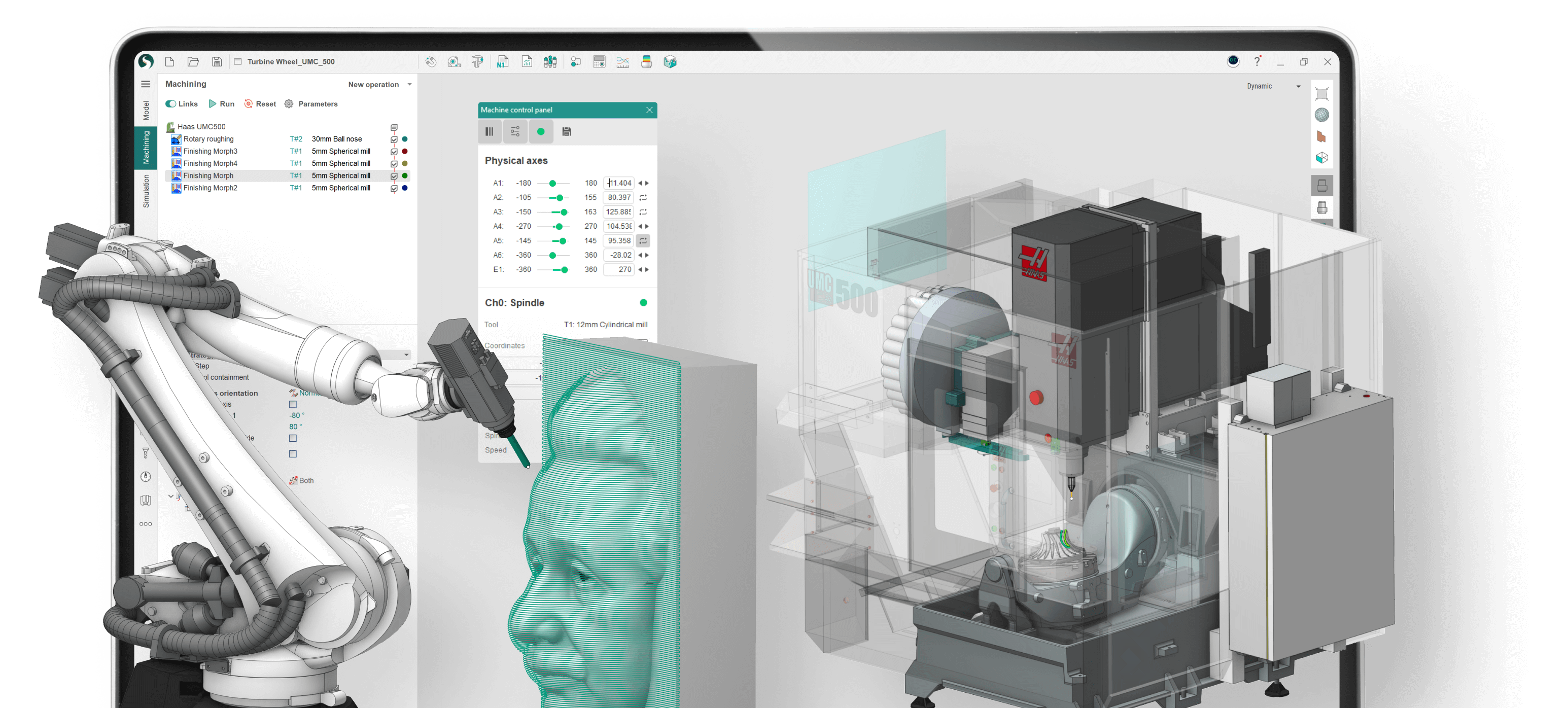

World class CAD/CAM software

Spectacular interface, easy-to-use, easy-to-learn

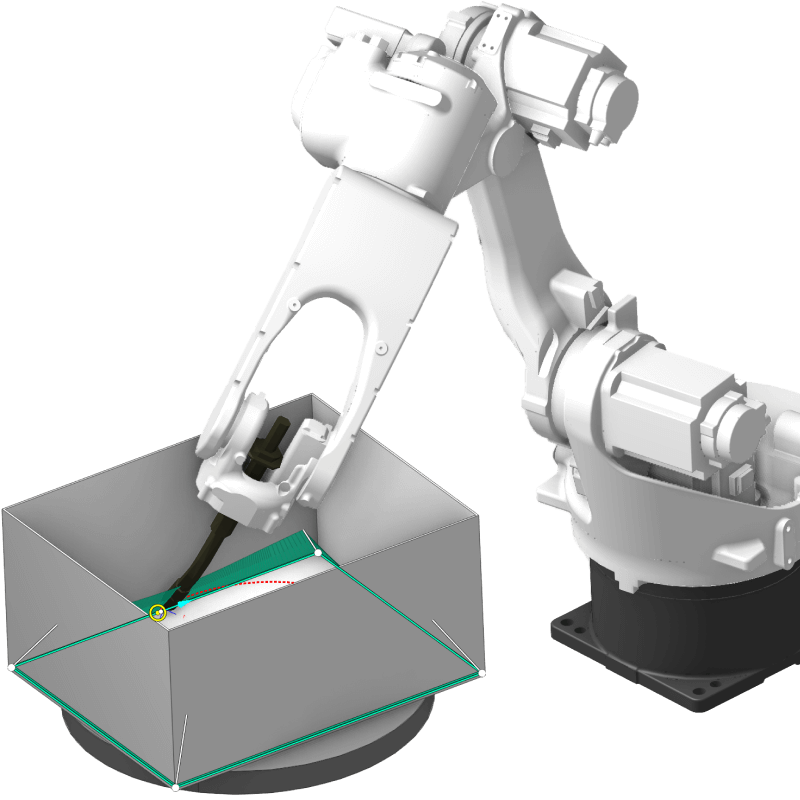

CAD/CAM for CNC machines since 1980s, Industrial robots OLP programming since 2008

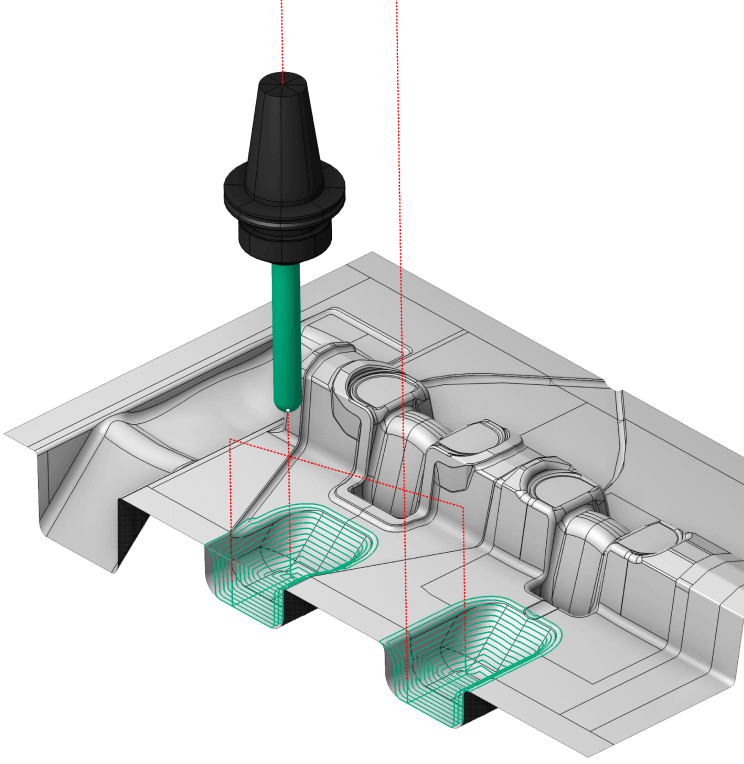

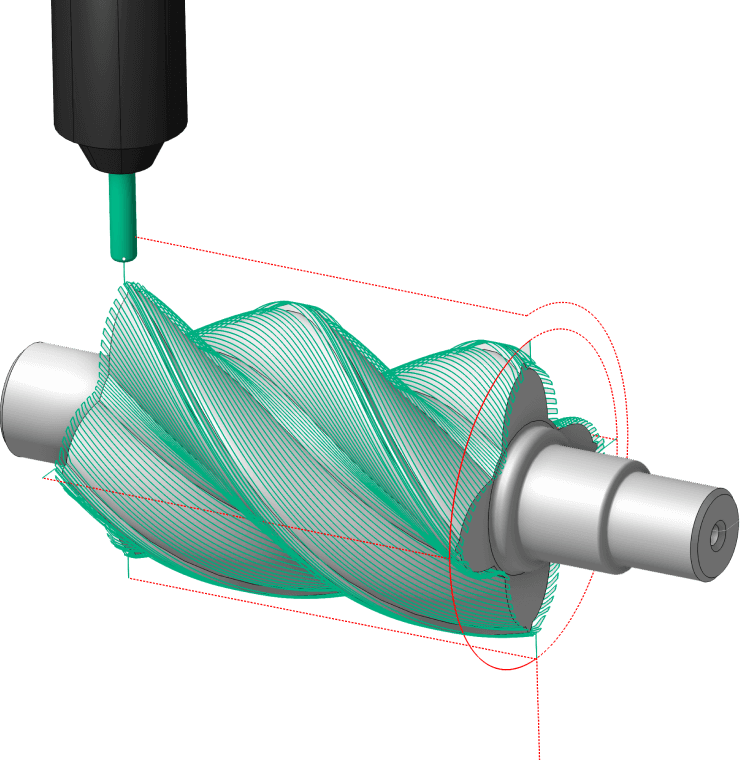

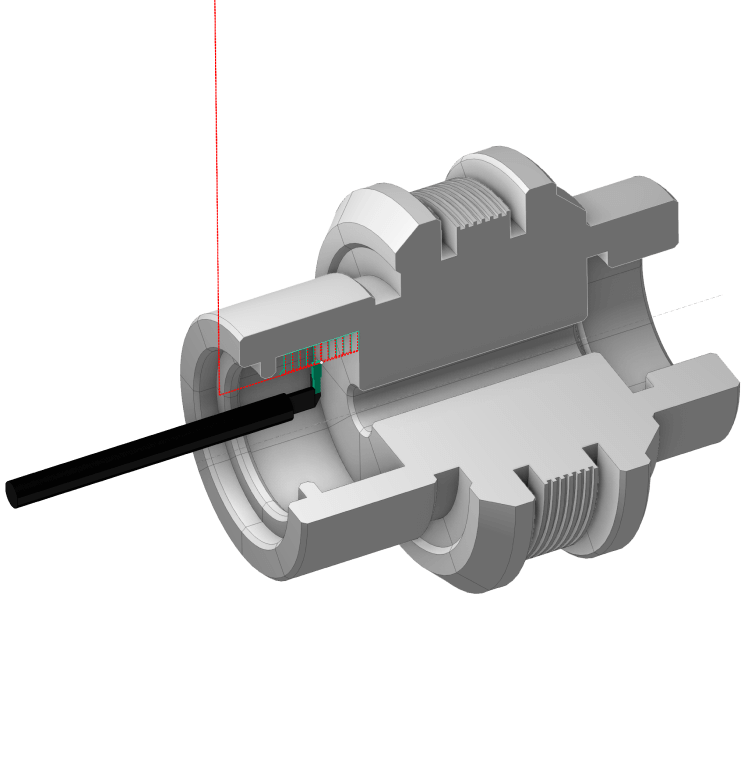

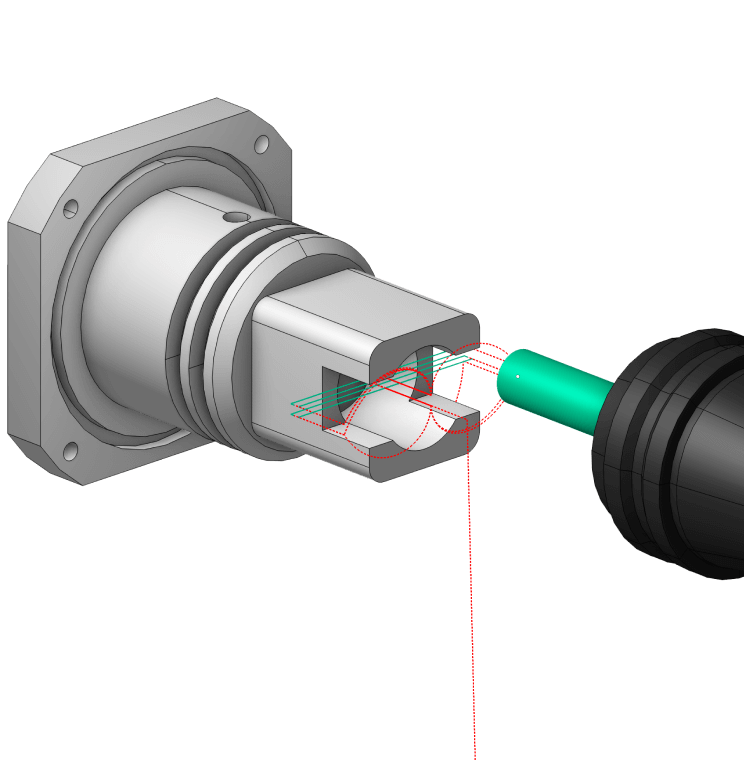

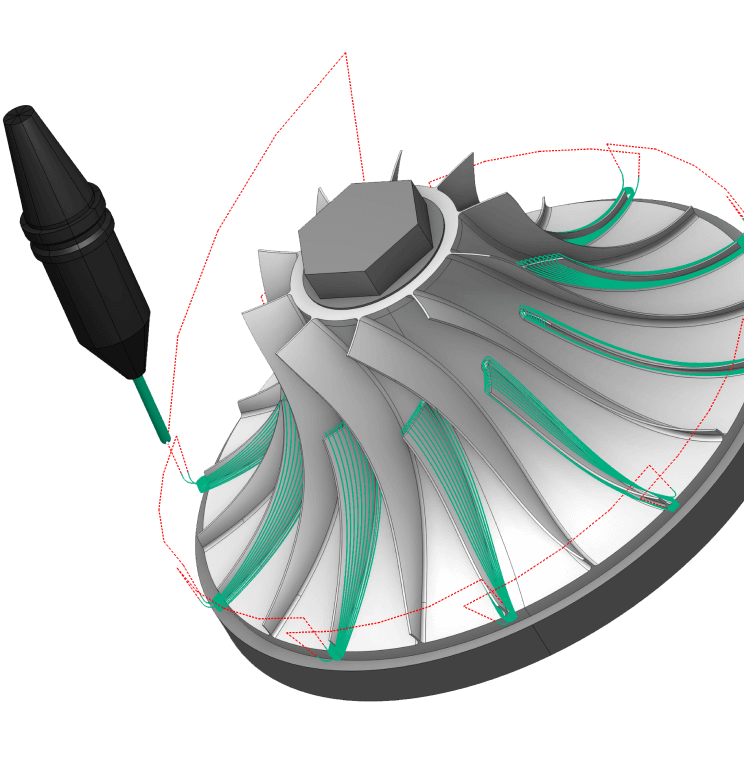

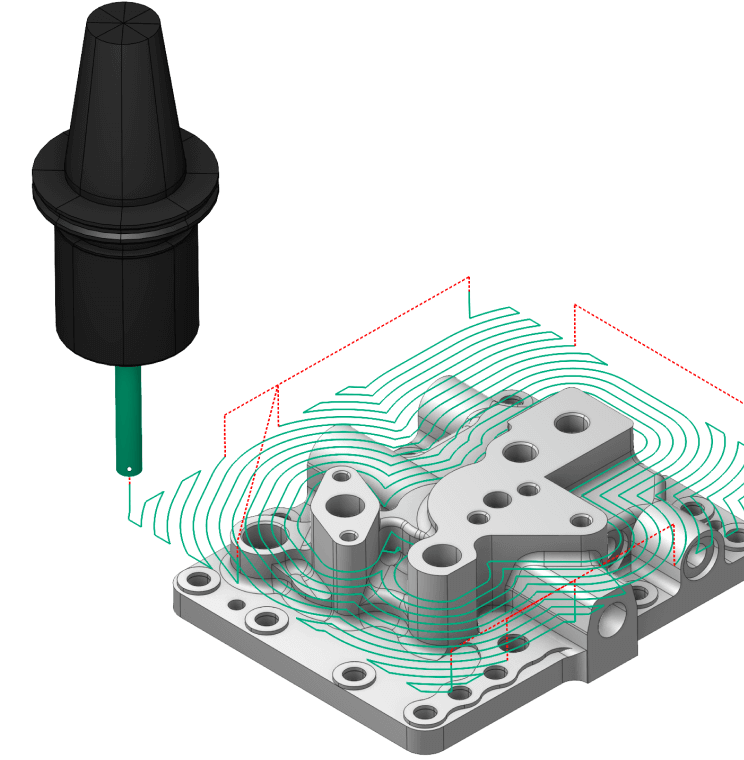

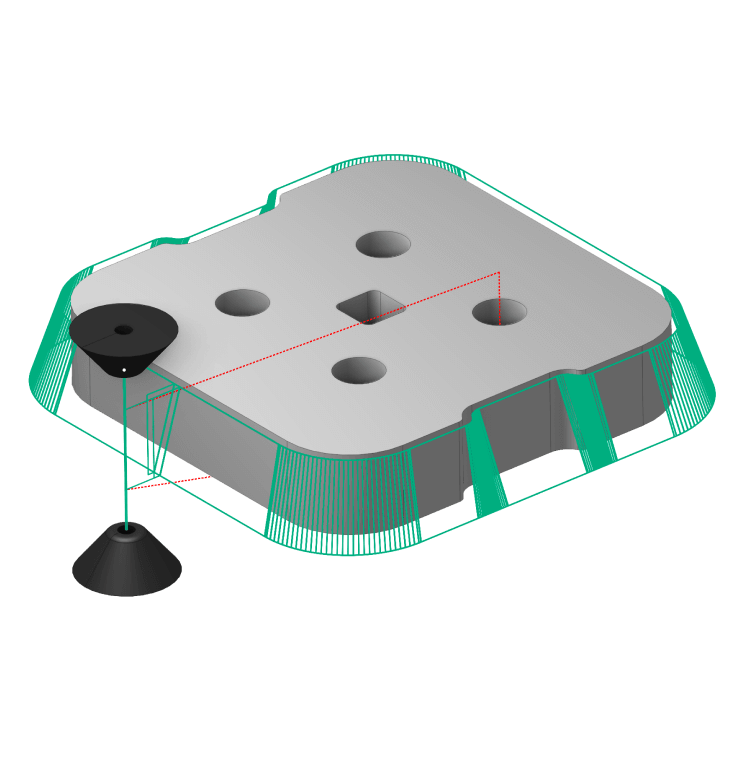

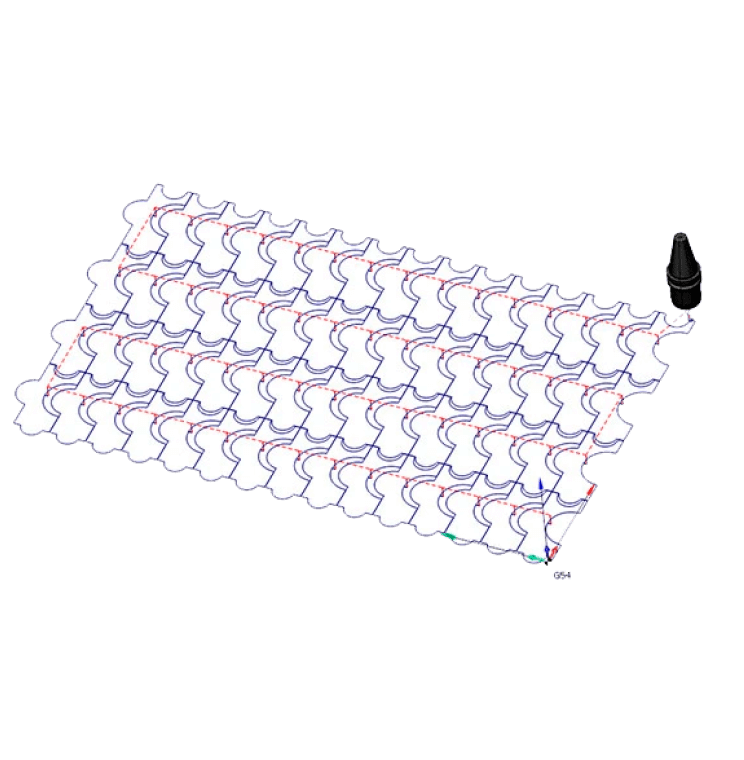

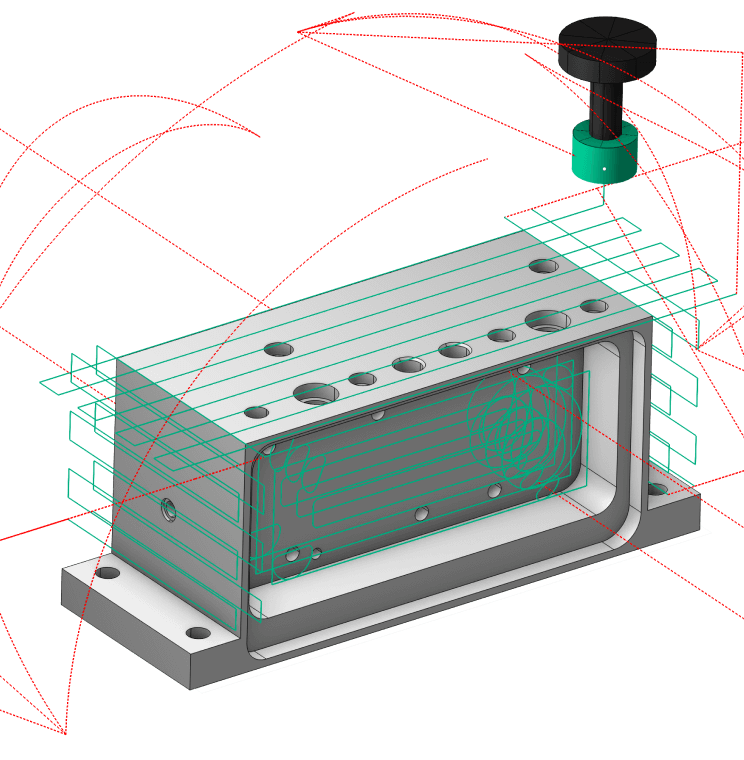

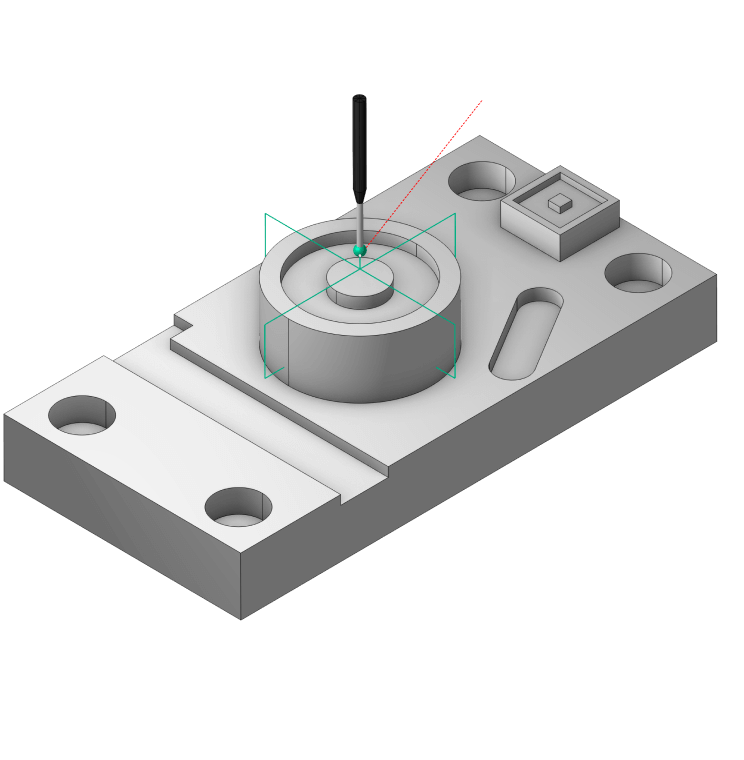

Applications for CNC

Technology highlight:

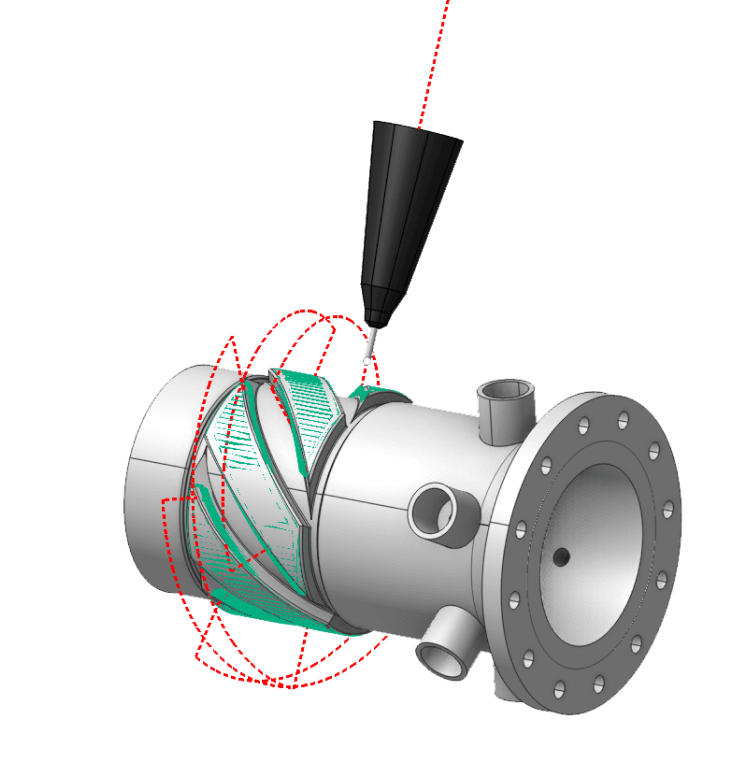

Adaptive SC

This high-speed machining cycle is specifically designed for roughing to substantially decrease cycle times and extend tool life. Its technology automatically regulates chip loads and lateral cutting forces while maintaining the cutter engagement angle and machine axes acceleration within optimal ranges.

With Adaptive SC, the machine can make deeper cuts at higher feedrates, which are also automatically optimized throughout the toolpath for maximum efficiency. In comparison to traditional machining methods, Adaptive SC provides the following benefits:

70%

reduction in cycle time

500%

increase in tool life

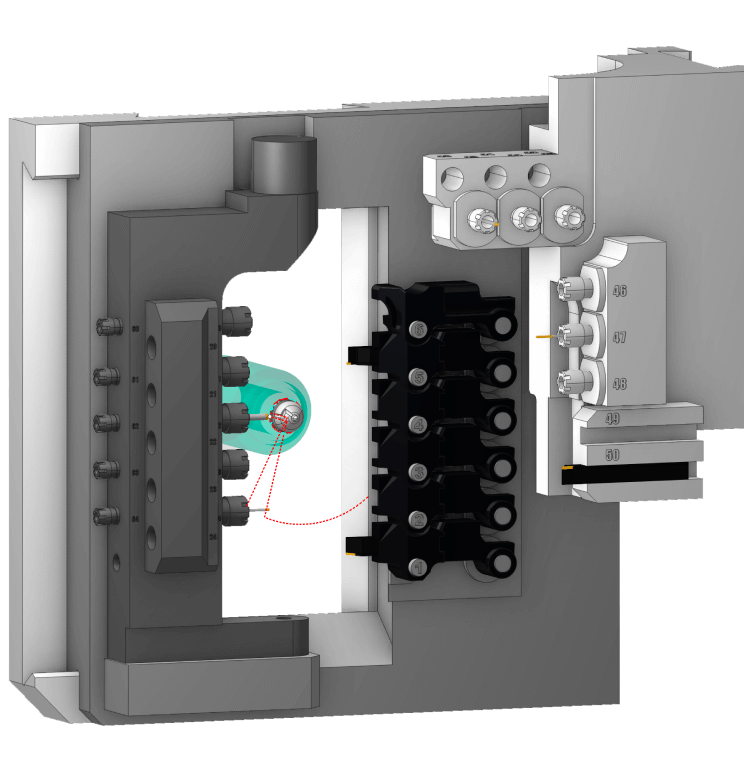

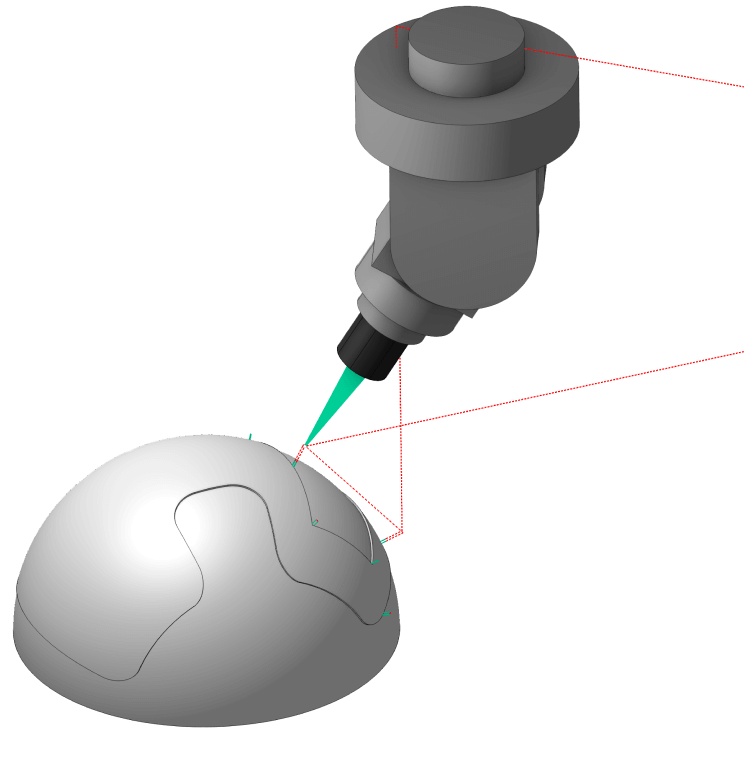

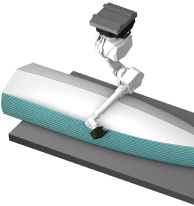

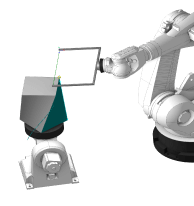

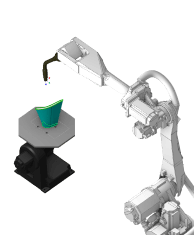

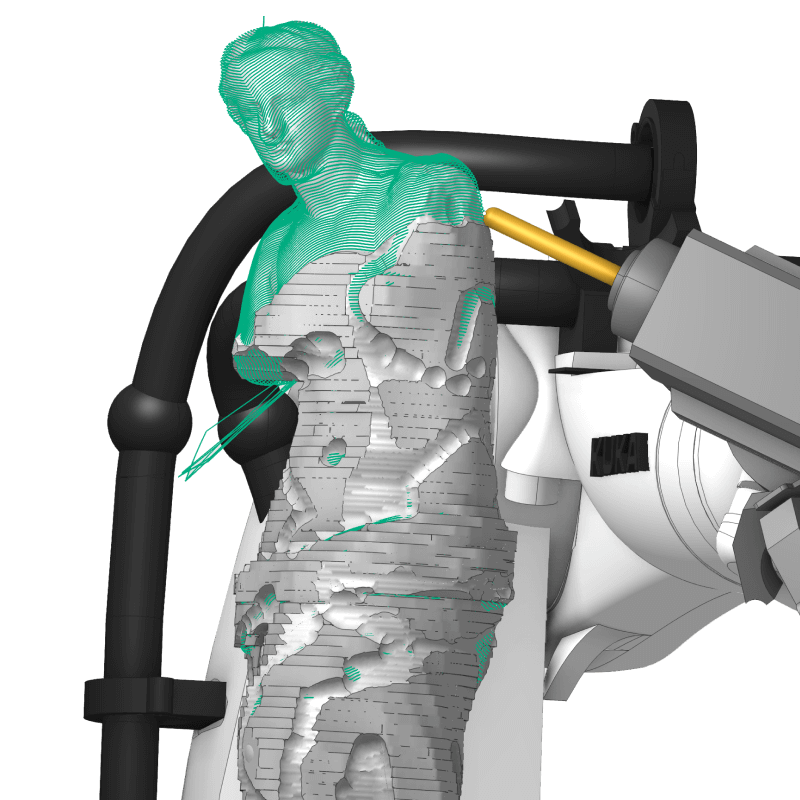

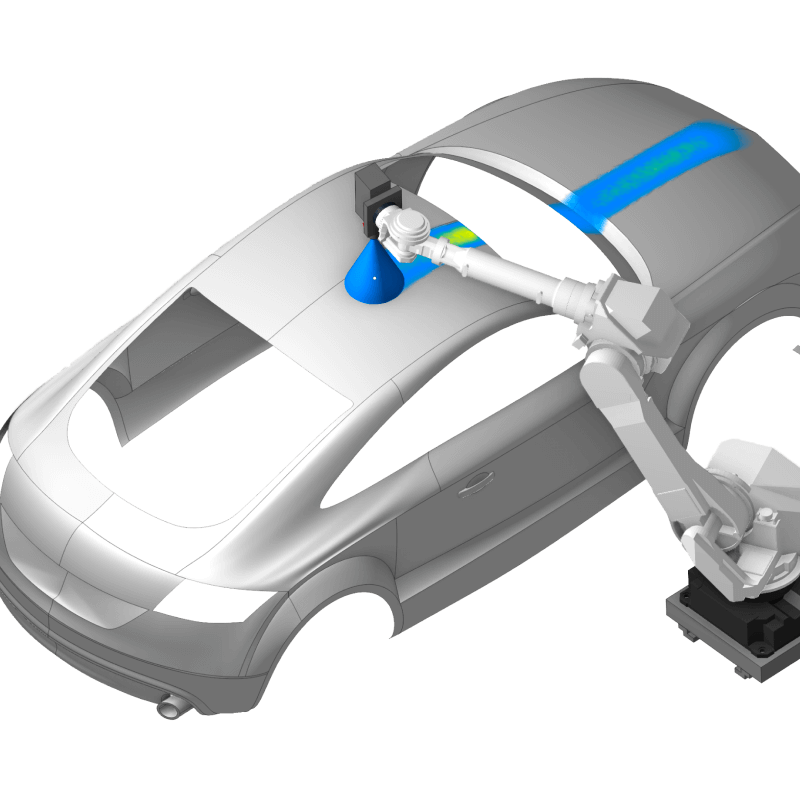

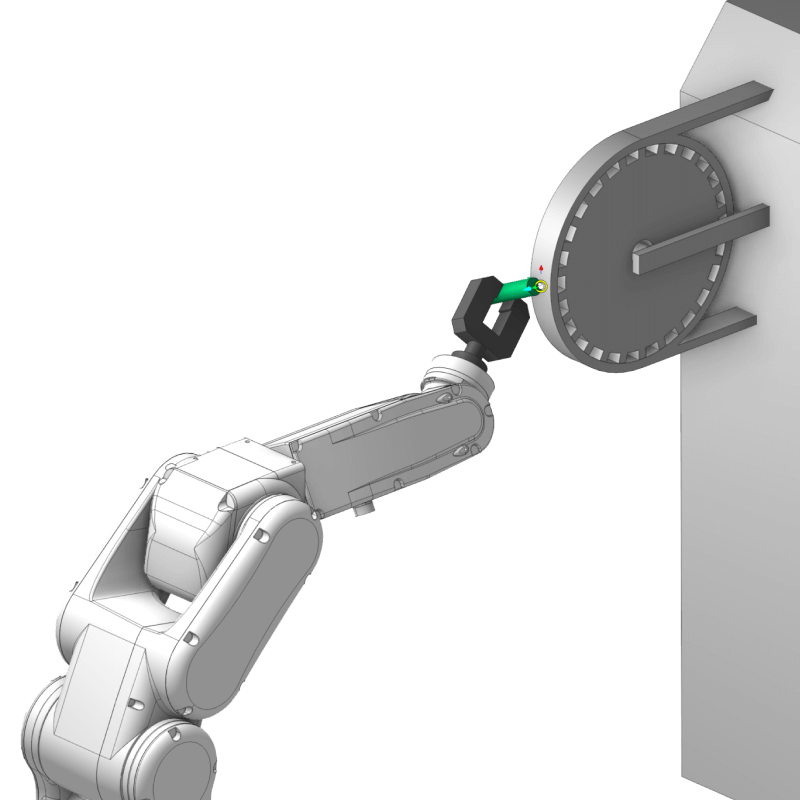

Applications for robots

Technology highlight:

additive and hybrid

Cutting‑edge and in‑demand technologies for additive and hybrid manufacturing using robots

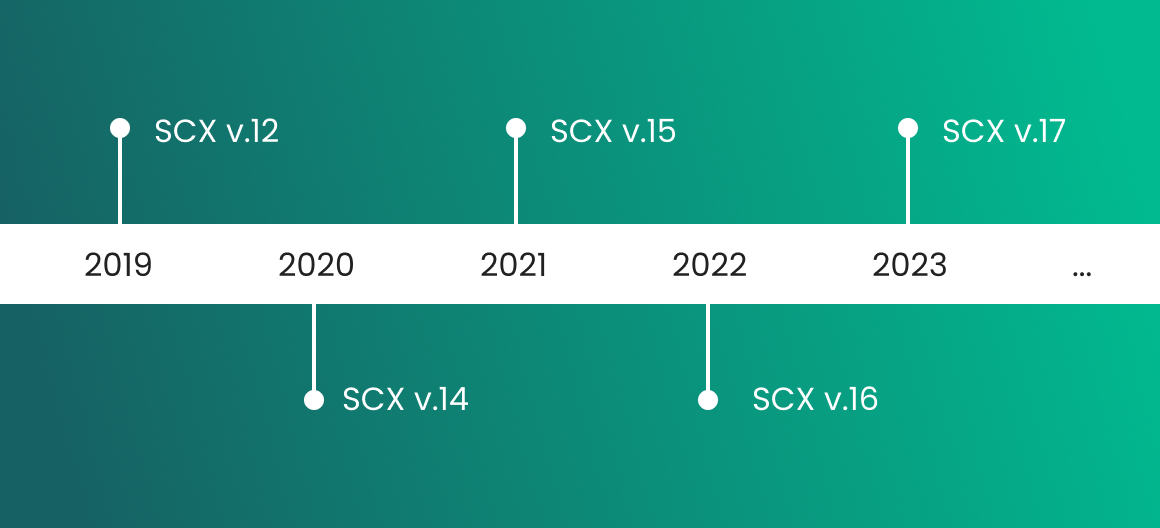

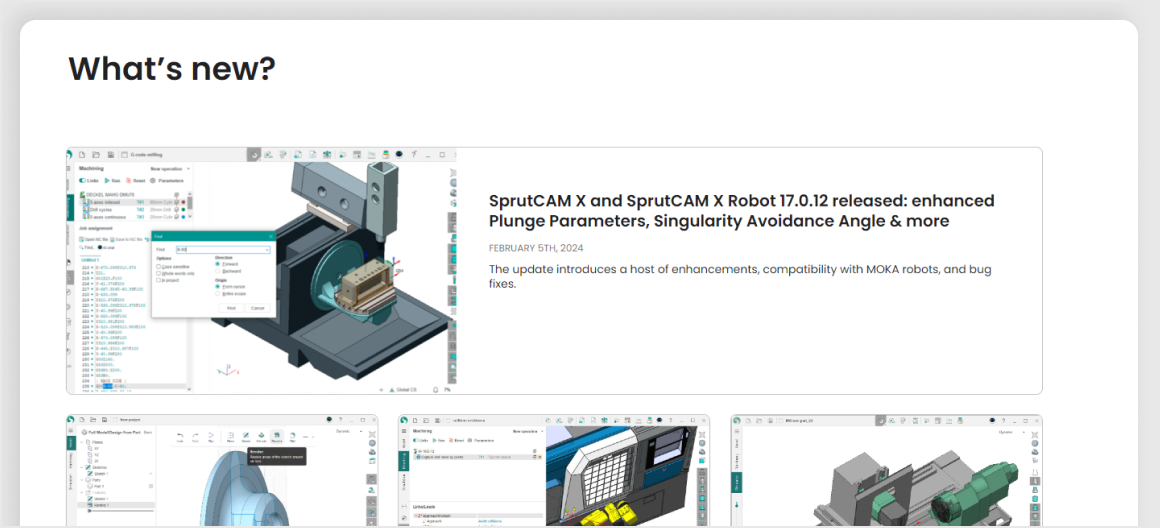

Regular updates and new version annually

New major version every year

Minor updates every month, check release notes ➜

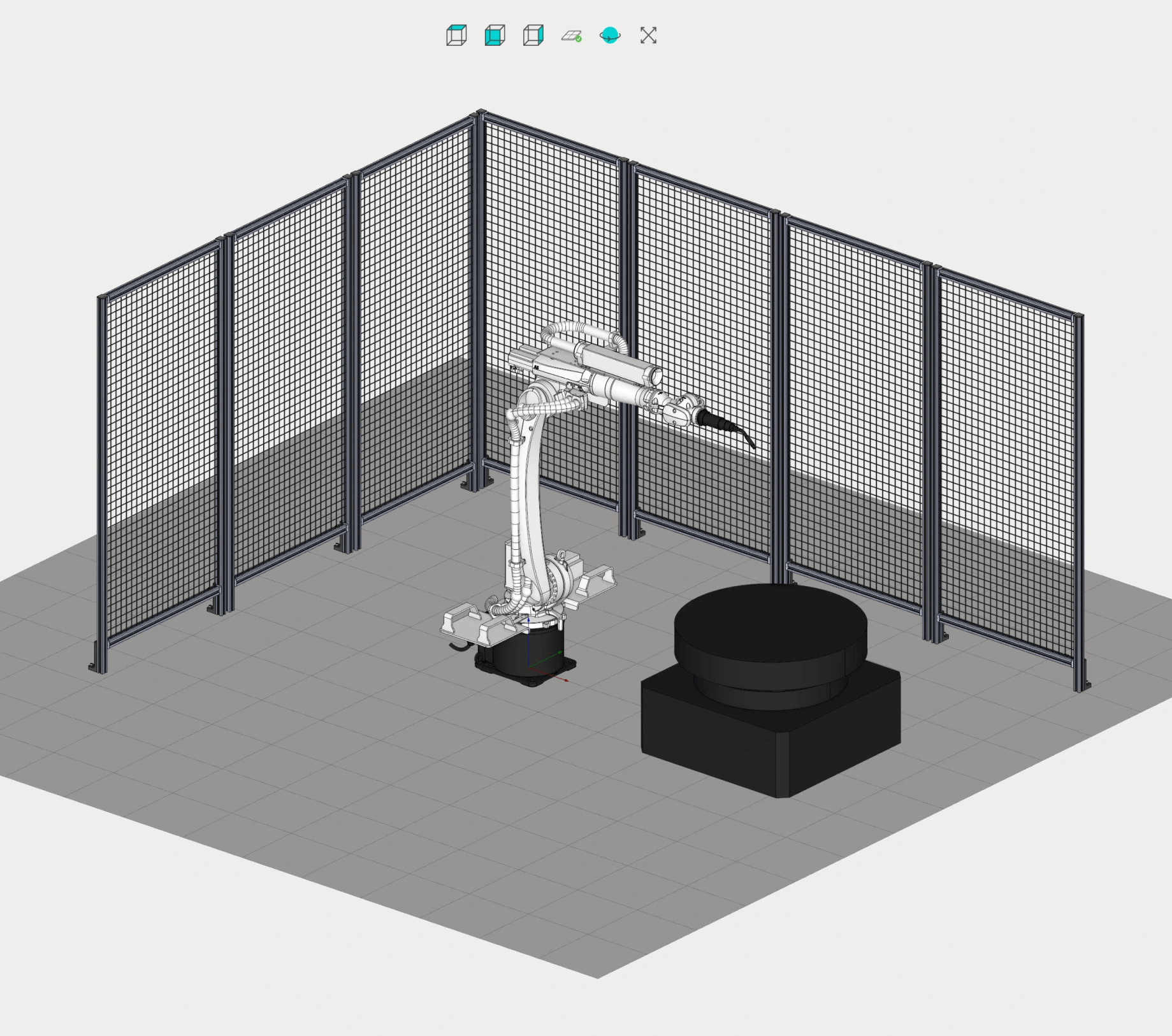

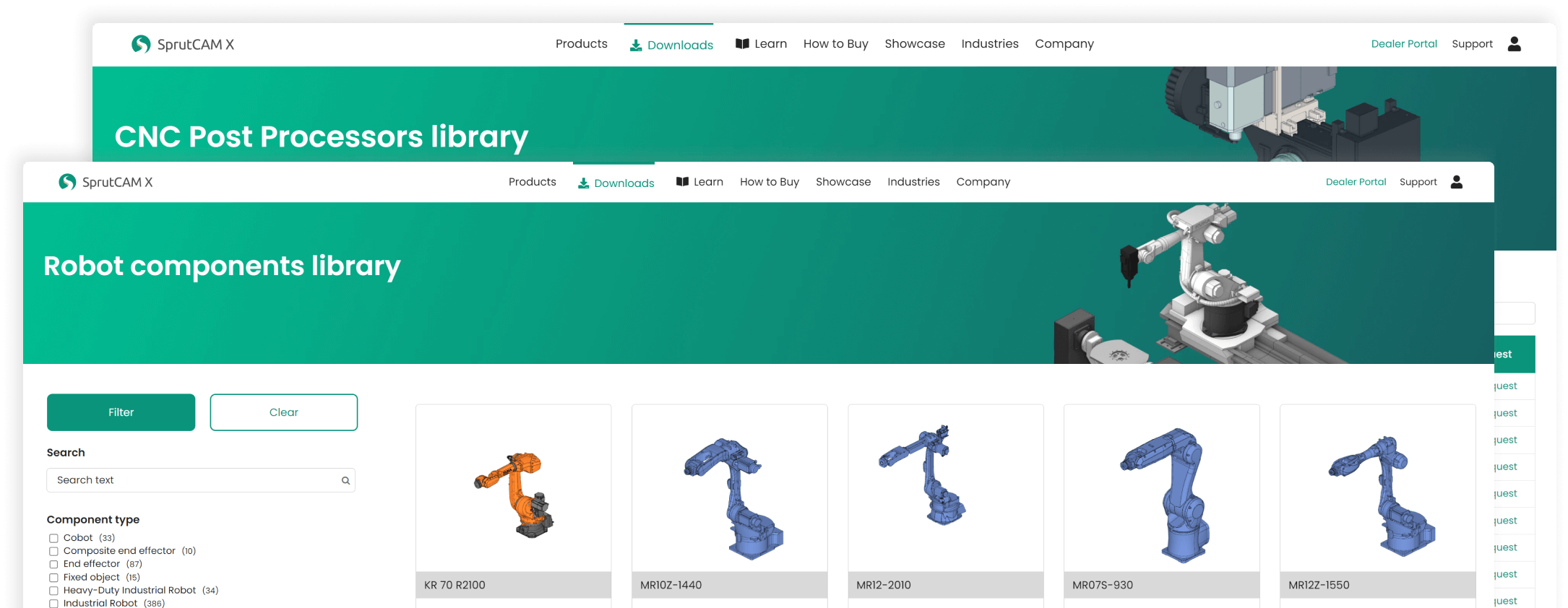

Postprocessors, CNC machine digital twins and Robotic Component libraries

free access for dealers

Open to integration

SprutCAM X for Developers is a set of APIs that enables the creation of custom applications for SprutCAM X through an open architecture, using widely-used programming languages. With it, you can automate intricate and repetitive tasks, integrate with third-party applications, and personalize the SprutCAM X interface to your liking, all in your preferred programming language.

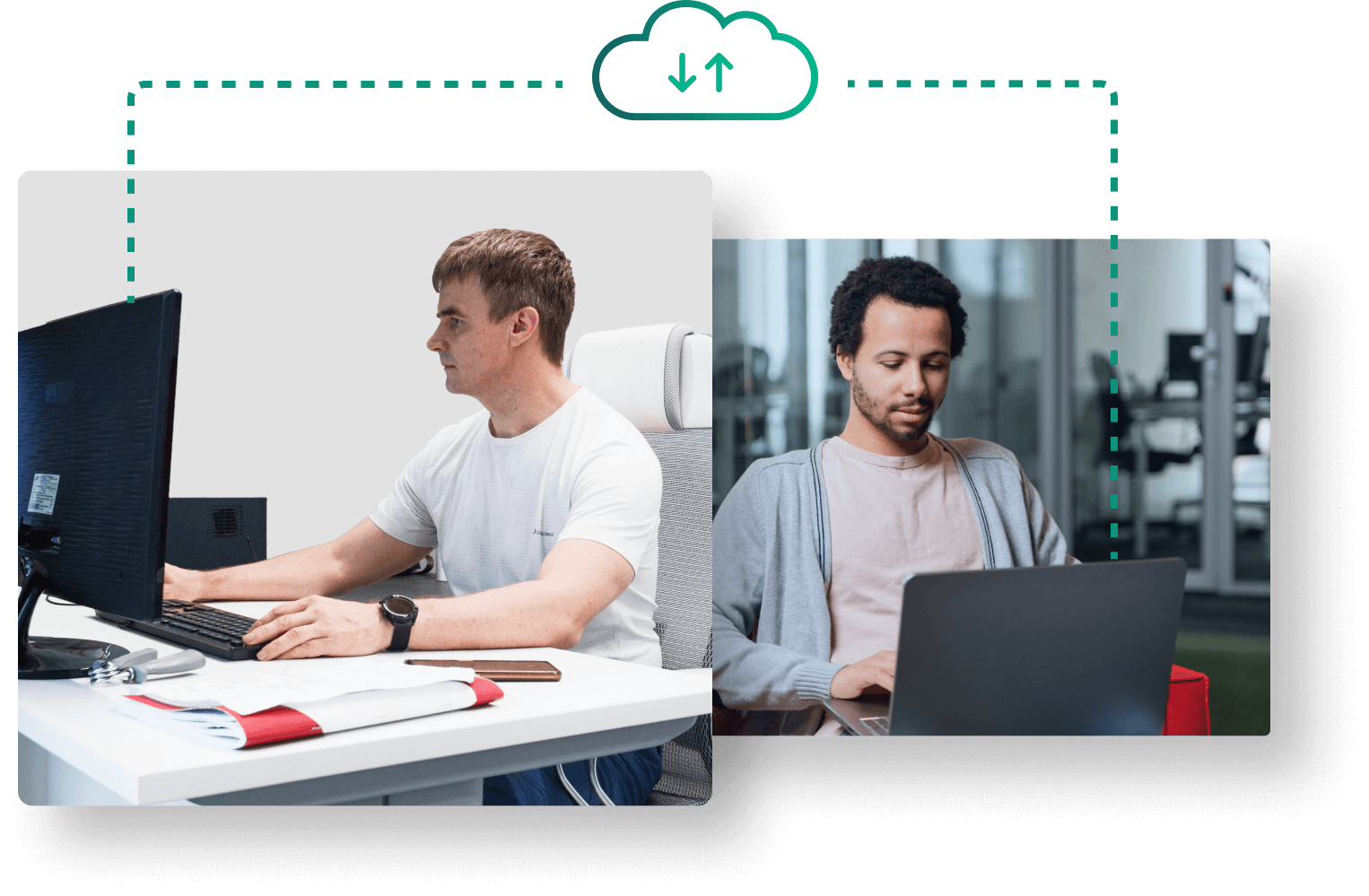

Cloud based collaboration platform for ultra-fast implementation and support

Technical support

Annual dealer conference

Company

Marketing kit

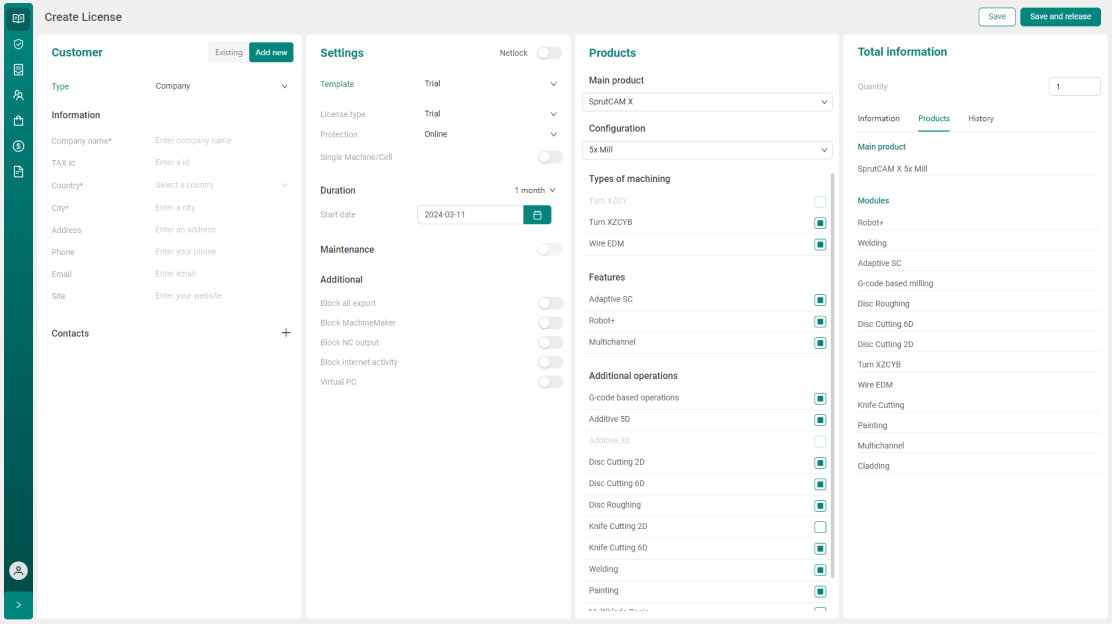

Doing effective business with online lisensing and ordering system

- Pricing based on regional RRP and individual dealer discount

- Avoid price competition with deal protection

- Create orders, licenses and invoices online

- Flexible payment terms with grace period

- Clear SMC (software maintenance contract) conditions to keep customers updated to the latest version

What company profiles are matching successful SprutCAM X dealer portrait

Ready to start onboarding?

Schedule a zoom call with SprutCAM X channel director